Design and Performance Optimization of Battery Pack with AI-Driven Thermal Runaway Prediction †

Abstract

1. Introduction

2. Literature Review

2.1. Air Cooling Methods for Battery Thermal Control

2.2. Effect of Battery Pack Design on Thermal Management Effectiveness

2.3. Effect of High Discharge Rates on Thermal Regulations

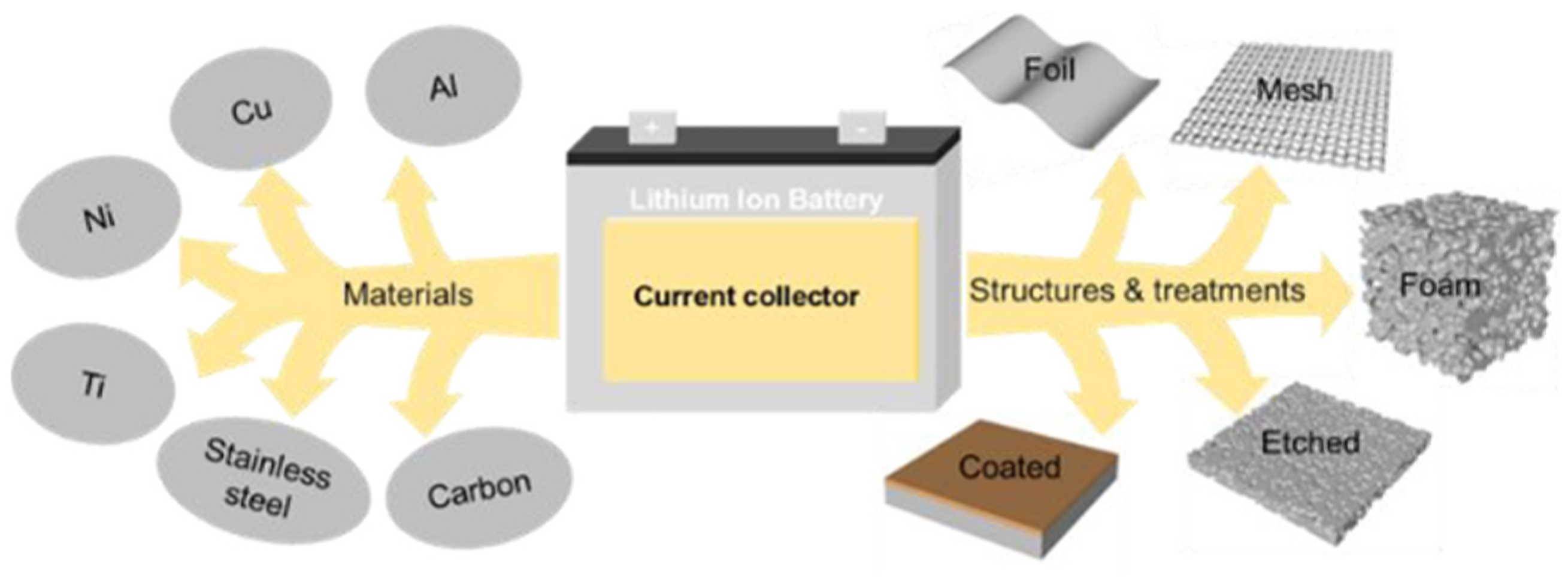

2.4. Effect of Busbars Material on Battery Thermal Performance

2.5. Thermal Runaway in Lithium-Ion Batteries

3. Methodology

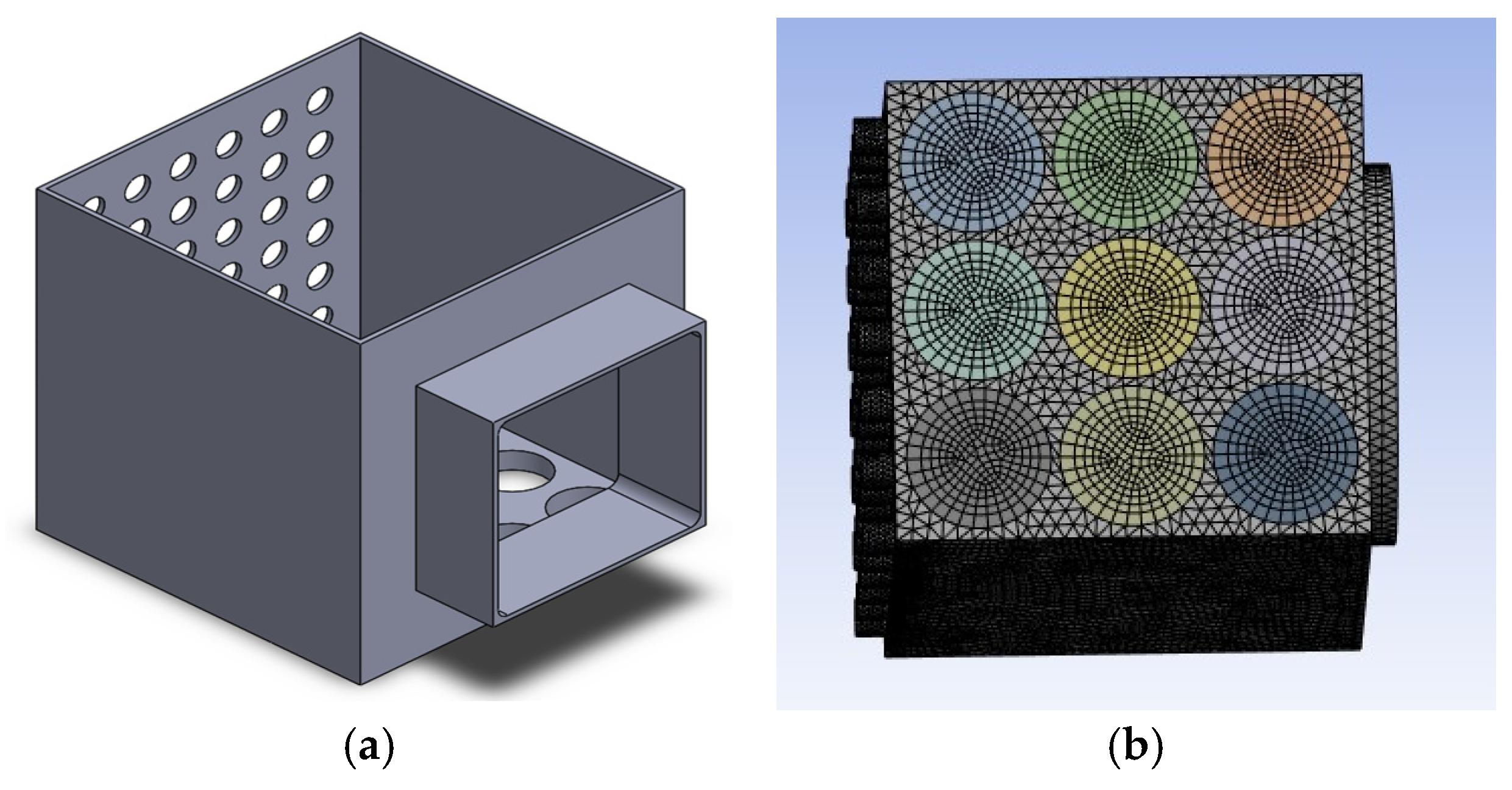

