Abstract

This work presents a new approach to introducing a new product in a production workshop, taking into account the products already introduced in the production lines. The proposal is based on a study of the skill requirements of the workforce and the mechanical modifications of the product, with a multi-criteria decision-making process using fuzzy logic. This approach makes it possible to select the most suitable production line, minimise the number of machine changes, and reduce the time required to adapt the workforce, while ensuring the shortest possible order processing time.

1. Introduction

In recent years, production volumes have decreased, while the number of collections and styles has increased. To remain competitive, apparel brands are striving to meet consumer demand within short timeframes. In some apparel manufacturing companies in Tunisia, a production line can process several products per day, particularly for workwear or technical apparel.

In this constantly evolving environment, buyers are looking for agile and proactive manufacturers who can produce quickly and adapt to unforeseen circumstances. On the other hand, manufacturers need to make optimal decisions while ensuring that customer requirements are met. To achieve this, production managers rely on a set of rules and instructions.

One of the main sources of lost time in the manufacturing process is the integration of a new model into the production line. Previous studies have shown that changeover time can exceed 30 min per workstation, with 45% of this time spent waiting for a mechanic.

Planning managers must therefore determine the most suitable production line for integrating a new product. This choice is influenced by a number of factors, including the operational sequence of current and future models and the versatility of the workforce. Assigning a product to a specific line has a direct impact on order throughput time (based on workstation changeover rates) and productivity (which depends on worker skills).

This study proposes the use of fuzzy logic as a decision-making tool to optimise the allocation of products to production lines, taking into account these criteria.

Nowadays, clothing is one of the basic human needs, and its production is very intensive [1]. On the other hand, garment manufacturing companies face unprecedented global competition and unpredictable demand fluctuations [2] and operate in a dynamic environment subject to seasonal changes in collection [3]. Optimisation research focuses on various organisational and managerial aspects through the analysis of different planning approaches [4], the evaluation of business performance and its resources [1], or a general view of the entire value chain. This can be complemented by the elimination of waste using, for example, lean methods. For production process optimisation, single-objective modelling is often used, but multi-criteria and multi-objective analysis have emerged in recent years [3,5]. Regarding production line balancing, it is a complex problem that depends on multiple parameters, such as the company’s resources, mainly human resources, while directly affecting the line’s productivity [6]. Since the transition to Industry 4.0, new terminologies have been used, such as multi-criteria decision-making, responsiveness to rapid changes, business proactivity, etc. [7].

This paper presents an alternative solution to the problem of launching new products (new orders) on assembly lines in the production workshop. Often, production managers select the line that is currently working on a model similar to the one to be produced. Then, when a workstation is changed or a new operation is added, the mechanic adjusts the workstation layout, and the operator is trained for the new task.

Preliminary studies have shown a significant loss of time during production startup due to worker adaptation time, machine setup changes, and mechanic interventions. In this study, we propose a proactive approach that anticipates the expected outcomes for each decision, based on two key criteria: the workstation changeover rate and the worker adaptation rate. A set of rules using fuzzy logic (Sigmoidal model) for criteria inference is proposed to assist managers in making decisions.

2. Research Problem and Resolution Methodology

In the textile and apparel industry, selecting the right production line to launch a new product is a critical decision. In a factory with multiple production lines, each line is assigned to a specific product based on a predefined machine sequence and specific settings. This decision has a direct impact on delivery time and key production indicators such as order throughput time and workstation efficiency.

Currently, this selection is based on a simple visual analysis of the new product compared to those already in production. This study proposes a more rigorous approach by comparing the operational sequence of the new product with that of the current products, while estimating the required model changeover time. It is a scientific and objective methodology, based on available resources, that assesses the impact on transition time.

In the preliminary studies, it was observed that the line changeover time had a significant impact on both line efficiency and throughput time. The analysis led to the identification of the operator adaptation time (Tadapt) to the new operation at the new workstation:

- -

- Operator adaptation to a new operation on a new machine takes about 40% of the operation time; operator adaptation to the same operation on a new machine takes about 30% of the operation time; and operator adaptation to a new operation on the same machine takes about 20% of the operation time.

- -

- Workstation setup time (for the same operation on the same machine) represents approximately 10% of the operating time.

