Introducing the IDEF0 Methodology in the Strategic Planning of Projects for Reclamation and Repurposing of Surface Mines †

Abstract

:1. Introduction

2. Mine Closure: Problems and Research Questions

3. Materials and Methods

3.1. The IDEF0 Process Modelling Method

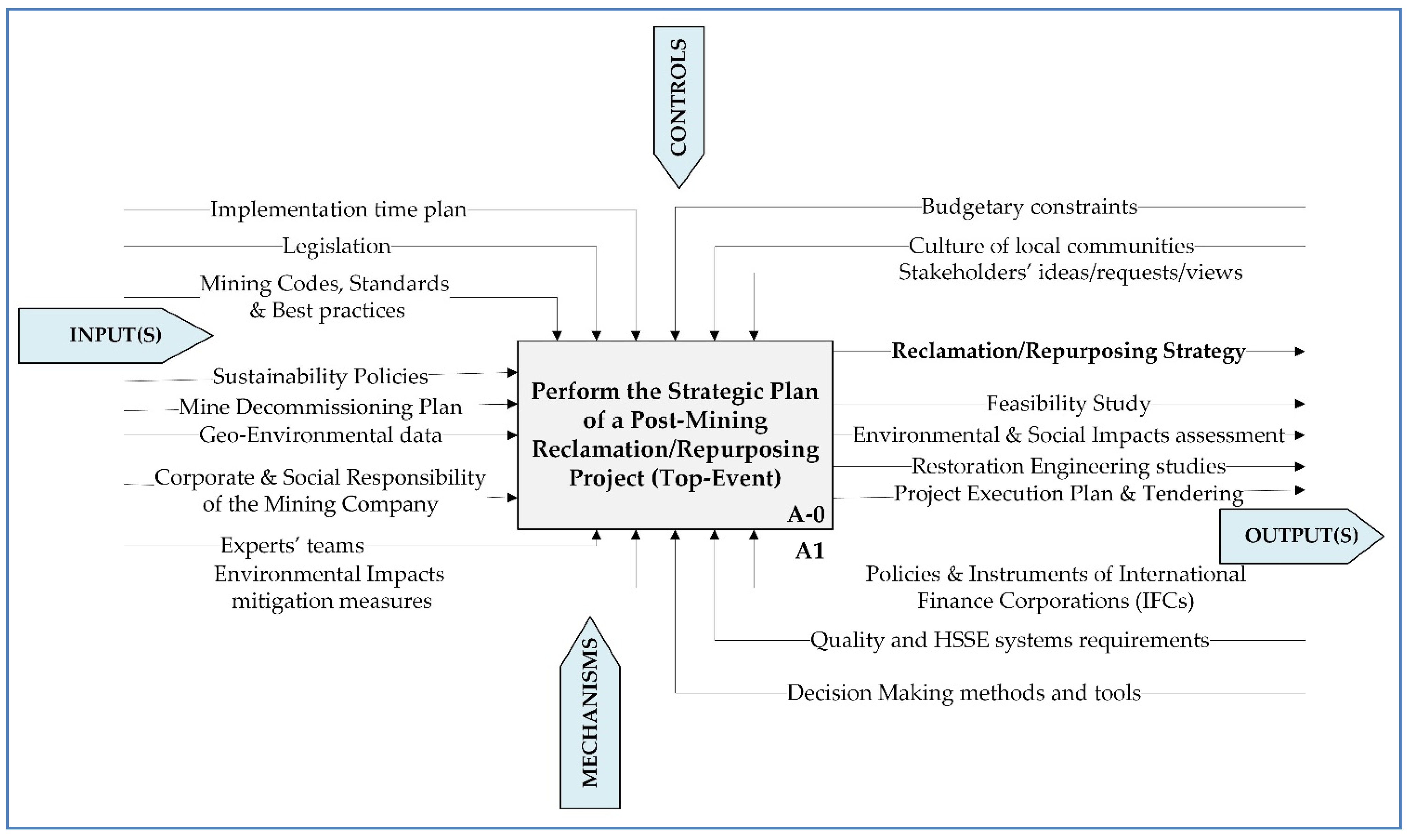

3.2. Case Study: An IDEF0 Post-Mining Strategic Model

