Abstract

Petroleum-derived polymers, such as polyethylene and polypropylene, are commonly used in food packing industries knowing the fact that these polymers cause serious threats to the ecosystem. Therefore, the development of low-cost, environmentally friendly, and biodegradable polymers to address this issue is an urgent need of the hour. Bacterial nanocellulose (BNC), with its extraordinary and differentiated properties, is gaining special attention in the food packaging industry. To reduce the cost, several low-cost substrates are utilized for the production of BNC. Therefore, the present study is focused on the production of low-cost BNC and its subsequent functionalization for smart packaging applications.

1. Introduction

The use of smart packaging systems composed of biodegradable polymeric materials has gained research attention recently due to their various unique properties in comparison to petro-chemical-based plastics [1,2]. Further, the widespread use of petroleum-derived plastics in packaging and their disposal have become a major concern due to their negative impact on the environment. In view of this, the design and fabrication of various biodegradable packaging materials from natural and biological origins have attracted attention from several researchers in recent years [3,4]. The basic functions of smart packaging are to maintain food quality and safety, prolong the shelf life, and inform the consumer about the quality of food using real-time monitoring techniques. Real-time monitoring can be accomplished using biosensors, time temperature indicators, or gas indicators, which sense, detect, or monitor internal or external change in the product zone [5]. The indicator is most useful in frozen foods as the maintenance of food quality and safety is an important parameter during storage and transportation. The cost of the biopolymer is an important aspect that needs to be assessed for the successful commercialization of this process.

Among various natural polymeric materials, cellulose obtained from a bacterial origin retains several extraordinary and differentiated properties and can be an ideal material for food packaging [6]. Among several bacterial species (Achromobacter, Alcaligenes, Aerobacter, Agrobacterium, Azotobacter, Pseudomonas, and Rhizobium), Komagataeibacter is known to be the industrial-important strain for the production of cellulose while utilizing several carbon/nitrogen sources [7,8]. However, the cost of this substrate, which accounts for 60–70% of the total production cost, is one of the major hindrances to the successful commercialization of the process [9]. In addition to the production cost, low BC yield and weak mechanical properties are the other parameters that hinders its further application in many sectors.

In view of the above limitations, the present review focused on the production of low-cost bacterial nanocellulose for smart packaging applications. The use of various low-cost substrates for the production of bacterial cellulose, the microorganisms used, and the process conditions are discussed in detail. In addition, the incorporation of nanomaterials and colorimetric indicators in the cellulose matrix for smart/intelligent packaging applications are highlighted.

2. Low-Cost Substrates for Production of Bacterial Cellulose

The conventional medium used for the production of bacterial cellulose is expensive and contains defined chemicals, such as glucose, yeast extract, peptone, ethanol, etc. [10]. The most common medium used for the production of bacterial cellulose is HS (Hestrin and Schramm) medium, which is composed of glucose, yeast extract, peptone, citric acid, and disodium phosphate [11]. The use of pure chemicals in defined medium increases the production cost of the process while limiting its large-scale production and industrial applicability. Therefore, finding a new effective and low-cost medium that can promote high yield and reduce the production cost is essential. In view of this, several low-cost medium/waste substrates are explored for the production of bacterial cellulose, which includes agricultural waste, crude glycerol, wastewater, food waste, fermentation wastewater, fruit juices, etc. A summary of the available literature on the production of bacterial cellulose from different waste/low-cost substrates is given in Table 1. The utilization of these waste substrates also reduces the environmental hazards associated upon their disposal to the environment. BC is synthesized extracellularly by both wild and mutant bacteria, such as Acetobacter, Gluconacetobacter, Azobacter, Pseudomonas, etc., while Gluconacetobacter hansenii, Gluconacetobacter xylinum, and Gluconacetobacter pasteurianus are the most effective and widely used strains for the production of BC when utilizing diverse substrates.

Table 1.

Various low-cost/waste substrates used for the production of bacterial cellulose.

