Effect of By-Pass Filter Dust on Durability of Self-Compacting Concrete †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.3. Testing

3. Results and Discussion

4. Conclusions

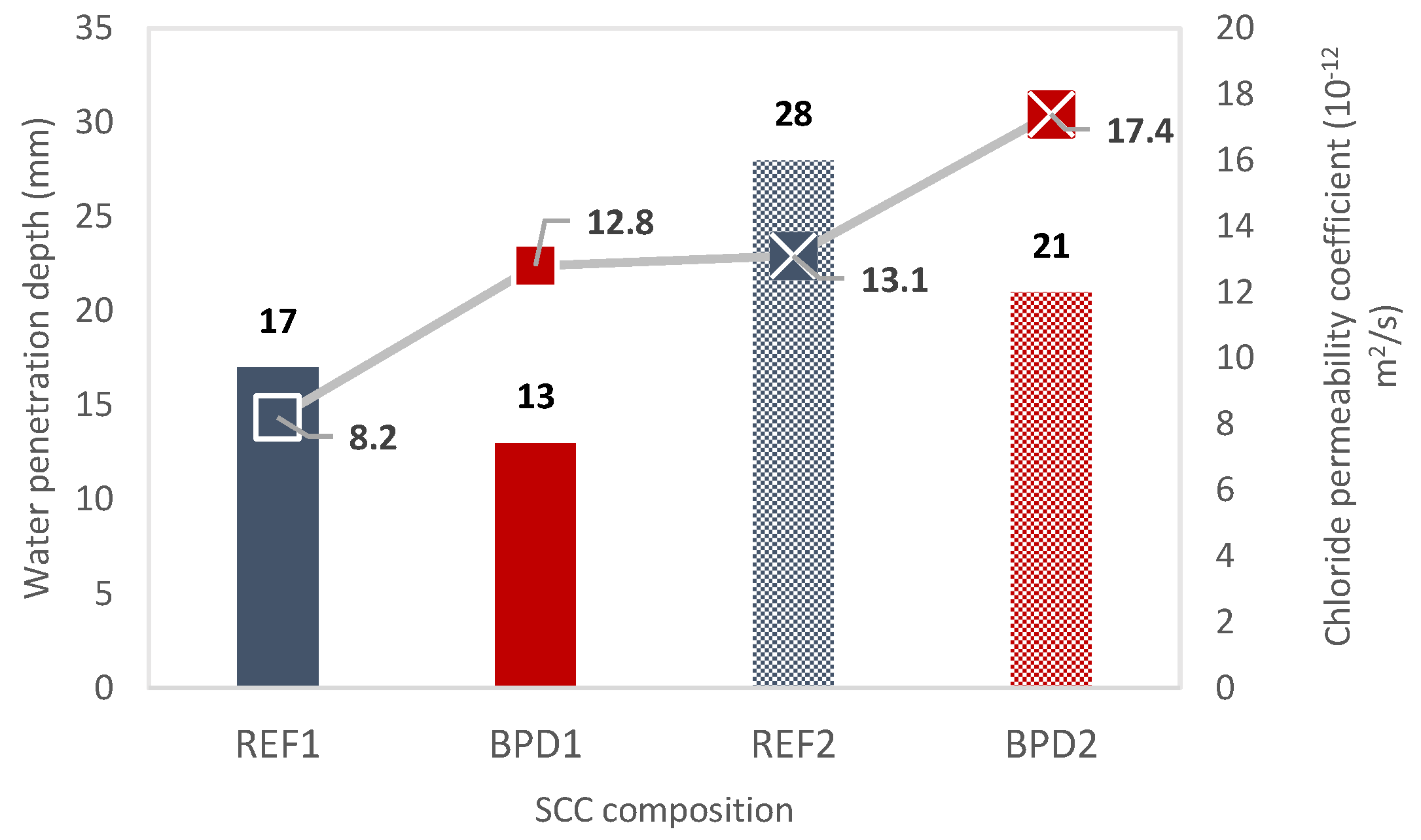

- ✓ BPD incorporation led to SCC with toned down water penetration depth as a consequence of the denser microstructure provided by the pozzolanic reaction of BPD.

