Study of Lead-Free Ferroelectric Composite Coatings by Impedance Spectroscopy †

Abstract

:1. Introduction

2. Methods

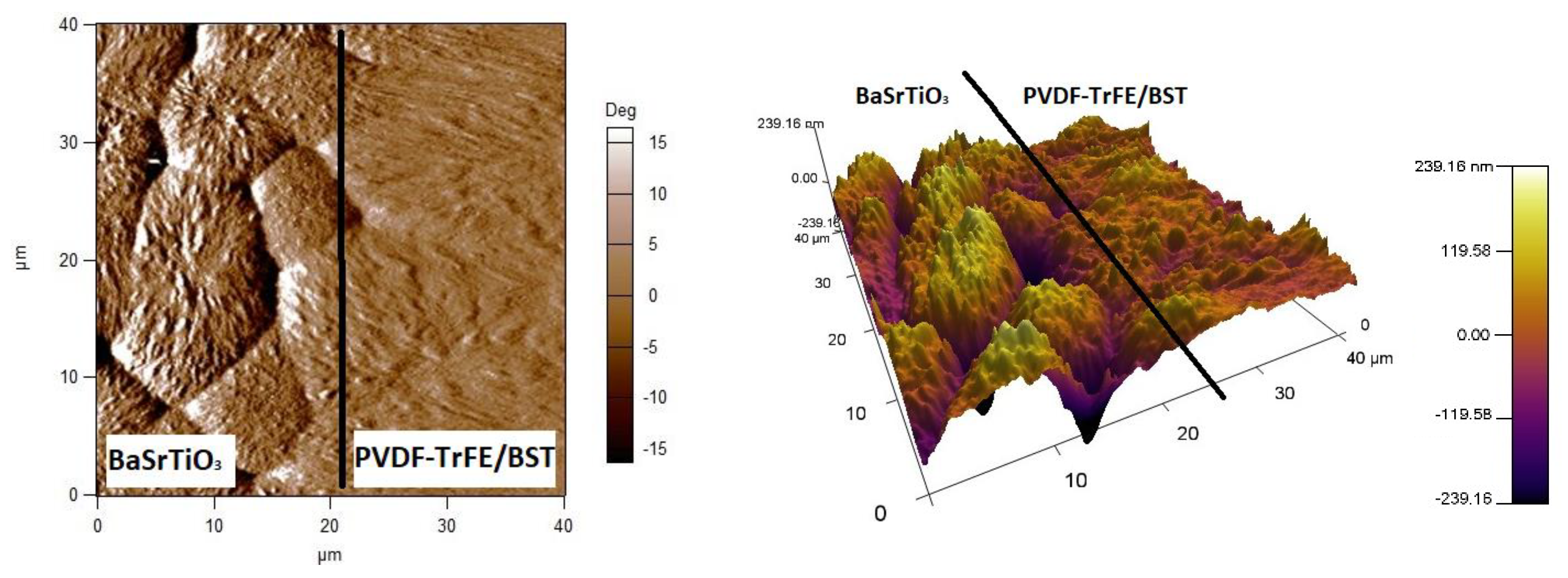

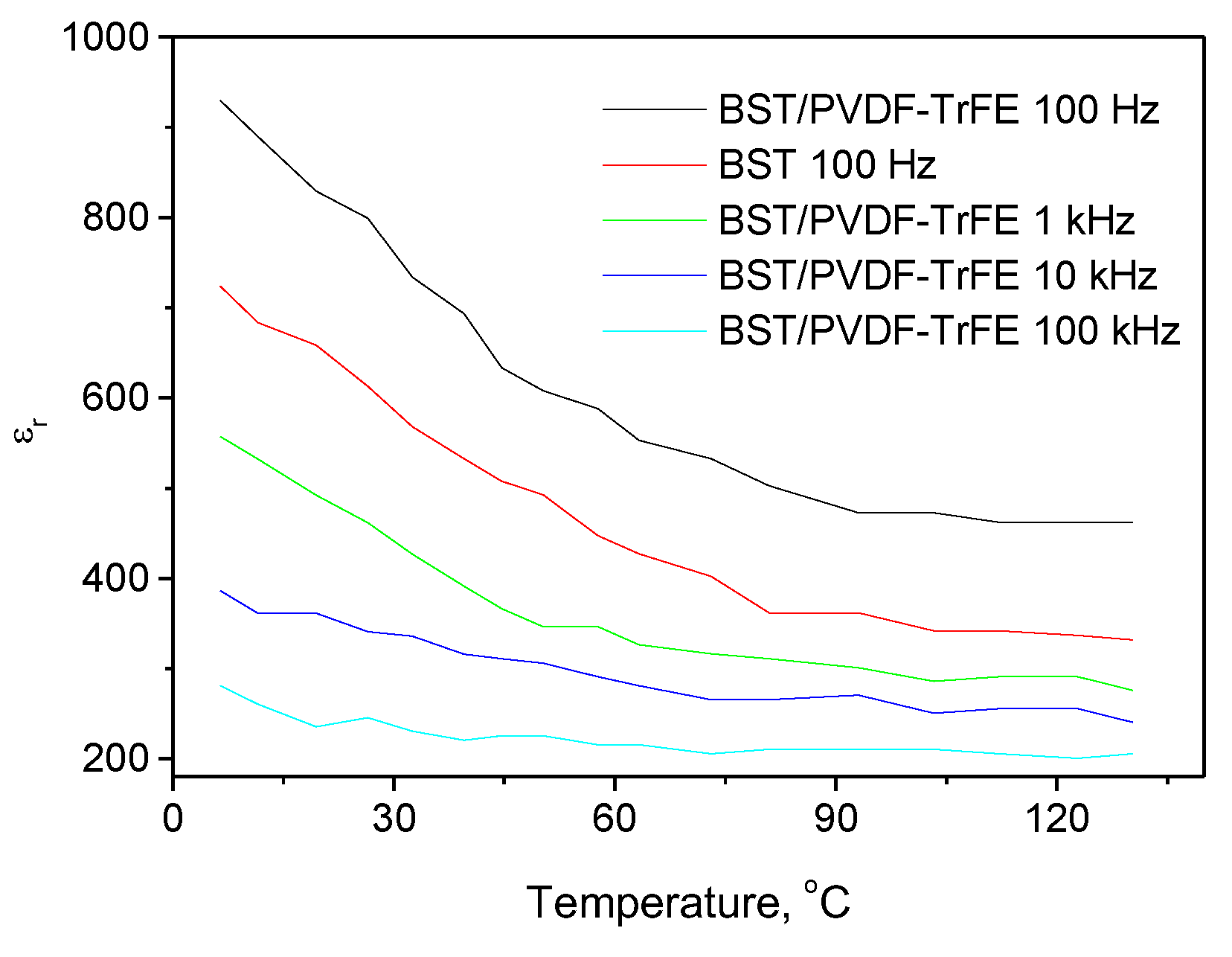

3. Results and Discussion

4. Conclusions

Acknowledgments

References

- Krishnaswamy, J.A.; Buroni, F.C.; García-Macías, E.; Melnik, R.; Rodriguez-Tembleque, L.; Saez, A. Design of lead-free PVDF/CNT/BaTiO3 piezocomposites for sensing and energy harvesting: the role of polycrystallinity, nanoadditives, and anisotropy. Smart Mater. Struct. 2019, 29, 1. [Google Scholar] [CrossRef]

- Zhou, S.; You, L.; Chaturvedi, A.; Morris, S.A.; Herrin, J.S.; Zhang, N.; Abdelsamie, A.; Hu, Y.; Chen, J.; Zhou, Y.; et al. Anomalous polarization switching and permanent retention in a ferroelectric ionic conductor. Mater. Horiz. 2020, 7, 263–274. [Google Scholar] [CrossRef]

- Schenk, T.; Hoffmann, M.; Pešić, M.; Park, M.H.; Richter, C.; Schroeder, U.; Mikolajick, T. Physical Approach to Ferroelectric Impedance Spectroscopy: The Rayleigh Element. Phys. Rev. Appl. 2018, 10, 064004. [Google Scholar] [CrossRef]

- Nikolova, B.; Nikolov, G.; Gieva, E.; Ruskova, I.; Mladenov, M. Influence of Temperature over Impedance of Different Inkjet Printed Patterns and Substrates. In Proceedings of the 2019 IEEE 31st International Conference on Microelectronics (MIEL), Niš, Serbia, 16–18 September 2019. [Google Scholar]