3.1. Simulation of the Battery Module

3.2. Governing Equations

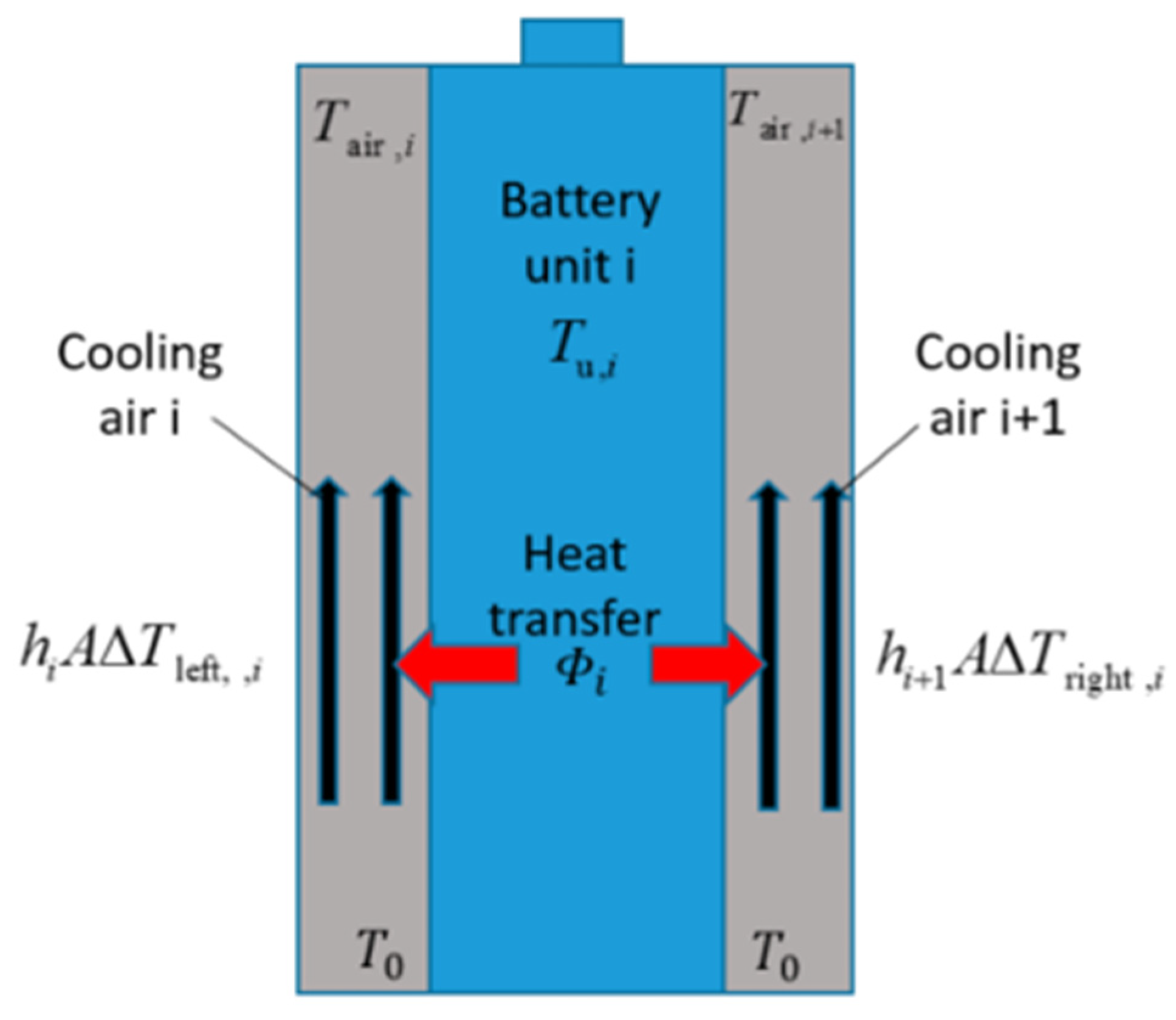

3.3. Heat Dissipation Model

- Each battery cell follows a simplified assumption of uniform temperature distribution, which allows calculation of average temperatures for each unit [12].

- The physical parameters of battery components are calculated through weighted average methodology [13].

- Heat exchange occurs solely within the cooling channels, simplifying the model by excluding other interactions between the air and the battery [12].