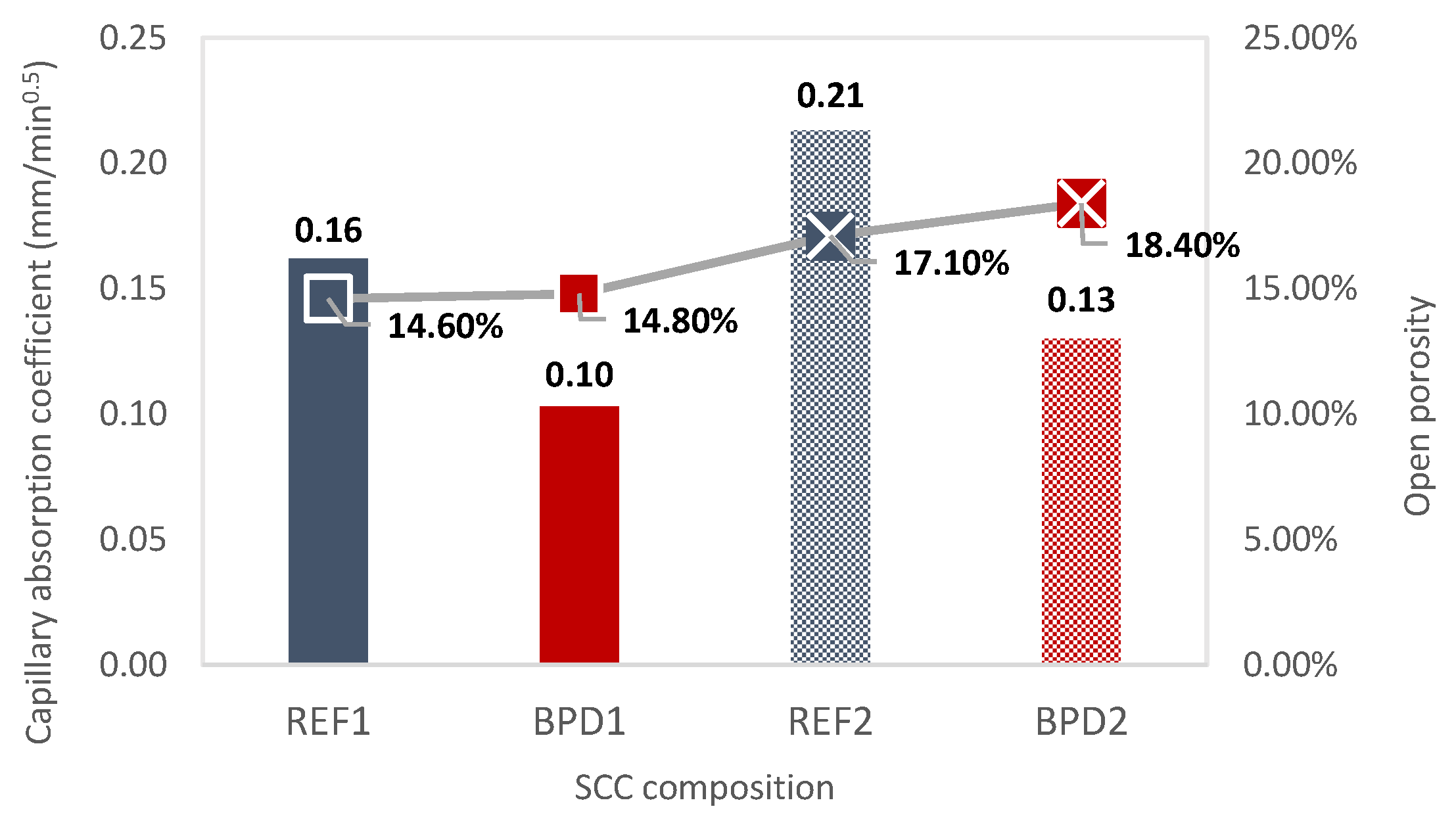

- ✓ The pozzolanic reactivity of BPD also led to SCC compositions with an enhanced capillary absorption coefficient. Concurrently, the open porosity was not notably affected by BPD’s existence.

