Abstract

After successful preparation of master batch formulations including polyhydroxybutyrate (PHB) and fibrillated cellulose, the compositions of PHB with different types and concentrations of fillers were used for the deposition of a coating on packaging paper grades, by using compression molding technique in a hydraulic press. The resulting paper coatings are demonstrated to provide a green solution for the production of protective barrier layer films with tunable hydrophobicity and oxygen barrier resistance. The processing of the nanocomposites into flat and homogeneous coatings was optimized for different conditions of molding temperature and times, in particular, the flow conditions of the coating under pressing in contact with the paper substrate strongly depends on the presence of fillers. The effects of filler types on adhesion of the coating at the paper/polymer interface were investigated and the poor adhesion of native PHB coatings was improved after hydrophobic surface modification of the nanocellulose fillers. Under compression molding, the unique inclusion styrene-maleimide nanoparticles with encapsulated wax attached to the nanocellulose fiber surface enhanced the flowing properties of the coating by eliminating fiber agglomeration in contact with the paper substrate and reducing the effects of fiber pull outs. Therefore, hydrophobic fiber modification and the role of wax as a lubricant is necessary to obtain a homogenous dispersion during compressing molding of coating materials for papers.

1. Introduction

The search of renewable materials for protective paper coatings with good barrier properties has become a most challenging issue for the replacement of common fossil-oil based plastics. In respect to the sustainable and green image of paper materials, however, the high porosity and hydrophilic nature of the cellulose fibers have to be covered with the application of a suitable coating layer. Amongst a broad variety of bio-based polymers for paper coating applications [1], the poly(lactic acid) or PLA and poly(hydroxyalkanoates) or PHA polymer grades offer best opportunities as thermoplastic materials that can be processed under continuous melt-processing conditions to provide a thick and continuous coating layer. Amongst the PHA family, the polyhydroxybutyrate (PHB) is a homopolymer with a high degree of crystallinity and it has consequently stiff and brittle mechanical properties in comparison with traditional packaging materials that are more ductile and better deformable. The copolymers of PHB can be made more flexible and less crystalline by introducing long alkyl side chain [2], or addition of filler materials. The PHA family is biodegradable in respect to the paper, and was therefore also used in other fields of the pulp and paper industry including the use as granules for internal sizing [3].

In recent reports, the PHB was applied as a coating material on paper surfaces through a solvent casting from chloroform [4]. However, the solvent casting techniques should obviously be avoided to reduce chemical’s consumption and extend the processing continuity of paper coating application. Therefore, the PHB can be applied by compression molding, but in that case additional chemical modification of the paperboard by acetylation reactions were needed to improve the adhesion between the coating layer and paper substrate [5]. The direct extrusion of hydroxybutyrate/3-hydroxyvalerate (PHB-V) copolymers as a paper coating exhibited an enormous improvement in water vapor transmission rates compared to polyethylene, but the incorporation of wax was required to further improve the water barrier properties [6]. The nanocellulose additives were investigated in order to improve the interaction between the layers and mechanical properties of the PHV/paperboard composites [7]: in that case, the cellulose nanocrystals were used in combination with additional plasticizers and deposited as bilayer composites by means of compression molding of pre-formed films from a solvent casting from dimethylformamide (DMF) solution. The nanocomposite films used as paperboard coating, presented good dispersion of the cellulose nanocrystals, being an important factor influencing the thermal, mechanical and barrier properties, and also affected the interfacial interaction degree between the coating and paperboard [8]. On the other hand, the inclusion of microfibrillated cellulose in coating layers may improve the mechanical and barrier properties of the paper more drastically due to the formation of a dense fibrillar network structure [9].

The research in this work will represent the incorporation of different types of fibrillated cellulose materials into a PHB coating that can be applied through compression molding.

