1. Introduction

Thermal energy waste has become a global concern, contributing significantly to inefficiencies in energy use and environmental degradation. Studies estimate that nearly 60–70% of primary energy from fossil fuels is lost as waste heat in industrial processes and power generation [

1]. With the rising global energy demand, projected to increase by 47% by 2050, and the environmental issues caused by fossil fuel consumption, there is an urgent need for sustainable energy recovery solutions [

2]. Power plants, industrial facilities, and vehicular engines are among the major sources of waste heat, releasing over 60 EJ (exajoules) of unused thermal energy annually [

3]. If properly captured and converted, this waste heat presents a valuable opportunity to improve overall energy efficiency.

Thermoelectric generators (TEGs), which operate on the seebeck effect, have emerged as a promising technology for converting waste heat into electrical power. These devices can harness heat from vehicle exhausts, industrial processes, and power plant emissions, generating electricity with conversion efficiencies ranging from 5% to 10% [

4]. Although TEGs currently exhibit lower efficiency than conventional heat recovery methods, their reliability, lack of moving parts, and minimal maintenance requirements make them suitable for long-term operation in diverse environments [

5]. Advances in thermoelectric materials, such as bismuth telluride (Bi

2Te

3) and skutterudites, have improved the performance of TEGs, achieving figure-of-merit (ZT) values greater than 1.5 [

6].

TEGs are particularly valuable in settings where traditional energy harvesting methods are impractical. Research has shown that using thermoelectric materials with high seebeck coefficients enables energy conversion from temperature differences as low as 5–10 °C, making them ideal for remote or off-grid locations [

6]. The incorporation of IoT technology enhances detection accuracy, overcoming the limitations of traditional smoke or heat-based fire alarms [

7]. By reducing dependency on non-renewable energy sources, TEGs offer a sustainable and eco-friendly solution for addressing the increasing global energy demand while lowering CO

2 emissions by up to 15% in industrial applications [

8].

The integration of TEGs with the Internet of Things (IoT) presents an innovative approach to enhancing both energy sustainability and fire safety. This study proposes a thermo-powered Thermo-Powered IoT smart fire detector systemSmart Fire Detector System, which leverages thermoelectric energy recovery to power a microcontroller, temperature sensors, an OLED display, and IoT connectivity. Unlike conventional fire detection systems that rely on external power sources, this system is self-sustaining, using heat from fires or industrial processes to generate electricity. Research indicates that IoT-based fire detection can reduce fire response times by up to 50%, significantly minimizing damage and casualties [

3].

The proposed system continuously monitors temperature variations through advanced sensors, displaying real-time data on an OLED screen while transmitting critical alerts to a cloud-based monitoring platform. This dual-layer monitoring system enables remote accessibility, allowing users to respond promptly to fire hazards from any location.

The operational framework of the system demonstrates how waste heat from industrial processes, vehicle exhausts, and direct fires can be efficiently captured by TEGs to power the IoT-based fire detection system. By converting excess heat into electrical power, the system supports global sustainability goals while improving fire safety. Research has shown that integrating TEGs with IoT systems can improve energy efficiency by 30% in industrial and commercial applications, reducing reliance on external power sources [

4].

As industries and governments seek renewable energy solutions, the demand for self-sustaining, energy-efficient safety systems continues to grow. The integration of thermoelectric technology with the IoT presents a scalable, cost-effective, and environmentally responsible approach to fire detection. By addressing critical global challenges such as waste heat recovery and fire safety, this study contributes to advancing sustainable energy applications and smart safety solutions for future technological developments.

2. Materials and Methods

The system harvests waste heat using TEGs (Generic Chinese OEM (Hebei, China) and regulates the generated power with a custom PCB made by us, for reliable energy management [

9]. An ESP32 microcontroller (Espressif Systems (Shanghai) Co., Ltd., Shanghai, China) processes temperature data from an IR flame sensor (Generic OEM, Shenzhen, China) [

10], which is sending real-time data to the cloud for remote monitoring [

11]. Local displays and cloud integration provide real-time visualization and scalability for fire detection across multiple locations.

