Preparation and Characterisation of PBAT-Based Biocomposite Materials Reinforced by Protein Complex Microparticles †

Abstract

:1. Introduction

2. Materials and Methods

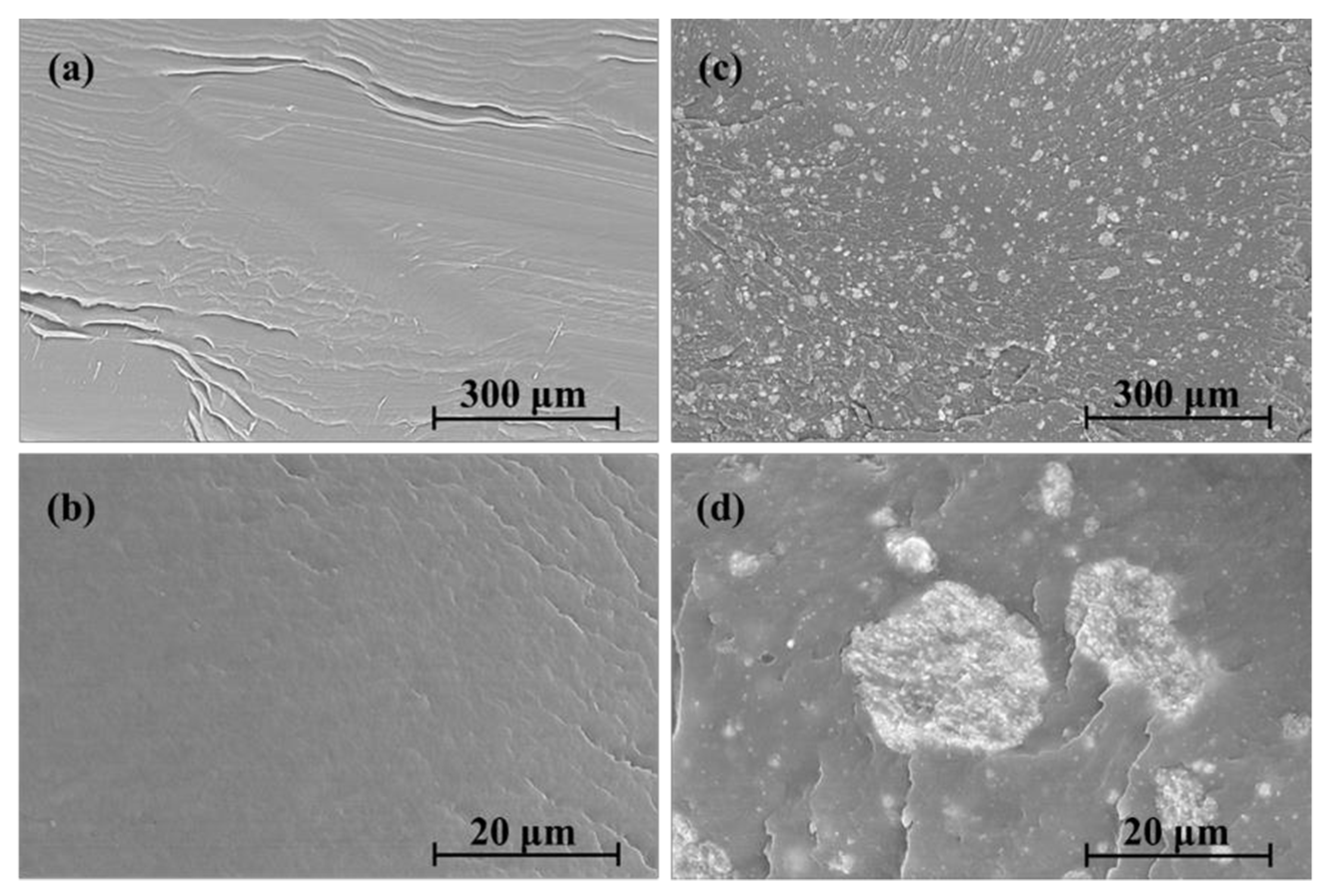

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Piergiovanni, L.; Limbo, S. Food packaging. In Materiali, Tecnologie e Qualità Degli Alimenti, 1st ed.; Springer: Berlin, Germany, 2010; pp. 1–576. [Google Scholar]