To select the most suitable production line for a new product, the following steps are necessary:

- -

- Identify the assembly sequence of the product, specifying the type of machine and the operations required.

- -

- Select a production line that handles a similar product and has a workforce capable of performing the operations required for the new model.

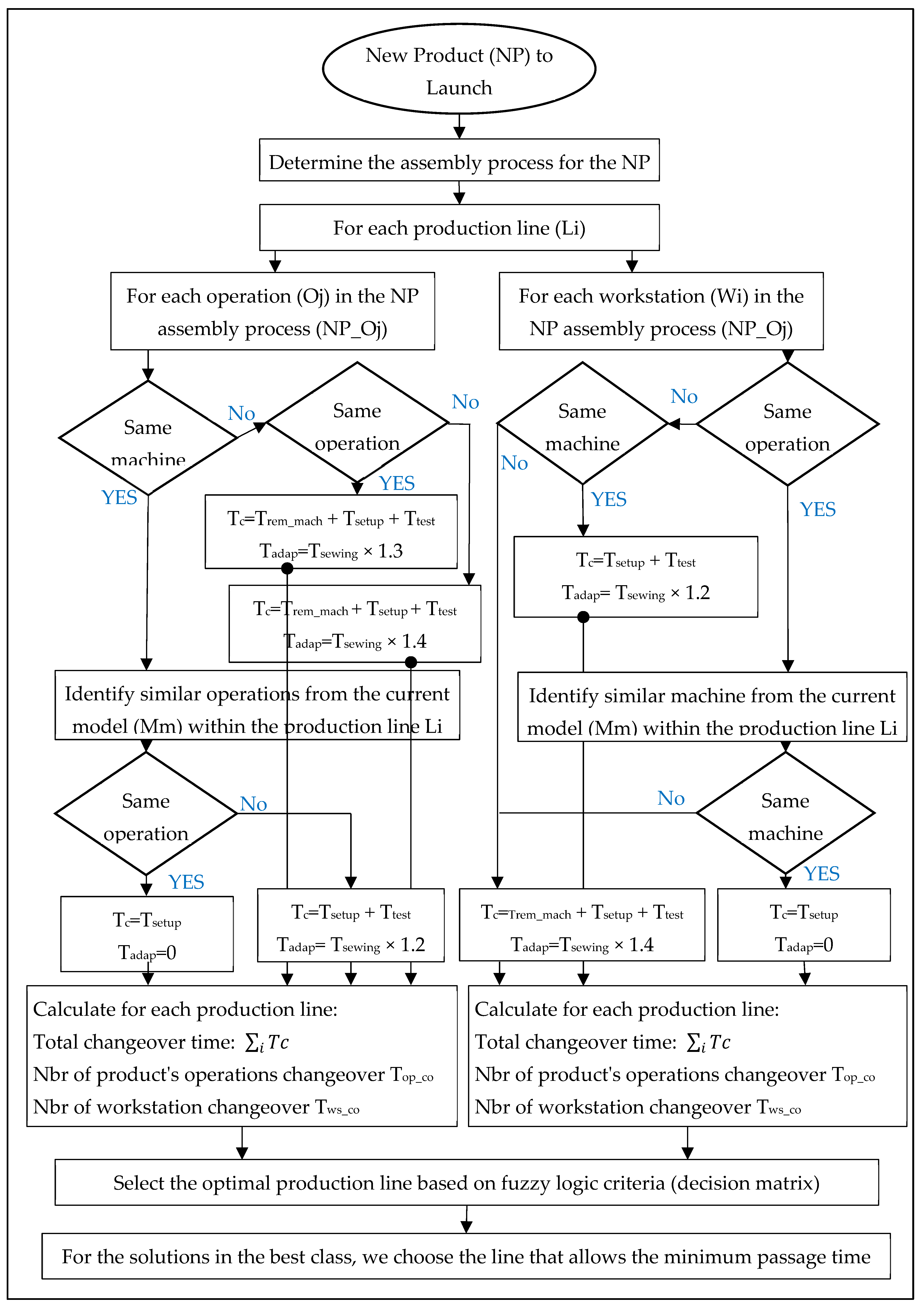

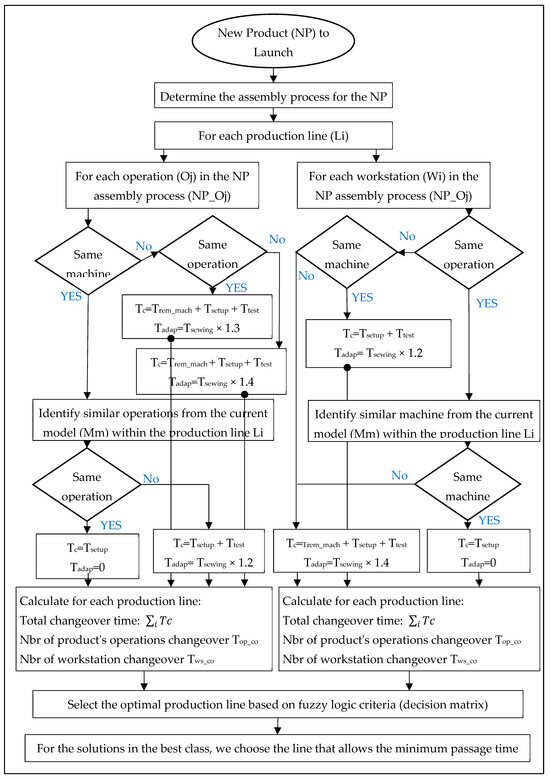

The following flowchart describes the proposed algorithm for implementing a new model.

2.1. Definitions

Through subsequent studies conducted in several garment manufacturing companies, we found that workstation changeover time refers to the time required to move from the last piece of the previous model to the fifth compliant piece of the new model. It can take three forms: machine changeover, setup (or adjustment) time, and testing time.

- ○

- TRem_mach: Removing the machine from the production line and replacing it with another available in the machine storage.

- ○

- Tsetup: Setup time, which includes adjusting the stitch density (number of stitches per centimetre), changing the presser foot, replacing the sewing thread and needle, etc., and minor adjustments made by the mechanic for each new operation.

- ○

- Ttest: Testing time, which involves producing a few trial pieces to assess stitch quality before validation by the line supervisor.

The workstation changeover time may include all three components (in case of machine replacement) or only the setup time (Tsetup) and testing time (Ttest). Often, the selection of the production line for introducing a new product is made by comparing it to existing products in the production workshop. The choice of the line is based on the similarity rate of the products, which is typically assessed visually.

In this work, as presented by the decision-making process in Figure 1, we propose comparing the operational sequence of the new product with those of the existing products in the production line using two approaches:

Figure 1.

Decision flowchart for selecting the production line to implement a new product.

- Approach 1: Based on the comparison of workstations between the new product and the current setup.

- Approach 2: Based on the comparison of the new product’s operations with the ongoing operations.

Each time, we calculate the product change score, which is the average of two values:

- The total number of machine changes: NMach_Chang;

- The total number of operation changes: Nop_Chang.

