Dual and Multi Energy XRT and CT Analyses Applied to Copper-Molybdenum Mineralizations in Porphyry Deposits †

Abstract

:1. Introduction

2. Materials and Methods

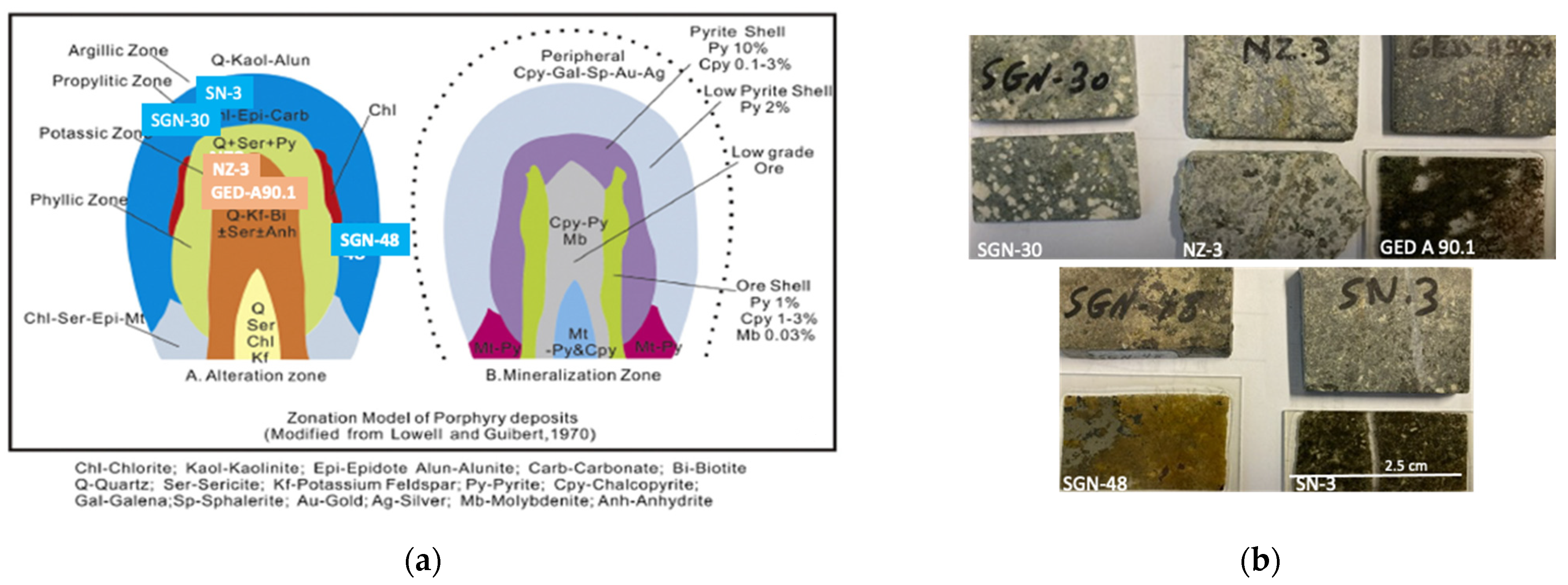

2.1. Samples

2.2. Mineralogy

2.3. X-ray Transmission

2.3.1. Dual Energy X-ray Transmission

2.3.2. Multi Energy X-ray Transmission

2.4. X-ray Computed Tomography

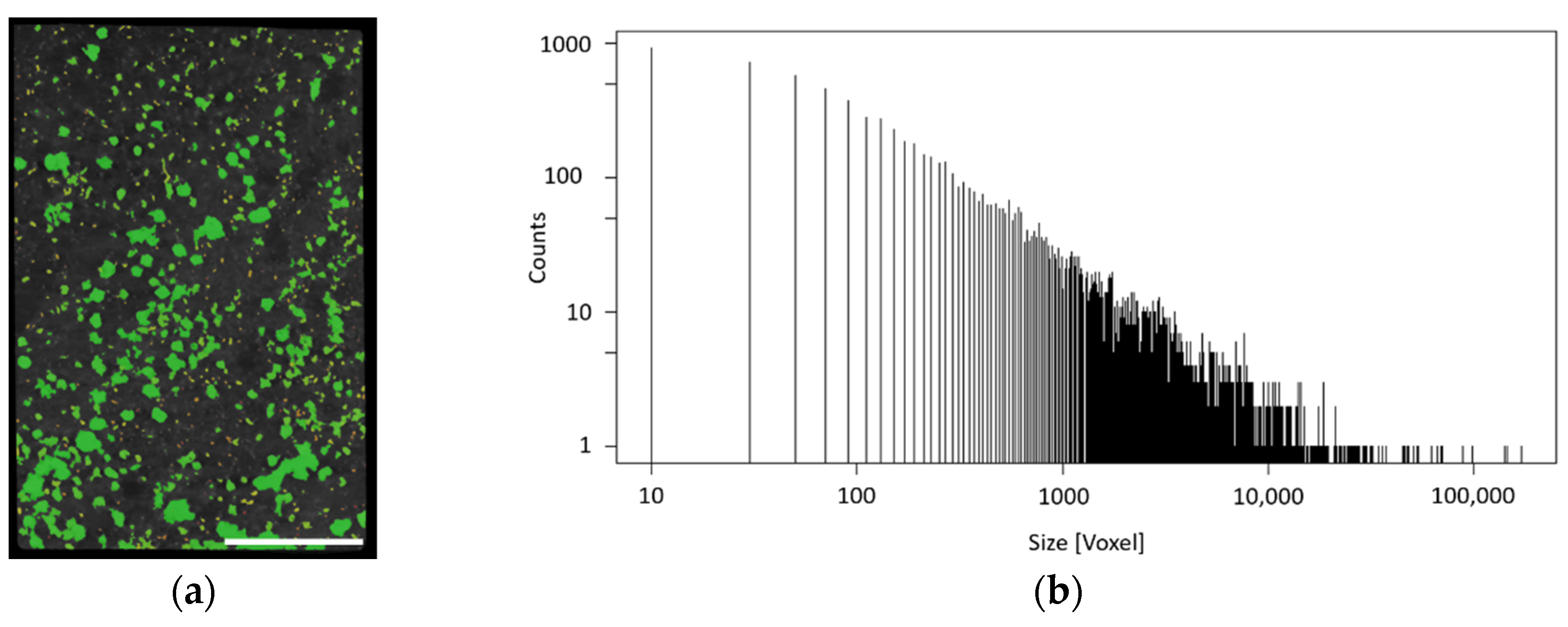

2.4.1. Measurements

2.4.2. Image Processing

3. Results

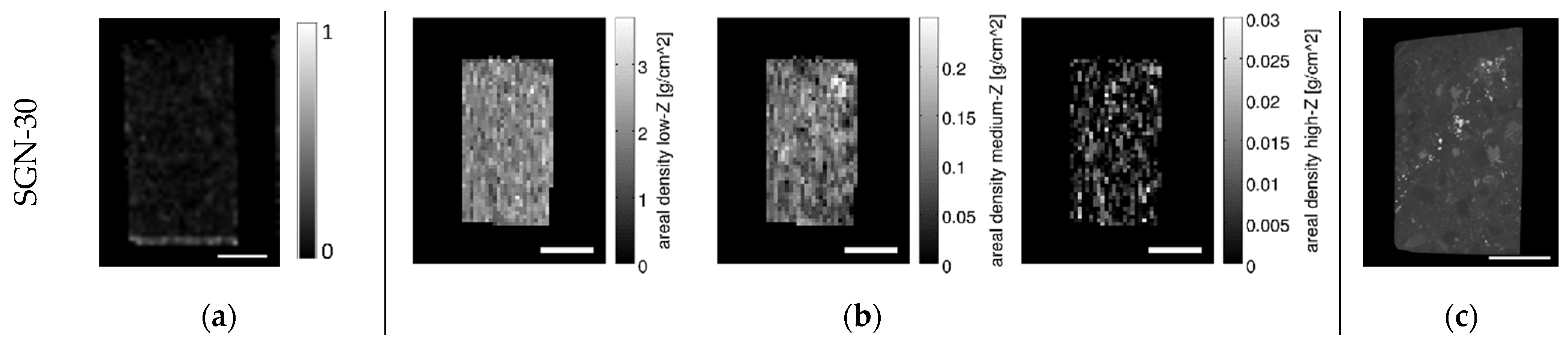

3.1. Potassic-Phyllic Zone

3.2. Propylitic Zone

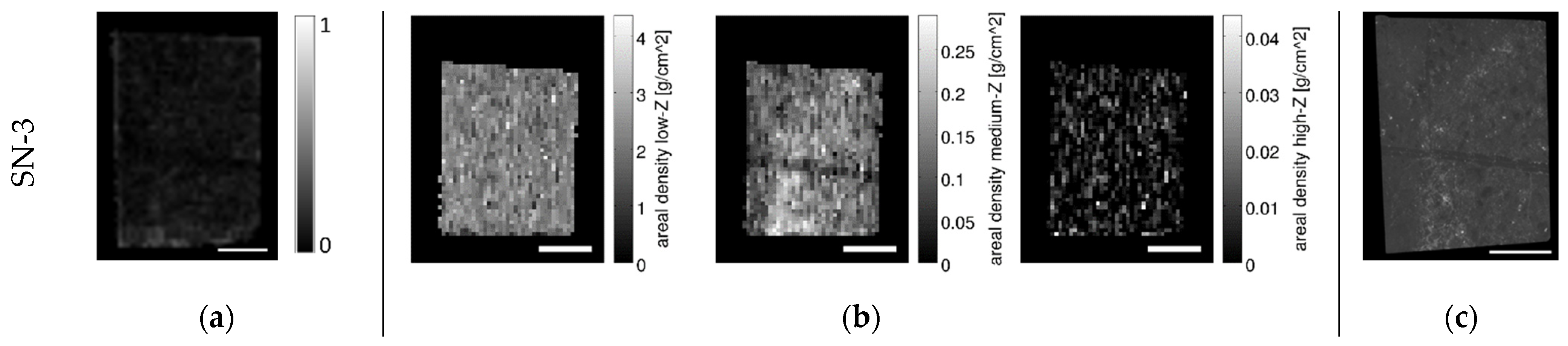

3.3. Phyllic-Argillic Zone

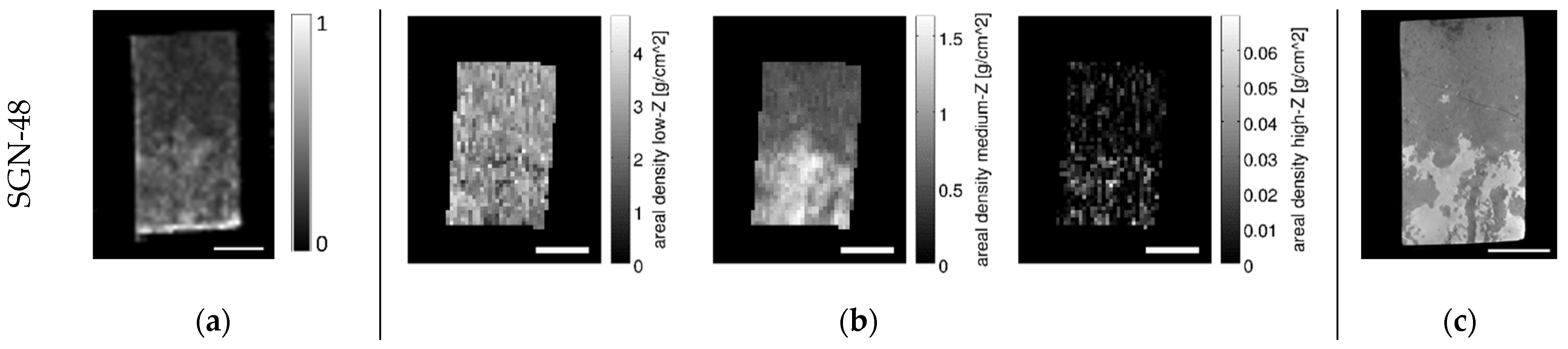

3.4. Peripheral Skarn

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World Bank Group. Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition. Available online: http://pubdocs.worldbank.org/en/961711588875536384/Minerals-for-Climate-Action-The-Mineral-Intensity-of-the-Clean-Energy-Transition.pdf (accessed on 30 September 2020).

