Advanced 3D Polymeric Sponges Offer Promising Solutions for Addressing Environmental Challenges in Qatar’s Marine Ecosystems †

Abstract

1. Introduction

2. Experimental Method

3. Results and Discussion

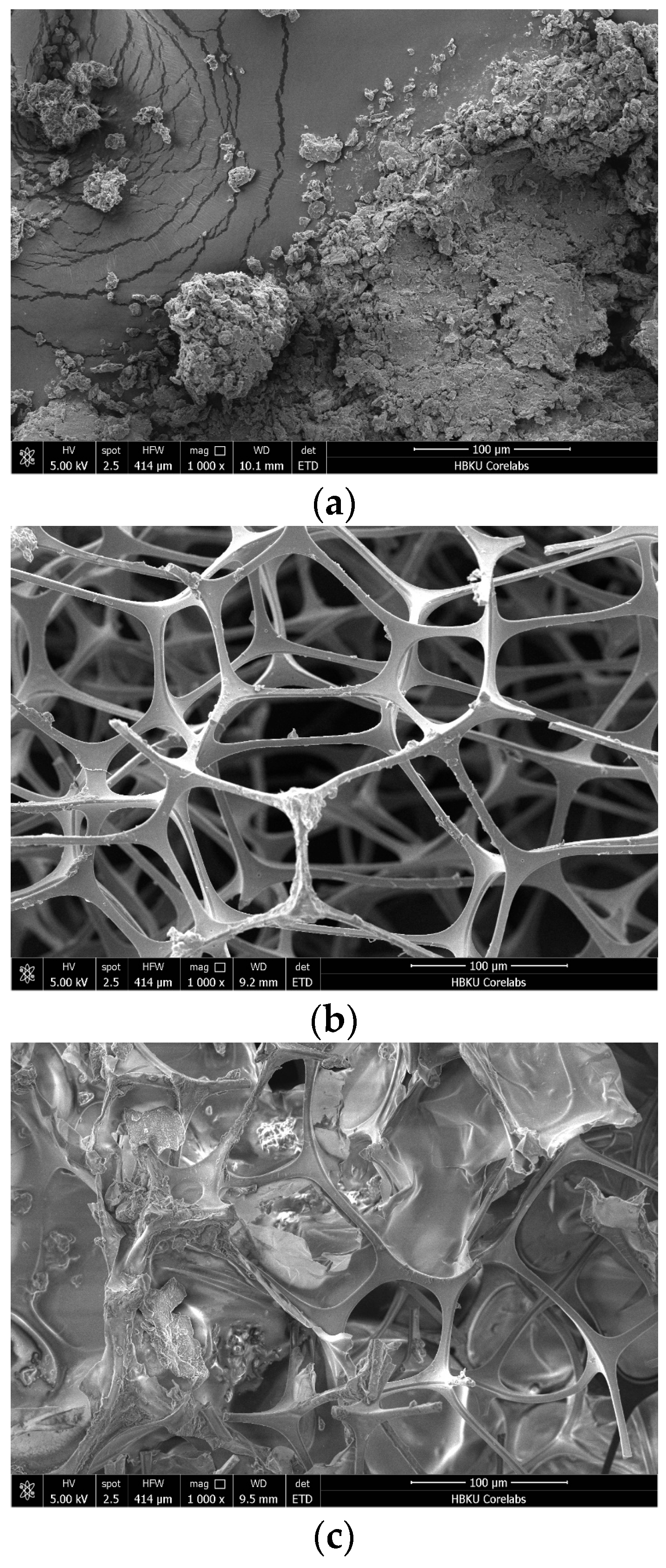

3.1. Scanning Electron Microscopy (SEM)

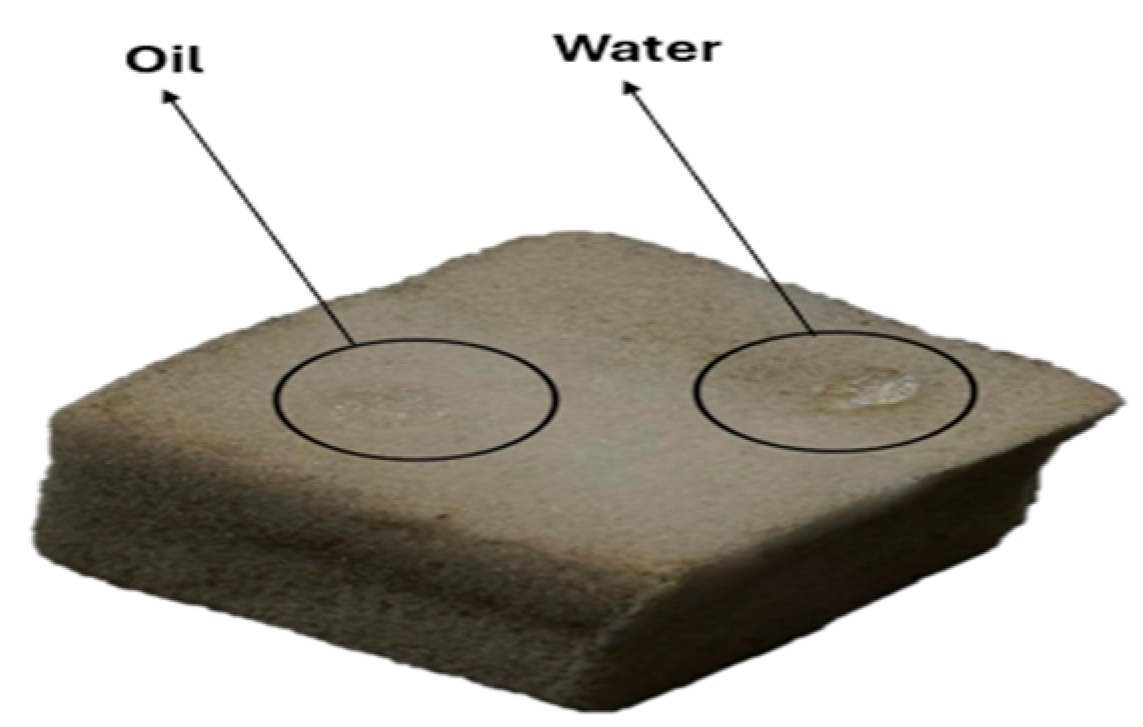

3.2. Preliminary Test of Oil and Water Adsorption

3.3. Analysis of Adsorption Capacity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ogunbiyi, O.; Al-Rewaily, R.; Saththasivam, J.; Lawler, J.; Liu, Z. Oil spill management to prevent desalination plant shutdown from the perspectives of offshore cleanup, seawater intake and onshore pretreatment. Desalination 2023, 564, 116780. [Google Scholar] [CrossRef]

- Ekunke, O.V.; Odor, G.E.; Sani, S.M.; Ojeilua, C.H.; Attairu, M.L.; Ahmed, M.A.; Elabor, I. A review of modern technologies and best practices for oil spill containment and response. World J. Adv. Res. Rev. 2025, 25, 2117–2128. [Google Scholar] [CrossRef]

- Ding, D.; Mao, H.; Chen, X.; Qiu, M.; Fan, Y. Underwater superoleophobic-underoil superhydrophobic Janus ceramic membrane with its switchable separation in oil/water emulsions. J. Membr. Sci. 2018, 565, 303–310. [Google Scholar] [CrossRef]

