Micromagnetic Simulations of Magnetic Particles Embedded in Magnetic or Non-Magnetic Matrices †

Abstract

:1. Introduction

2. Materials and Methods

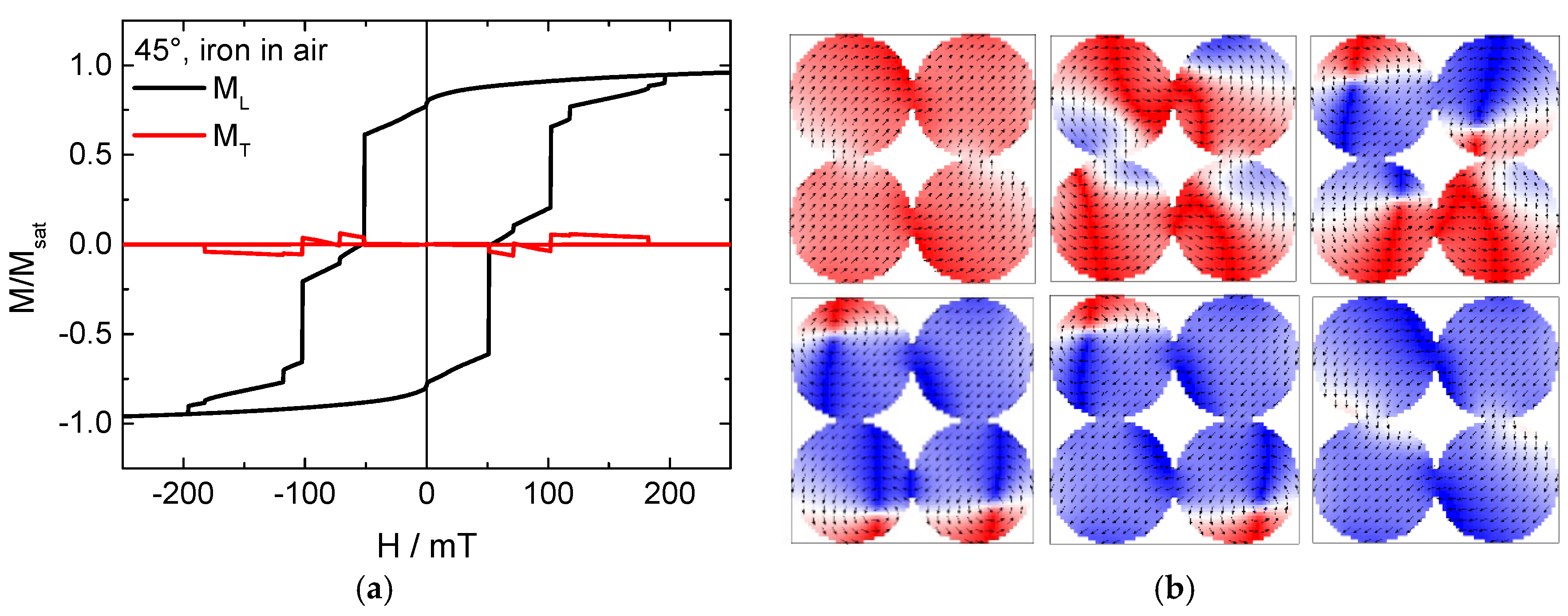

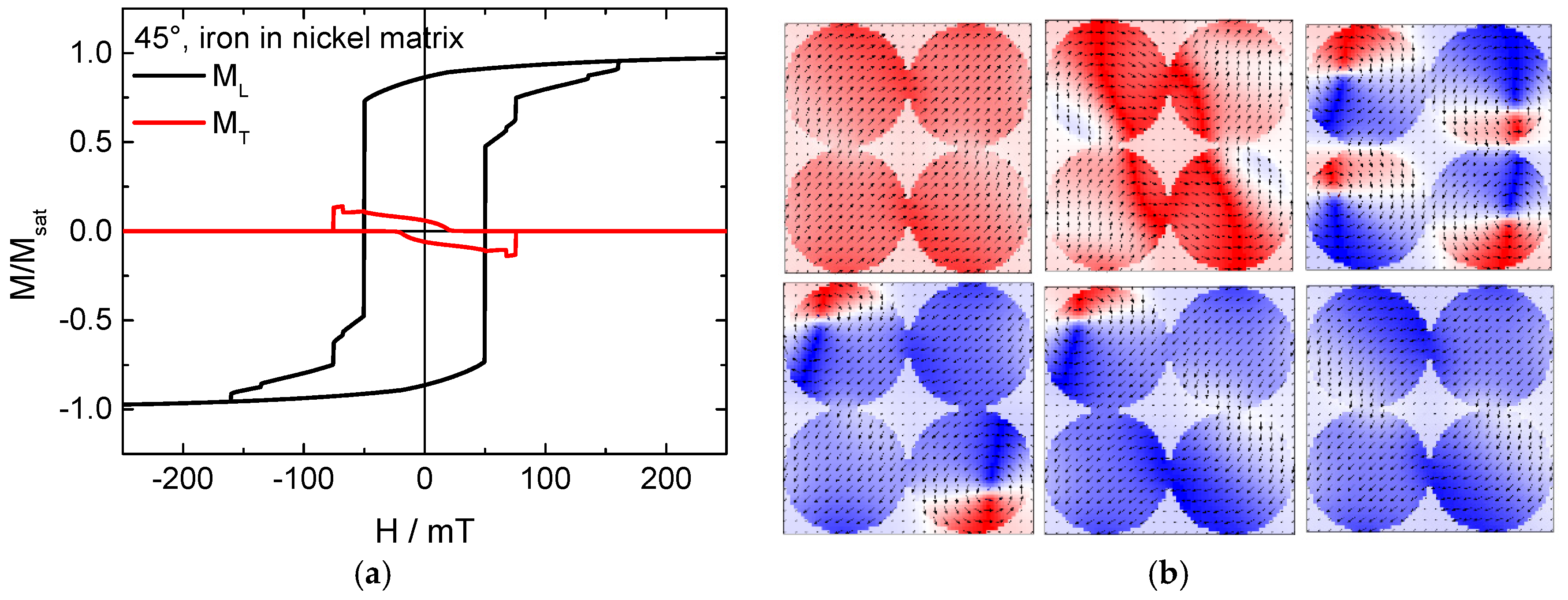

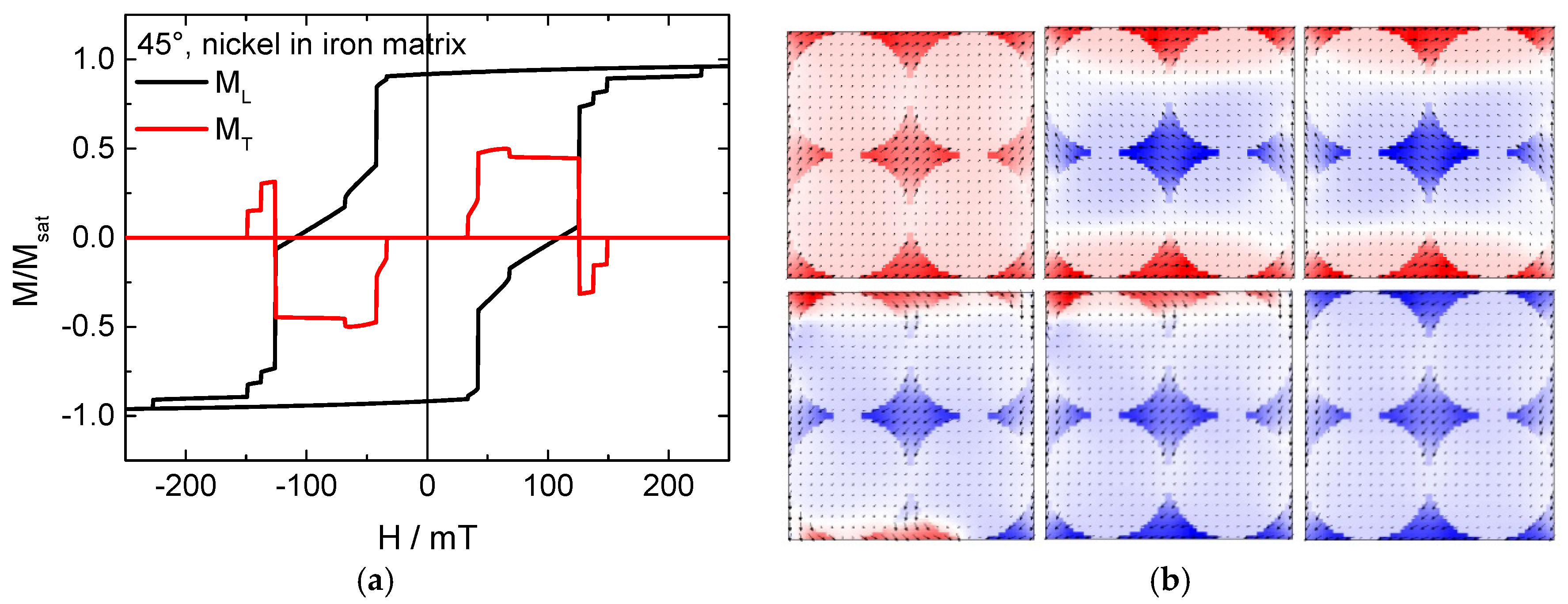

3. Results and Discussion

4. Conclusions

Supplementary Materials

References

- Nogués, J.; Sort, J.; Langlais, V.; Skumryev, V.; Surinach, S.; Munoz, J.S.; Baro, M.D. Exchange bias in nanostructures. Phys. Rep. 2005, 422, 65. [Google Scholar] [CrossRef]

- Fokin, N.; Grothe, T.; Mamun, A.; Trabelsi, M.; Klöcker, M.; Sabantina, L.; Döpke, C.; Blachowicz, T.; Hütten, A.; Ehrmann, A. Magnetic