- Tabelin, C.B.; Park, I.; Phengsaart, T.; Jeon, S.; Villacorte-Tabelin, M.; Alonzo, D.; Yoo, K.; Ito, M.; Hiroyoshi, N. Copper and critical metal production from porphyry ores and E-wastes: A review of resource availability, processing/recycling challenges, socio-environmental aspects and sustainability issues. Resour. Conserv. Recycl. 2021, 170, 105610. [Google Scholar] [CrossRef]

- Sillitoe, R.H. Porphyry copper systems. Econ. Geol. 2010, 105, 3–41. [Google Scholar] [CrossRef] [Green Version]

- Aikawa, K.; Ito, M.; Segawa, T.; Jeon, S.; Park, I.; Tabelin, C.B.; Hiroyoshi, N. Depression of lead-activated sphalerite by pyrite via galvanic interactions: Implications to the selective flotation of complex sulfide ores. Miner. Eng. 2020, 152, 106367. [Google Scholar] [CrossRef]

- ANCORELOG: Analytical Core Logging System. Available online: https://eitrawmaterials.eu/project/ancorelog/ (accessed on 28 June 2021).

- Bauer, C.; Wagner, R.; Orberger, B.; Firsching, M.; Ennen, A.; Garcia Pina, C.; Wagner, C.; Honarmand, M.; Nabatian, G.; Monsef, I. Potential of Dual and Multi Energy XRT and CT Analyses on Iron Formations. Sensors 2021, 21, 2455. [Google Scholar] [CrossRef] [PubMed]

- Omrani, J.; Agard, P.; Whitechurch, H.; Benoit, M.; Prouteau, G.; Jolivet, J. Arc-magnetism an subduction history beneath the Zagros Mountain, Iran: A new report of adakites and geodynamic consequences. Lithos 2008, 106, 380–398. [Google Scholar] [CrossRef]

- Hassanpour, H.; Alirezaei, S.; Selby, D.; Sergeev, S. SHRIMP zircon U–Pb and biotite and hornblende Ar–Ar geochronology of Sungun, Haftcheshmeh, Kighal, and Niaz porphyry Cu–Mo systems: Evidence for an early Miocene porphyry-style mineralization in northwest Iran. Int. J. Earth Sci. 2015, 104, 45–59. [Google Scholar] [CrossRef]

- Lowell, J.D.; Guilbert, J.M. Lateral and Vertical Alteration-Mineralization Zoning in Porphyry Ore Deposits. Econ. Geol. 1970, 65, 373–408. [Google Scholar] [CrossRef]

- Firsching, M.; Nachtrab, F.; Uhlmann, N.; Hanke, R. Multi-Energy X-ray Imaging as a Quantitative Method for Materials Characterization. Adv. Mater. 2011, 23, 2655–2656. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, R.E. Estimator for photon counting energy selective X-ray imaging with multibin pulse height analysis. Med. Phys. 2011, 38, 2324–2334. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, R.E. Efficient, Non-Iterative Estimator for Imaging Contrast Agents with Spectral X-ray Detectors. IEEE Trans. Med. Imaging 2016, 35, 1138–1146. [Google Scholar] [CrossRef] [PubMed]