- ✓ The chloride diffusion coefficient was adversely affected by BPD incorporation, which could be partly attributed to its higher Cl− content compared to MP.

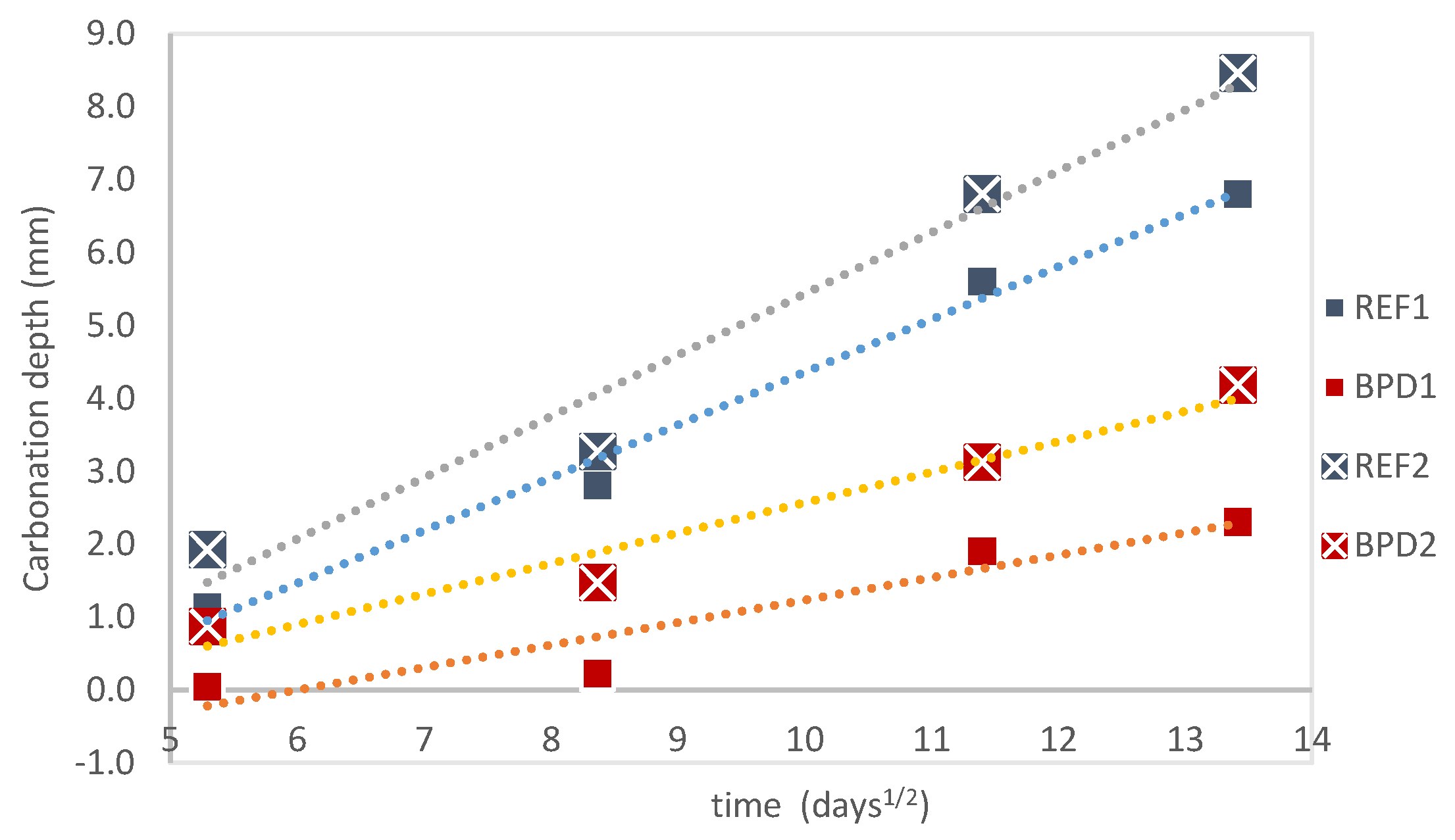

- ✓ The carbonation resistance values of compositions with BPD were significantly upgraded on account of the decreased gas permeability due to high pozzolanicity of BPD.

