Petrology and Genesis of the Italian Zeolite Tuffs Used in the Construction Industry †

Abstract

1. Introduction

2. Materials and Methods

2.1. Geology of the Zeolitic Deposits

2.1.1. Naples Area

2.1.2. Rome Area

2.1.3. Viterbo-Pitigliano-Sorano Area

2.2. Analytical Techniques

2.2.1. Mineralogical Analysis

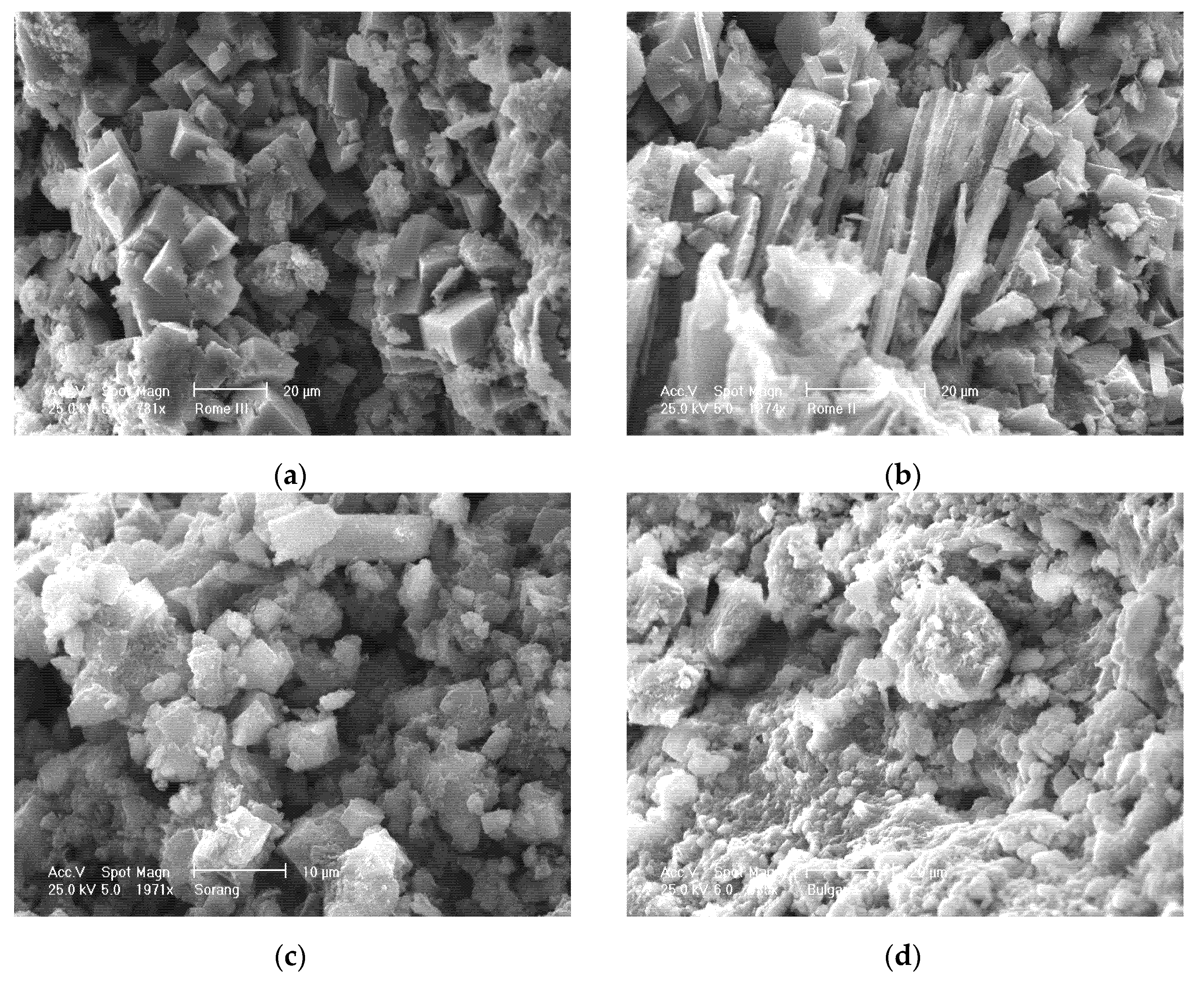

2.2.2. Scanning Electron Microscopy

2.2.3. Bulk Rock Chemistry

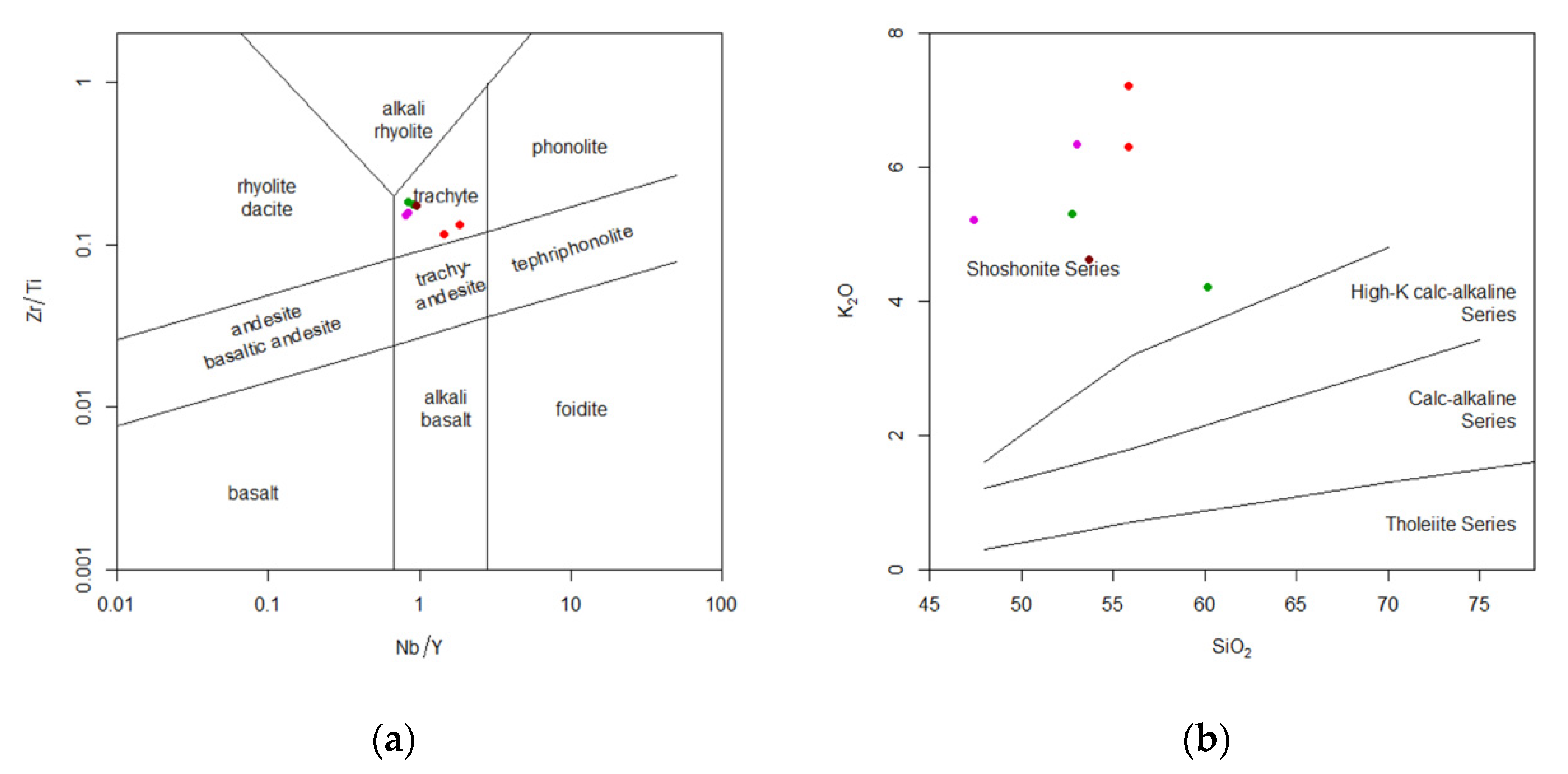

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Marantos, I.; Christidis, G.E.; Ulmanu, M. Zeolite formation and deposits. In Handbook of Natural Zeolites; Inglezakis, V.J., Zorpas, A.A., Eds.; Bentham Science Publishers: Sharjah, United Arab Emirates, 2011; pp. 28–51. [Google Scholar]

- Gottardi, G.; Obradovic, J. Sedimentary Zeolites in Europe. Fortschr. Miner. 1978, 56, 316–366. [Google Scholar]

- Hay, R.L.; Sheppard, R.A. Zeolites in Open Hydrologic Systems. In Mineralogy and Geology of Natural Zeolites; Mumpton, F.A., Ed.; Mineralogical Society of America Reviews in Mineralogy: Chantilly, VA, USA, 1981; Volume 4, pp. 93–102. [Google Scholar]