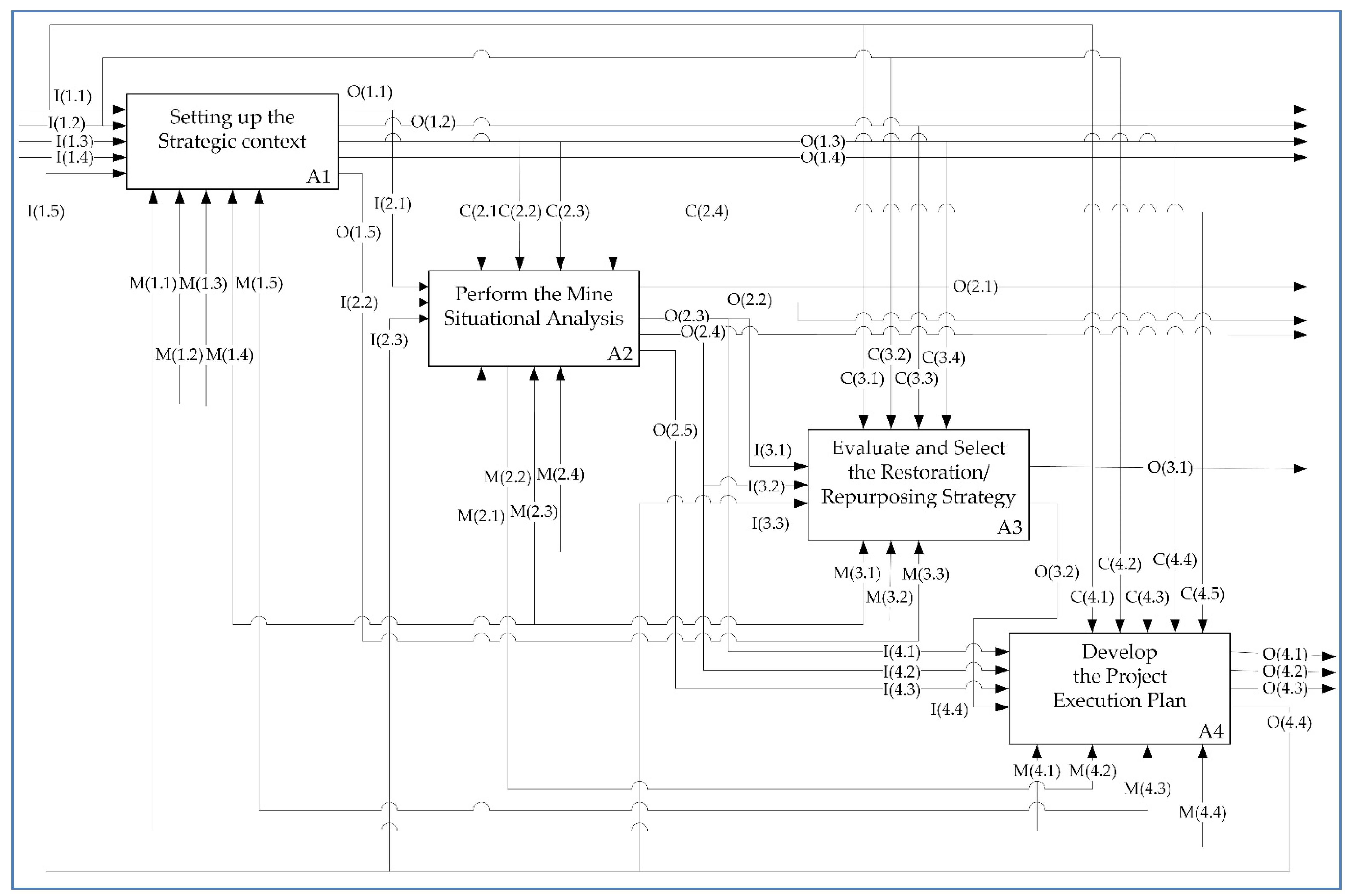

3.3. Analysis and Validation of Sub-Processes

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chuman, T. Restoration Practices used on Post mining Sites and Industrial Deposits in the Czech Republic with an Example of Natural Restoration of Granodiorite Quarries and Spoil Heaps. J. Landsc. Ecol. 2015, 8, 29–46. [Google Scholar] [CrossRef] [Green Version]