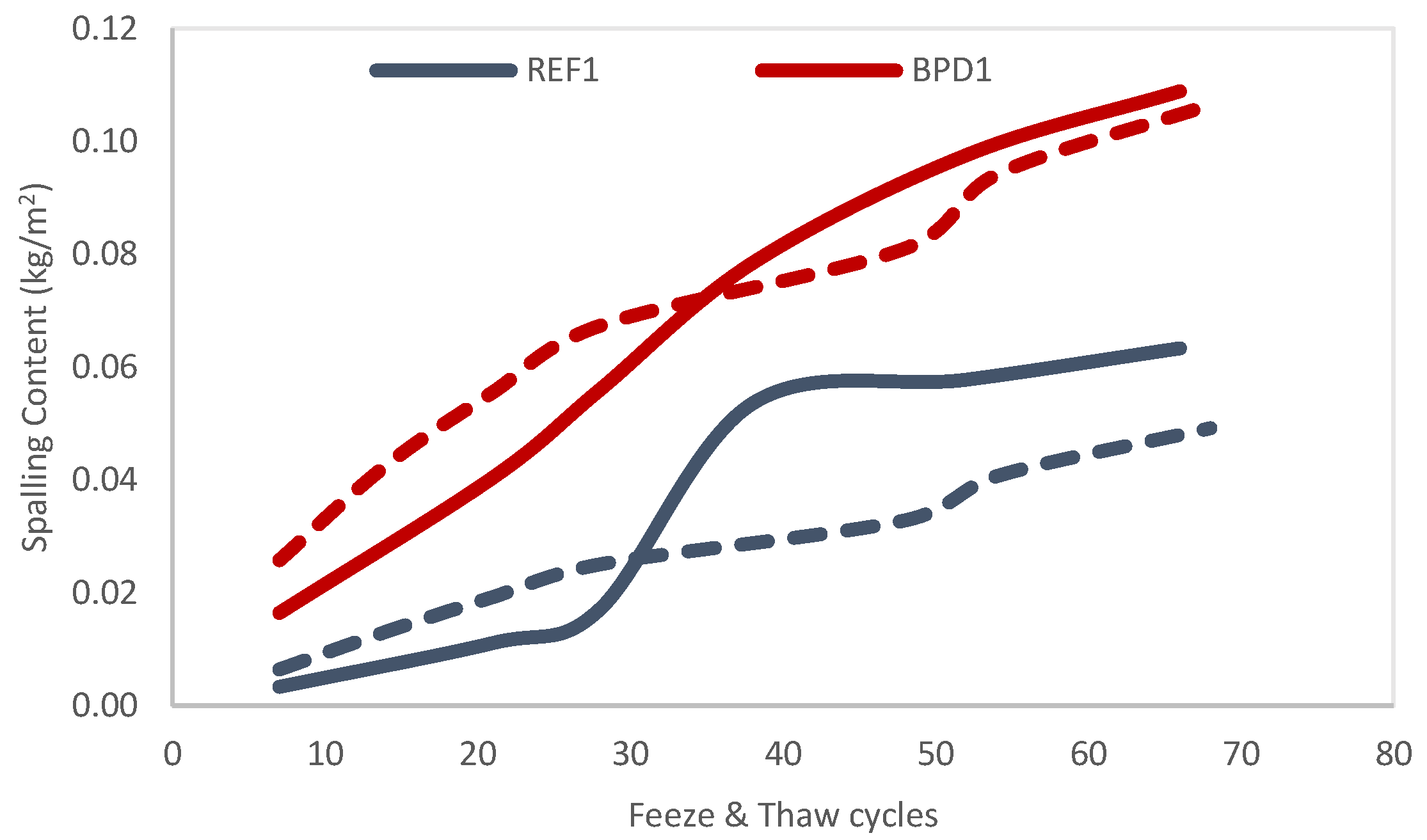

- ✓ The denser microstructure of the cement paste of SCC containing BPD leads to decreased freeze and thaw resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okamura, H.; Ouchi, M. Sel-Compacting Concrete. J. Adv. Concr. Technol. 2003, 1, 5–15. [Google Scholar] [CrossRef]

- The European Project Group. The European Guidelines for Self-Compacting Concrete; The European Project Group: San Polo d’Enza, Italy, 2005; p. 63. [Google Scholar]

- Khayat, K.; De Schutter, G. State-of-the-Art Report on the Mechanical Properties of Self-Compacting Concrete (SCC); Springer: Berlin/Heidelberg, Germany, 2014; Available online: https://biblio.ugent.be/publication/4343086 (accessed on 1 September 2021).

- Jawahar, J.G.; Sashidhar, C.; Reddy, I.V.R.; Peter, J.A. Optimization of superplasticiser and viscosity modifying agent in self compacting mortar. Asian J. Civ. Eng. 2013, 14, 71–86. [Google Scholar]

- Leemann, A.; Winnefeld, F. The effect of viscosity modifying agents on mortar and concrete. Cem. Concr. Compos. 2007, 29, 341–349. [Google Scholar] [CrossRef]

- Miranda, A.; Souza, D.; De Carvalho, F.; Ferreira, C.; Santos, R.; Gonçalves, L.; Andr, R. On the strategies to improve the eco-efficiency of self-compacting concrete using industrial waste: An analytical review. Constr. Build. Mater. 2022, 347, 128634. [Google Scholar] [CrossRef]