2. Materials and Methods

2.1. Materials

The PHB grade Mirel M2100 (Metabolix GmbH, Köln, Germany) was used as a standard grade of polymer pellets. In addition, three types of fibrillated cellulose were incorporated. One grade of commercial microfibrillated cellulose or MFC of Arbocell P1011 (JRS Fibers, Rosenberg, Germany) was received and used as an aqueous dispersion with 20% solid content. A second grade of microfibrillated cellulose was modified by deposition of hydrophobic nanoparticles in parallel with a previously described method [10]. In short, modified microfibrillated cellulose or mMFC was obtained by reacting with styrene maleic anhydride in presence of carnauba wax and ammonium hydrixide, resulting in hybrid core-shell nanoparticles of encapsulated wax into a styrene-maleimide polymer shell that are deposited onto the fiber surface. A third grade nanofibrillated cellulose or NFC of type E167 was purchased (VTT Technical Research Centre, Espoo, Finland). The morphology of the three different cellulose types as virgin material included in the PHB nanocomposite films differs in the diameter of the cellulose fibers and tendency for fiber network formation.

2.2. PHB/Nanocellulose Master Batch Formulations

The master batches of PHB with different types and concentrations of the fibrillated cellulose were processed in parallel with the earlier report [11], following a process using propylene carbonate as a recyclable solvent for the PHB in combination with polyethylene glycol used to disperse the cellulose fibers. The prepared solutions with fibrillated cellulose were equalized with an appropriate amount of water in order to account for the variations in solid content of the original fibrillated cellulose materials. The suspensions of fibrillated cellulose grades were slowly mixed accordingly with the PHB solution at 140 °C for 5 min under continuous stirring, and subsequently precipitated in a cold-water bath at 4 °C to obtain master batch pellets. Master batches were then washed with hot water at 75 °C for about 25 min to fully diffuse out the solvents. Finally, the master batch compositions were dried at 80 °C for 24 h in a circulating air oven for complete water removal. The master batches were prepared by incorporating fiber weight fractions of 0, 1, 5 wt.-% (see Table 1) for each fiber type. For creating the reference PHB batch without fibrillated cellulose, the native pellets were processed under the same solvent and precipitation conditions as before, without addition of fibrillated cellulose suspensions.

Table 1.

Overview of polyhydroxybutyrate (PHB)/nanocellulose masterbatch formulations and films for deposition as a paper coating.

2.3. PHB/Nanocellulose Film Formation on Paper Substrates

The master batches containing the PHB and fibers in different concentrations were formed as a film on top of a paper substrate by compression molding in a hydraulically heated press (LaboPress P 200 S, Vogt Maschinenbau GmbH, Berlin, Germany) at 180 °C. The granulated master batch products were placed on top of a paper sheet in between two sheets of Teflon and pre-heated during closing of the die for 2 min without pressure and finally compressed for 10 s with a maximum pressure of 50 bars. After hot pressing, the coated papers were cooled down to room temperature and removed from the Teflon sheets. For each film, 500 mg of master batch was used. A reference paper grade was used for deposition of the films, including bleached Kraft pulp and internal sizing (350 µm thickness). Before film deposition, the papers were dried at 60 °C for 12 h to remove the adsorbed moisture.

2.4. Analytical Evaluation of Coated Paper Substrates

Scanning electron microscopy (SEM) was performed on a tabletop SEM TM3000 (Hitachi, Krefeld, Germany), at an acceleration voltage of 15 kV and magnifications up to 1000×. The cross sections were obtained by cryo-fracturing in liquid nitrogen.

The static water contact angles were measured by sessile drop tests on a Digidrop device (GBX, Bourg-en-Peage, France), placing a constant water droplet volume of 5 µL during a fixed period of 5 s before taking a screenshot for droplet analysis. As the present samples include the deposition of a continuous film onto a paper substrate, the absorbing effect of water into the porous paper was limited. The contact angles were determined by an elliptical fitting procedure measuring the left and right contact angle, while the reported values are averaged between both. The contact angle was measured at five different positions on the coated surfaces.

