Review on Thermal Energy Storing Phase Change Material-Polymer Composites in Packaging Applications †

Abstract

:1. Introduction

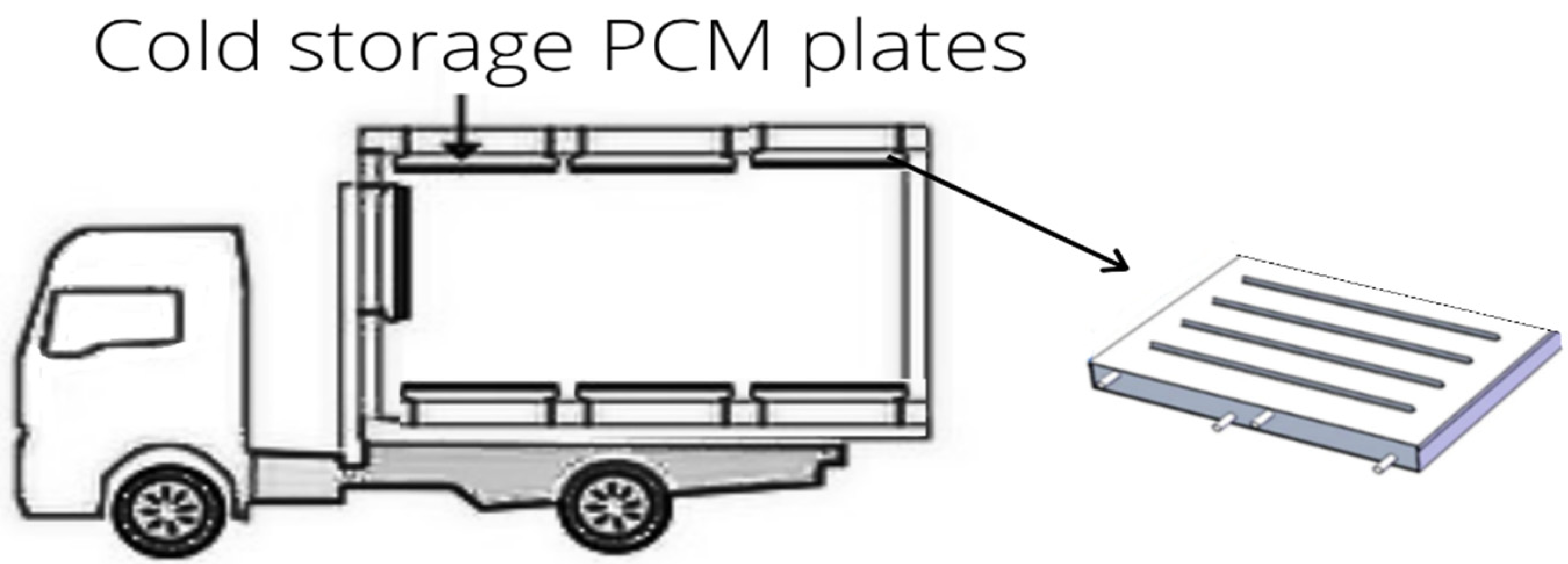

2. Large Container Shipments

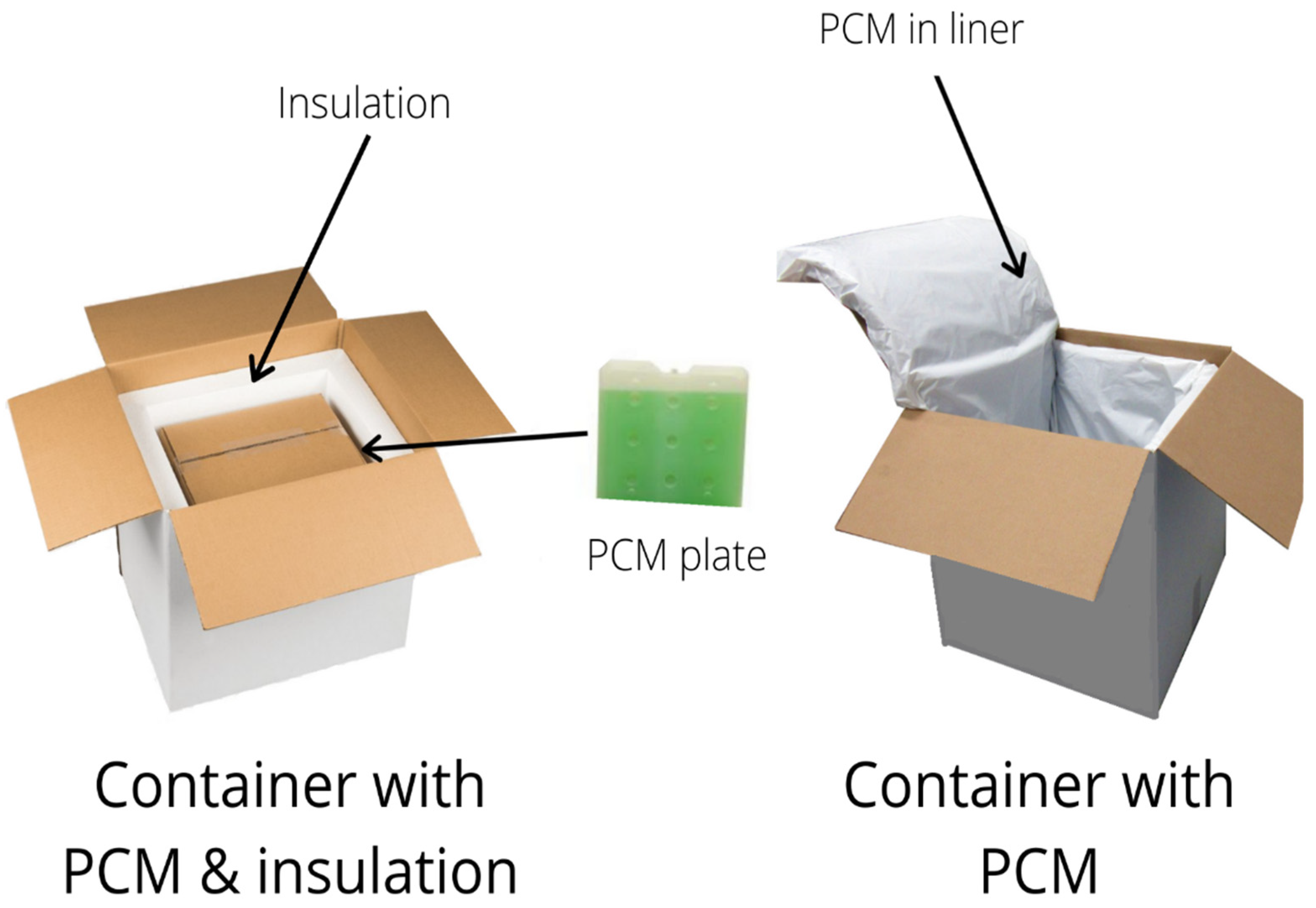

3. Small Container Packages

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Temperature Controlled Packaging Solutions Market by Type (Active, Passive), Product, Usability (Single, Reuse), Revenue type (Product, Service), End-Use Industry (Pharma and Biopharma) & Region—Trends and Forecasts Up to 2026. Available online: https://www.marketsandmarkets.com/Market-Reports/temperature-controlled-packaging-solutions-market-5227701.html (accessed on 29 September 2021).

- Vaccine Fridge Keeps Its Cool during 10-Day Power Cut. Available online: https://www.newscientist.com/article/mg20927944-000-vaccine-fridge-keeps-its-cool-during-10-day-power-cut (accessed on 29 September 2021).

- Tong, S.; Nie, B.; Li, Z.; Jin, Y.; Ding, Y.; Hu, H. Investigation of the cold thermal energy storage reefer container for cold chain application. Energy Storage Sci. Technol. 2020, 9, 211–216. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X.; Xu, X.; Zhao, Y. Thermomechanical Analysis and Numerical Simulation of Storage Type Multi-Temperature Refrigerated Truck. Int. J. Sci. 2020, 7, 261–270. [Google Scholar]

- Mousazade, A.; Rafee, R.; Valipour, M.S. Thermal performance of cold panels with phase change materials in a refrigerated truck. Int. J. Refrig. 2020, 120, 119–126. [Google Scholar] [CrossRef]