- Pavloudakis, F.; Roumpos, C.; Karlopoulos, E.; Koukouzas, N. Planning and implementing surface mines reclamation works under the new EU strategy for the transition of lignite intensive regions to a post-mining era. In Proceedings of the 12th International Conference of Mine Closure, Leipzig, Germany, 3–7 September 2018; pp. 139–146. [Google Scholar]

- Spanidis, P.M.; Roumpos, C.; Pavloudakis, F. A Multi-Criteria Methodology for Low-Risk Evaluation of Mine Closure Resto-ration in Continuous Surface Lignite Mining Projects. In Proceedings of the 14th Intl. Symposium of Continuous Surface Mining (ISCSM), Thessaloniki, Greece, 23–26 September 2018; pp. 563–578. [Google Scholar]

- Pavloudakis, F.; Roumpos, C.; Spanidis, P.-M. Optimisation of surface mining operation based on a circular economy model. In Circular Economy and Sustainability; Elsevier Publications: Amsterdam, The Netherlands, 2021; article in press. [Google Scholar]

- McCullough, C.D. Key. Mine Closure Lessons to Be Learned; Australian Centre for Geomechanics: Perth, Australia, 2016; pp. 319–332. ISBN 978-0-99248810-4-9. [Google Scholar]

- Stacey, J.; Naude, A.; Hermanus, M.; Frankel, P. The socio-economic aspects of mine closure and sustainable development: Literature overview and lessons for the socio-economic aspects of closure-Report-1. J. S. Afr. Inst. Mining Metallurgy 2010, 110, 379–394. [Google Scholar]

- Zhao, Y.; Zang, L.; Li, Z.; Qin, J. Discussion on the Model of Mining Circular Economy. Energy Procedia 2012, 16, 438–443. [Google Scholar] [CrossRef] [Green Version]

- European Commission (EC). Development of a guidance document on best practices in the Extractive Waste Management Plans-Circular Economy Action; Eco Efficiency Consulting and Engineering Ltd. in collaboration with WEFalck, Pöyry Finland Oy, Botond Kertész & CRS Ingenería; European Commission: Brussels, Belgium, 2019; p. 46. [Google Scholar]

- Prach, K.; Hobbs, R.J. Spontaneous succession versus technical reclamation in the restoration of disturbed sites. Restor. Ecol. 2008, 16, 363–366. [Google Scholar] [CrossRef]

- Roumpos, C.; Pavloudakis, F.; Galetakis, M. Modelling and evaluation of open-pit lignite mines exploitation strategy. In Proceedings of the 2nd International Conference on Sustainable Development Indicators in the Mineral Industry (SDIMI 2005), Aachen, Germany, 18–20 May 2005; pp. 1127–1139. [Google Scholar]

- Nickols, F. Strategy, Strategic Management, Strategic Planning and Strategic Thinking. DISTANCE CONSULTING LLC. 2011. Available online: https://nickols.us/~nickols1/strategy_etc.pdf (accessed on 2 April 2021).

- Artto, K.; Kujala, J.; Perttu, D.; Martinsuo, M. What is a Project Strategy? Int. J. Proj. Manag. 2001, 26, 4–12. [Google Scholar] [CrossRef] [Green Version]

- Lundgren, B.; Bjork, B.-C. A model integrating the facilities management process with the building end user’s business processes (ProFacil). Nordic J. Surveying Real Estate Res. 2004, 1/2, 190–204. [Google Scholar]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Grefen, P. Using business process models for the specification of manufacturing operations. Comp. Ind. 2020, 123, 1–21. [Google Scholar] [CrossRef]

- Kassem, M.; Dawood, N.; Mitchell, D. A Structured Methodology for Enterprise Modelling: A case study for Modelling the Operation of a British Organization. J. Inf. Technol. Constr. 2011, 16, 381–410. [Google Scholar]

- ISO/TR 9007. Information Processing Systems—Concepts and Terminology for the Conceptual Schema and the Information Base; International Organization for Standardizations (ISO): Geneve, Switzerland, 1987. [Google Scholar]

- Lang, A.-M.; Ellefmo, S.-L.; Aasly, K. Geo-metallurgical Flowsheet as a tool for designing and communicating the Geo-Metallurgical Programs. Minerals 2018, 8, 372. [Google Scholar] [CrossRef] [Green Version]