The oxygen transmission rates (OTR) were determined according to DIN 53380-3 with measurements at 23 °C and 50% relative humidity with the barrier layer towards the sensor side of the Mocon Twin instrument (Mocon Inc., Minneapolis, MN, USA). The samples were masked using aluminum films in order to stabilize the samples and averaged from two measurements.

3. Results

3.1. Paper Coating Morphology

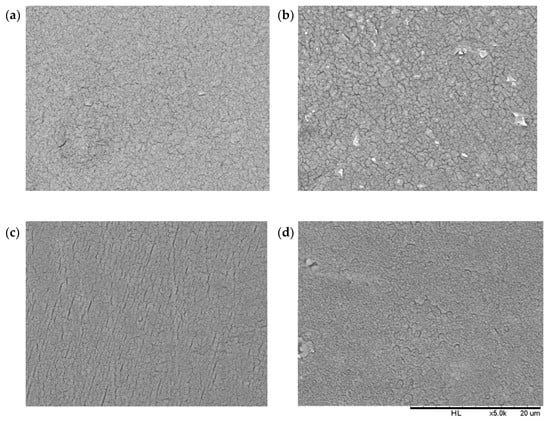

The surface morphology of PHB/fiber coatings observed by SEM evaluation is shown in the top-view images in Figure 1, as an illustrative example for the pure PHB coating and the PHB coating filled with 5 wt.-% MFC, NFC, mMFC respectively. The surface morphology and topography can be specifically distinguished between the various coating types. In particular, the addition of MFC causes coarsening of the surface structure and shows exposure of some separate paper fibers at the surface in parallel with the creation of pores at the surface. The surface of NFC coatings illustrates a more closed coating structure with a finer and more homogeneous morphology. The surface of the mMFC coatings becomes very smooth and flattened with a densely closed surface structure with good coverage and no fiber pull-outs at the surface. The observed features were also slightly visible on the coatings with 1 wt.-% fillers, with few cracking in the 1 wt.-% MFC and NFC coatings and slight flattening of the 1 wt.-% mMFC coating.

Figure 1.

SEM evaluation of PHB/fibrillated cellulose paper coatings in top view at comparable magnification 5000×, including (a) pure PHB, (b) MFC-5 coating, (c) NFC-5 coating, and (d) mMFC-5 coating (same scale-bar applies to all figures).

