Work-Hardening Behavior of Cold Rolled EUROFER97 Steel for Nuclear Fusion Applications †

Abstract

:1. Introduction

2. Material and Methods

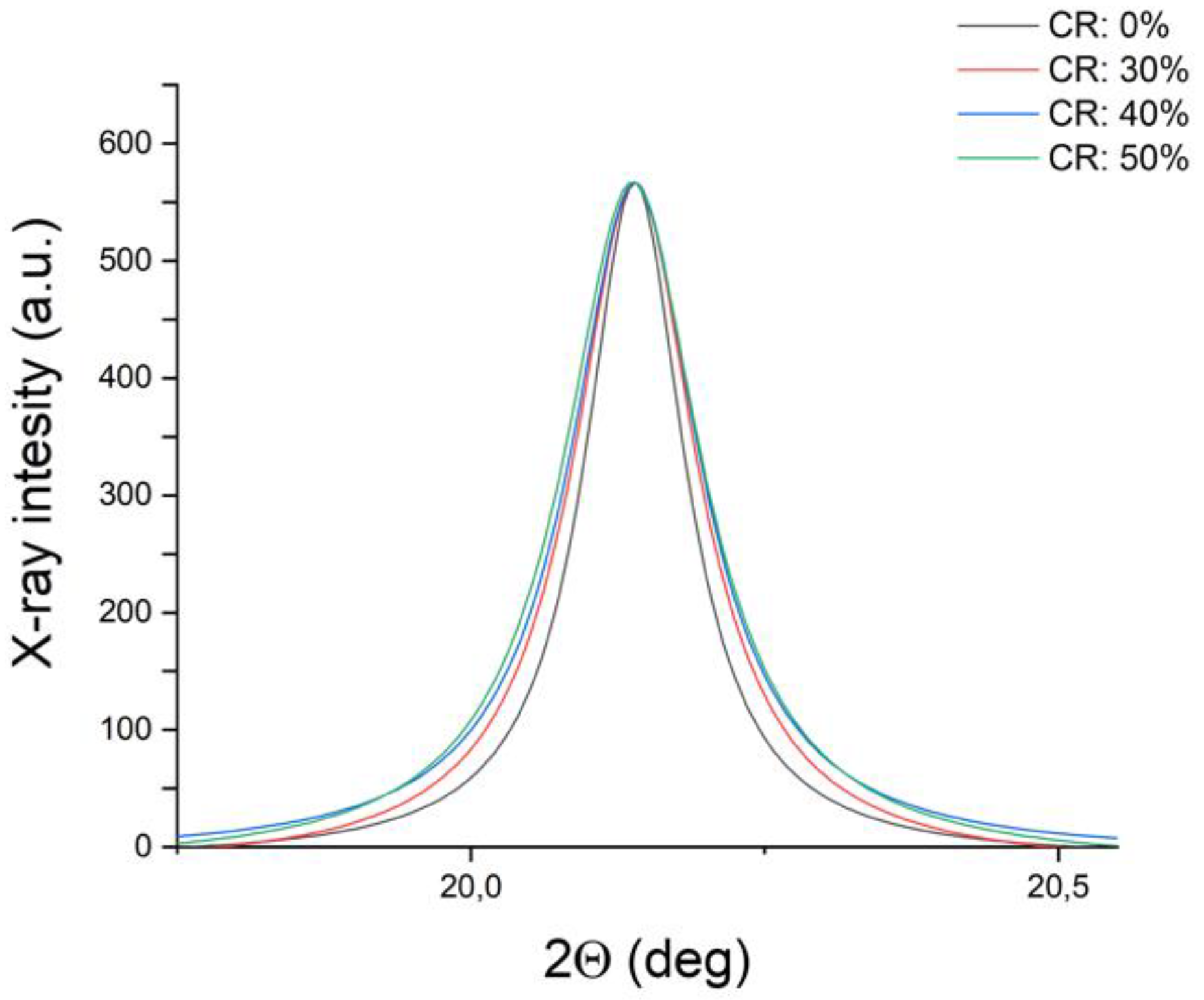

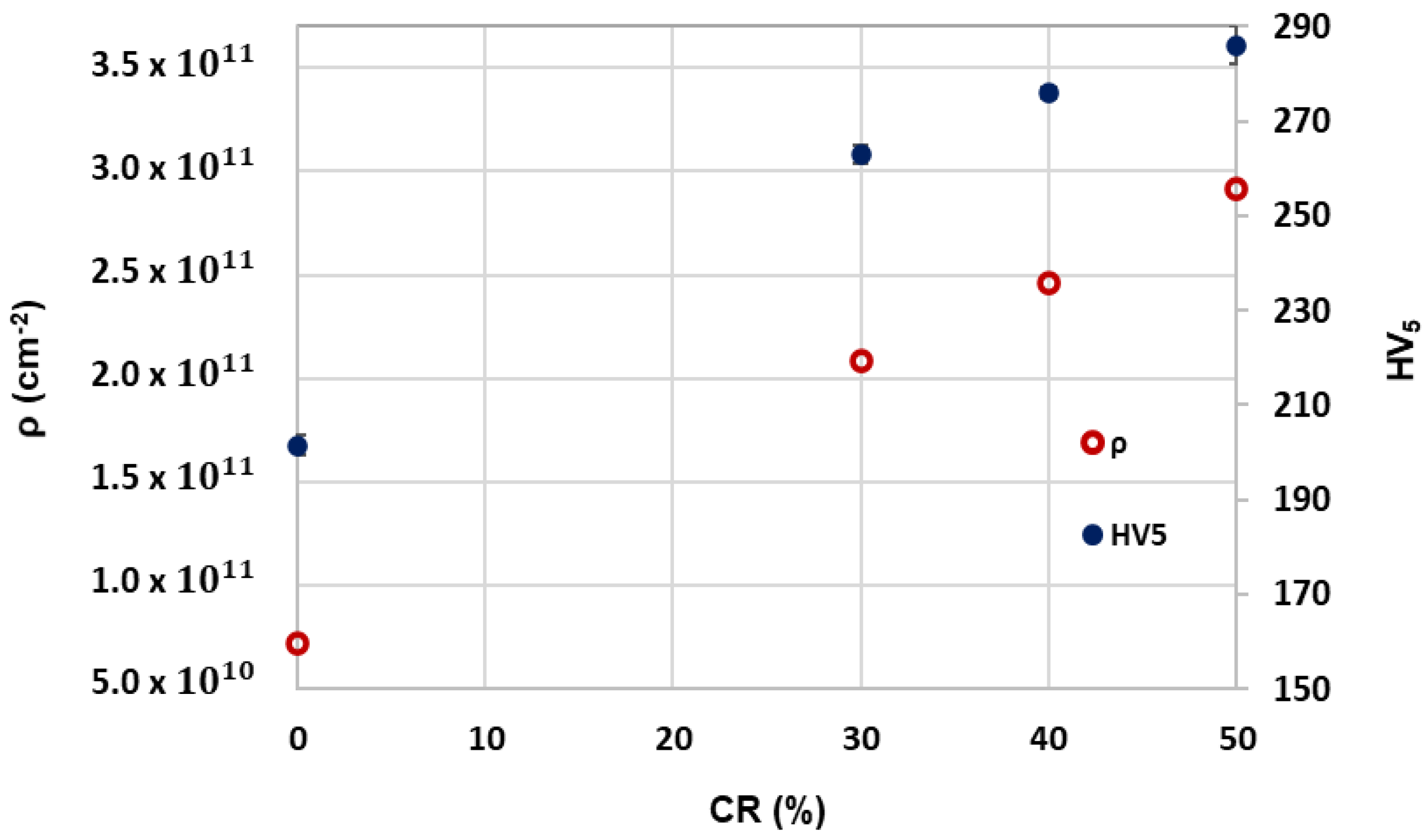

3. Results and Discussion

4. Conclusions

References

- Rieth, M.; Schirra, M.; Falkenstein, A.; Graf, P.; Heger, S.; Kempe, H.; Lindau, R.; Zimmermann, H. EUROFER 97, Tensile, Charpy, Creep and Structural Tests; Forschungszentrum Karlsruhe GmbH Technik und Umwelt: Karlsruhe, Germany, 2003. [Google Scholar]

