1. Introduction

The mining industry is a well-developed sector and usually determines the socioeconomic status of a nation. New methodologies are introduced constantly regarding mining processes’ optimization and, also, minimization of their environmental footprint. Towards the sustainable operation of a mining facility, water management is considered to be a high-priority aspect, being a crucial resource at present. Indeed, such industries consume large quantities of water, and, as a result, equally large quantities of tailings are produced. Their treatment is mandatory, according to national and international organizations, and water recovery is strongly recommended. A useful tool in achieving sustainable water management is water balance, which requires constant quality and quantity monitoring [

1].

Abandoning conventional tailings disposal techniques, i.e., storage facilities and dams, and applying alternative approaches may limit the environmental risks and, at the same time, be cost efficient [

2]. Tailings ponds failure is the major concern in those cases, and, in the past, relevant events have caused severe degradation of the surrounding area. An alternative approach, which is comparatively simple to implement, is tailings thickening [

3]. Τhe application of such technology in a mining plant offers significant advantages such as a reduction in the volume of waste and the possibility of water recovery [

4]. Thickened tailings limit the risk of the abovementioned pond failure due to the more stable dry slurry deposition. In addition, the plant may operate under a closed water loop system, through its recovery and recycling, technically isolated from the surrounding water systems [

5].

Grecian Magnesite S.A. (GM) is a magnesite mining company, which aims at tailings valorization through a sustainable approach. GM produces and commercializes several Mg-based products, such as caustic calcined magnesia (CCM), dead-burned magnesia (DBM), magnesium carbonate (raw magnesite) and basic monolithic refractories. GM’s major deposits and production facilities are in Gerakini, Chalkidiki, N. Greece. Ιn this study, the environmental impact of mining and industrial activities is examined, and the water management issues are addressed, as an important part of the overall footprint. For production purposes, water is applied in large quantities for several uses such as ore washing, road wetting, machinery cooling and tree and plant irrigation. The main sources of this water are surface water from precipitation harvesting and surface runoff in “natural” reservoirs, along with groundwater which is utilized for human consumption and irrigation of olive trees at remediate older mining sites. In total, 5 × 106–8 × 106 m3 of wastewater, consisting mainly of muddy water, is produced from the magnesite ore washing facilities each year. This wastewater is appropriately treated in settling tanks (thickeners) in order to remove/separate the solid content and to recover the supernatant water.

2. Materials and Methods

2.1. Wasterwater Treatment

Wastewater, mainly produced by the magnesite ore facilities (i.e., vibrating washing screens), is treated by settling tanks applying the flocculation process. In addition, pre-beneficiation (Pre-BF) wastewater and beneficiation (BF) wastewater are treated separately. Pre-BF solid–liquid separation is conducted in a twin-thickening tank system (

Figure 1a), and BF in a single-tank system (

Figure 1b) by gravity. Flocculant solution, consisting of the anionic polyacrylamide FLOCAN 23-20 produced by SNF FLOERGER, is added by dosing pumps in order to enhance sludge settlement during both processes.

2.2. Water and Tailings Quantity and Quality

Data regarding water consumption and sludge (tailings) production from the thickening tanks were collected for a period of 11 years (2010–2020) and are presented in this study. Moreover, quality data are also presented. The tanks’ clarified supernatant water was fully chemically analyzed, and the EN 12457-1 [

6] leachability protocol was applied in tailings.

3. Results

3.1. Water Recovery

The sludge from the pre-BF thickeners had a solid content of between 28 and 36%. The upper limit was achieved with flocculant dosing, and the lower limit was reached without polymer addition. The obtained effluent TSS concentration was in the range 30–100 mg/L. The sludge from the BF thickener had a solid content of between 16 and 23%. Flocculant was typically added. The obtained TSS concentration in the clarified medium was in the range 10–50 mg/L.