3.4. Initial and Boundary Conditions

3.5. AI Model Development

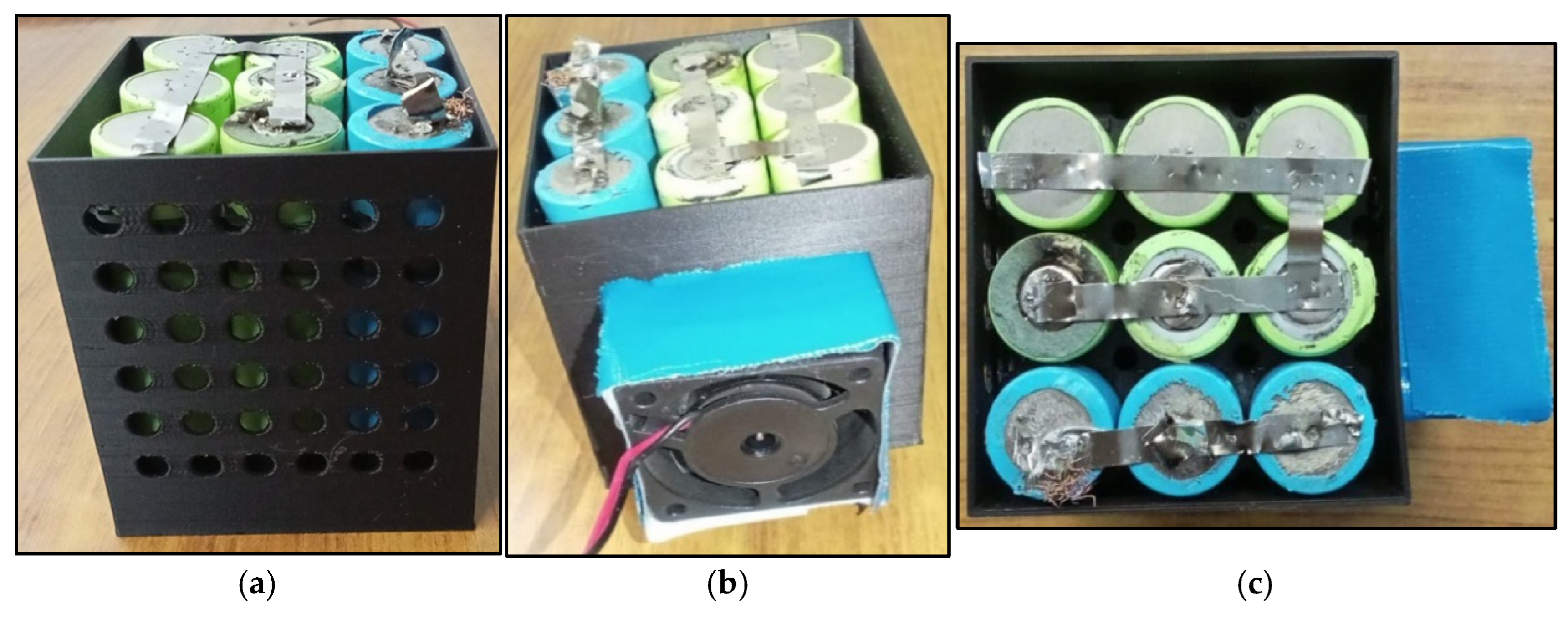

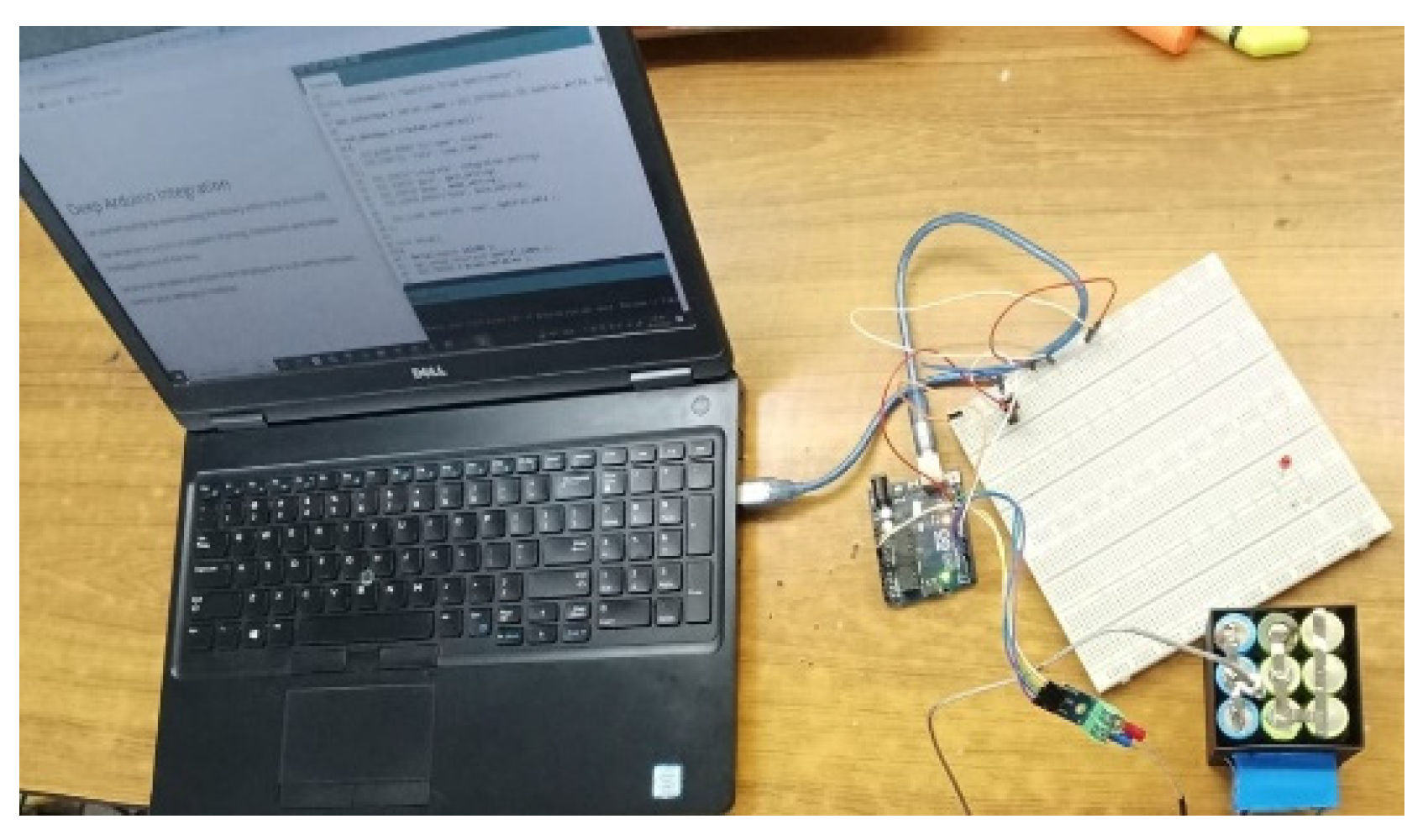

4. Experimental Setup

5. Results and Discussion

5.1. Simulation Results

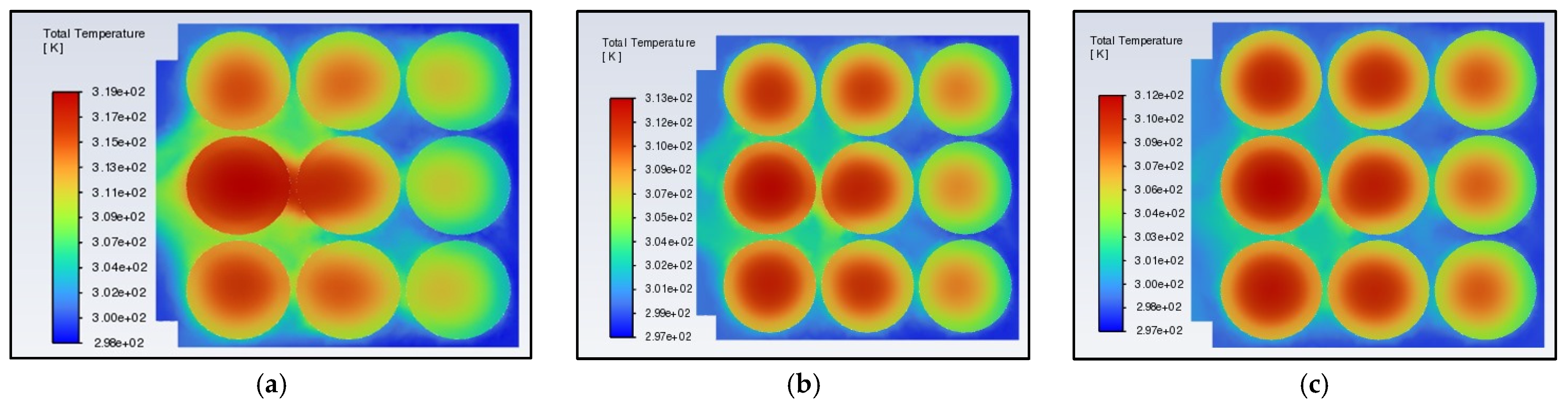

5.1.1. Air Cooling with Different Pack Configuration

5.1.2. Air Cooling with Different Inlet Velocity

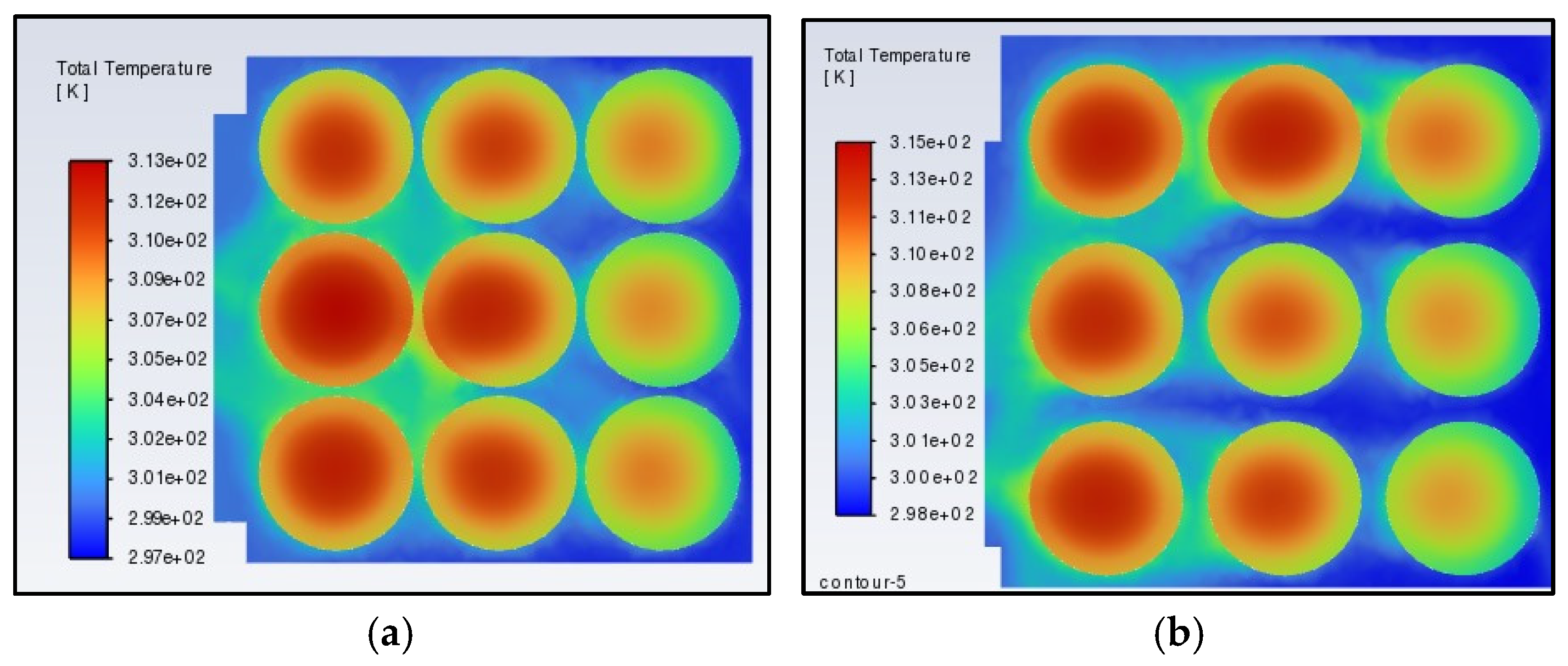

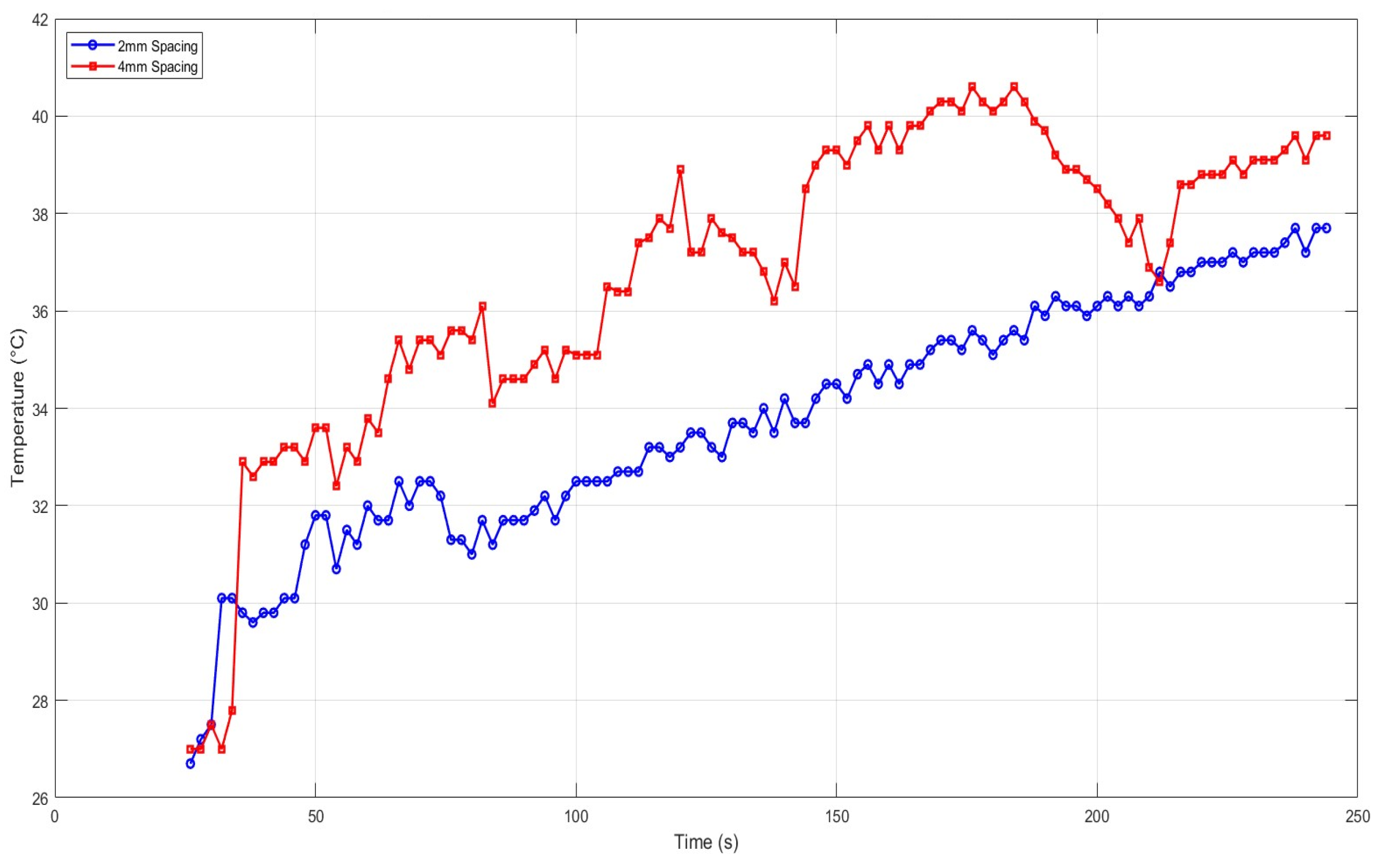

5.1.3. Air Cooling with Different Cell Spacing

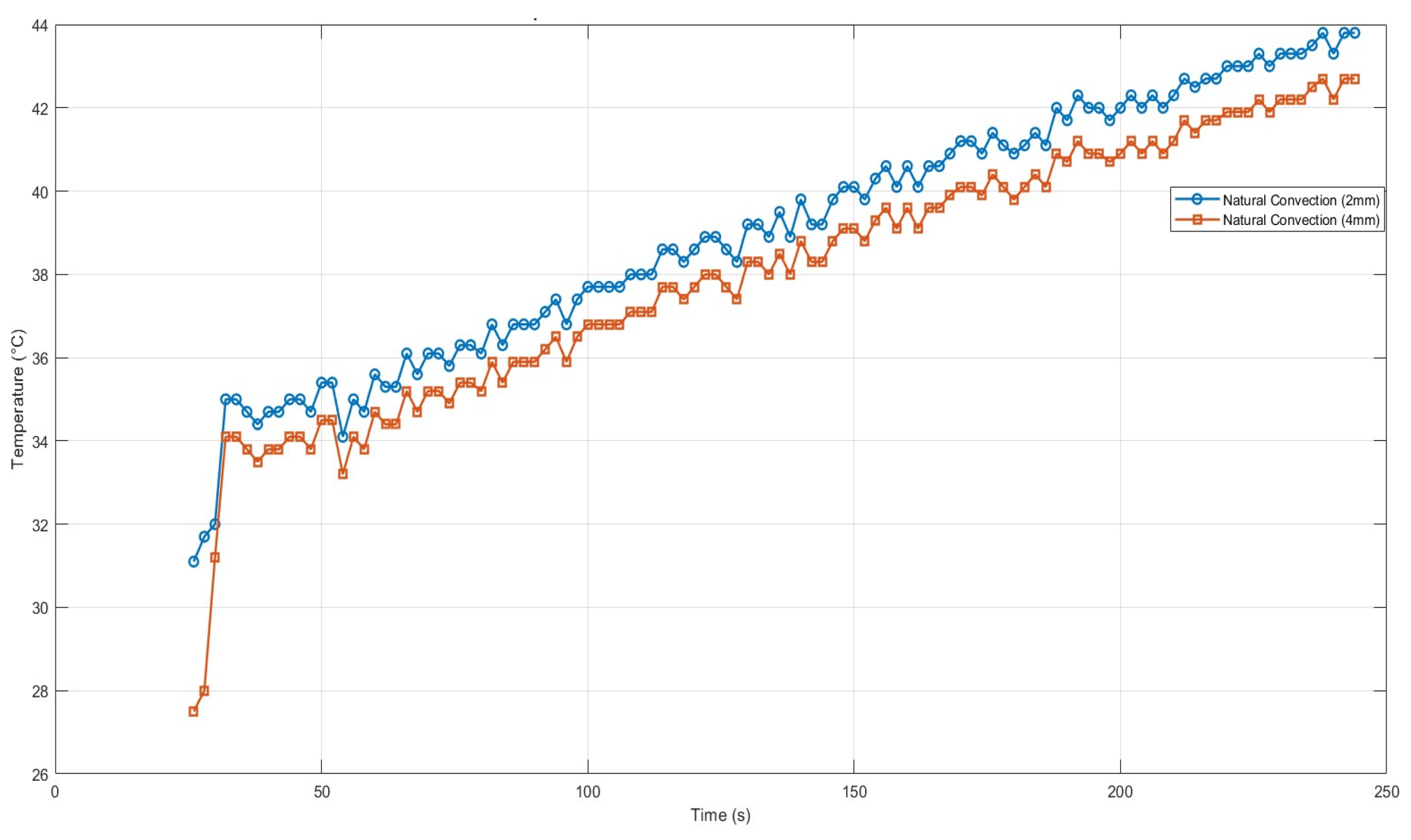

5.2. Experimental Results