2.2. Rules and Table of Values

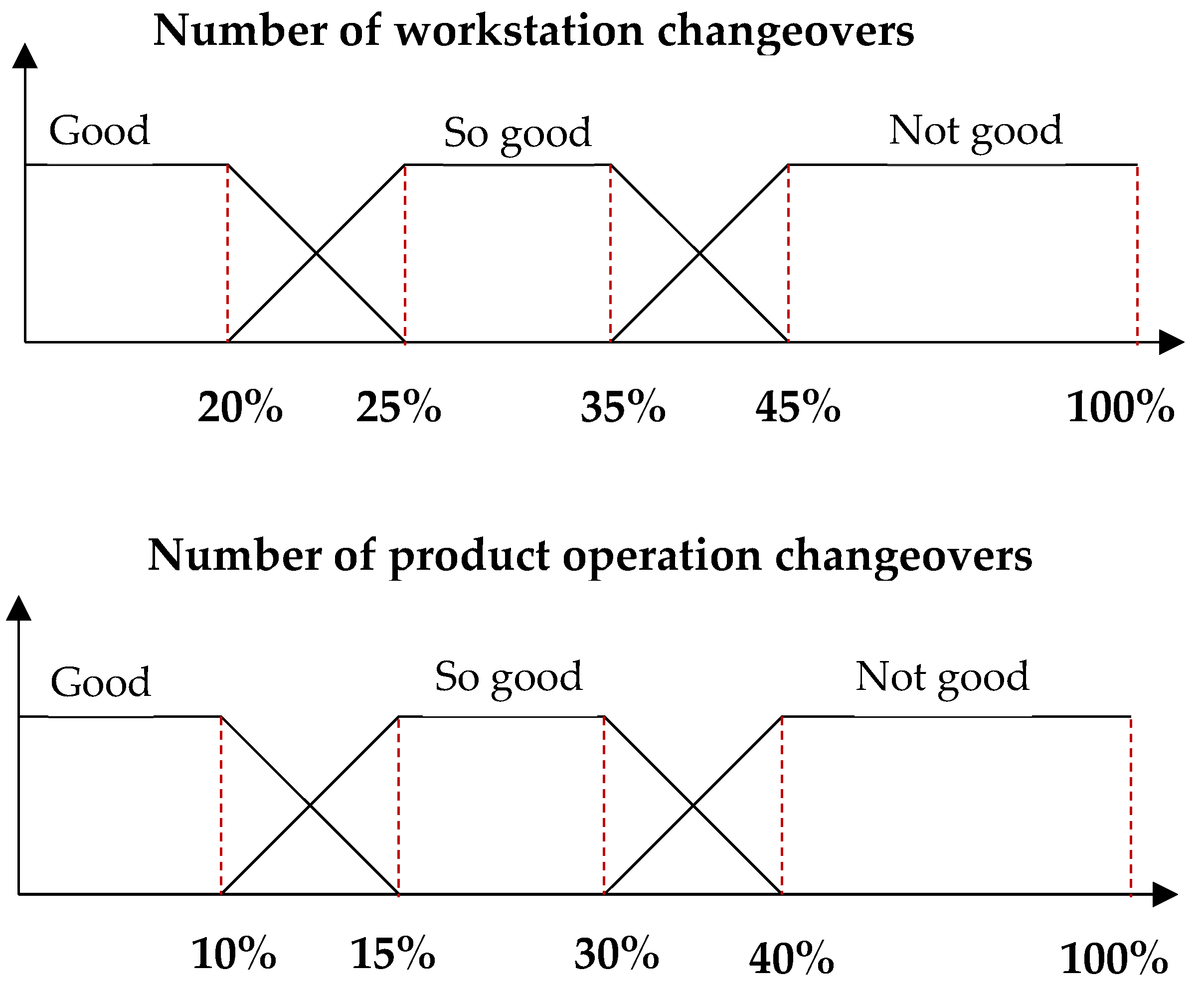

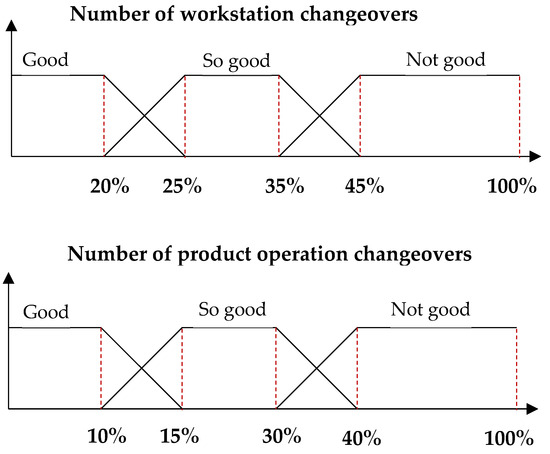

To determine the most suitable production line for launching the new product, we use the decision matrix (Table 1) and fuzzy inference (Figure 2).

Table 1.

Decision matrix.

Figure 2.

Fuzzy inference.

The choice of production line for the new product must ensure a smooth transition of workstations. The production managers propose the following priority rules:

- Minimise the number of workstation changes.

- Maximise the number of operations that are already mastered by the workers on the line.

- The same operators must remain on the production line (no operators from other lines, even if they have mastered the operation).

- If the number of workstations to be changed is high, the number of worker adaptations should be minimised, and vice versa.

All these rules are transformed into a decision matrix.

The contribution of fuzzy logic comes when the calculated values represent borderline conditions. In such cases, the decision tolerates a combination of both conditions, weighted by a coefficient.

To implement the new approach, a case study is proposed on a production workshop consisting of three lines (Table 2), each defined by a specific sequence of machines and manufacturing operations. The aim is to determine the most suitable line for the integration of a new product.

Table 2.