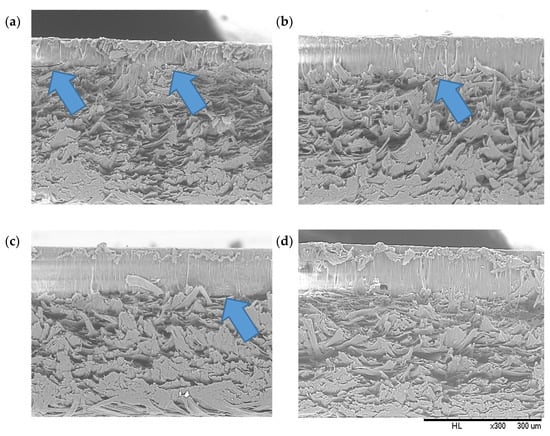

The cross-sections of PHB/fiber coated papers are presented in Figure 2, for the same coatings as before with 5 wt.-% MFC, NFC, mMFC respectively. The application of a coating with either neat PHB or PHB/fiber master batches having very low fiber concentrations resulted into the rather compact and thin coating films in contrast with the more bulky coating films containing a higher fiber concentration, although the same amount of materials were used. In addition, the neat PHB coating develops poor adhesion between the coating and paper as indicated through interface voids in the figure, and similar observations were seen for other PHB/fiber coatings at low fiber fractions. For PHB/NFC coatings, almost similar cross-sectional morphologies are observed as for P-PHB coating with no visible effect of the NFC in the coating material. The remaining interface defects indicate that PHB/NFC master batches were not able to flow uniformly over paper during pressing while they get agglomerated over the paper surface (some agglomerates were seen on visual inspection). This may be attributed to the high affinity of NFC and cellulose fibers due to alike chemistry and high tendency of interaction through plenty of hydroxyl bonds at the surface. In case of PHB/MFC coating few fiber pullouts from the coating are observed, while a major fraction of the fibers agglomerate over the paper surface in similarity with the PHB/NFC coating. However, in case of PHB/mMFC coatings clear differences and better processing performance are observed in relation with other coatings. Even at high mMFC concentrations, a very homogeneous dispersion of mMFC is clearly evidenced with no fiber pullouts. This observation clearly indicates that hydrophobic surface modification of MFC results into a better interaction of the fillers with the polymer material. Moreover, better flow properties of mMFC coatings over the paper surface occur without agglomeration and ‘sticking’ interactions between the fillers and the paper substrate regulated through the different surface chemistry. The hydrophobic modification of cellulosic nanofibers is beneficial for a homogenous dispersion and smooth interactions with a paper substrate through the lubricating wax.

Figure 2.

SEM evaluation of PHB/fibrillated cellulose paper coatings in cross-sectional view at comparable magnification 5000×, including (a) pure PHB, (b) MFC-5 coating, (c) NFC-5 coating, and (d) mMFC-5 coating (same scale-bar applies to all figures). Blue arrows point to interface defects between coating and paper substrate.

3.2. Paper Coating Physical Properties

A summary of the physical properties of the paper coatings, including static water contact angle and OTR values, are given in Table 2.

Table 2.

Water contact angles (WCA) and oxygen transmission rates (OTR) for PHB/fibrillated coatings on paper.

The water contact angles decrease in relation with the pure PHB coating upon addition of MFC and NFC in the PHB coating. However, at high MFC concentration (more than 5 wt.-%) slight increase is observed in the water contact angles of the PHB/MFC films. Due to the hydrophilic surface property of NFC/MFC, it is evident that the polar character of the film intensifies with the increasing NFC/MFC fraction in the PHB matrix resulting in the decrease of the water contact angles. At high MFC concentrations, however, the existence of coating defect.s such as single fiber protrusions and/or MFC agglomerations that both increase the intrinsic surface roughness of the coating, may enhance the hydrophobicity of the film. A very significant improvement in hydrophobicity is observed by the addition of mMFC in the PHB coatings, bringing the water contact angles near 90° for a concentration of 1 wt.-% mMFC. However, a further increase in the mMFC concentration resulted in a decrease of contact angles. The obtained high water contact angles generally result from the combined effects of surface roughness of the films (as previously seen in SEM images) in addition to the presence of hydrophobic wax (as determined from FTIR) over the rough structures, which further augments the surface hydrophobicity of the coatings.

The variations in OTR reflect a general tendency of the entire coating morphology, and is mainly influenced by the homogeneity and porosity of the coatings. Therefore, the pure PHB films with a relatively dense structure provide a relatively low OTR value. The effect of MFC in the coating is disadvantageous for improving the OTR value, as a relatively open surface structure has developed with voids in the bulk of the material and the creation of inappropriate adhesion at the interface between the coating and the paper substrate. The mMFC results in the best improvement of OTR values, as the coating forms a very dense and closed morphology with a smooth interface at the paper surface. The OTR improves at higher concentrations of the mMFC fibers in the coating as the smoothening is enhanced in presence of the wax. The NFC does not uniquely provide an improvement in OTR at low concentrations, but it might be expected that the network formation becomes better developed at the highest concentrations for the formation of a torturous path in the coating, as reflected in a decrease in OTR at high concentrations of NFC. Otherwise, the lower concentrations of NFC perform similar to worse than the pure PHB coating, as related to previous random porous coating structure and interface defects.