- Sheppard, R.A. Descriptive Model of Sedimentary Zeolites—Deposit Subtype: Zeolites in Tuffs of Open Hydrologic Systems. In Some Industrial Mineral Deposit Models: Descriptive Deposit Models; Open-File Report, 91-11A; Orris, G.J., Bliss, J.D., Eds.; U.S. Geological Survey: Reston, VA, USA, 1991; pp. 13–15. [Google Scholar]

- Stamatakis, M.G.; Hall, A.; Hein, J.R. The zeolite deposits of Greece. Miner. Depos. 1996, 31, 473–481. [Google Scholar] [CrossRef]

- de Gennaro, M.; Langella, A. Italian zeolitized rocks of technological interest. Miner. Depos. 1996, 31, 452–472. [Google Scholar] [CrossRef]

- Stamatakis, M.G.; Hall, A.; Lutat, U.; Walsh, J.N. Mineralogy, origin and commercial value of the zeolite¬-rich tuffs in the Petrota¬-Pentalofos area, Evros County, Greece. Estud. Geol. 1998, 54, 315–322. [Google Scholar] [CrossRef]

- Virta, R.L. Zeolites (Natural). In Mineral Commodity Summaries; U.S. Geological Survey: Reston, VA, USA, 2015; pp. 184–185. [Google Scholar]

- de Gennaro, M.; Colella, C.; Franco, E.; Aiello, R. Italian zeolites 1. Mineralogical and technical features of Neapolitan yellow tuff. Ind. Miner. 1983, 186, 47–53. [Google Scholar]

- Perrotta, A.; Scarpati, C. Plinian versus co-ignimbrite volume in large explosive eruptions: The example of the Campanian Ignimbrite eruption. Miner. Petrol. 2003, 79, 67–78. [Google Scholar] [CrossRef]

- De Gennaro, R.; Cappelletti, P.; Cerric, G.; de’Gennaro, M.; Dondi, M.; Langella, A. Neapolitan Yellow Tuff as raw material for lightweight aggregates in lightweight structural concrete production. Appl. Clay Sci. 2005, 28, 309–319. [Google Scholar] [CrossRef]

- Caputo, D.; Lucolano, F.; Pepe, F.; Colella, C. Modeling of water and ethanol adsorption data on a commercial zeolite-rich tuff and prediction of the relevant binary isotherms. Microporous Mesoporous Mater. 2007, 105, 260–267. [Google Scholar] [CrossRef]

