Parametric Optimization of High-Dielectric Organic Thin-Film Solar Cells †

Abstract

1. Introduction

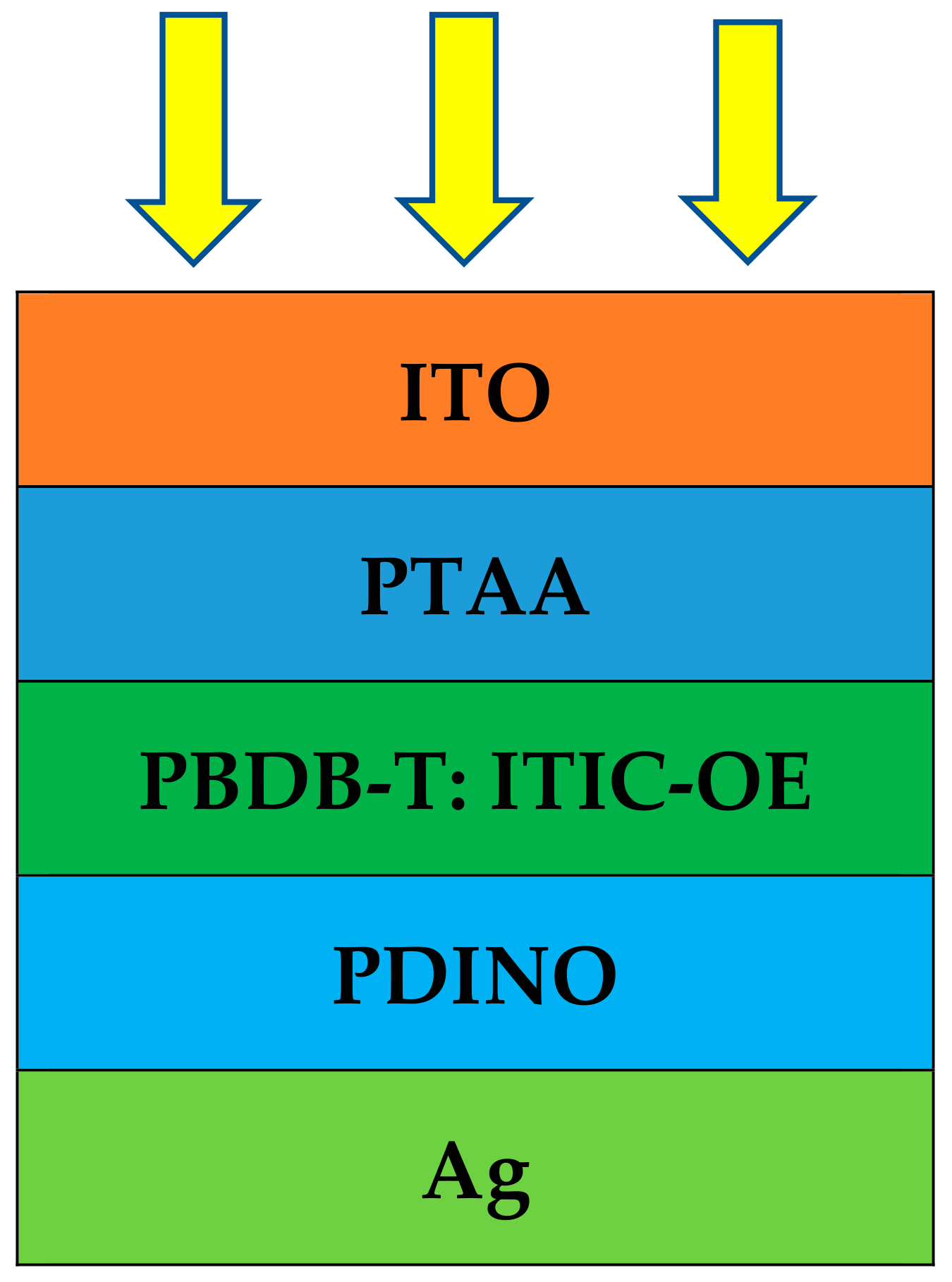

2. Methodology Approach

SCAPS—1D Software and Simulation Parameters

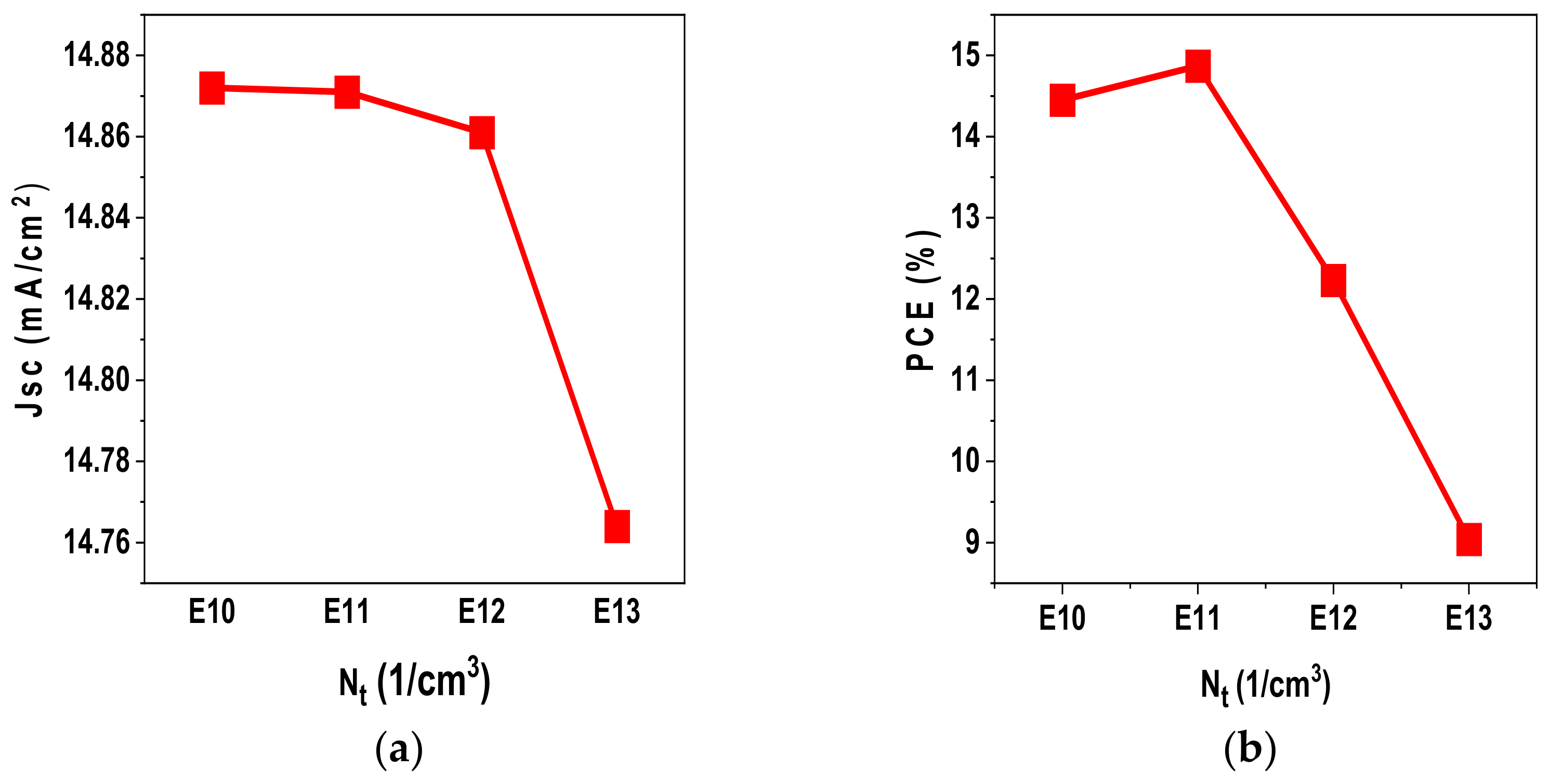

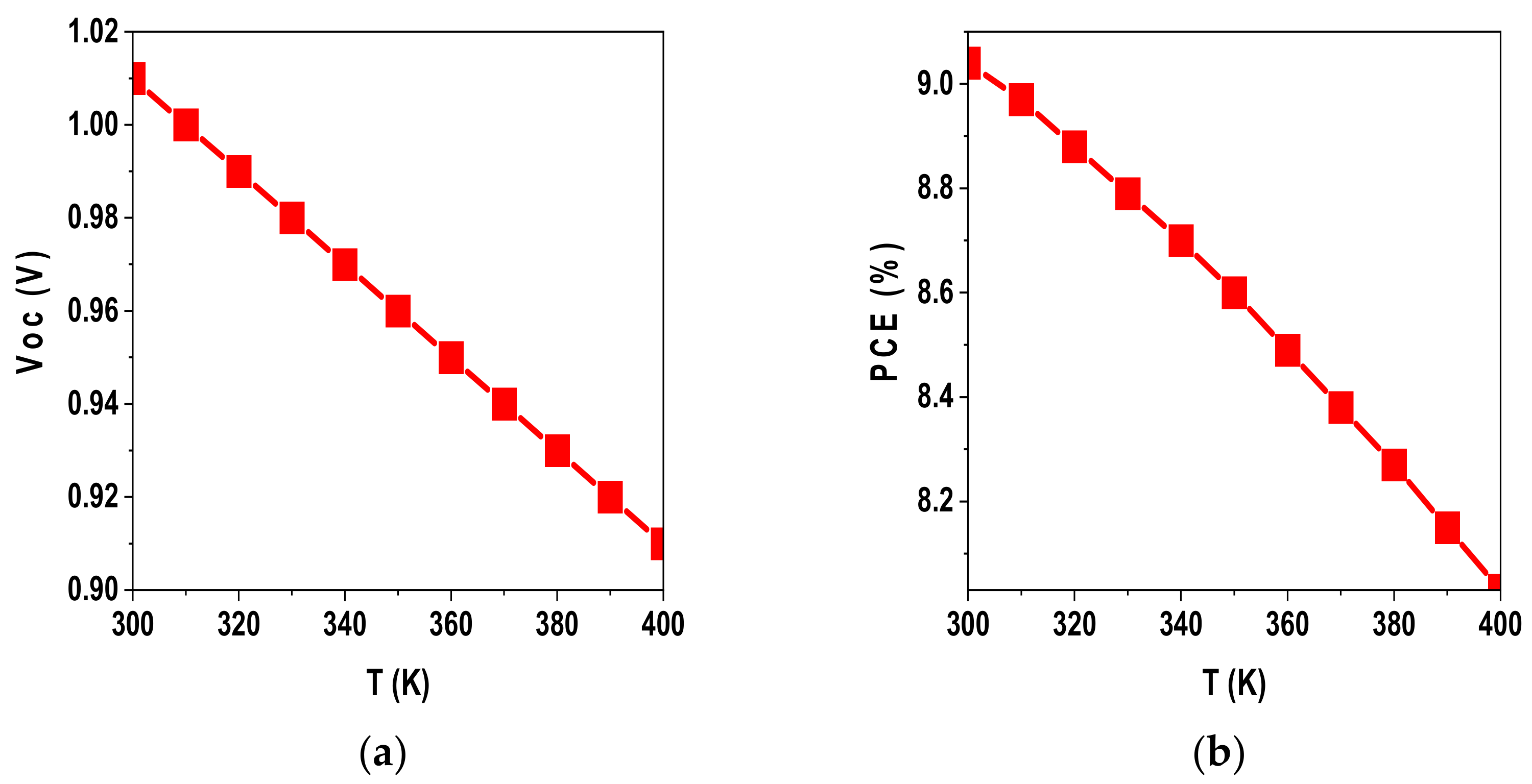

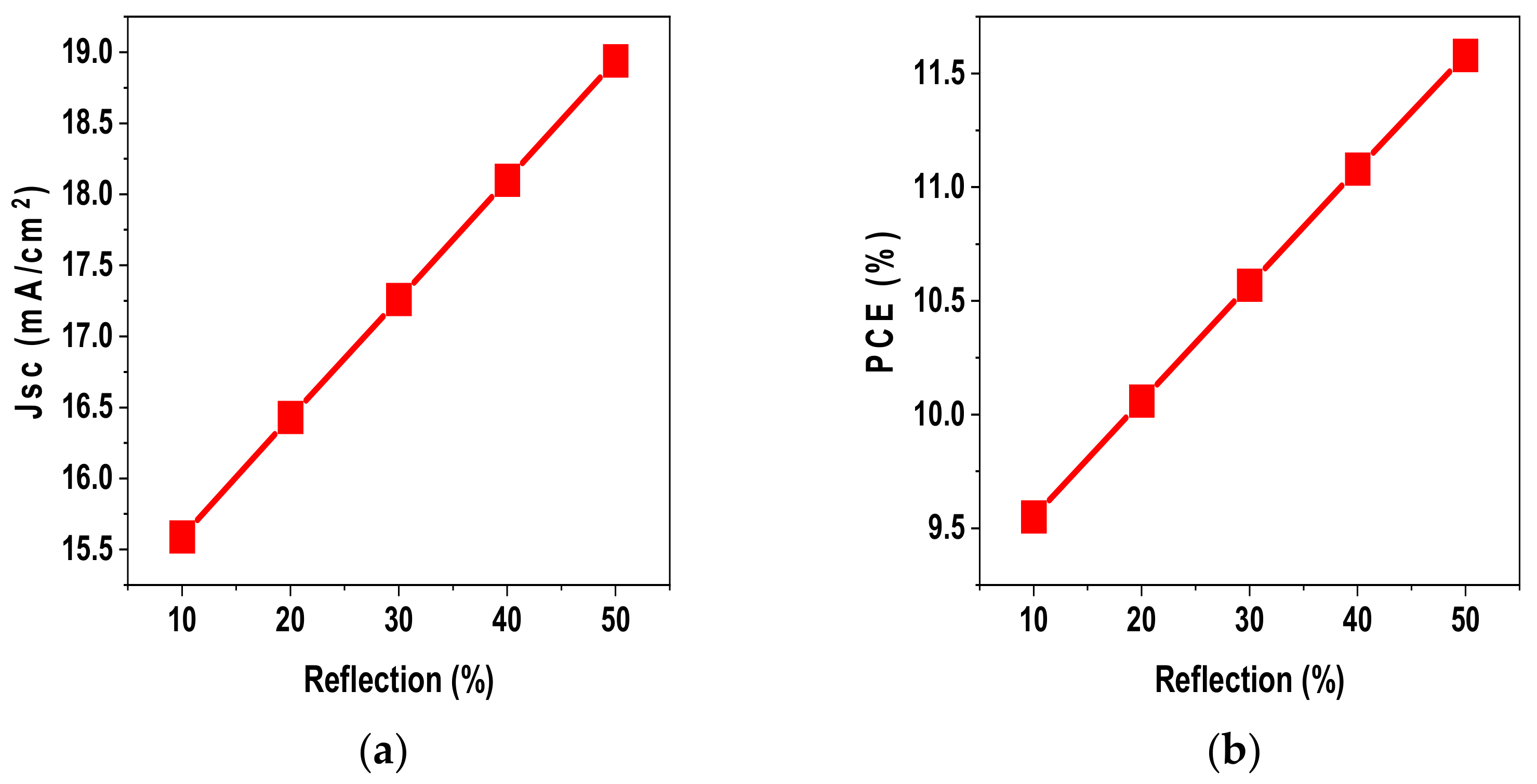