Case study: a production workshop with three production lines and a new product to be scheduled.

The program analyses the operations of the new product by comparing them with the workstations of each production line. At the end of the simulation, it will estimate the total changeover time, the number of workstations that need to be modified, and the number of operations that require worker adaptation. The production line selected for the new product will be the one that meets the best conditions according to the decision matrix.

3. Results and Discussions

The results of the numerical simulation are summarised in the Table 3.

Table 3.

Results of numerical simulation.

The results highlight the importance of the approach chosen and its impact on both the adaptation time and, above all, the rate of mobilisation of the company’s resources. The combination of the two approaches makes it possible to

- -

- Identify the ideal line of work for the introduction of the new product;

- -

- Forecast the number of workstation changes and the number of new operations.

These two criteria enable managers to make the right decisions according to the skills of their mechanics and the versatility of the workforce. The impact will be greater because the vision will cover all the products to be launched in a short period of time.

4. Conclusions

This work presents a new methodology for planning new products in a multi-line production workshop. It is a multi-criteria and proactive logic that takes into account the capacities of the company (the versatility of the workforce and the workload of the mechanics). The result will be in the form of a choice matrix, which will help to make the right decision.

The comparison between the two approaches shows that the performance obtained depends on the initial choice. Choosing a production line composed of machines similar to those already programmed for the new product reduces the machine changeover rate, which represents a significant amount of time. However, this choice is not always feasible, as the skills of the workers must also be taken into account. To make the right decision, this study has shown that both approaches need to be considered simultaneously. Fuzzy logic, based on rules established by industrial managers, allows the combination of both approaches to achieve a better result.

This work will be complemented by the integration of additional rules and selection criteria to better reflect industrial constraints, along with the application of the Gaussian model for fuzzy logic. This is a necessary step towards the automatic implementation of new production orders.

Author Contributions

Conceptualization, B.K.; software, B.K.; validation and formal analysis, A.B.; writing—original draft preparation, B.K. and A.B.; writing—review and editing, M.A. and M.H. All authors have read and agreed to the published version of the manuscript.

Funding

The project receives funding through the 20/PRD-25 program, established under the TUNISO-MOROCCAN cooperation framework.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors express their gratitude to the Ministry of Higher Education and Scientific Research for their financial support with the R&D project (ref. 20/PRD-25) in the frame of the TUNISO-MOROCCAN cooperation programme.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ewnetu, M.; Gzate, Y. Assembly operation productivity improvement for garment production industry through the integration of lean and work-study, a case study on Bahir Dar textile share company in garment, Bahir Dar, Ethiopia. Heliyon 2023, 9, e17917. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.X.; Ngai, E.W.T.; Yang, C.; Liang, X. RFID-based intelligent decision support system architecture for production monitoring and scheduling in a distributed manufacturing environment. Int. J. Prod. Econ. 2015, 159, 16–28. [Google Scholar] [CrossRef]

- Rossi, A.; Tiacci, L.; Simonetti, M. A Mixed Integer Programming model to optimize production planning in the luxury textile industry; 6th International Conference on Industry 4.0 and Smart Manufacturing. Procedia Comput. Sci. 2025, 253, 1175–1184. [Google Scholar] [CrossRef]

- Dinh, T.H.; Nguyen, T.T.T.; Do, T.T.T.; Nguyen, T.V.T.; Nguyen, H.L.; Do, V.T. Selection supplier for Textile and Garment enterprises in Vietnam using association rules. Asian J. Ship. Log. 2024, 40, 206–212. [Google Scholar] [CrossRef]

- Wang, C.N.; Wei, Y.C.; So, P.Y.; Nguyen, V.T.; Phuc, P.N.K. Optimization Model in Manufacturing Scheduling for the Garment Industry. Comput. Mater. Contin. 2022, 71, 5875. [Google Scholar] [CrossRef]

- Teshome, M.M.; Meles, T.Y.; Yang, C.L. Productivity improvement through assembly line balancing by using simulation modeling in case of Abay garment industry Gondar. Heliyon 2024, 10, e23585. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Chua, P.C.; Liu, B.; Moon, S.K.; Lope, M. A hybrid data-driven optimization and decision-making approach for a digital twin environment: Towards customizing production platforms. Int. J. Prod. Econ. 2025, 279, 109447. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).