RAFT-Mediated Radiation Grafting on Natural Fibers in Aqueous Emulsion †

Abstract

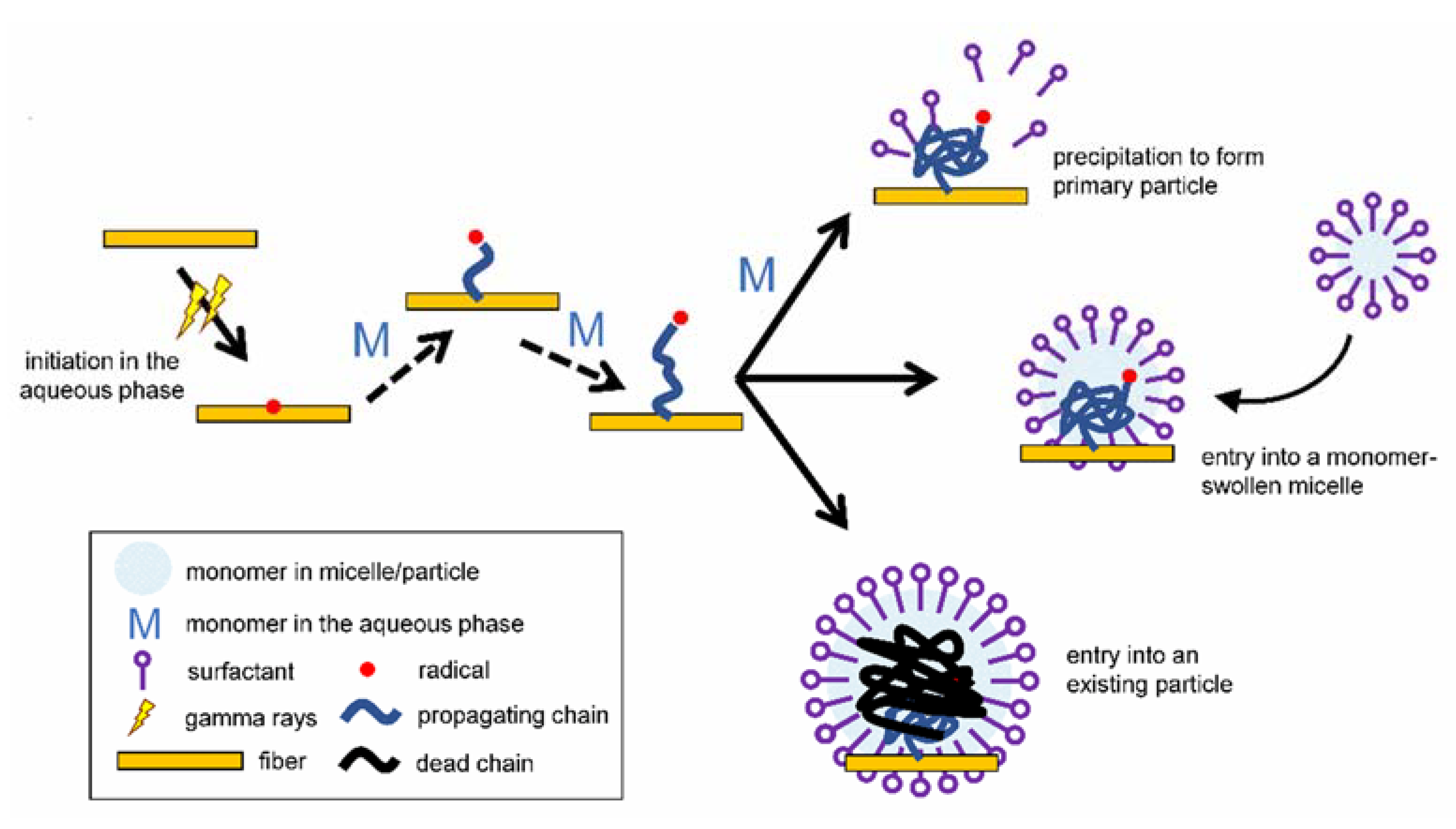

:1. Introduction

2. Materials and Methods

2.1. Emulsion Preparation

2.2. Radiation Grafting of Abaca Fibers

2.3. Characterization

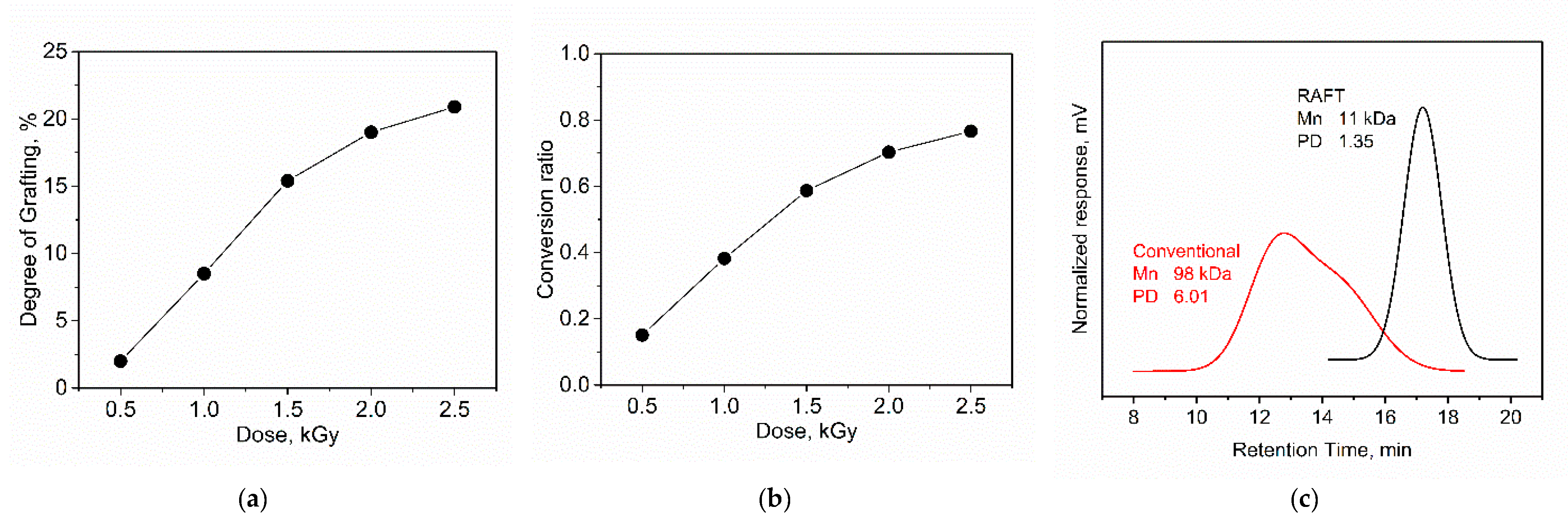

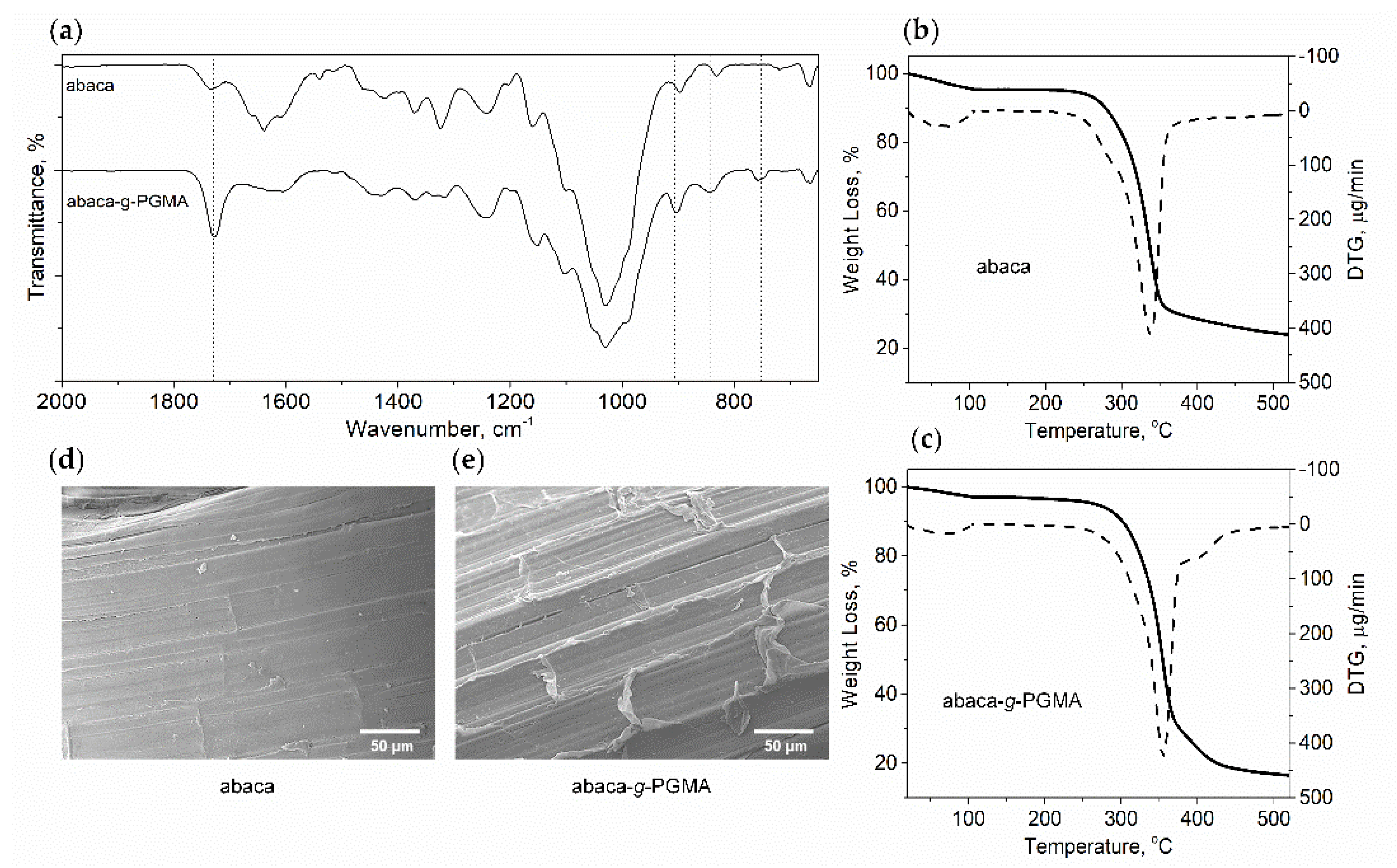

3. Results and Discussion

4. Conclusions

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Dubé, M.A. Green Emulsion Polymerization Technology BT—Polymer Reaction Engineering of Dispersed Systems: Volume I; Pauer, W., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 65–100. ISBN 978-3-319-73479-8. [Google Scholar]

- Chern, C.S. Emulsion polymerization mechanisms and kinetics. Prog. Polym. Sci. 2006, 31, 443–486. [Google Scholar] [CrossRef]

