Physical Investigation of Spin-Coated MoS2 Films †

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

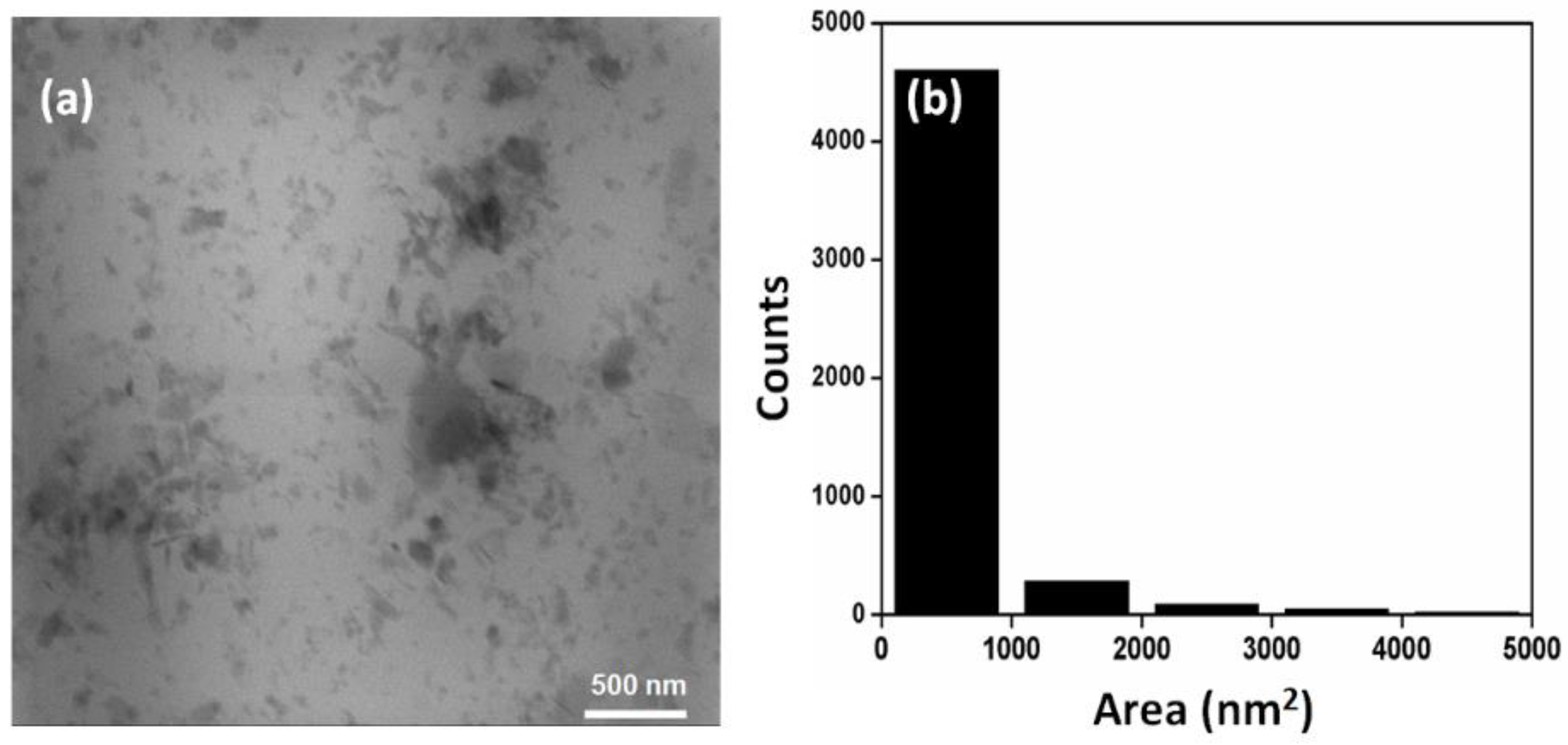

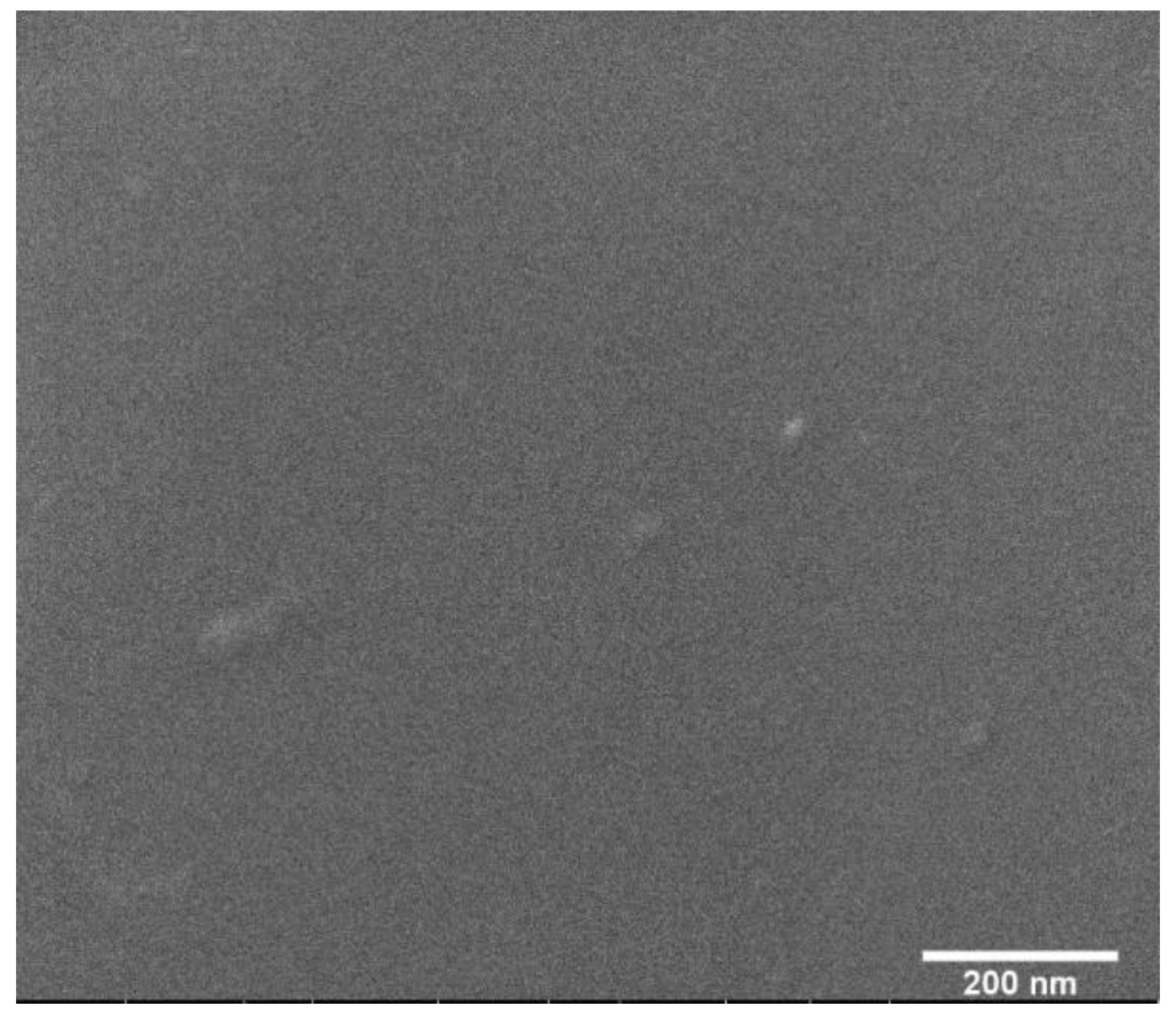