- Meko, B.; Ighalo, J.O.; Ofuyatan, O.M. Enhancement of self-compactability of fresh self-compacting concrete: A review. Clean. Mater. 2021, 1, 100019. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N.; Shi, Z.; Jia, H. A review on effects of limestone powder on the properties of concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R.; Belarbi, R. Sustainable and Greener Self-Compacting Concrete incorporating Industrial By-Products: A Review. J. Clean. Prod. 2021, 284, 124803. [Google Scholar] [CrossRef]

- Santos, S.; da Silva, P.R.; de Brito, J. Self-compacting concrete with recycled aggregates—A literature review. J. Build. Eng. 2019, 22, 349–371. [Google Scholar] [CrossRef]

- Ashteyat, A.M.; Haddad, R.H.; Obaidat, Y.T. Case study on production of self compacting concrete using white cement by pass dust. Case Stud. Constr. Mater. 2018, 9, e00190. [Google Scholar] [CrossRef]

- Coleman, N.J.; Trice, C.J.; Nicholson, J.W. 11 Å tobermorite from cement bypass dust and waste container glass: A feasibility study. Int. J. Miner. Process. 2009, 93, 73–78. [Google Scholar] [CrossRef]

- Singh, N.B.; Bhattacharjee, K.N.; Shukla, A.K. Effect of alkali bypass dust on the hydration of granulated blast furnace slag blended cement. Cem. Concr. Res. 1995, 25, 883–892. [Google Scholar] [CrossRef]