- Lovell, P.A.; Schork, F.J. Fundamentals of Emulsion Polymerization. Biomacromolecules 2020, 21, 4396–4441. [Google Scholar] [CrossRef] [PubMed]

- Wada, Y.; Tamada, M.; Seko, N.; Mitomo, H. Emulsion grafting of vinyl acetate onto preirradiated poly(3-hydroxybutyrate) film. J. Appl. Polym. Sci. 2008, 107, 2289–2294. [Google Scholar] [CrossRef]

- Seko, N.; Bang, L.T.; Tamada, M. Syntheses of amine-type adsorbents with emulsion graft polymerization of glycidyl methacrylate. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2007, 265, 146–149. [Google Scholar] [CrossRef]

- Madrid, J.F.; Lopez, G.E.P.; Abad, L.V. Application of full-factorial design in the synthesis of polypropylene-g-poly(glycidyl methacrylate) functional material for metal ion adsorption. Radiat. Phys. Chem. 2017, 136, 54–63. [Google Scholar] [CrossRef]

- Madrid, J.F.; Ueki, Y.; Seko, N. Abaca/polyester nonwoven fabric functionalization for metal ion adsorbent synthesis via electron beam-induced emulsion grafting. Radiat. Phys. Chem. 2013, 90, 104–110. [Google Scholar] [CrossRef]

- Feng, C.; Huang, X. Polymer Brushes: Efficient Synthesis and Applications. Acc. Chem. Res. 2018, 51, 2314–2323. [Google Scholar] [CrossRef] [PubMed]

- Barsbay, M.; Güven, O.; Stenzel, M.H.; Davis, T.P.; Barner-Kowollik, C.; Barner, L. Verification of controlled grafting of styrene from cellulose via radiation-induced RAFT polymerization. Macromolecules 2007, 40, 7140–7147. [Google Scholar] [CrossRef] [Green Version]

- Madrid, J.F.; Ueki, Y.; Abad, L.V.; Yamanobe, T.; Seko, N. RAFT-mediated graft polymerization of glycidyl methacrylate in emulsion from polyethylene/polypropylene initiated with γ-radiation. J. Appl. Polym. Sci. 2017, 134, 45270. [Google Scholar] [CrossRef]