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. London, Ser. B 2009, 364, 1977–1984. [Google Scholar] [CrossRef] [PubMed]

- Harrison, J.P.; Boardman, C.; O’Callaghan, K.; Delort, A.-M.; Song, J. Biodegradability standards for carrier bags and plastic films in aquatic environments: A critical review. R. Soc. Open Sci. 2018, 5, 171792. [Google Scholar] [CrossRef] [Green Version]

- Xiong, S.-J.; Pang, B.; Zhou, S.-J.; Li, M.-K.; Yang, S.; Wang, Y.-Y.; Shi, Q.; Wang, S.-F.; Yuan, T.-Q.; Sun, R.-C. Economically competitive biodegradable PBAT/lignin composites: Effect of lignin methylation and compatibilizer. ACS Sustain. Chem. Eng. 2020, 8, 5338–5346. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M.F. An overview on properties and applications of poly(butyleneadipate-co-terephthalate)–PBAT based composites. Polym. Eng. Sci. 2019, 59, E7–E15. [Google Scholar] [CrossRef] [Green Version]

- Volanti, M.; Cespi, D.; Passarini, F.; Neri, E.; Cavani, F.; Mizsey, P.; Fozer, D. Terephthalic acid from renewable sources: Early-stage sustainability analysis of a bio-PET precursor. Green Chem. 2019, 21, 885–896. [Google Scholar] [CrossRef]

- Skoog, E.; Shin, J.H.; Saez-Jimenez, V.; Mapelli, V.; Olsson, L. Biobased adipic acid—The challenge of developing the production host. Biotechnol. Adv. 2018, 36, 2248–2263. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.G.C.; Ferreira, T.F.; Borges, É.R. Identification of potential technologies for 1,4-Butanediol production using prospecting methodology. J. Chem. Technol. Biotechnol. 2020, 95, 3057–3070. [Google Scholar] [CrossRef]

- Kijchavengkul, T.; Auras, R.; Rubino, M.; Ngouajio, M.; Fernandez, R.T. Assessment of aliphatic–aromatic copolyester biodegradable mulch films. Part I: Field study. Chemosphere 2008, 71, 942–953. [Google Scholar] [PubMed]

- Jian, J.; Xiangbin, Z.; Xianbo, H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26. [Google Scholar] [CrossRef]

- Lawton, J.W. Zein: A history of processing and use. Cereal Chem. 2002, 79, 1–18. [Google Scholar] [CrossRef]

- Oymaci, P.; Altinkaya, S.A. Improvement of barrier and mechanical properties of whey protein isolate based food packaging films by incorporation of zein nanoparticles as a novel bionanocomposite. Food Hydrocolloids 2016, 54, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.-H.; Wang, B.; Field, P.D.; Aglan, H.A. Characteristics of edible films made from dairy proteins and zein hydrolysate cross-linked with transglutaminase. Int. J. Food Sci. Technol. 2004, 39, 287–294. [Google Scholar] [CrossRef]

- Kadam, D.M.; Thunga, M.; Srinivasan, G.; Wang, S.; Kessler, M.R.; Grewell, D.; Yu, C.; Lamsal, B. Effect of TiO2 nanoparticles on thermo-mechanical properties of cast zein protein films. Food Packag. Shelf Life 2017, 13, 35–43. [Google Scholar] [CrossRef] [Green Version]

- Anaya-Esparza, L.M.; Villagrán-de la Mora, Z.; Rodríguez-Barajas, N.; Sandoval-Contreras, T.; Nuño, K.; López-de la Mora, D.A.; Pérez-Larios, A.; Montalvo-González, E. Protein–TiO2: A functional hybrid composite with diversified applications. Coatings 2020, 10, 1194. [Google Scholar] [CrossRef]

- Guo, X.; Ren, C.; Zhang, Y.; Cui, H.; Shi, C. Stability of zein-based films and their mechanism of change during storage at different temperatures and relative humidity. J. Food Process. Preserv. 2020, 44, e14671. [Google Scholar] [CrossRef]

- Százdi, L.; Pukánszky, B.; Vancso, G.J.; Pukánszky, B. Quantitative estimation of the reinforcing effect of layered silicates in PP nanocomposites. Polymer 2006, 47, 4638–4648. [Google Scholar] [CrossRef]