2.1. Heat Energy Harvesting

The system leverages TEGs with attached aluminum plates and heat sinks to capture and convert waste heat into electrical energy using the Seebeck effect. A temperature gradient (ΔT) across the TEG generates voltage, powering the fire detection system. The generated voltage can be calculated using Equation (1).

where S is the Seebeck coefficient of the TEG material and ΔT is the temperature difference across the TEG (K).

The electrical energy generated by TEGs is regulated and stored in a battery system. The battery ensures a consistent power supply, enabling the uninterrupted operation of sensors, microcontrollers, and communication modules even during heat fluctuations.

2.1.1. Fire Detection and Monitoring

The system uses IR Flame Sensor for monitoring. These sensors provide accurate temperature readings, which are sent to the ESP32 microcontroller for analysis. The microcontroller checks the readings against set thresholds to detect possible fires. A fire is identified when the temperature rises sharply above normal levels in a short time. When this happens, the system triggers an alarm and sends real-time data to the cloud for remote monitoring. The thresholds are carefully set to avoid false detection.

2.1.2. Data Visualization and Alerts

Temperature readings are displayed locally using an OLED screen, providing real-time feedback. Additionally, the ESP32 uploads the data to a cloud platform [

12] for remote monitoring and analytics.

2.1.3. Cloud Integration and Scalability

The IoT-based system allows multiple nodes to communicate and share data with a centralized cloud platform. This feature enables real-time alerts and detailed historical data analysis for fire monitoring across various locations.