4. Conclusions

The processing of nanocomposite coatings including PHB and different types of fibrillated cellulose can be performed successfully by compression molding in order to form a tight and homogeneous coating on paper substrates. The morphology of the coated surfaces and adhesion with the paper substrates strongly depends on the type fibrillated. It is inferred that the inclusion of hydrophobically modified microfibrillated cellulose enhances the smoothness of the coating in parallel with the adhesion to the paper substrate, thereby forming a most homogeneous layer with the lowest oxygen transmission rate and highest contact angles. The mechanisms influencing the coating formation are attributed to the flow properties at the interface between the coating and the paper substrate, in parallel with the presence of wax providing smoother coating surfaces through lubricating properties as the coating/substrate interface. The latter conditions agree with highest water contact angles and lowest oxygen transmission rates. At given concentrations of the mMFC, a combination of hydrophobicity and low OTR can be achieved.

Author Contributions

Both authors contributed to the same amount in the full research and writing process, including conceptualization, V.K.R. and P.S.; materials synthesis, and sample preparation, V.K.R; analytical experiments, V.K.R. and P.S.; data processing, V.K.R.; writing V.K.R. and P.S.

Funding

This research was funded by Baden-Wurttemberg Ministry of Science and Arts.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rastogi, V.K.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 557–930. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Lee, K.J.; Azemi, M.N. Comparing the degradation of Poly-B-(hydroxybutyrate), poly-B-(hydroxbutyrate-co-valerate)(PHBV) and PHBV/cellulose tricate blend. Malays. Polym. J. 2006, 1, 39–46. [Google Scholar]

- Bourbonnais, R.; Marchessault, R.H. Application of polyhydroxyalkanoate granules for sizing of paper. Biomacromolecules 2010, 11, 989–993. [Google Scholar] [CrossRef] [PubMed]

- Cyras, V.P.; Commisso, M.S.; Mauri, A.N.; Vázquez, A. Biodegradable double-layer films based on biological resources: Polyhydroxybutyrate and cellulose. J. Appl. Polym. Sci. 2007, 106, 749–756. [Google Scholar] [CrossRef]

- Cyras, V.P.; Soledad, C.M.; Analía, V. Biocomposites based on renewable resource: Acetylated and non-acetylated cellulose cardboard coated with polyhydroxybutyrate. Polymer 2009, 50, 6274–6280. [Google Scholar] [CrossRef]

- Kuusipalo, J. PHB/V in Extrusion Coating of Paper and Paperboard—Study of Functional Properties. J. Polym. Environ. 2000, 8, 49–57. [Google Scholar] [CrossRef]

- Seoane, I.T.; Luzi, F.; Puglia, D.; Cyras, V.P.; Manfredi, L.B. Enhancement of paperboard performance as packaging material by layering with plasticized polyhydroxybutyrate/nanocellulose coatings. J. Appl. Polym. Sci. 2018, 135, 46872. [Google Scholar] [CrossRef]

- Seoane, I.T.; Manfredi, L.B.; Cyras, V.P. Bilayer biocomposites based on coated cellulose paperboard with films of polyhydroxybutyrate/cellulose nanocrystals. Cellulose 2018, 25, 2419–2434. [Google Scholar] [CrossRef]

- Levoine, N.; Desloges, I.; Khelfi, B.; Bras, J. Impact of different coating processes of microfibrillated cellulose on the mechanical and barrier properties of paper. J. Mater. Sci. 2014, 49, 2879–2893. [Google Scholar] [CrossRef]

- Rastogi, V.K.; Stanssens, D.; Samyn, P. Mechanism for tuning the hydrophobicity of microfibrillated cellulose films by controlled thermal release of encapsulated wax. Materials 2014, 7, 7196–7216. [Google Scholar] [CrossRef] [PubMed]

- Rastogi, V.K.; Samyn, P. Influencing crystallization of polyhydroxybutyrate by micro- to nanofibrillated cellulose additives: A study on the effect of fiber morphology. Express Polym. Lett. 2020, 14, 115–133. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).