- Pegoretti, A.; Dorigato, A.; Penati, A. Tensile mechanical response of polyethylene—Clay nanocomposites. eXPRESS Polym. Lett. 2007, 1, 123–131. [Google Scholar] [CrossRef]

- Nanni, A.; Messori, M. Thermo-mechanical properties and creep modelling of wine lees filled Polyamide 11 (PA11) and Polybutylene succinate (PBS) bio-composites. Compos. Sci. Technol. 2020, 188, 107974. [Google Scholar] [CrossRef]

- Dorigato, A.; D’Amato, M.; Pegoretti, A. Thermo-mechanical properties of high density polyethylene—Fumed silica nanocomposites: Effect of filler surface area and treatment. J. Polym. Res. 2012, 19, 9889. [Google Scholar] [CrossRef]

- Kang, S.; Hong, S.I.; Choe, C.R.; Park, M.; Rim, S.; Kim, J. Preparation and characterization of epoxy composites filled with functionalized nanosilica particles obtained via sol–gel process. Polymer 2001, 42, 879–887. [Google Scholar] [CrossRef]

| Sample | E (MPa) | σY (MPa) | σB (MPa) | εB (MPa) | T (MJ/m3) |

|---|---|---|---|---|---|

| PBAT | 126 ± 12 | 8.1 ± 0.2 | 13 ± 1 | 4.0 ± 0.8 | 45 ± 6 |

| PBAT + 5.3P | 131 ± 10 | 8.4 ± 0.2 | 12 ± 1 | 3.7 ± 0.3 | 35 ± 4 |

| PBAT + 11.1P | 149 ± 4 | 8.8 ± 0.2 | 11 ± 1 | 3.5 ± 0.2 | 32 ± 3 |

| PBAT + 25P | 186 ± 11 | 8.9 ± 0.1 | 9 ± 1 | 2.7 ± 0.2 | 22 ± 2 |

| Sample | E’ @ 0 °C (MPa) | E’ @ 20 °C (MPa) | E’ @ 40 °C (MPa) | Tg (°C) |

|---|---|---|---|---|

| PBAT | 273 ± 60 | 202 ± 50 | 155 ± 50 | −20.4 ± 0.9 |

| PBAT + 5.3P | 297 ± 60 | 224 ± 70 | 182 ± 60 | −20.3 ± 0.8 |

| PBAT + 11P | 319 ± 70 | 239 ± 60 | 192 ± 70 | −18.3 ± 0.5 |

| PBAT + 25P | 395 ± 50 | 294 ± 50 | 235 ± 60 | −17.9 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Togliatti, E.; Laporta, C.C.; Grimaldi, M.; Pitirollo, O.; Cavazza, A.; Pugliese, D.; Milanese, D.; Sciancalepore, C. Preparation and Characterisation of PBAT-Based Biocomposite Materials Reinforced by Protein Complex Microparticles. Mater. Proc. 2021, 7, 20. https://doi.org/10.3390/IOCPS2021-12019

Togliatti E, Laporta CC, Grimaldi M, Pitirollo O, Cavazza A, Pugliese D, Milanese D, Sciancalepore C. Preparation and Characterisation of PBAT-Based Biocomposite Materials Reinforced by Protein Complex Microparticles. Materials Proceedings. 2021; 7(1):20. https://doi.org/10.3390/IOCPS2021-12019

Chicago/Turabian StyleTogliatti, Elena, Cosimo C. Laporta, Maria Grimaldi, Olimpia Pitirollo, Antonella Cavazza, Diego Pugliese, Daniel Milanese, and Corrado Sciancalepore. 2021. "Preparation and Characterisation of PBAT-Based Biocomposite Materials Reinforced by Protein Complex Microparticles" Materials Proceedings 7, no. 1: 20. https://doi.org/10.3390/IOCPS2021-12019

APA StyleTogliatti, E., Laporta, C. C., Grimaldi, M., Pitirollo, O., Cavazza, A., Pugliese, D., Milanese, D., & Sciancalepore, C. (2021). Preparation and Characterisation of PBAT-Based Biocomposite Materials Reinforced by Protein Complex Microparticles. Materials Proceedings, 7(1), 20. https://doi.org/10.3390/IOCPS2021-12019