3. Results and Discussion

4. Parametric Optimization and Comparative Analysis with Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nithya, K.S.; Sudheer, K.S. Device Modelling of Non-Fullerene Organic Solar Cell with Inorganic CuI Hole Transport Layer Using SCAPS 1-D. Optik 2020, 217, 164790. [Google Scholar] [CrossRef]

- Gasparini, N.; Wadsworth, A.; Moser, M.; Baran, D.; McCulloch, I.; Brabec, C.J. The Physics of Small Molecule Acceptors for Efficient and Stable Bulk Heterojunction Solar Cells. In Advanced Energy Materials; Wiley-VCH Verlag: Hoboken, NJ, USA, 2018. [Google Scholar] [CrossRef]

- Lin, Y.; Zhan, X. Non-Fullerene Acceptors for Organic Photovoltaics: An Emerging Horizon. In Materials Horizons; Royal Society of Chemistry: London, UK, 2014; pp. 470–488. [Google Scholar] [CrossRef]

- Eftaiha, A.F.; Sun, J.P.; Hill, I.G.; Welch, G.C. Recent Advances of Non-Fullerene, Small Molecular Acceptors for Solution Processed Bulk Heterojunction Solar Cells. J. Mater. Chem. A Mater. 2014, 2, 1201–1213. [Google Scholar] [CrossRef]