- Abdelgader, H.S.; Amran, M.; Kurpinska, M.; Mosaberpanah, M.A.; Murali, G.; Fediuk, R. Cement kiln dust. In Sustainable Concrete Made with Ashes Dust from Different Sources, Materials, Properties and Applications; Woodhead Publishing: Sawston, UK, 2021; pp. 451–479. [Google Scholar] [CrossRef]

- Kounadis, A.; Badogiannis, E.G.; Retsa, N.; Angelopoulos, P.M.; Marinos, I. Hydration heat, rheology and strength of self-compacting sustainable mortars containing alternative filler materials. J. Mater. Civ. Eng. 2022, 34, 1–10. [Google Scholar] [CrossRef]

- Uysal, M.; Yilmaz, K.; Ipek, M. The effect of mineral admixtures on mechanical properties, chloride ion permeability and impermeability of self-compacting concrete. Constr. Build. Mater. 2012, 27, 263–270. [Google Scholar] [CrossRef]

- Pineaud, A.; Pimienta, P.; Rémond, S.; Carré, H. Mechanical properties of high performance self-compacting concretes at room and high temperature. Constr. Build. Mater. 2016, 112, 747–755. [Google Scholar] [CrossRef]

- Kounadis, A.; Badogiannis, E.; Angelopoulos, P.M.; Petrakis, D.; Tsiaras, V.-O. Rheology, Mechanical Properties and Durability of Self-Compacting Concrete Using Sustainable Expanded Perlite Microspheres; Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Dirk, S., Eds.; Springer: Cham, Switzerland, 2023; pp. 1–12. [Google Scholar] [CrossRef]

| Property or Characteristic | Cement | MP | BPD | LS (0/4) | LS (4/8) | LS (8/16) |

|---|---|---|---|---|---|---|

| Specific Gravity | 3.15 | 2.70 | 2.80 | 2.69 | 2.71 | 2.71 |

| Specific Surface Area (cm2/g) | 3470 | 12,700 | 5000 | - | - | - |

| d10 (μm) | 4.74 | 1.44 | 12.95 | <63 | 1900 | 5790 |

| d50 (μm) | 19.82 | 4.88 | 50.72 | 890 | 4310 | 7940 |

| d90 (μm) | 57.41 | 12.27 | 115.63 | 3150 | 6400 | 10,800 |

| Water | Cement | MP | BPD | LS (0/4) | LS (4/8) | LS (8/16) | SP/cement | w/c | w/p | |

|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (kg/m3) | (%) | |||

| REF1 | 180 | 300 | 200 | 0 | 900 | 560 | 240 | 1.7 | 0.60 | 0.36 |

| BPD1 | 180 | 300 | 100 | 100 | 900 | 560 | 240 | 3.1 | 0.60 | 0.36 |

| REF2 | 198 | 300 | 250 | 0 | 900 | 525 | 225 | 1.5 | 0.66 | 0.36 |

| BPD2 | 198 | 300 | 100 | 150 | 900 | 525 | 225 | 2.7 | 0.66 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kounadis, A.; Tsivolas, K.; Badogiannis, E. Effect of By-Pass Filter Dust on Durability of Self-Compacting Concrete. Mater. Proc. 2023, 15, 26. https://doi.org/10.3390/materproc2023015026

Kounadis A, Tsivolas K, Badogiannis E. Effect of By-Pass Filter Dust on Durability of Self-Compacting Concrete. Materials Proceedings. 2023; 15(1):26. https://doi.org/10.3390/materproc2023015026

Chicago/Turabian StyleKounadis, Andreas, Konstantinos Tsivolas, and Efstratios Badogiannis. 2023. "Effect of By-Pass Filter Dust on Durability of Self-Compacting Concrete" Materials Proceedings 15, no. 1: 26. https://doi.org/10.3390/materproc2023015026

APA StyleKounadis, A., Tsivolas, K., & Badogiannis, E. (2023). Effect of By-Pass Filter Dust on Durability of Self-Compacting Concrete. Materials Proceedings, 15(1), 26. https://doi.org/10.3390/materproc2023015026