- Pansini, M.; de Gennaro, R.; Parlato, L.; de’Gennaro, M.; Langella, A.; Marocco, A.; Cappelletti, P.; Mercurio, M. Use of Sawing Waste from Zeolitic Tuffs in the Manufacture of Ceramics. Adv. Mater. Sci. Eng. 2010, 2010, 820541. [Google Scholar] [CrossRef][Green Version]

- Jackson, M.D.; Chae, S.R.; Mulcahy, S.R.; Meral, C.; Taylor, R.; Li, P.; Emwas, A.H.; Moon, J.; Yoon, S.; Vola, G.; et al. Unlocking the secrets of Al-tobermorite in Roman seawater concrete. Am. Mineral. 2013, 98, 1669–1687. [Google Scholar] [CrossRef]

- Passaglia, E.; Vezzalini, G. Crystal chemistry of diagenetic zeolites in volcanoclastic deposits of Italy. Contrib. Mineral. Petrol. 1985, 90, 190–198. [Google Scholar] [CrossRef]

- de’Gennaro, M.; Cappelletti, P.; Langella, A.; Perrotta, A.; Scarpati, C. Genesis of zeolites in the Neapolitan Yellow Tuff: Geological, volcanological and mineralogical evidence. Contrib. Mineral. Petrol. 2000, 139, 17–35. [Google Scholar] [CrossRef]

- de’Gennaro, B.; Aprea, P.; Colella, C. Impianto pre-pilota per la rimozione di ammonio da reflui dell’industria conciaria con letti di tufo zeolitico. In Proceedings of the 6° Convegno Nazionale AIMAT, Modena, Italy, 8–11 September 2002. [Google Scholar]

- Sparks, R.S.J. Stratigraphy and geology of the ignimbrites of Vulsini Volcano Central Italy. Geol. Rundsch. 1975, 64, 497–523. [Google Scholar] [CrossRef]

- Lombardi, G. Thermal analysis in the investigation of zeolitized and altered volcanics of Latium, Italy. Clay Miner. 1984, 19, 789–801. [Google Scholar] [CrossRef]

- Laurora, A.; Vezzalini, M.G.; Brigatti, M.F.; Malferrari, D. Technical report on: Mineralogical features of the quarry materials. In Water Pollution Reduction and Water Saving Using Natural Zeolitite Cycle Life. LIFE+2010—Project Code: LIFE+10ENV/IT/000321; Deliverable Product of the UniMORE Research Units: Modena, Italy, 2012; 20p. [Google Scholar]

- de Gennaro, B.; Colella, A.P.; Aprea, P.; Colella, C. Evaluation of an intermediate-silica sedimentary chabazite as exchanger for potentially radioactive cations. Microporous Mesoporous Mater. 2003, 61, 159–165. [Google Scholar] [CrossRef]

- Vezzoli, L.; Conticelli, S.; Innocenti, F.; Landi, P.; Manetti, P.; Palladino, D.M.; Trigila, R. Stratigraphy of the Latera Volcanic Complex: proposals for a new nomenclature. Per. Mineral. 1987, 56, 89–110. [Google Scholar]

- Stamatakis, M.G.; Fragoulis, D.; Papageorgiou, A.; Chaniotakis, E.; Bedelean, J.; Csiric, G. Clinoptilolite-rich tuffs from Greece, Romania and Hungary and their industrial potential as cement additive. In Proceedings of the 3rd Congress of Mineral Wealth, Athens, Greece, 22–24 November 2000; pp. 451–457. [Google Scholar]

- Stamatakis, M.G.; Stamataki, I.S.; Giannatou, S.; Vasilatos, C.; Drakou, F.; Mitsis, I.; Xinou, K. Characterization and evaluation of chabazite-and mordenite-rich tuffs, and their mixtures as soil amendments and slow release fertilizers. Arch. Agron. Soil Sci. 2017, 63, 735–747. [Google Scholar] [CrossRef]