- Zhu, G.; Li, X.; Zhang, X. Fabrication of a superhydrophobic-superoleophilic particle material for oil-water separation and oil extraction. Colloids Surf. A Physicochem. Eng. Asp. 2023, 681, 132811. [Google Scholar] [CrossRef]

- Ahmad, N.N.R.; Ang, W.L.; Leo, C.P.; Mohammad, A.W.; Hilal, N. Current advances in membrane technologies for saline wastewater treatment: A comprehensive review. Desalination 2021, 517, 115170. [Google Scholar] [CrossRef]

- Ahmed, R.M.; Anis, B.; Khalil, A.S. Facile surface treatment and decoration of graphene-based 3D polymeric sponges for high performance separation of heavy oil-in-water emulsions. J. Environ. Chem. Eng. 2021, 9, 105087. [Google Scholar] [CrossRef]

- Tran, M.L.; Van Tran, T.T.; Juang, R.-S.; Nguyen, C.H. Graphene oxide crosslinked chitosan composites for enhanced adsorption of cationic dye from aqueous solutions. J. Taiwan Inst. Chem. Eng. 2023, 142, 104678. [Google Scholar] [CrossRef]

- Aziz, N.A.A.A. Surface Modification of Graphene Oxide by D-Glucose in Epoxy Resin Composites for Anticorrosive Coating. Master’s Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2023. [Google Scholar]