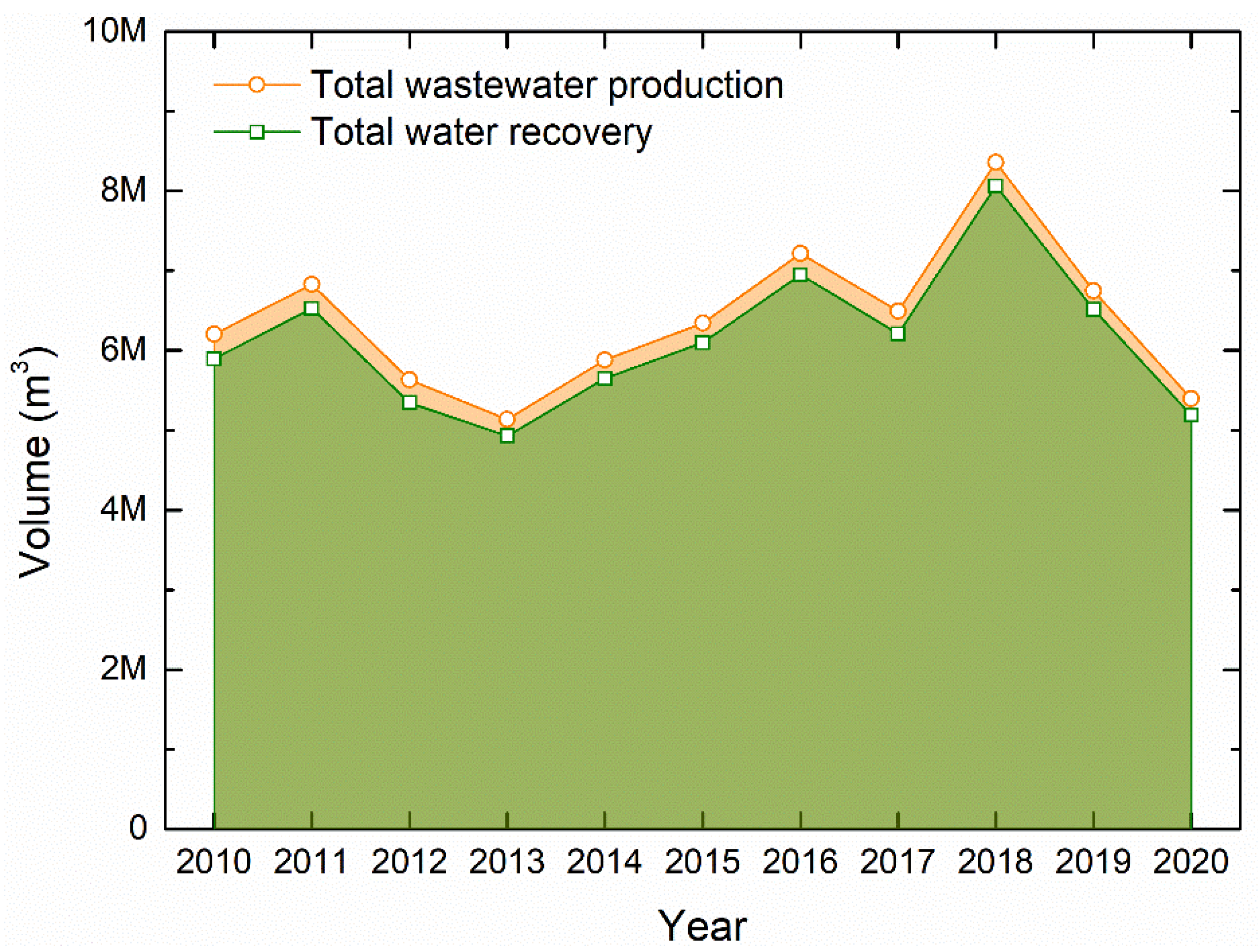

The average annual wastewater production in the reporting period (2010–2020) amounted to 6.4 Mm

3, with approximately 95.3% of it, namely, 6.1 Μm

3 per year, being recovered as clarified effluent (

Figure 2). The remaining 4.7% corresponded to the thickening tanks’ underflow that was safely deposited into tailings ponds. Correspondingly, 0.26 Mm

3 of sludge was produced on average.