- Pandiev, I.; Aleksandrova, M.; Kolev, G. Design and Implementation of Interface Circuits Intended for Printed Piezoelectric Micropower Harvesters on Flexible Substrates. IOP Conf. Series: Mater. Sci. Eng. 2020, 876, 012007. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, C.; Wu, M.; Dong, H.; Li, L. Ultra-high energy density thin-film capacitors with high power density using BaSn0.15Ti0.85O3/Ba0.6Sr0.4TiO3 heterostructure thin films. J. Power Sources 2019, 412, 648–654. [Google Scholar] [CrossRef]

- Gautam, C.R.; Kumar, D.; Singh, P.; Parkash, O. Study of Impedance Spectroscopy of Ferroelectric (Pb Sr) TiO3 Glass Ceramic System with Addition of La2O3. Int. Sch. Res. Netw. ISRN Spectrosc. 2012, 2012. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrova, M.; Pandiev, I.; Tsanev, T.; Dobrikov, G. Study of Lead-Free Ferroelectric Composite Coatings by Impedance Spectroscopy. Mater. Proc. 2020, 2, 11. https://doi.org/10.3390/CIWC2020-06812

Aleksandrova M, Pandiev I, Tsanev T, Dobrikov G. Study of Lead-Free Ferroelectric Composite Coatings by Impedance Spectroscopy. Materials Proceedings. 2020; 2(1):11. https://doi.org/10.3390/CIWC2020-06812

Chicago/Turabian StyleAleksandrova, Mariya, Ivailo Pandiev, Tsvetozar Tsanev, and Georgi Dobrikov. 2020. "Study of Lead-Free Ferroelectric Composite Coatings by Impedance Spectroscopy" Materials Proceedings 2, no. 1: 11. https://doi.org/10.3390/CIWC2020-06812

APA StyleAleksandrova, M., Pandiev, I., Tsanev, T., & Dobrikov, G. (2020). Study of Lead-Free Ferroelectric Composite Coatings by Impedance Spectroscopy. Materials Proceedings, 2(1), 11. https://doi.org/10.3390/CIWC2020-06812