- Mokoena, L.; Mofokeng, J. Synthesis and characterization of graphene oxide (GO) for the removal of lead ions in water. Carbon Trends 2024, 15, 100339. [Google Scholar] [CrossRef]

- Ikhsan, S.N.W.; Yusof, N.; Aziz, F.; Ismail, A.F.; Shamsuddin, N.; Jaafar, J.; Salleh, W.N.W.; Goh, P.S.; Lau, W.J.; Misdan, N. Synthesis and Optimization of Superhydrophilic-Superoleophobic Chitosan–Silica/HNT Nanocomposite Coating for Oil–Water Separation Using Response Surface Methodology. Nanomaterials 2022, 12, 3673. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; He, H.; Wang, Y.; Huang, Y.; Zhang, T.C.; Yuan, S. Superhydrophobic sponge-like chitosan/CNTs/silica composite for selective oil absorption and efficient separation of water-in-oil emulsion. Carbohydr. Polym. 2025, 353, 123256. [Google Scholar] [CrossRef] [PubMed]

- Liang, F.; Hou, T.; Li, S.; Liao, L.; Li, P.; Li, C. Elastic, super-hydrophobic and biodegradable chitosan sponges fabricated for oil/water separation. J. Environ. Chem. Eng. 2021, 9, 106027. [Google Scholar] [CrossRef]

- Rahaman, H.; Islam, R.; Islam, R.; Alam, S.N.; Rahman, S.; Rahman, A.; Begum, B.A. Preparation, characterization, and adsorption kinetics of graphene oxide/chitosan/carboxymethyl cellulose composites for the removal of environmentally relevant toxic metals. Int. J. Biol. Macromol. 2023, 257, 128357. [Google Scholar] [CrossRef] [PubMed]

- Kahya, N.; Erim, F.B. Graphene oxide/chitosan-based composite materials as adsorbents in dye removal. Chem. Eng. Commun. 2021, 209, 1711–1726. [Google Scholar] [CrossRef]

- Chang, Y.S.; Munro, C.J.; Fortunato, L.; AlAli, A.; Marciulescu, C.; Harvey, S.L.; Vrouwenvelder, J.; Arafat, H.; Dumée, L.F. Macrofouling remediation strategies for water intakes of desalination and other industrial plants—A review. Desalination 2024, 590, 117987. [Google Scholar] [CrossRef]

| GO Loading (%) | Weight of Sponge (g) | Weight the Modified Sponge with GO/Chitosan (g) | Weight After oil Adsorption (g) | Weight of Oil Adsorbed (g) | Adsorption Capacity (g/g) |

|---|---|---|---|---|---|

| 3% | 0.1120 | 0.1431 | 7.4976 | 7.3545 | 51.4 |

| 6% | 0.1353 | 0.1441 | 3.0733 | 2.9292 | 20.3 |

| 9% | 0.1330 | 0.1722 | 3.5056 | 3.3334 | 19.4 |

| 12% | 0.1260 | 0.1300 | 3.4517 | 3.3217 | 25.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helally, M.; Sliem, M.H.; Al-Qahtani, N. Advanced 3D Polymeric Sponges Offer Promising Solutions for Addressing Environmental Challenges in Qatar’s Marine Ecosystems. Mater. Proc. 2025, 22, 4. https://doi.org/10.3390/materproc2025022004

Helally M, Sliem MH, Al-Qahtani N. Advanced 3D Polymeric Sponges Offer Promising Solutions for Addressing Environmental Challenges in Qatar’s Marine Ecosystems. Materials Proceedings. 2025; 22(1):4. https://doi.org/10.3390/materproc2025022004

Chicago/Turabian StyleHelally, Mohamed, Mostafa H. Sliem, and Noora Al-Qahtani. 2025. "Advanced 3D Polymeric Sponges Offer Promising Solutions for Addressing Environmental Challenges in Qatar’s Marine Ecosystems" Materials Proceedings 22, no. 1: 4. https://doi.org/10.3390/materproc2025022004

APA StyleHelally, M., Sliem, M. H., & Al-Qahtani, N. (2025). Advanced 3D Polymeric Sponges Offer Promising Solutions for Addressing Environmental Challenges in Qatar’s Marine Ecosystems. Materials Proceedings, 22(1), 4. https://doi.org/10.3390/materproc2025022004