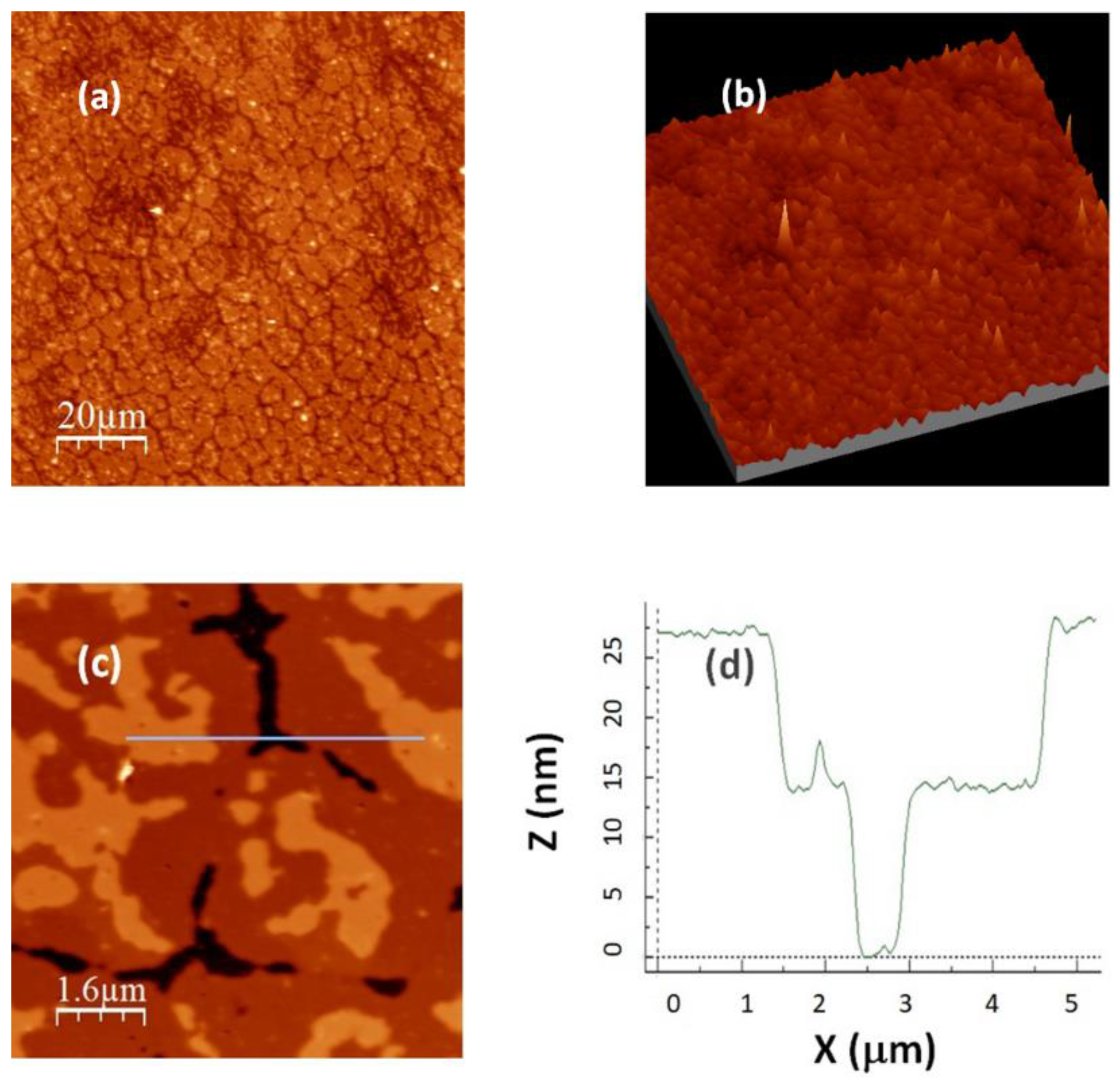

3.1. STEM, SEM and AFM Measurements

3.2. Micro-Raman Spectroscopy Measurements

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Li, H.; Zhang, Q.; Yap, C.C.R.; Tay, B.K.; Edwin, T.H.T.; Olivier, A.; Baillargeat, D. From Bulk to Monolayer MoS2: Evolution of Raman Scattering. Adv. Funct. Mater. 2012, 22, 1385–1390. [Google Scholar] [CrossRef]