3.2. Supernatant Wastewater and Tailings

With the exception of TSS and turbidity, the treated wastewater was of similar quality to reservoir water. The higher TSS and turbidity values were attributed to the incomplete solid separation, whereas residual acrylamide measurements were consistently below the detection limit, indicating that polymer addition had no adverse effect on the clarified effluent quality. On the other hand, the sludge leaching test according to the EN 12457 protocol (

Table 1) indicated that the tailings did not qualify for disposal in hazardous waste landfills, and thus they were stored safely in pods. The only element that exceeded the regulation limit was F

-, which presented a 630 mg/kg leachable concentration, while the hazardous waste limit is 500 mg/kg.

3.3. Recovered Wastewater Reuse

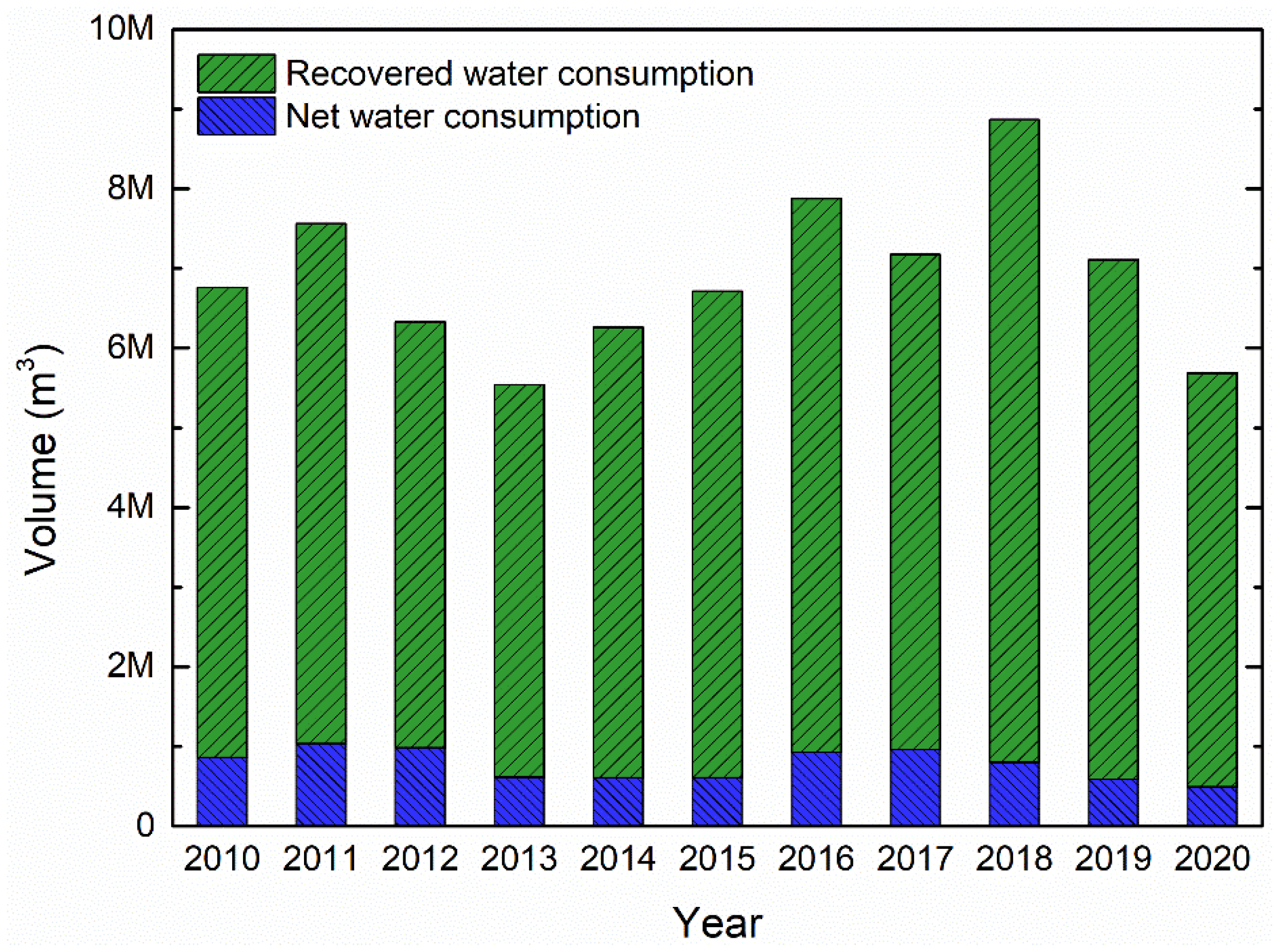

The average annual water consumption within the Yerakini Mines amounts to 6.9 Mm

3. The significant variations in water consumption over the presented period of time, according to

Figure 3, were attributed to the annual quantity of magnesite production since they are proportional factors. Based on the data also presented in

Figure 3, up to 89% of this water came from the treated/recovered wastewater, whereas the remaining 11% was derived from fresh water, namely, reservoir and well water.

4. Discussion

The water recovery reaches up to 96% (v/v), whereas the remaining sludge waste is safely deposited in tailings ponds. Critical water quality parameters are systematically examined to assess the water’s potential for reuse. In most cases, thickeners obtain over 95% TSS removal, whereas the recovered wastewater is suitable for direct reuse in magnesite ore washing facilities. The recovered water stands for almost 89% (v/v) of the total water consumption for all uses within the industrial processing and mine activities, significantly reducing freshwater consumption.