- Kalender, W.A.; Seissler, W.; Klotz, E.; Vock, P. Spiral volumetric CT with single breath-hold technique continuous transport and scanner rotation. Radiology 1990, 176, 181–183. [Google Scholar] [CrossRef]

- Bauer, C.; Wagner, R.; Firsching, M.; Orberger, B.; Lucic, J.; Ennen, A.; Wörlein, N.; Dubos, J.L.; Banchet, J.; Milazzo, J.-M.; et al. Recycling of Mn-processing dusts: Quality control through 3D computed tomography. In Proceedings of the IMPC 2020: International Mineral Processing Congress, Cape Town, South Africa, 18–22 October 2020; pp. 3551–3560. [Google Scholar]

- Bharodiya, A.K.; Gonsai, A.M. An intelligent assistive algorithm for bone tumor detection from human X-ray images based on binary Blob analysis. Int. J. Inf. Technol. 2020, 107, 2411–2502. [Google Scholar] [CrossRef]

- Vincent, L.; Soille, P. Watersheds in digital spaces: An efficient algorithm based on immersion simulations. IEEE Trans. Pattern Anal. Mach. Intell. 1991, 13, 583–598. [Google Scholar] [CrossRef] [Green Version]

- Taguchi, K.; Iwanczyk, J.S. Vision 20/20: Single photon counting X-ray detectors in medical imaging. Med. Phys. 2013, 40, 100901. [Google Scholar] [CrossRef] [PubMed]

| Alteration Zone | Sample | Medium-Z Elements Median DE-XRT | Medium-Z Elements Median ME-XRT | High-Z Elements Median ME-XRT | Medium- and High-Z Elements CT |

|---|---|---|---|---|---|

| potassic-phyllic | GED-A90.1 | 17.8% | 13.3% | 0.7‰ | 15.1% |

| NZ-3 | 20.9% | 17.5% | 3.7‰ | 17.5% | |

| propylitic | SGN-30 | 6.5% | 5.4% | 1.2‰ | 7.4% |

| phyllic-argillic | SN-3 | 6.9% | 5.6% | 1.3‰ | 7.8% |

| peripheral skarn | SGN-48 | 26.6% | 20.8% | 1.1‰ | 20.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bauer, C.; Wagner, R.; Orberger, B.; Firsching, M.; Wagner, C.; Boudouma, O.; Siahcheshm, K. Dual and Multi Energy XRT and CT Analyses Applied to Copper-Molybdenum Mineralizations in Porphyry Deposits. Mater. Proc. 2021, 5, 27. https://doi.org/10.3390/materproc2021005027

Bauer C, Wagner R, Orberger B, Firsching M, Wagner C, Boudouma O, Siahcheshm K. Dual and Multi Energy XRT and CT Analyses Applied to Copper-Molybdenum Mineralizations in Porphyry Deposits. Materials Proceedings. 2021; 5(1):27. https://doi.org/10.3390/materproc2021005027

Chicago/Turabian StyleBauer, Christine, Rebecca Wagner, Beate Orberger, Markus Firsching, Christiane Wagner, Omar Boudouma, and Kamal Siahcheshm. 2021. "Dual and Multi Energy XRT and CT Analyses Applied to Copper-Molybdenum Mineralizations in Porphyry Deposits" Materials Proceedings 5, no. 1: 27. https://doi.org/10.3390/materproc2021005027

APA StyleBauer, C., Wagner, R., Orberger, B., Firsching, M., Wagner, C., Boudouma, O., & Siahcheshm, K. (2021). Dual and Multi Energy XRT and CT Analyses Applied to Copper-Molybdenum Mineralizations in Porphyry Deposits. Materials Proceedings, 5(1), 27. https://doi.org/10.3390/materproc2021005027