- Akinsola, A.; Dawood, N.; Hobbs, B. Construction Planning Process Improvement Using Information Technology Tools; paper w78-2000-40.content; Construction Informatics Digital Library: Reykjavik, Iceland, 2000; ISSN 2706-6568. [Google Scholar]

- Jeong, K.-Y.; Wu, L.; Hong, J.-D. IDEF method simulation model design and development. J. Ind. Eng. Man. 2009, 2, 337–359. [Google Scholar]

- Toba, A.-L.; Seck, M. Modelling Social, Economic, Technical and Environmental components in an Energy system. Procedia Comput. Sci. 2016, 95, 400–407. [Google Scholar] [CrossRef] [Green Version]

- Waissi, G.; Demir, M.; Humble, J.; Lev, B. Automation Strategy using IDEF0-A proof of concept. Op. Res. Perspect. 2015, 2, 106–113. [Google Scholar] [CrossRef] [Green Version]

- Kusiak, A.; Larson, N. System Reliability and Risk Assessment: A Quantitative extension of IDEF Methodologies. AAAI Technical Report SS-94-04. 1994. Available online: www.aaai.org (accessed on 5 April 2021).

- Saaty, T.L. The Analytic Hierarchy Process; McGraw Hill International: New York, NY, USA, 1980. [Google Scholar]

- Saaty, T.L. Decision making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Velasquez, M.; Hester, P.T. An Analysis of Multi-Criteria Decision Making Methods. Int. J. Oper. Res. 2013, 10, 56–66. [Google Scholar]

| A-0: Strategic Planning for a Reclamation/Repurposing Project (top event) | |||

| Sub-Process-ID: A1-Setting-up the Strategic context | |||

| A(1.1) | Analysis of Sustainability policies | A(1.6) | Analysis of Strengths and Weaknesses |

| A(1.2) | Consideration of environmental impacts | A(1.7) | Scope pre-screening |

| A(1.3) | Consideration of socio-economic impacts | A(1.8) | Preliminary time planning |

| A(1.4) | Investigation of Reclamation/Repurposing technologies | A(1.9) | Budgetary estimation of alternative Reclamation/Repurposing scenarios |

| A(1.5) | First round of Stakeholders Engagement | A(1.10) | Outlining the concept of Strategy(ies) |

| Sub-Process-ID: A2-Geo-Environmental Data Collection & Situational Analysis | |||

| A(2.1) | Preparation of site layouts for the landscape and landforms | A(2.7) | Sampling of contaminated/polluted receptors (soil-waters-air) |

| A(2.2) | Analysis of mine’s waste management records/procedures | A(2.8) | Impact analysis and mitigation measures |

| A(2.3) | Analysis of Satellite Imagery and Remote Sensing data | A(2.9) | Review of previous mine development plans and risk assessments |

| A(2.4) | Analysis of biotic, non-biotic and ecological factors | A(2.10) | Considering the legislative constraints and development programs |

| A(2.5) | Analysis of socio-economic factors, land use and infrastructures | A(2.11) | Evaluating the mining material and space suitability for 3R initiatives |

| A(2.6) | Geological, geotechnical and geophysical investigation | A(2.12) | Second round of Stakeholders Engagement |

| Sub-Process-ID: A3-Selection of the Reclamation/Repurposing Strategy | |||

| A(3.1) | Identification of the alternative Strategies | A(3.6) | Finalizing the Cost Analysis (for each strategy) |

| A(3.2) | Submission of the Reclamation/Repurposing Plan to Stakeholders | A(3.7) | Finalizing the Feasibility assessment |

| A(3.3) | Public Consultation | A(3.8) | Selection of Strategy (Multi-Criteria Decision Making-MCDM method) |

| A(3.4) | Consideration of Stakeholders’/Authorities’ feedback | A(3.9) | Approval of the selected Strategy |

| A(3.5) | Filling the gaps and reformulating the strategies | ||

| Sub-Process-ID: A4-Performing the Project Execution Plan | |||

| A(4.1) | Developing the Project and Construction Management systems | A(4.4) | Work and Cost breakdown analysis |

| A(4.2) | Preparation of Tendering | A(4.5) | Setup the Quality, Risk and HSSE Management systems |