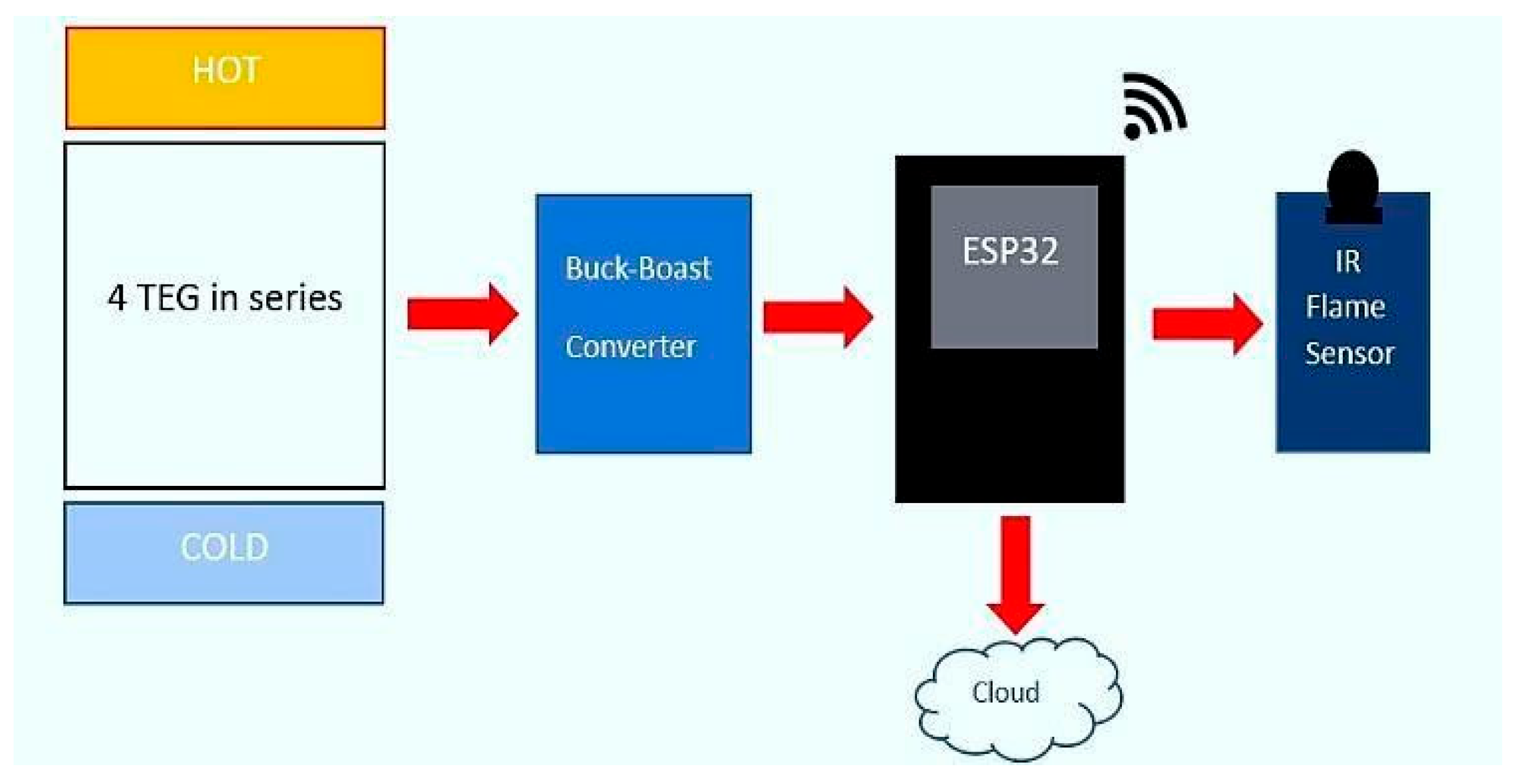

Figure 1 depicts a system where TEGs generate power from a temperature gradient, which is then regulated using a buck-boost converter. The power is supplied to an ESP32 microcontroller, connected to an IR flame sensor for fire detection, and cloud connectivity for data transmission is ensured.

2.2. Hardware Setup

The system’s TEG unit converts heat into electricity, regulated by a custom PCB for stable power supply. An IR flame sensor and ESP32 enable real-time monitoring and control, with data visualized locally on an OLED screen (Generic OEM, Shenzhen, China) and remotely via cloud integration.

2.2.1. Thermoelectric Generation Unit

The thermoelectric generation (TEG) unit forms the core of the system. It consists of a TEG module placed between an aluminum plate and a heat sink. When heat from the source passes through the module, a temperature gradient is created across it, generating a measurable voltage based on V = SΔT. This setup maximizes heat transfer efficiency, ensuring optimal energy generation.