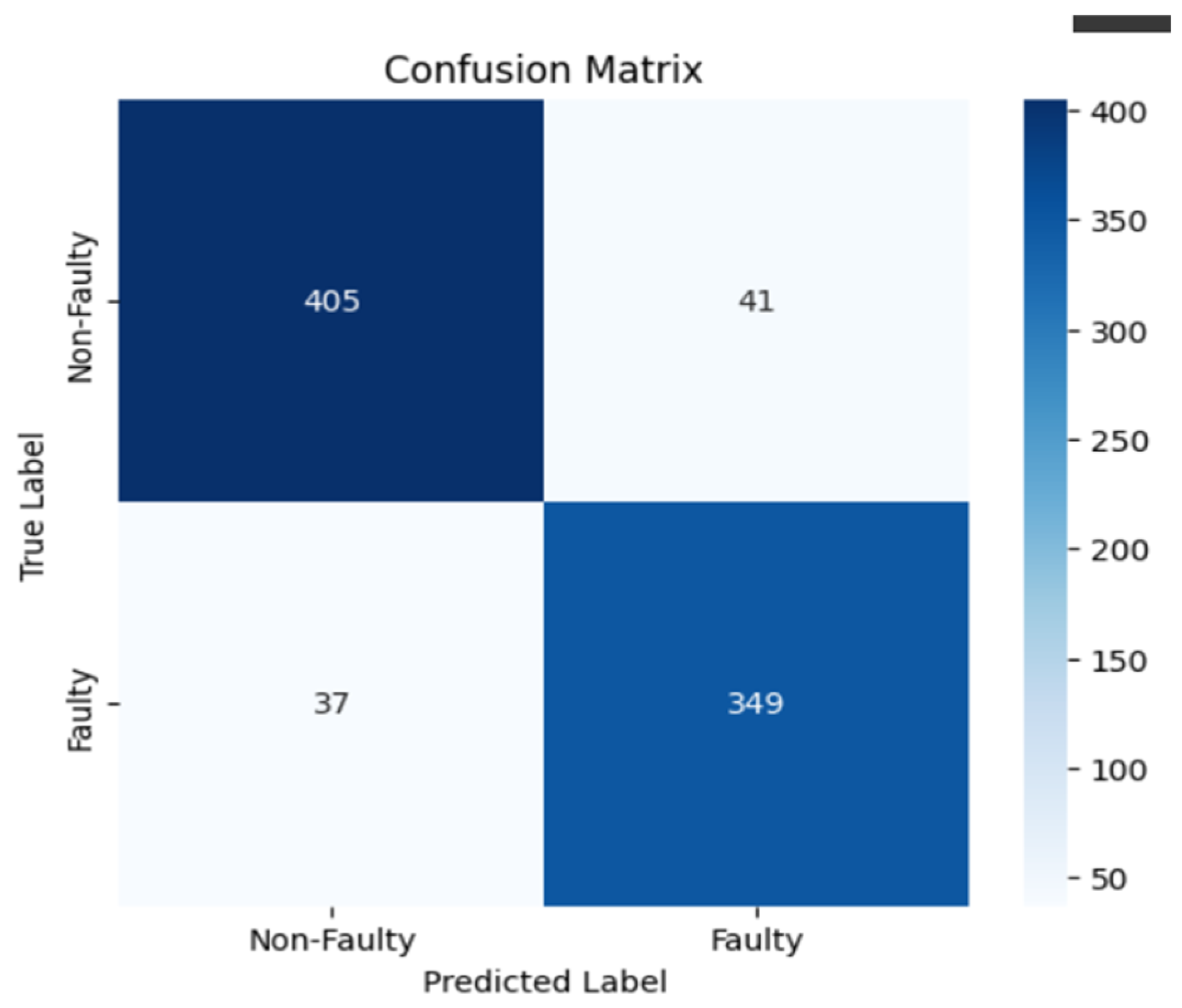

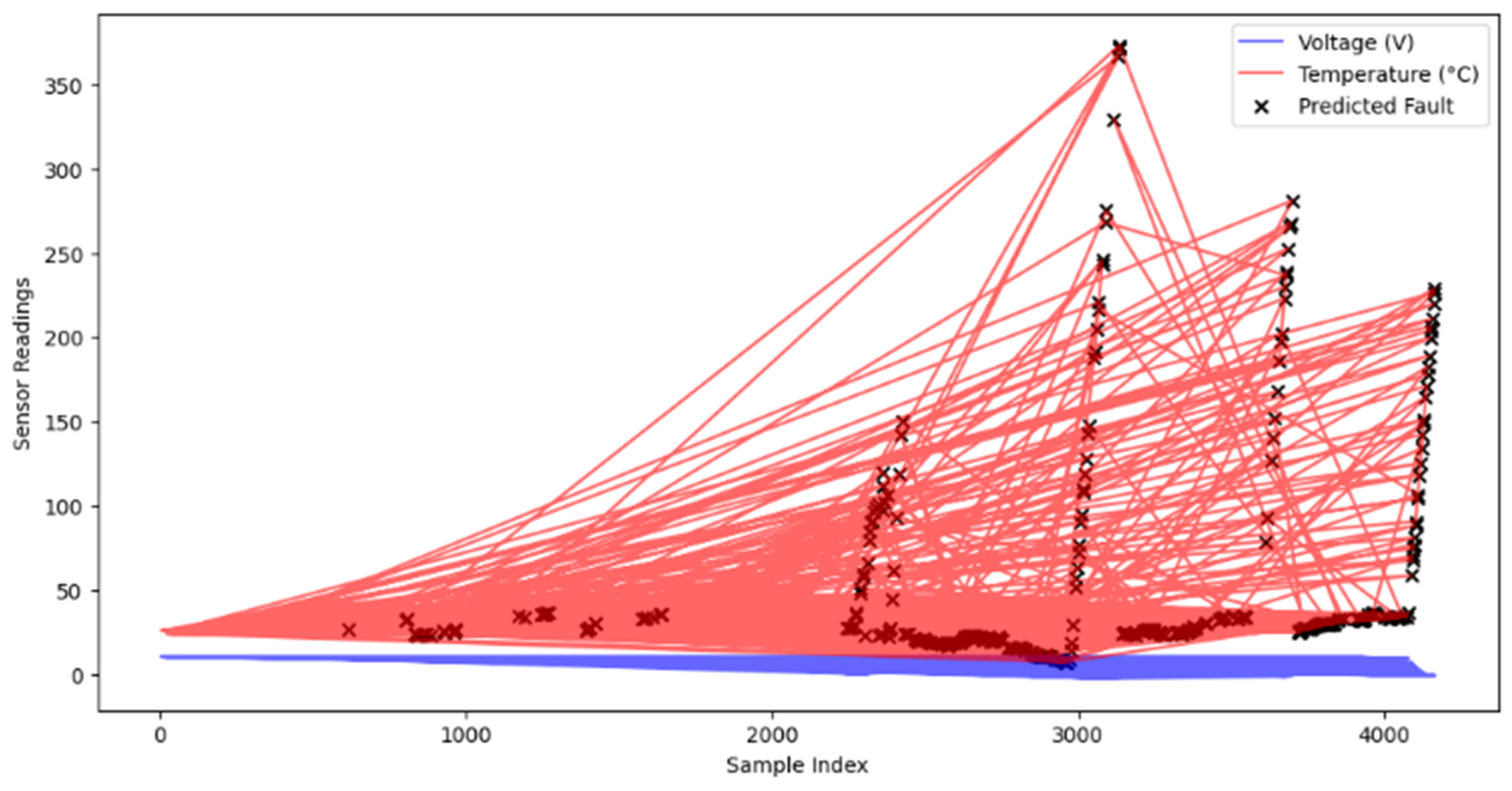

5.3. Fault Detection and Machine Learning Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BTMS | Battery Thermal Management System |

| EV | Electric Vehicle |

| AI | Artificial Intelligence |

| SOH | State-Of-Health |

| PCM | Phase-Change Materials |

References

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Arora, S. Selection of thermal management system for modular battery packs of electric vehicles: A review of existing and emerging technologies. J. Power Sources 2018, 407, 536–552. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Huo, Y.; Liu, X.; Li, Y. Thermal management of cylindrical power battery module for extending the life of new energy electric vehicles. Appl. Therm. Eng. 2015, 85, 33–43. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O.; Chong, W.T.; Kuan, S.H.; Yew, M.C. Computational fluid dynamic and thermal analysis of Lithium-ion battery pack with air cooling. Appl. Energy 2016, 177, 783–792. [Google Scholar] [CrossRef]

- Peng, X.; Ma, C.; Garg, A.; Bao, N.; Liao, X. Thermal performance investigation of an air-cooled lithium-ion battery pack considering the inconsistency of battery cells. Appl. Therm. Eng. 2019, 153, 42–51. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Zhan, Z.; Qian, Z.; Fan, J.; Jiang, Z.; Yang, J.; Wei, X. Effects of the different air cooling strategies on cooling performance of a lithium-ion battery module with baffle. Appl. Therm. Eng. 2018, 144, 236–246. [Google Scholar] [CrossRef]

- Gao, T.; Wang, Z.; Chen, S.; Guo, L. Hazardous characteristics of charge and discharge of lithium-ion batteries under adiabatic environment and hot environment. Int. J. Heat Mass Transf. 2019, 141, 672–683. [Google Scholar] [CrossRef]

- Feng, X.; Zheng, S.; He, X.; Wang, L.; Zhang, X.; Ouyang, M. Thermal runaway propagation model for designing a safer battery pack with 25Ah LiNixCoyMnzO2 large format lithium-ion battery. Appl. Energy 2015, 154, 554–565. [Google Scholar] [CrossRef]

- Sabbah, R.; Kizilel, R.; Selman, J.R.; Al-Hallaj, S. Active (air-cooled) vs. passive (phase change material) thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution. J. Power Sources 2008, 182, 630–638. [Google Scholar] [CrossRef]