- Zilnyk, K.D.; Oliveira, V.B.; Sandim, H.R.Z.; Möslang, A.; Raabe, D. Martensitic transformation in Eurofer-97 and ODS-Eurofer steels: A comparative study. J. Nucl. Mater. 2015, 462, 360–367. [Google Scholar] [CrossRef]

- Tavassoli, A.A.F.; Alamo, A.; Bedel, L.; Forest, L.; Gentzbittel, J.M.; Rensman, J.W.; Diegele, E.; Lindau, R.; Schirra, M.; Schmitt, R.; et al. Materials design data for reduced activation martensitic steel type EUROFER. J. Nucl. Mater. 2004, 329–333, 257–262. [Google Scholar] [CrossRef]

- Gaganidze, E.; Gillemot, F.; Szenthe, I.; Gorley, M.; Rieth, M.; Diegele, E. Development of EUROFER97 database and material property handbook. Fusion Eng. Des. 2018, 135, 9–14. [Google Scholar] [CrossRef]

- Di Schino, A.; Testani, C.; Pilloni, L. Effect of thermo-mechanical parameters on the mechanical properties of Eurofer97 steel for nuclear applications. Open Eng. 2018, 8, 349–353. [Google Scholar] [CrossRef]

- Chen, X.; Bhattacharya, A.; Sokolov, M.A.; Clowers, L.N.; Yamamoto, Y.; Graening, T.; Linton, K.D.; Katoh, Y.; Rieth, M. Mechanical properties and microstructure characterization of Eurofer97 steel variants in EUROfusion program. Fusion Eng. Des. 2019, 146, 2227–2232. [Google Scholar] [CrossRef]

- Montanari, R.; Filacchioni, G.; Iacovone, B.; Plini, P.; Riccardi, B. High temperature indentation tests on fusion reactor candidate materials. J. Nucl. Mater. 2007, 367–370A, 648–652. [Google Scholar] [CrossRef]

- Fernández, P.; Lancha, A.M.; Lapeña, J.; Hernández-Mayoral, M. Metallurgical characterization of the reduced activation ferritic/martensitic steel Eurofer’97 on as-received condition. Fusion Eng. Des. 2001, 58–59, 787–792. [Google Scholar] [CrossRef]

- Tavassoli, A.A.F.; Diegele, E.; Lindau, R.; Luzginova, N.; Tanigawa, H. Current status and recent research achievements in ferritic/martensitic steels. J. Nucl. Mater. 2014, 455, 269–276. [Google Scholar] [CrossRef]

- Mergia, K.; Boukos, N. Structural, thermal, electrical and magnetic properties of Eurofer 97 steel. J. Nucl. Mater. 2008, 373, 1–8. [Google Scholar] [CrossRef]

- Cahn, R.W.; Haasen, P.; Kramer, E.J. Material Science and Technology, Nuclear Material; VCH Verlagsgesellschaft mbH: Weinheim, Germany, 1994. [Google Scholar]

- Weiß, O.J.; Gaganidze, E.; Aktaa, J. Quantitative characterization of microstructural defects in up to 32 dpa neutron irradiated EUROFER97. J. Nucl. Mater. 2012, 426, 52–58. [Google Scholar] [CrossRef]

- Puype, A.; Malerba, L.; De Wispelaere, N.; Petrov, R.; Sietsma, J. Effect of processing on microstructural features and mechanical properties of a reduced activation ferritic/martensitic EUROFER steel grade. J. Nucl. Mater. 2017, 494, 1–9. [Google Scholar] [CrossRef]

- Lindau, R.; Möslang, A.; Rieth, M.; Klimiankou, M.; Materna-Morris, E.; Alamo, A.; Tavassoli, A.A.F.; Cayron, C.; Lancha, A.M.; Fernandez, P.; et al. Present development status of EUROFER and ODS-EUROFER for application in blanket concepts. Fusion Eng. Des. 2005, 75–79, 989–996. [Google Scholar] [CrossRef]

- Fu, J.; Brouwer, J.C.; Hendrikx, R.W.A.; Richardson, I.M.; Hermans, M.J.M. Microstructure characterisation and mechanical properties of ODS Eurofer steel subject to designed heat treatments. Mater. Sci. Eng. A 2020, 770. [Google Scholar] [CrossRef]