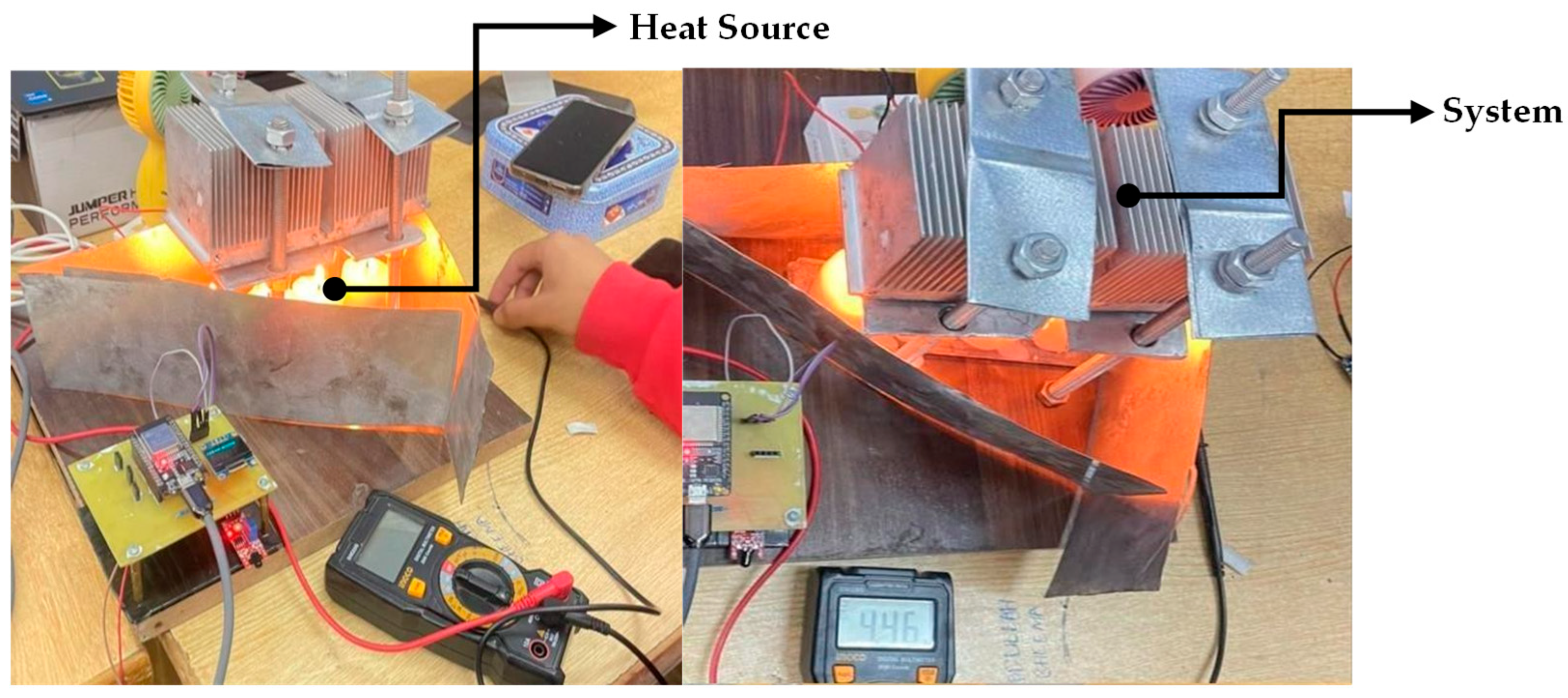

Figure 2 shows the assembly consisting of TEG modules sandwiched between aluminum heat sinks to create a temperature gradient. The top heat sinks dissipate heat, while the bottom heat sinks are exposed to a cooler environment, enabling efficient power generation. The structure is held together with threaded rods, bolts, and metal plates to ensure proper thermal contact and mechanical stability. Electrical connections from the TEG modules provide power to the system’s components.