- Behi, H.; Chen, C.; Jiang, J.; Zhang, W.; Wang, Y.; Ma, L. A new concept of thermal management system in Li-ion battery using air cooling and heat pipe for electric vehicles. Appl. Therm. Eng. 2020, 174, 115280. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy. Appl. Therm. Eng. 2017, 123, 1322–1333. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O. Electrochemical-thermal analysis of 18650 Lithium Iron Phosphate cell. Energy Convers. Manag. 2013, 75, 162–174. [Google Scholar] [CrossRef]

- Chen, J.; Xuan, D.; Wang, B.; Jiang, R. Structure optimization of battery thermal management systems using sensitivity analysis and stud genetic algorithms. Appl. Sci. 2021, 11, 7440. [Google Scholar] [CrossRef]

- Li, A.; Zhao, B.; Zhang, S.; Luo, Z.; Zhang, G.; Wei, H. Thermal propagation modelling of abnormal heat generation in various battery cell locations. Batteries 2022, 8, 216. [Google Scholar] [CrossRef]

- Spinner, N.S.; Hinnant, K.M.; Mazurick, R.; Brandon, A.; Rose-Pehrsson, S.L.; Tuttle, S.G. Novel 18650 lithium-ion battery surrogate cell design with anisotropic thermophysical properties for studying failure events. J. Power Sources 2016, 312, 172–183. [Google Scholar] [CrossRef]

- Finegan, D.P.; Darcy, E.; Keyser, M.; Tjaden, B.; Heenan, T.M.M.; Jervis, R.; Brett, D.J.L. In-operando high-speed tomography of lithium-ion batteries during thermal runaway. Nat. Commun. 2015, 6, 6924. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium-ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Song, L.; Zheng, Y.; Xiao, Z.; Wang, C.; Long, T. Review on thermal runaway of lithium-ion batteries for electric vehicles. J. Electron. Mater. 2022, 51, 30–46. [Google Scholar] [CrossRef]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium-ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Lin, L.S.; Li, J.L.; Fishman, I.M.; Torres-Castro, L.; Preger, Y.; De Angelis, V.; Lamb, J.; Zhu, X.Q.; Allu, S.; Wang, H. Mechanically induced thermal runaway severity analysis for Li-ion batteries. J. Energy Storage 2023, 61, 106798. [Google Scholar] [CrossRef]

- Townsend, D.I.; Tou, J.C. Thermal hazard evaluation by an accelerating rate calorimeter. Thermochim. Acta 1980, 37, 1–30. [Google Scholar] [CrossRef]

- Lin, L.; Wang, H.; Li, J.; Torres-Castro, L.; Preger, Y.; De Angelis, V. Mechanically induced thermal runaway for Li-ion batteries. Mendeley Data 2023. [Google Scholar] [CrossRef]

| Electrical Conductivity (MS/m) | Resistivity (Ω·m × 10−8) | Density (g/cm3) | Thermal Conductivity (W/m·K) | Weight Considerations for EVs | Impact on Heat Dissipation | Suitability for High-Current EVs | |

|---|---|---|---|---|---|---|---|

| Copper (Cu) | 58.0 | 1.68 | 8.96 | 401 | Heavy, adds weight | Excellent, low heat accumulation | Ideal for high-power EVs |

| Aluminum (Al) | 37.7 | 2.65 | 2.70 | 237 | Lightweight, reduces weight | Moderate, needs better cooling | Good for moderate-power EVs |

| Nickel (Ni) | 14.3 | 6.84 | 8.90 | 90 | Heavy, corrosion-resistant | Poor, increases battery temperature | Not ideal for high discharge |

| Titanium (Ti) | 2.4 | 42.0 | 4.51 | 21.9 | Moderate weight | Poor, increases energy loss | Not suitable for EVs |

| Stainless Steel | 1.4 | 69.0 | 7.80 | 16 | Heavy, robust | Very poor, requires advanced cooling | Not recommended for EVs |

| Carbon-based (Graphene, CNTs) | Variable (10–30) | Variable (3–10) | Low-Moderate | Variable (100–200) | Very light, flexible | Good, reduces hot spots | Promising for next-gen EVs |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Nominal Voltage, (V) | 3.7 | Nominal Capacity, (A) | 2.5 |

| Mass, (kg) | 0.045 | Diameter, (mm) | 18 |

| Length, (m) | 65 | Thermal Conductivity, () | , [16] |

| Density, () | 2722 | Specific Heat Capacity, () | 1200 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Outer diameter, (mm) | 50 | Module case size (Length × width × height), (mm) | 62 × 62 × 65 |

| Inlet air temperature, (°C) | 26 | Inlet air velocity at 12 V, (m·s−1) | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, J.; Jan, S.; Ifitkhar, S.; Yaqoob, A.; Rehman, U.U.; Cheema, T.A.; Alam, S.; Habib, U. Design and Performance Optimization of Battery Pack with AI-Driven Thermal Runaway Prediction. Mater. Proc. 2025, 23, 17. https://doi.org/10.3390/materproc2025023017

Khan J, Jan S, Ifitkhar S, Yaqoob A, Rehman UU, Cheema TA, Alam S, Habib U. Design and Performance Optimization of Battery Pack with AI-Driven Thermal Runaway Prediction. Materials Proceedings. 2025; 23(1):17. https://doi.org/10.3390/materproc2025023017

Chicago/Turabian StyleKhan, Jalal, Sher Jan, Sami Ifitkhar, Ajmal Yaqoob, Ubaid Ur Rehman, Taqi Ahmad Cheema, Shahid Alam, and Usman Habib. 2025. "Design and Performance Optimization of Battery Pack with AI-Driven Thermal Runaway Prediction" Materials Proceedings 23, no. 1: 17. https://doi.org/10.3390/materproc2025023017

APA StyleKhan, J., Jan, S., Ifitkhar, S., Yaqoob, A., Rehman, U. U., Cheema, T. A., Alam, S., & Habib, U. (2025). Design and Performance Optimization of Battery Pack with AI-Driven Thermal Runaway Prediction. Materials Proceedings, 23(1), 17. https://doi.org/10.3390/materproc2025023017