- Reshmi, S.; Akshaya, M.V.; Satpati, B.; Basu, P.K.; Bhattacharjee, K. Structural stability of coplanar 1T-2H superlattice MoS2under high energy electron beam. Nanotechnology 2018, 29, 205604. [Google Scholar] [CrossRef] [PubMed]

- Eda, G.; Fujita, T.; Yamaguchi, H.; Voiry, D.; Chen, M.; Chhowalla, M. Coherent Atomic and Electronic Heterostructures of Single-Layer MoS2. ACS Nano 2012, 6, 7311–7317. [Google Scholar] [CrossRef] [PubMed]

- Nicolosi, V.; Chhowalla, M.; Kanatzidis, M.G.; Strano, M.S.; Coleman, J.N. Liquid Exfoliation of Layered Materials. Science 2013, 340, 1226419. [Google Scholar] [CrossRef]

- Mansukhani, N.D.; Guiney, L.M.; Kim, P.J.; Zhao, Y.; Alducin, D.; Ponce, A.; Larios, E.; Yacaman, M.J.; Hersam, M.C. High-Concentration Aqueous Dispersions of Nanoscale 2D Materials Using Nonionic, Biocompatible Block Copolymers. Small 2016, 12, 294–300. [Google Scholar] [CrossRef] [PubMed]

- Saito, R.; Tatsumi, Y.; Huang, S.; Ling, X.; Dresselhaus, M.S. Raman spectroscopy of transition metal dichalcogenides. J. Phys. Condens. Matter 2016, 28, 353002. [Google Scholar] [CrossRef] [PubMed]

- WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 13705. [CrossRef] [PubMed]

- Chen, J.M.; Wang, C.S. Second order Raman spectrum of MoS2. Solid State Commun. 1974, 14, 857–860. [Google Scholar] [CrossRef]

- Chi, Z.-H.; Zhao, X.-M.; Zhang, H.; Goncharov, A.F.; Lobanov, S.S.; Kagayama, T.; Sakata, M.; Chen, X.-J. Pressure-Induced Metallization of Molybdenum Disulfide. Phys. Rev. Lett. 2014, 113, 36802. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Yan, H.; Brus, L.E.; Heinz, T.F.; Hone, J.; Ryu, S. Anomalous Lattice Vibrations of Single- and Few-Layer MoS2. ACS Nano 2010, 4, 2695–2700. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, R.R.; Biswas, S.K. Deformation and friction of MoS2 particles in liquid suspensions used to lubricate sliding contact. Thin Solid Film. 2010, 518, 5995–6005. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Politano, G.G.; Castriota, M.; Santo, M.P.D.; Pipita, M.M.; Desiderio, G.; Vena, C.; Versace, C. Physical Investigation of Spin-Coated MoS2 Films. Mater. Proc. 2021, 4, 3. https://doi.org/10.3390/IOCN2020-08005

Politano GG, Castriota M, Santo MPD, Pipita MM, Desiderio G, Vena C, Versace C. Physical Investigation of Spin-Coated MoS2 Films. Materials Proceedings. 2021; 4(1):3. https://doi.org/10.3390/IOCN2020-08005

Chicago/Turabian StylePolitano, Grazia Giuseppina, Marco Castriota, Maria Penelope De Santo, Mario Michele Pipita, Giovanni Desiderio, Carlo Vena, and Carlo Versace. 2021. "Physical Investigation of Spin-Coated MoS2 Films" Materials Proceedings 4, no. 1: 3. https://doi.org/10.3390/IOCN2020-08005

APA StylePolitano, G. G., Castriota, M., Santo, M. P. D., Pipita, M. M., Desiderio, G., Vena, C., & Versace, C. (2021). Physical Investigation of Spin-Coated MoS2 Films. Materials Proceedings, 4(1), 3. https://doi.org/10.3390/IOCN2020-08005