properties of electrospun magnetic nanofiber mats after stabilization and carbonization. Materials 2020, 13, 1552. [Google Scholar] [CrossRef] [PubMed]

- Wachowiak, A.; Wiebe, J.; Bode, M.; Pietzsch, O.; Morgenstern, M.; Wiesendanger, R. Direct Observation of Internal Spin Structure of Magnetic Vortex Cores. Science 2002, 298, 577–580. [Google Scholar] [CrossRef] [PubMed]

- Mejia-López, J.; Altbir, D.; Romero, A.H.; Batlle, X.; Roshchin, I.V.; Li, C.-P.; Schuller, I.K. Vortex state and effect of anisotropy in sub-100-nm magnetic nanodots. J. Appl. Phys. 2006, 100, 104319. [Google Scholar] [CrossRef]

- Vavassori, P.; Bovolenta, R.; Metlushko, V.; Ilic, B. Vortex rotation control in Permalloy disks with small circular voids. J. Appl. Phys. 2006, 99, 053902. [Google Scholar] [CrossRef]

- Guslienko, K.Y.; Aranda, G.R.; Gonzalez, J.M. Topological gauge field in nanomagnets: Spin-wave excitations over a slowly moving magnetization background. Phys. Rev. B 2010, 81, 014414. [Google Scholar] [CrossRef]

- Ehrmann, A.; Blachowicz, T. Systematic study of magnetization reversal in square Fe nanodots of varying dimensions in different orientations. Hyperfine Interact. 2018, 239, 48. [Google Scholar] [CrossRef]

