The use of nanoparticles in electrospinning has gained great attention in recent years, due to nanoparticle characteristics, namely their high surface area to volume ratio [1]. Magnesium oxide nanoparticles (MgO NPs) and copper oxide nanoparticles (CuO NPs) are known for their antimicrobial properties, thermal and electric ability, and are extensively used in several fields, including biomedical, environmental remediation, energy storage, catalysis, among others [2,3]. Since electrospinning uses an electrical field to stretch the polymeric solution into the collector, the nanoparticle’s conductivity and their electrical charges might lead to particle agglomeration [4]. In fact, the agglomeration of the nanoparticles induces beads and non-continuous fibers formation, compromising the electrospun mesh morphology, and their performance. To overcome the aforementioned drawbacks, magnetic stirring is commonly used to disperse the nanoparticles into the solution, although this does not prevent the particle’s agglomeration. Another methodology used includes the nanoparticle’s dispersion by ultra-sounds, although only a few works are describing its use and the dispersion depends on several parameters, such as amplitude (ꓮ; µm), frequency (ƒ; Hz), and power (P; W).

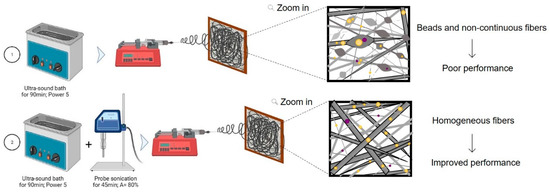

In this work, two different methodologies were tested to disperse efficiently the nanoparticles to obtain beads-free polycaprolactone (PCL)/MgO/CuO electrospun fibers using the processing parameters of the control condition, specifically: 15 kV; 0.8 mL/h; and 15 cm. The first methodology consists on nanoparticle dispersion into a polymeric solution using an ultrasound bath for 90 min. The second methodology uses a sonication probe for 45 min (A = 80%, ƒ = 26.18 kHz, and P = 50 W) after the ultrasound bath (Figure 1). The fiber’s morphology was assessed by Scanning Electron Microscope (SEM) and the particle’s distribution through energy-dispersive X-ray spectroscopy (EDX). Moreover, the mechanical and thermal stability of electrospun fibers were investigated to understand the impact that particle dispersion has on the structure’s stability and, thus, in their performance, depending on the final application. The second methodology revealed better results allowing the obtaining of homogenous fibers, well-dispersed nanoparticles, and a lower number of beads, resulting in the highest tensile strength and improved thermal stability. This may be attributed to acoustic cavitation, which results in the formation, growth, and collapse of microbubbles in liquids, de-aggregating the nanoparticles [5]. The results obtained demonstrated that the sequential methodology (ultrasound bath followed by sonication probe) prior to electrospun PCL/MgO/CuO reduces the agglomeration of the nanoparticles improving the electrospun fiber’s properties.

Figure 1.

Comparison of the two different methodologies to disperse the metallic nanoparticles into the PCL solution, and the influence of these factors on the morphology of the fibers produced.

Author Contributions

Conceptualization, J.R.D.; methodology, C.A.M.F. and S.F.C.G.; software, C.A.M.F.; validation, J.R.D.; formal analysis, J.R.D.; investigation, C.A.M.F., S.F.C.G. and J.R.D.; resources, J.R.D.; data curation, C.A.M.F., S.F.C.G. and J.R.D.; writing—original draft preparation, C.A.M.F.; writing—review and editing, J.R.D.; visualization, J.R.D.; supervision, J.R.D.; project administration, N.A., A.M. and J.R.D.; funding acquisition, N.A., A.M. and J.R.D. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Fundação para a Ciência e a Tecnologia (FCT) through the grants awarded to Carolina Ferreira (2021.04541.BD) and Sara Guerreiro (2021.05893.BD). FCT also supported this work through the following Projects: UIDB/04044/2020, UIDP/04044/2020. This study was also supported by PAMI-ROTEIRO/0328/2013 (Nº022158), and SpinningTNT (POCI-01-02B7-FEDER-069285).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Slavin, Y.N.; Asnis, J.; Häfeli, U.O.; Bach, H. Metal nanoparticles: Understanding the mechanisms behind the antibacterial activity. J. Nanobiotechnol. 2017, 15, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Suryavanshi, A.; Khanna, K.; Sindhu, K.R.; Bellare, J.; Srivastava, R. Magnesium oxide nanoparticle-loaded polycaprolactone composite electrospun fiber scaffolds for bone-soft tissue engineering applications: In-vitro and in-vivo evaluation. Biomed. Mater. 2017, 12, 055011. [Google Scholar] [CrossRef] [PubMed]

- Hashmi, M.; Ullah, S.; Kim, I.S. Copper oxide (CuO) loaded polyacrylonitrile (PAN) nanofiber membranes for antimicrobial breath mask applications. Curr. Res. Biotechnol. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Dias, J.R.; Alves, A.I.F.; Ferreira, C.A.M.; Alves, N.M. Electrospinning Fabrication Strategies: From Conventional to Advanced Approaches. In Electrospun Materials and Their Allied Applications, 1st ed.; John Wiley & Sons, Ltd.: New York, NY, USA, 2020; pp. 1–52. [Google Scholar] [CrossRef]

- Priyadarshi, A.; Khavari, M.; Subroto, T.; Prentice, P.; Pericleous, K.; Eskin, D.; Durodola, J.; Tzanakis, I. Mechanisms of ultrasonic de-agglomeration of oxides through in-situ high-speed observations and acoustic measurements. Ultrason. Sonochem. 2021, 79, 105792. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).