- Testani, C.; Di Nunzio, P.; Salvatori, I. Manufacturing of ODS RAFM Steel: Mechanical and Microstructural Characterization. MSF 2016, 879, 1639–1644. [Google Scholar] [CrossRef]

- Fava, A.; Montanari, R.; Richetta, M.; Testani, C.; Varone, A. Analysis of Strengthening Mechanisms in Nano-ODS Steel Depending on Preparation Route. J. Mater. Sci. Eng. 2018, 07. [Google Scholar] [CrossRef]

- De Sanctis, M.; Fava, A.; Lovicu, G.; Montanari, R.; Richetta, M.; Testani, C.; Varone, A. Temperature dependent mechanical behaviour of ODS steels. Mater. Sci. Forum 2018, 941, 257–262. [Google Scholar] [CrossRef]

- Pickering, F.B.; Gladman, T. Metallurgical Developments in Carbon Steels; ISI Special Report: London, UK, 1963. [Google Scholar]

- Di Schino, A.; Di Nunzio, P.E.; Turconi, G.L. Microstructure Evolution during Tempering of Martensite in a Medium-C Steel. Mater. Sci. Forum 2007, 558, 1435–1441. [Google Scholar] [CrossRef]

- Di Schino, A.; Alleva, L.; Guagnelli, M. Microstructure evolution during quenching and tempering of martensite in a medium C steel. Mater. Sci. Forum 2012, 715–716, 860–865. [Google Scholar] [CrossRef]

- Pilloni, L.; Cristalli, C.; Tassa, O.; Salvatori, I.; Storai, S. Grain size reduction strategies on Eurofer. Nucl. Mater. Energy 2018, 17, 129–136. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debyescherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Takebayashi, S.; Kunieda, T.; Yoshinaga, N.; Ushioda, K.; Ogata, S. Comparison of the dislocation density in martensitic steels evaluated by some X-ray diffraction methods. ISIJ Int. 2010, 50, 875–882. [Google Scholar] [CrossRef]

- Stornelli, G.; Montanari, R.; Testani, C.; Pilloni, L.; Napoli, G.; di Pietro, O.; di Schino, A. Microstructure Refinement Effect on EUROFER 97 Steel for Nuclear Fusion Application. Mater. Sci. Forum 2021, 1016, 1392–1397. [Google Scholar] [CrossRef]

| Cr | C | Mn | V | W | Ta | Ti | N |

| 8.93 | 0.12 | 0.47 | 0.2 | 1.07 | 0.14 | 0.009 | 0.018 |

| P | S | B | Si | Nb | Mo | Ni | Cu |

| <0.005 | 0.004 | <0.001 | 0.006 | 0.002 | 0.0015 | 0.002 | 0.003 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stornelli, G.; Schino, A.D.; Montanari, R.; Testani, C.; Varone, A.; Mancini, S. Work-Hardening Behavior of Cold Rolled EUROFER97 Steel for Nuclear Fusion Applications. Mater. Proc. 2021, 3, 21. https://doi.org/10.3390/IEC2M-09242

Stornelli G, Schino AD, Montanari R, Testani C, Varone A, Mancini S. Work-Hardening Behavior of Cold Rolled EUROFER97 Steel for Nuclear Fusion Applications. Materials Proceedings. 2021; 3(1):21. https://doi.org/10.3390/IEC2M-09242

Chicago/Turabian StyleStornelli, Giulia, Andrea Di Schino, Roberto Montanari, Claudio Testani, Alessandra Varone, and Silvia Mancini. 2021. "Work-Hardening Behavior of Cold Rolled EUROFER97 Steel for Nuclear Fusion Applications" Materials Proceedings 3, no. 1: 21. https://doi.org/10.3390/IEC2M-09242

APA StyleStornelli, G., Schino, A. D., Montanari, R., Testani, C., Varone, A., & Mancini, S. (2021). Work-Hardening Behavior of Cold Rolled EUROFER97 Steel for Nuclear Fusion Applications. Materials Proceedings, 3(1), 21. https://doi.org/10.3390/IEC2M-09242