2.2.2. Energy Management Circuit

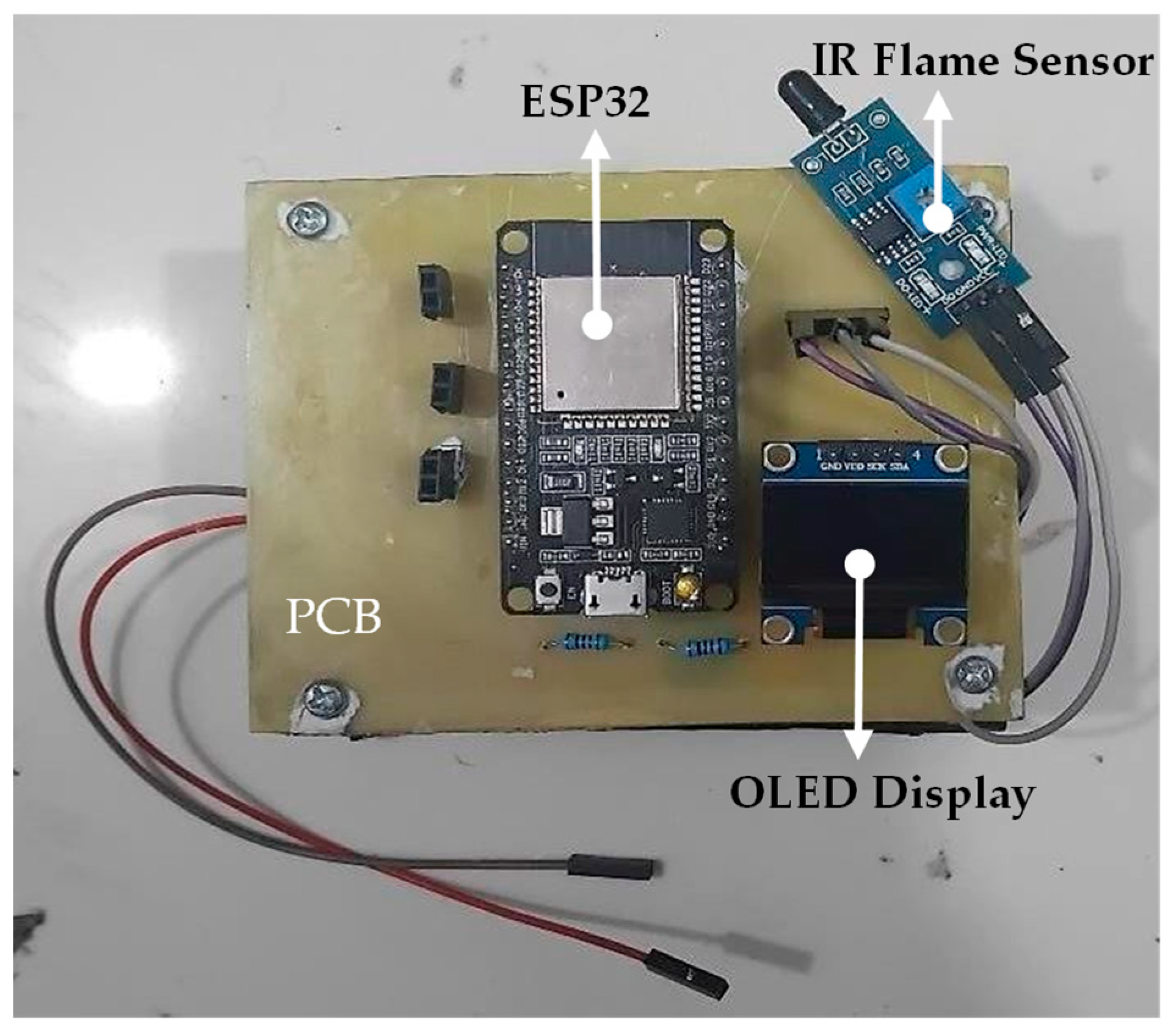

The system includes a custom-designed PCB for energy management. This circuit regulates the voltage generated by the TEG module and efficiently manages battery storage. The design ensures stable power supply to the components, enhancing reliability and performance. An image of the PCB with labeled components provides a clear understanding of its layout and functionality.

Figure 3 shows that the setup includes an ESP32 microcontroller as the central processing unit, interfaced with an IR flame sensor for flame detection and an OLED display for the local monitoring of the system status. The IR flame sensor detects the presence of a flame, while the ESP32 processes the data and transmits it to the cloud for remote monitoring via wireless communication. The circuit is mounted on a custom PCB to ensure an organized and reliable layout for the components.

2.2.3. Monitoring and Control

The IR flame sensor is integrated to monitor heat levels accurately. These sensors send data to an ESP32 microcontroller, which processes the information and transmits it to the cloud for remote access. Locally, the ESP32 also drives an OLED screen that displays real-time temperature data. The setup ensures robust monitoring and control of the system.

2.2.4. Data Visualization and Experimental Setup

Data visualization is achieved through both local and remote interfaces. The OLED screen provides a real-time display of temperature readings at the hardware level. Simultaneously, data transmitted to the cloud can be accessed through a laptop or smartphone. This enables remote monitoring and further analysis of the collected data.

Figure 4 depicts a thermoelectric generation experiment that likely demonstrates how heat energy is converted into electrical energy using thermoelectric modules. The metal structure and heat sinks help regulate heat distribution across the thermoelectric modules. A circuit board with connected components processes the output, while a multimeter measures electrical parameters such as voltage or current. This setup might aim to showcase power generation efficiency, testing thermal-to-electrical energy conversion for practical applications.

3. Results

The proposed “Thermo-powered IoT Fire Detection System” was successfully developed and tested. The system demonstrated efficient energy harvesting using thermoelectric generators (TEGs) from various heat sources, including bike exhaust and direct fire. The generated power was able to reliably operate the ESP32 microcontroller, IR flame sensor, and OLED display, ensuring consistent functionality even during heat fluctuations. The data of temperature difference between the hot and cold side of thermoelectric module surfaces and the voltages that are produced as a result of the temperature difference in the thermoelectric module is shown in

Table 1.