- Pearce, J.A. A User’s Guide to Basalt Discrimination Diagrams. In Trace Element Geochemistry of Volcanic Rocks: Applications for Massive Sulphide Exploration; Wyman, D.A., Ed.; Geological Association of Canada, Short Course Notes: Ottawa, ON, Canada, 1996; Volume 12, pp. 79–113. [Google Scholar]

- Peccerillo, A.; Taylor, S.R. Geochemistry of Eocene Calc-Alkaline Volcanic Rocks from the Kastamonu Area, Northern Turkey. Contrib. Mineral. Petrol. 1976, 58, 63–81. [Google Scholar] [CrossRef]

| Sample | Mineral Phases 2 | |||||

|---|---|---|---|---|---|---|

| Phil | Chab | Qtz | Sm/Sep | Fl | Ill | |

| SRN-1 | MJ | TR | TR | |||

| SRN-2 | MJ | TR | TR | |||

| VIT-1 | MJ | TR | TR | |||

| ROM-2 | MD | MJ | TR | TR | MD | TR |

| ROM-3 | TR | MJ | MD | MD | TR | TR |

| NAP-1 | MJ | TR | MD | TR | ||

| NAP-2 | MJ | MD | MJ | TR | ||

| SOR-1 | SOR-2 | VIT-1 | NAP-1 | NAP-6 | ROM2 | ROM3 | |

|---|---|---|---|---|---|---|---|

| % | |||||||

| SiO2 | 60.17 | 52.77 | 53.68 | 55.82 | 55.85 | 53.02 | 47.40 |

| Al2O3 | 12.22 | 17.05 | 16.47 | 16.95 | 16.63 | 17.03 | 14.72 |

| Fe2O3 | 2.72 | 3.72 | 3.70 | 4.03 | 4.42 | 5.11 | 5.09 |

| CaO | 5.12 | 5.40 | 4.84 | 2.02 | 4.20 | 4.69 | 9.83 |

| MgO | 0.98 | 1.45 | 1.39 | 0.94 | 0.96 | 1.34 | 1.31 |

| K2O | 4.21 | 5.30 | 4.62 | 7.22 | 6.31 | 6.34 | 5.22 |

| Na2O | 0.84 | 0.63 | 0.67 | 2.08 | 0.95 | 1.22 | 0.54 |

| P2O5 | 0.35 | 0.41 | 0.25 | 0.68 | 0.65 | 0.77 | 0.50 |

| SO3 | 0.07 | 0.09 | 0.14 | 0.11 | 0.10 | 0.40 | 0.12 |

| TiO2 | 0.41 | 0.48 | 0.43 | 0.40 | 0.43 | 0.52 | 0.46 |

| MnO | 0.07 | 0.09 | 0.06 | 0.07 | 0.10 | 0.08 | 0.07 |

| LOI | 13.03 | 12.75 | 13.91 | 9.67 | 9.35 | 9.74 | 15.05 |

| Total | 100.19 | 100.14 | 100.16 | 99.99 | 99.95 | 100.30 | 100.31 |

| ppm | |||||||

| Cl | 193 | 211 | 120 | 390 | 263 | 248 | 191 |

| Sc | BDL 1 | BDL | BDL | BDL | BDL | BDL | BDL |

| V | 65 | 91 | 67 | 71 | 58 | 108 | 97 |

| Cr | 2 | 3 | 13 | 2 | 2 | 3 | 39 |

| Co | 5.2 | 6.6 | 6.6 | 7 | 9 | 12 | 17 |

| Ni | 4 | 3.4 | 8 | 2 | 4 | 8 | 21 |

| Cu | 16 | 28 | 32 | 73 | 47 | 44 | 113 |

| Zn | 73 | 91 | 79 | 168 | 232 | 261 | 120 |

| Ga | 21 | 26 | 19 | 18 | 19 | 22 | 17 |

| Ge | 1 | 1 | 1 | 2 | 2 | 0.7 | 0.7 |

| As | 12.7 | 13.2 | 9 | 12 | 3 | 37 | 14 |