- Urbani, C.N.; Nguyen, H.N.; Monteiro, M.J. RAFT-Mediated Emulsion Polymerization of Styrene using a Non-Ionic Surfactant. Aust. J. Chem. 2006, 59, 728. [Google Scholar] [CrossRef]

- Perrier, S. 50th Anniversary Perspective: RAFT Polymerization—A User Guide. Macromolecules 2017, 50, 7433–7447. [Google Scholar] [CrossRef]

- Prescott, S.W.; Ballard, M.J.; Rizzardo, E.; Gilbert, R.G. RAFT in Emulsion Polymerization: What Makes it Different? Aust. J. Chem. 2002, 55, 415–424. [Google Scholar] [CrossRef]

- Luo, Y.; Tsavalas, J.; Schork, F.J. Theoretical aspects of particle swelling in living free radical miniemulsion polymerization. Macromolecules 2001, 34, 5501–5507. [Google Scholar] [CrossRef]

- Luo, Y.; Cui, X. Reversible addition–fragmentation chain transfer polymerization of methyl methacrylate in emulsion. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 2837–2847. [Google Scholar] [CrossRef]

- Ma, H.; Morita, K.; Hoshina, H.; Seko, N. Synthesis of Amine-type Adsorbents with Emulsion Graft Polymerization of 4-hydroxybutyl Acrylate Glycidylether. Mater. Sci. Appl. 2011, 2, 776–784. [Google Scholar] [CrossRef] [Green Version]

- Moad, G.; Barner-Kowollik, C. The Mechanism and Kinetics of the RAFT Process: Overview, Rates, Stabilities, Side Reactions, Product Spectrum and Outstanding Challenges. In Handbook of RAFT Polymerization; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; pp. 51–104. [Google Scholar]

- Barner, L.; Zwaneveld, N.; Perera, S.; Pham, Y.; Davis, T.P. Reversible addition–fragmentation chain-transfer graft polymerization of styrene: Solid phases for organic and peptide synthesis. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 4180–4192. [Google Scholar] [CrossRef]

- Li, Y.; Schadler, L.S.; Benicewicz, B.C. Surface and particle modification via the RAFT process: Approach and properties. In Handbook of RAFT Polymerization; Wiley Online Library: Hoboken, NJ, USA, 2008. [Google Scholar]

- Madrid, J.F.; Barsbay, M.; Abad, L.; Güven, O. Grafting of N, N-dimethylaminoethyl methacrylate from PE/PP nonwoven fabric via radiation-induced RAFT polymerization and quaternization of the grafts. Radiat. Phys. Chem. 2016, 124, 145–154. [Google Scholar] [CrossRef]

- Sharif, J.; Mohamad, S.F.; Fatimah Othman, N.A.; Bakaruddin, N.A.; Osman, H.N.; Güven, O. Graft copolymerization of glycidyl methacrylate onto delignified kenaf fibers through pre-irradiation technique. Radiat. Phys. Chem. 2013, 91, 125–131. [Google Scholar] [CrossRef]

- Ananthalakshmi, N.R.; Wadgaonkar, P.P.; Sivaram, S.; Varma, I.K. Thermal behaviour of glycidyl methacrylate homopolymers and copolymers. J. Therm. Anal. Calorim. 1999, 58, 533–539. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barba, B.J.D.; Peñaloza, D.P., Jr.; Seko, N.; Madrid, J.F. RAFT-Mediated Radiation Grafting on Natural Fibers in Aqueous Emulsion. Mater. Proc. 2021, 7, 4. https://doi.org/10.3390/IOCPS2021-11243

Barba BJD, Peñaloza DP Jr., Seko N, Madrid JF. RAFT-Mediated Radiation Grafting on Natural Fibers in Aqueous Emulsion. Materials Proceedings. 2021; 7(1):4. https://doi.org/10.3390/IOCPS2021-11243

Chicago/Turabian StyleBarba, Bin Jeremiah D., David P. Peñaloza, Jr., Noriaki Seko, and Jordan F. Madrid. 2021. "RAFT-Mediated Radiation Grafting on Natural Fibers in Aqueous Emulsion" Materials Proceedings 7, no. 1: 4. https://doi.org/10.3390/IOCPS2021-11243

APA StyleBarba, B. J. D., Peñaloza, D. P., Jr., Seko, N., & Madrid, J. F. (2021). RAFT-Mediated Radiation Grafting on Natural Fibers in Aqueous Emulsion. Materials Proceedings, 7(1), 4. https://doi.org/10.3390/IOCPS2021-11243