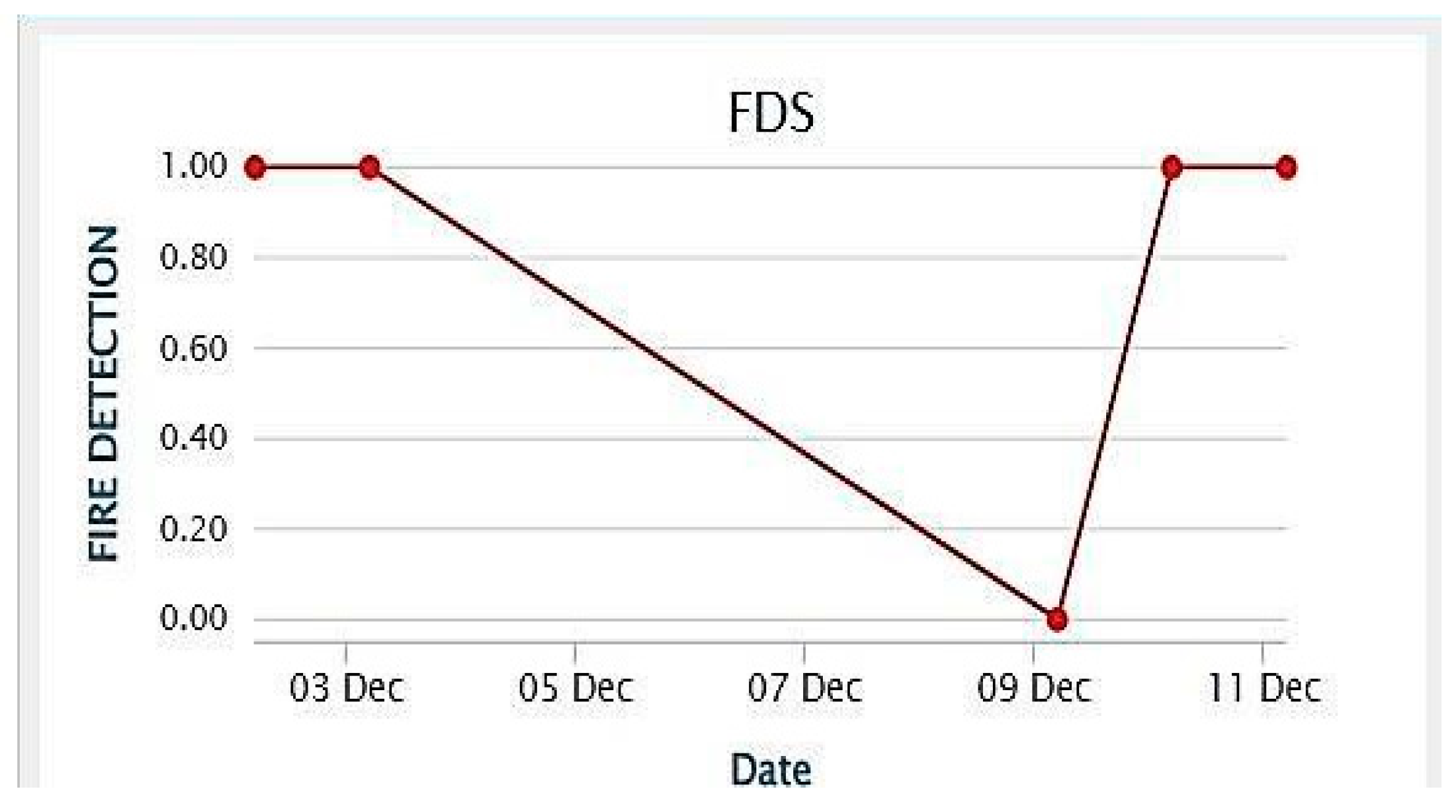

The IR flame sensor accurately detected fire incidents by analyzing sudden spikes in infrared radiation, triggering timely alarms and transmitting data to the cloud.

Local monitoring via the OLED display provided real-time temperature readings, while the cloud platform offered remote access to fire alerts and historical data.

Figure 5 shows the screenshot of the cloud interface, highlighting the seamless data integration, real-time visualization, and remote monitoring capabilities. The system was validated for its ability to deliver accurate fire detection with minimal false alarms, demonstrating its scalability and reliability across multiple test environments.