3. Incorporation of Nanomaterials

The incorporation of nanomaterials into the BC matrix improved its properties for several applications. These modifications of BC can further improve or add additional features to the matrix, such as antimicrobial activity, catalytic activity, electromagnetic property, antioxidant activity, etc., and can be achieved by modifying the surface of BC. A detailed discussion on various types of surface modification was given in a recent review by Aziz et al. [12]. In this process, the BC matrix acts as the scaffold to support the reinforcement materials, while the reinforcement materials improve the biological and physico-chemical properties of the composite matrix. A wide range of reinforcement materials, including natural and synthetic polymers, nanoparticles, and inorganic nanomaterials, are explored for the synthesis of BC composites. Among these nanoparticles, metal nanoparticles (Fe, Ag, Au, Ni, Pd, and Pt), metal oxide nanoparticles (MgO, CuO, FeO, ZnO, etc.), and carbonaceous materials (carbon nanotubes and graphene) are successfully used during this process. The incorporation of these nanoparticles improves the mechanical, rheological, moisture uptake properties and antimicrobial properties of the BC composite. Recent studies have reported the use of silver, zinc oxide, and titanium oxide NPs in the development of antibacterial nanopackaging films. However, the major drawback of this process is the migration of these nanoparticles from the packaging materials to the food samples, causing carcinogenicity [13,14].

4. Intelligent Packaging

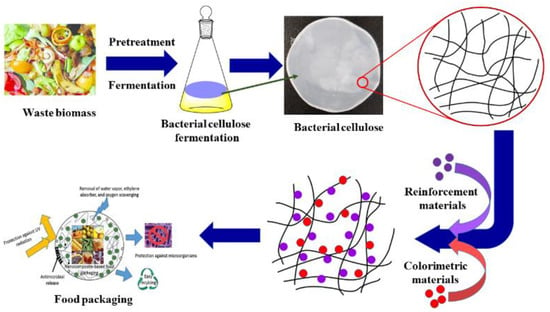

In addition to the development of biobased polymers for packaging, modern day packaging materials also inform the real-time quality of food to the consumer and its suitability for consumption. These intelligent/smart packaging systems monitor the freshness, microbial growth, and any other chemical changes of the product by measuring the change in pH, temperature, humidity, production of gases, such as ammonia, ethylene, carbon dioxide, hydrogen sulfide, and volatile compounds, and pathogens and their metabolites [15,16]. The use of synthetic indicators in food packaging applications is preferred less due their toxicity, carcinogenic property, and ability to interfere with biological systems. Hence, colorimetric indicators from natural sources are promoted. Among the different sensors used in smart packaging applications, natural indicators are most preferred due to their biodegradability, easy preparation methods, less toxicity, ecofriendly nature, low cost, etc. [17]. These natural halochromic materials are incorporated into the cellulose nanocomposite matrix and change their color with a change in the physiological condition of the packaged food. A list of natural colorants and their sources is given in Table 2. A schematic representation of the process is shown in Figure 1.

Table 2.

Summary of natural colorants and their sources. Adopted and revised with permission from Alizadeh-Sani et al. [17]. Copyright 2020, Elsevier.

Figure 1.

A schematic representation of development of cellulose nanocomposite from waste/low-cost substrates and its subsequent application in intelligent packaging.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest.

References

- Youssef, A.M.; El–Sayed, S.M.; El–Sayed, H.S.; Salama, H.H.; Mohamed, H.F.; Abd ElSalam, M.A. Novel bionanocomposite materials used for packaging skimmed milk acid coagulated cheese (Karish). Int. J. Biol. Macromol. 2018, 115, 1002–1011. [Google Scholar] [CrossRef] [PubMed]

- Youssef, A.M.; Assem, F.; Essam, M.; Elaaser, M.; Ibrahim, O.; Mahmoud, M.; Abd ElSalam, M. Development of a novel bionanocomposite material and its use in packaging of Ras cheese. Food Chem. 2019, 270, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh–Sani, M.; Hamishehkar, H.; Khezerlou, A.; Azizi–Lalabadi, M.; Azadi, Y.; Nattagh–Eshtivani, E.; Fasihi, M.; Ghavami, A.; Aynehchi, A.; Ehsani, A. Bioemulsifiers derived from microorganisms: Applications in the drug and food industry. Adv. Pharm. Bull. 2018, 8, 191. [Google Scholar] [CrossRef] [PubMed]