- Nielsen, C.B.; Holliday, S.; Chen, H.Y.; Cryer, S.J.; McCulloch, I. Non-Fullerene Electron Acceptors for Use in Organic Solar Cells. Acc. Chem. Res. 2015, 48, 2803–2812. [Google Scholar] [CrossRef] [PubMed]

- Yao, H.F.; Hou, J.H. Design and application of highly efficient polymers for polymer solar cells. Acta Polym. Sin. 2016, 1468–1481. [Google Scholar] [CrossRef]

- Zhang, F.; Johansson, M.; Andersson, M.R.; Hummelen, J.C.; Inganäs, O. Polymer Photovoltaic Cells with Conducting Polymer Anodes. Adv. Mater. 2002, 14, 662–665. [Google Scholar] [CrossRef]

- Wong, K.W.; Yip, H.L.; Luo, Y.; Wong, K.Y.; Lau, W.M.; Low, K.H.; Chow, H.F.; Gao, Z.Q.; Yeung, W.L.; Chang, C.C. Blocking Reactions between Indium-Tin Oxide and Poly (3,4-Ethylene Dioxythiophene):Poly(Styrene Sulphonate) with a Self-Assembly Monolayer. Appl. Phys. Lett. 2002, 80, 2788–2790. [Google Scholar] [CrossRef]

- Kemerink, M.; Timpanaro, S.; De Kok, M.M.; Meulenkamp, E.A.; Touwslager, F.J. Three-Dimensional Inhomogeneities in PEDOT:PSS Films. J. Phys. Chem. B 2004, 108, 18820–18825. [Google Scholar] [CrossRef]

- Levermore, P.A.; Chen, L.; Wang, X.; Das, R.; Bradley, D.D.C. Highly Conductive Poly(3,4-Ethylenedioxythiophene) Films by Vapor Phase Polymerization for Application in Efficient Organic Light-Emitting Diodes. Adv. Mater. 2007, 19, 2379–2385. [Google Scholar] [CrossRef]

- Li, S.S.; Tu, K.H.; Lin, C.C.; Chen, C.W.; Chhowalla, M. Solution-Processable Graphene Oxide as an Efficient Hole Transport Layer in Polymer Solar Cells. ACS Nano 2010, 4, 3169–3174. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.K.; Chang, M.Y.; Ho, K.S.; Hsieh, T.H.; Tsai, J.L.; Huang, P.C. Electrochemically Deposited Nano Polyaniline Films as Hole Transporting Layers in Organic Solar Cells. Sol. Energy Mater. Sol. Cells 2014, 128, 198–203. [Google Scholar] [CrossRef]

- Sit, W.Y.; Eisner, F.D.; Lin, Y.H.; Firdaus, Y.; Seitkhan, A.; Balawi, A.H.; Laquai, F.; Burgess, C.H.; McLachlan, M.A.; Volonakis, G.; et al. High-Efficiency Fullerene Solar Cells Enabled by a Spontaneously Formed Mesostructured CuSCN-Nanowire Heterointerface. Adv. Sci. 2018, 5, 1700980. [Google Scholar] [CrossRef]

- Widianto, E.; Firdaus, Y.; Shobih; Pranoto, L.M.; Triyana, K.; Santoso, I.; Nursam, N.M. Device Modeling of Two-Dimensional Hole Transport Materials for Boosting the Performance of Non-Fullerene Acceptor Bulk Heterojunction Organic Solar Cells. Opt. Mater. 2022, 132, 112771. [Google Scholar] [CrossRef]

- Khan, M.R.; Jarząbek, B. Optimization and Efficiency Enhancement of Modified Polymer Solar Cells. Polymers 2023, 15, 3674. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Xie, B.; Duan, C.; Wang, Z.; Fan, B.; Zhang, K.; Lin, B.; Colberts, F.J.M.; Ma, W.; Janssen, R.A.J.; et al. A High Dielectric Constant Non-Fullerene Acceptor for Efficient Bulk-Heterojunction Organic Solar Cells. J. Mater. Chem. A Mater. 2018, 6, 395–403. [Google Scholar] [CrossRef]

- Burgelman, M.; Nollet, P.; Degrave, S. Modelling Polycrystalline Semiconductor Solar Cells. Thin Solid Film. 2000, 361, 527–532. [Google Scholar] [CrossRef]