Author Contributions

Conceptualization, I.T. and A.Z.; methodology, I.T., E.T. and A.Z.; software, E.K.; validation, I.T., E.T. and A.Z.; formal analysis, E.K.; investigation, I.T. and E.T.; resources, I.T.; data curation, I.T. and E.K.; writing—original draft preparation, E.K.; writing—review and editing, I.T., E.T., E.K. and A.Z.; visualization, E.K.; supervision, A.Z.; project administration, I.T.; funding acquisition, I.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been co-financed by the European Union and Greek national funds through the Operational Program Competitiveness, Entrepreneurship and Innovation, under the call RESEARCH—CREATE—INNOVATE (project code: T1EDK-03543).

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Punkkinen, H.; Rasanen, L.; Mroueh, U.M.; Korkealaakso, J.; Luoma, S.; Kaipainen, T.; Backnas, S.; Turunen, K.; Hentinen, K.; Pasanen, A.; et al. Guidelines for Mine Water Management, VTT Technology 266; VTT Technical Research Centre of Finland Ltd.: Helsinki, Finland, 2016; pp. 27–32. [Google Scholar]

- Gao, L.; Bryan, B.A.; Liu, J.; Li, W.; Chen, Y.; Liu, R.; Barrett, D. Managing too little and too much water: Robust mine-water management strategies under variable climate and mine conditions. J. Clean. Prod. 2017, 162, 1009–1020. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef] [Green Version]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Kinnunen, P.; Obenaus-Emler, R.; Raatikainen, J.; Guignot, S.; Guimerà, J.; Ciroth, A.; Heiskanen, K. Review of closed water loops with ore sorting and tailings valorisation for a more sustainable mining industry. J. Clean. Prod. 2021, 278, 123237–123248. [Google Scholar] [CrossRef]

- European Committee for Standardization. ΕΝ 12457-2: Characterization of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size below 4 mm (without or with Size Reduction); European Standard: Brussels, Belgium, 2002. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).