- Ehrmann, A.; Blachowicz, T. Vortex and double-vortex nucleation during magnetization reversal in Fe nanodots of different dimensions. J. Magn. Magn. Mater. 2019, 475, 727–733. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Martínez-Goyeneche, L.; Álvarez-Alonso, P.; Fernández, A. Enhancement the perpendicular magnetic anisotropy of nanopatterned hard/soft bilayer magnetic antidot arrays for spintronic applications. Nanotechnology 2020, 31, 485708. [Google Scholar] [CrossRef] [PubMed]

- Verba, R.V.; Navas, D.; Bunyaev, S.A.; Hierro-Rodriguez, A.; Guslienko, K.Y.; Ivanov, B.A.; Kakazei, G.N. Helicity of magnetic vortices and skyrmions in soft ferromagnetic nanodots and films biased by stray radial fields. Phys. Rev. B 2020, 101, 064429. [Google Scholar] [CrossRef]

- Negusse, E.; Williams, C.M. Magnetically induced enhanced exchange spring effect in CoFe2O4/CoFe2/CoFe2O4 films. IEEE Trans. Magn. 2020, 56, 7516705. [Google Scholar] [CrossRef]

- Kim, H.-Y.; Park, H.-K.; Ju, Y.-W. Fabrication of the novel Fe2+αO3+α-CoFe2O4 composite fibers and their magnetic properties. J. Korean Ceram. Soc. 2020, 57, 423–431. [Google Scholar] [CrossRef]

- Zhang, X.; Kan, X.C.; Wang, M.; Rao, R.; Qian, N.X.; Zheng, G.H.; Ma, Y.Q. Mechanism of enhanced magnetization in CoFe2O4/La0.7Sr0.3MnO3 composites with different mass ratios. Ceram. Int. 2020, 46, 14847–14856. [Google Scholar] [CrossRef]

- Sudsom, D.; Juhász Junger, I.; Döpke, C.; Blachowicz, T.; Hahn, L.; Ehrmann, A. Micromagnetic Simulation of Vortex Development in Magnetic Bi-Material Bow-Tie Structures. Cond. Matter 2020, 5, 5. [Google Scholar] [CrossRef]

- Sudsom, D.; Blachowicz, T.; Hahn, L.; Ehrmann, A. Vortex nucleation and propagation in magnetic double-wedges and semi-squares for reliable quaternary storage systems. J. Magn. Magn. Mater. 2020, 514, 167294. [Google Scholar] [CrossRef]

- Donahue, M.J.; Porter, D.G. OOMMF User’s Guide, Version 1.0; Interagency Report NISTIR 6376; National Institute of Standards and Technology: Gaithersburg, MD, USA, 1999. [Google Scholar]

- Gilbert, T.L. A phenomenological theory of damping in ferromagnetic materials. IEEE Trans. Magn. 2004, 40, 3443–3449. [Google Scholar] [CrossRef]

- Dang Xuan, N.; Döpke, C.; Blachowicz, T.; Ehrmann, A. Magnetization reversal in hexagonal nanomagnets. Act. Phys. Pol. 2020, 137, 395–403. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sudsom, D.; Ehrmann, A. Micromagnetic Simulations of Magnetic Particles Embedded in Magnetic or Non-Magnetic Matrices. Mater. Proc. 2021, 4, 80. https://doi.org/10.3390/IOCN2020-07940

Sudsom D, Ehrmann A. Micromagnetic Simulations of Magnetic Particles Embedded in Magnetic or Non-Magnetic Matrices. Materials Proceedings. 2021; 4(1):80. https://doi.org/10.3390/IOCN2020-07940

Chicago/Turabian StyleSudsom, Devika, and Andrea Ehrmann. 2021. "Micromagnetic Simulations of Magnetic Particles Embedded in Magnetic or Non-Magnetic Matrices" Materials Proceedings 4, no. 1: 80. https://doi.org/10.3390/IOCN2020-07940

APA StyleSudsom, D., & Ehrmann, A. (2021). Micromagnetic Simulations of Magnetic Particles Embedded in Magnetic or Non-Magnetic Matrices. Materials Proceedings, 4(1), 80. https://doi.org/10.3390/IOCN2020-07940