| A(4.3) | Organization and Planning of the project | A(4.6) | Setup Environmental Monitoring and Management |

| A(4.7) | Request for Proposal (RfP) and Bidders evaluation | ||

| Description of Entities | Processes | |||

|---|---|---|---|---|

| A1 | A2 | A3 | A4 | |

| Mine Decommissioning Plan | I(1.1) | C(2.1) | C(3.1) | C(4.1) |

| Policies/Regulations for the Sustainable development & Circular Economy | I(1.2) | C(3.2) | C(4.2) | |

| Mine Company Corporate & Social Responsibility | I(1.3) | |||

| Mine Operation and Field inspection archives | I(1.4) | |||

| Lessons Learned | I(1.5) | I(2.3) | I(3.3) | O(4.4) |

| Pre-feasibility assessment | O(1.1) | I(2.1) | ||

| Reclamation Planning and Timeline | O(1.2) | C(2.2) | C(3.3) | C(4.3) |

| Preliminary Cost Estimation (CAPEX & OPEX) | O(1.3) | C(2.3) | C(3.4) | |

| Risk and Natural Hazards assessment | O(1.4) | C(4.4) | ||

| Stakeholders feedback (Authorities, Municipalities, NGOs, etc.) | O(1.5) | M(3.3) | ||

| Standards for Quality, HSSE and Risk management | M(1.1) | M(2.1) | M(4.1) | |

| Policies/Instruments of International Finance Corporations (IFC) | M(1.2) | |||

| Business and Financial analysis tools (SWOT, BCA, NPV/IRR, etc.) | M(1.3) | |||

| Legislation for occupational health & safety | C(2.4) | C(4.5) | ||

| Satellite Imagery and Remote Sensing data | I(2.2) | |||

| Situational analysis of the mine | O(2.1) | |||

| Environmental & Social Impacts Assessment (ESIA) | O(2.2) | I(3.1) | ||

| Mine landscape and landforms upgrading plan | O(2.3) | I(4.1) | ||

| Feasibility study (final) | O(2.4) | I(3.2) | I(4.2) | |

| Engineering studies (specifications, technical reports, area layouts, etc.) | O(2.5) | I(4.3) | ||

| Design Codes, Standards and best practices of mining industry | M(2.2) | M(4.2) | ||

| Public Consultation Minutes of Meeting (MOMs)/protocols | O(3.1) | |||

| Reclamation/Repurposing Strategy (selected) | O(3.2) | I(4.4) | ||

| Expert teams (managers, engineers, ecologists, financial analysts, etc.) | M(1.4) | M(2.3) | M(3.1) | |

| Decision Making software tools (for AHP, TOPSIS or other methods) | M(3.2) | |||

| Project Development and Execution plan | O(4.1) | |||

| Tender packages | O(4.2) | |||

| Detailed Cost Analysis | O(4.3) | |||

| Project & Risk management tools (MS-Project, @Risk, etc.) | M(1.5) | M(4.3) | ||

| Environmental & Social Impacts mitigation measures/plans (ESIA content) | M(4.4) | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spanidis, P.-M.; Pavloudakis, F.; Roumpos, C. Introducing the IDEF0 Methodology in the Strategic Planning of Projects for Reclamation and Repurposing of Surface Mines. Mater. Proc. 2021, 5, 26. https://doi.org/10.3390/materproc2021005026

Spanidis P-M, Pavloudakis F, Roumpos C. Introducing the IDEF0 Methodology in the Strategic Planning of Projects for Reclamation and Repurposing of Surface Mines. Materials Proceedings. 2021; 5(1):26. https://doi.org/10.3390/materproc2021005026

Chicago/Turabian StyleSpanidis, Philip-Mark, Francis Pavloudakis, and Christos Roumpos. 2021. "Introducing the IDEF0 Methodology in the Strategic Planning of Projects for Reclamation and Repurposing of Surface Mines" Materials Proceedings 5, no. 1: 26. https://doi.org/10.3390/materproc2021005026

APA StyleSpanidis, P.-M., Pavloudakis, F., & Roumpos, C. (2021). Introducing the IDEF0 Methodology in the Strategic Planning of Projects for Reclamation and Repurposing of Surface Mines. Materials Proceedings, 5(1), 26. https://doi.org/10.3390/materproc2021005026