- Salem, M.S.; Shaker, A.; Salah, M.M. Device Modeling of Efficient PBDB-T:PZT-Based All-Polymer Solar Cell: Role of Band Alignment. Polymers 2023, 15, 869. [Google Scholar] [CrossRef]

- Sen, R.; Yadav, M. An Investigation on Organic and Inorganic Materials for Hole Transport Layer in Lead-Free Third-Generation Solar Cell. J. Opt. 2023, 52, 672–682. [Google Scholar] [CrossRef]

- Abdelaziz, W.; Zekry, A.; Shaker, A.; Abouelatta, M. Numerical Study of Organic Graded Bulk Heterojunction Solar Cell Using SCAPS Simulation. Sol. Energy 2020, 211, 375–382. [Google Scholar] [CrossRef]

- Nithya, K.S.; Sudheer, K.S. Device Modelling and Optimization Studies on Novel ITIC-OE Based Non-Fullerene Organic Solar Cell with Diverse Hole and Electron Transport Layers. Opt. Mater. 2022, 123, 111912. [Google Scholar] [CrossRef]

- Tariq Jan, S.; Noman, M. Influence of Layer Thickness, Defect Density, Doping Concentration, Interface Defects, Work Function, Working Temperature and Reflecting Coating on Lead-Free Perovskite Solar Cell. Sol. Energy 2022, 237, 29–43. [Google Scholar] [CrossRef]

| Parameters | HTL [18,19] | ETL [20] | Active Layer [16,21] |

|---|---|---|---|

| Thickness, d (nm) | 40 | 50 | 70 |

| Acceptor density, NA (1/cm3) | 1 × 1017 | - | 0 |

| Donor density, ND (1/cm3) | - | 2 × 1021 | 0 |

| Band gap, Eg (eV) | 2.96 | 2.98 | 1.2 |

| Electron mobility, μn (cm2/Vs) | 1 × 10−4 | 2 × 10−6 | 1.2 × 10−5 |

| Hole mobility, μp (cm2/Vs) | 4 × 10−3 | 1 × 10−3 | 3.5 × 10−4 |

| Dielectric permittivity, ε | 9 | 5 | 6.1 |

| Electron affinity, χ (eV) | 2.3 | 4.11 | 4.030 |

| Defect density, Nt (1/cm3) | 1 × 1014 | 1 × 1014 | 1 × 1013 |

| Nt (1/cm3) | 1010 | 1011 | 1012 | 1013 |

| Ln (nm) | 560 | 180 | 56 | 18 |

| τn (µs) | 10,000 | 1000 | 100 | 10 |

| Parameter | Value |

|---|---|

| Thickness of active layer, nm | 70 |

| Thickness of HTL, nm | 40 |

| Defect density, 1/cm3 | 1 × 1013 |

| Temperature, K | 300 |

| Reflective coating, % | 50 |

| Parameters | Simulation without Reflective Coating | Simulation with Reflective Coating | Experimental [16] |

|---|---|---|---|

| Voc (V) | 1.0140 | 1.0276 | 0.85 |

| FF (%) | 60.42 | 59.50 | 67 |

| Jsc (mA/cm2) | 14.76 | 18.940 | 14.8 |

| PCE (%) | 9.04 | 11.58 | 8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.R.; Jarząbek, B. Parametric Optimization of High-Dielectric Organic Thin-Film Solar Cells. Mater. Proc. 2024, 17, 16. https://doi.org/10.3390/materproc2024017016

Khan MR, Jarząbek B. Parametric Optimization of High-Dielectric Organic Thin-Film Solar Cells. Materials Proceedings. 2024; 17(1):16. https://doi.org/10.3390/materproc2024017016

Chicago/Turabian StyleKhan, Muhammad Raheel, and Bożena Jarząbek. 2024. "Parametric Optimization of High-Dielectric Organic Thin-Film Solar Cells" Materials Proceedings 17, no. 1: 16. https://doi.org/10.3390/materproc2024017016

APA StyleKhan, M. R., & Jarząbek, B. (2024). Parametric Optimization of High-Dielectric Organic Thin-Film Solar Cells. Materials Proceedings, 17(1), 16. https://doi.org/10.3390/materproc2024017016