| Se | 3 | 2.3 | 2.5 | 2 | 3 | 4 | 3 |

| Br | 3.4 | 1.7 | 2.7 | 1 | 1 | 1.6 | 1 |

| Rb | 425 | 465 | 390 | 269 | 279 | 452 | 255 |

| Sr | 874 | 926 | 1078 | 535 | 498 | 1042 | 1757 |

| Y | 25 | 31 | 24 | 25 | 29 | 31 | 32 |

| Zr | 446 | 509 | 449 | 275 | 343 | 492 | 415 |

| Nb | 21 | 28 | 23 | 36 | 53 | 26 | 26 |

| Mo | 0.5 | 0.1 | 1 | 1 | 0.7 | 2.3 | 0.7 |

| Ag | 0.1 | 0.1 | BDL | 1 | 0.2 | 0.1 | 0.5 |

| Cd | 0.9 | 1.2 | 0.5 | 2.4 | 5.5 | 7 | 35 |

| Sn | 4.9 | 4.6 | 3.5 | 4.6 | 5 | 6 | 5 |

| Sb | 1 | 1.1 | 0.4 | 1 | 0.5 | 4 | 4 |

| Te | 0.7 | 1.1 | 0.1 | BDL | 0.2 | 0.1 | BDL |

| I | BDL | BDL | 0.4 | BDL | 0.1 | 0.9 | 1.2 |

| Cs | 44 | 48.8 | 41 | 15 | 18 | 56 | 35 |

| Ba | 454 | 503 | 436 | 868 | 459 | 743 | 618 |

| La | 118 | 138 | 102 | 60 | 76 | 142 | 144 |

| Sm | 9 | 7 | 8 | 7 | 8 | 11 | 10 |

| Ce | 203 | 234 | 188 | 108 | 129 | 250 | 243 |

| BDL | 73 | 86 | 65 | 45 | 52 | 95 | 90 |

| Yb | 0.4 | 0.9 | BDL | 4 | BDL | 0.6 | BDL |

| Hf | 5.4 | 6 | 4.3 | BDL | 2 | 3.7 | BDL |

| W | 13 | 6 | 9 | 9 | 17 | 8 | 18 |

| Hg | 0.7 | 0.8 | 0.8 | 0.5 | 0.4 | 0.6 | 0.5 |

| Tl | 3 | 3.7 | 1.7 | 1.9 | 2.4 | 1.6 | 1 |

| Pb | 103 | 106 | 96 | 54 | 52 | 108 | 193 |

| Bi | 0.8 | 1.3 | 1.9 | 0.9 | 0.8 | 1.9 | 2.9 |

| Th | 60 | 83 | 72 | 20 | 16 | 99 | 76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stamatakis, M.G.; Vasilatos, C.; Stamataki, I.S. Petrology and Genesis of the Italian Zeolite Tuffs Used in the Construction Industry. Mater. Proc. 2021, 5, 7. https://doi.org/10.3390/materproc2021005007

Stamatakis MG, Vasilatos C, Stamataki IS. Petrology and Genesis of the Italian Zeolite Tuffs Used in the Construction Industry. Materials Proceedings. 2021; 5(1):7. https://doi.org/10.3390/materproc2021005007

Chicago/Turabian StyleStamatakis, Michael G., Charalampos Vasilatos, and Ioanna Stefania Stamataki. 2021. "Petrology and Genesis of the Italian Zeolite Tuffs Used in the Construction Industry" Materials Proceedings 5, no. 1: 7. https://doi.org/10.3390/materproc2021005007

APA StyleStamatakis, M. G., Vasilatos, C., & Stamataki, I. S. (2021). Petrology and Genesis of the Italian Zeolite Tuffs Used in the Construction Industry. Materials Proceedings, 5(1), 7. https://doi.org/10.3390/materproc2021005007