- Khezrian, A.; Shahbazi, Y. Application of nanocompostie chitosan and carboxymethyl cellulose films containing natural preservative compounds in minced camel’s meat. Int. J. Biol. Macromol. 2018, 106, 1146–1158. [Google Scholar] [CrossRef] [PubMed]

- De Jong, A.R.; Boumans, H.; Slaghek, T.; Van Veen, J.; Rijk, R.; Van Zandvoort, M. Active and intelligent packaging for food: Is it the future? Food Addit. Contam. A 2005, 22, 975–979. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zhu, C.; Yang, J.; Nie, Y.; Chen, C.; Sun, D. Recent advances in bacterial cellulose. Cellulose 2014, 21, 1–30. [Google Scholar] [CrossRef]

- Lin, D.; Liu, Z.; Shen, R.; Chen, S.; Yang, X. Bacterial cellulose in food industry: Current research and future prospects. Int. J. Biol. Macromol. 2020, 158, 1007–1019. [Google Scholar] [CrossRef] [PubMed]

- Szymanska-Chargot, M.; Chylinska, M.; Cybulska, J.; Kozioł, A.; Pieczywek, P.M.; Zdunek, A. Simultaneous influence of pectin and xyloglucan on structure and mechanical properties of bacterial cellulose composites. Carbohydr. Polym. 2017, 174, 970–979. [Google Scholar] [CrossRef] [PubMed]

- Jedrzejczak-Krzepkowska, M.; Kubiak, K.; Ludwicka, K.; Bielecki, S. Bacterial nanocellulose synthesis, recent findings. In Bacterial Nanocellulose: From Biotechnology to Bio-Economy; Gama, M., Dourado, F., Bielecki, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 19–46. ISBN 9780444634665. [Google Scholar]

- Ayed, L.; Abid, S.B.; Hamdi, M. Development of a beverage from red grape juice fermented with the Kombucha consortium. Ann. Microbiol. 2017, 67, 111–121. [Google Scholar] [CrossRef]

- Hestrin, S.; Schramm, M. Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem. J. 1954, 58, 345. [Google Scholar] [CrossRef] [PubMed]

- Aziz, T.; Farid, A.; Haq, F.; Kiran, M.; Ullah, A.; Zhang, K.; Li, C.; Ghazanfar, S.; Sun, H.; Ullah, R.; et al. A Review on the Modification of Cellulose and Its Applications. Polymers 2022, 14, 3206. [Google Scholar] [CrossRef] [PubMed]

- Youssef, A.M.; Youssef, M.; Ayad, D.M.; Sarhan, A.A. A novel approach to prepare Poly (vinyl acetate)/Ag nanocomposite for effective antimicrobial coating applications. Polym. Plast. Technol. Eng. 2015, 54, 1735–1742. [Google Scholar] [CrossRef]

- Takeuchi, M.T.; Kojima, M.; Luetzow, M. State of the art on the initiatives and activities relevant to risk assessment and risk management of nanotechnologies in the food and agriculture sectors. Food Res. Int. 2014, 64, 976–981. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and intelligent packaging in meat industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Huang, X.-w.; Zou, X.-b.; Shi, J.-y.; Li, Z.-h.; Zhao, J.-w. Colorimetric sensor arrays based on chemo-responsive dyes for food odor visualization. Trends Food Sci. Technol. 2018, 81, 90–107. [Google Scholar]

- Alizadeh-Sani, M.; Mohammadian, E.; Rhim, J.W.; Jafari, S.M. pH-sensitive (halochromic) smart packaging films based on natural food colorants for the monitoring of food quality and safety. Trends Food Sci. Technol. 2020, 105, 93–144. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).