- Radebe, T.B.; Huan, Z.; Baloyi, J. Simulation of eutectic plates in medium refrigerated transport. J. Eng. Des. Technol. 2021, 19, 62–80. [Google Scholar] [CrossRef]

- Principi, P.; Fioretti, R.; Copertaro, B. Energy saving opportunities in the refrigerated transport sector through Phase Change Materials (PCMs) application. J. Phys. Conf. Ser. 2017, 923, 12043. [Google Scholar] [CrossRef]

- Fioretti, R.; Principi, P.; Copertaro, B. A refrigerated container envelope with a PCM (Phase Change Material) layer: Experimental and theoretical investigation in a representative town in Central Italy. Energy Convers. Manag. 2016, 122, 131–141. [Google Scholar] [CrossRef]

- Nie, B.; She, X.; Zou, B.; Li, Y.; Li, Y.; Ding, Y. Discharging performance enhancement of a phase change material based thermal energy storage device for transport air-conditioning applications. Appl. Therm. Eng. 2020, 165, 114582. [Google Scholar] [CrossRef]

- Nie, B.; She, X.; Du, Z.; Xie, C.; Li, Y.; He, Z.; Ding, Y. System performance and economic assessment of a thermal energy storage based air-conditioning unit for transport applications. Appl. Energy 2019, 251, 113254. [Google Scholar] [CrossRef]

- Johnston, J.H.; Grindrod, J.E.; Dodds, M.; Schimitschek, K. Composite nano-structured calcium silicate phase change materials for thermal buffering in food packaging. Curr. Appl. Phys. 2008, 8, 508–511. [Google Scholar] [CrossRef]

- Leducq, D.; Ndoye, F.T.; Charriau, C.; Alvarez, G. Thermal protection of ice cream during storage and transportation. Refrig. Sci. Technol. 2015, 4614–4619. [Google Scholar] [CrossRef]

- Ünal, M.; Konuklu, Y.; Paksoy, H. Thermal buffering effect of a packaging design with microencapsulated phase change material. Int. J. Energy Res. 2019, 43, 4495–4505. [Google Scholar] [CrossRef]

- Yin, H.; Gao, S.; Cai, Z.; Wang, H.; Dai, L.; Xu, Y.; Liu, J.; Li, H. Experimental and numerical study on thermal protection by silica aerogel based phase change composite. Energy Rep. 2020, 6, 1788–1797. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Zhou, S.; Wang, Y.; Lu, L. Experimental and application study of Na 2 SO 4 ·10H 2 O with additives for cold storage. J. Therm. Anal. Calorim. 2019, 136, 505–512. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Q.; Bian, W.; Ye, L.; Yang, X.; Song, X. Preservation of traditional Chinese pork balls supplemented with essential oil microemulsion in a phase-change material package. J. Sci. Food Agric. 2020, 100, 2288–2295. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Piontek, U. Improving performance of cold-chain insulated container with phase change material: An experimental investigation. Appl. Sci. 2017, 7, 1288. [Google Scholar] [CrossRef] [Green Version]

- Booska, R. Thermal Receptacle with Phase Change Material. U.S. Patent 10,595,654, 24 March 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amberkar, T.; Mahanwar, P. Review on Thermal Energy Storing Phase Change Material-Polymer Composites in Packaging Applications. Mater. Proc. 2021, 7, 14. https://doi.org/10.3390/IOCPS2021-11218

Amberkar T, Mahanwar P. Review on Thermal Energy Storing Phase Change Material-Polymer Composites in Packaging Applications. Materials Proceedings. 2021; 7(1):14. https://doi.org/10.3390/IOCPS2021-11218

Chicago/Turabian StyleAmberkar, Tejashree, and Prakash Mahanwar. 2021. "Review on Thermal Energy Storing Phase Change Material-Polymer Composites in Packaging Applications" Materials Proceedings 7, no. 1: 14. https://doi.org/10.3390/IOCPS2021-11218

APA StyleAmberkar, T., & Mahanwar, P. (2021). Review on Thermal Energy Storing Phase Change Material-Polymer Composites in Packaging Applications. Materials Proceedings, 7(1), 14. https://doi.org/10.3390/IOCPS2021-11218