Optimizing Order Scheduling in Morocco’s Garment Industry for Fast Fashion: A K-Means Clustering-Driven Approach †

Abstract

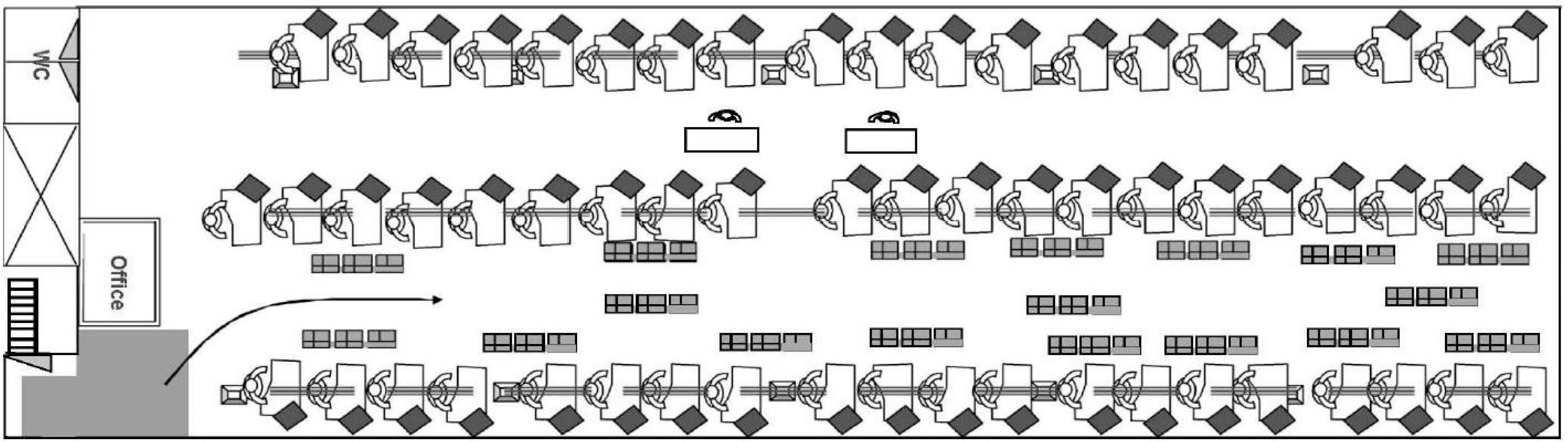

1. Introduction

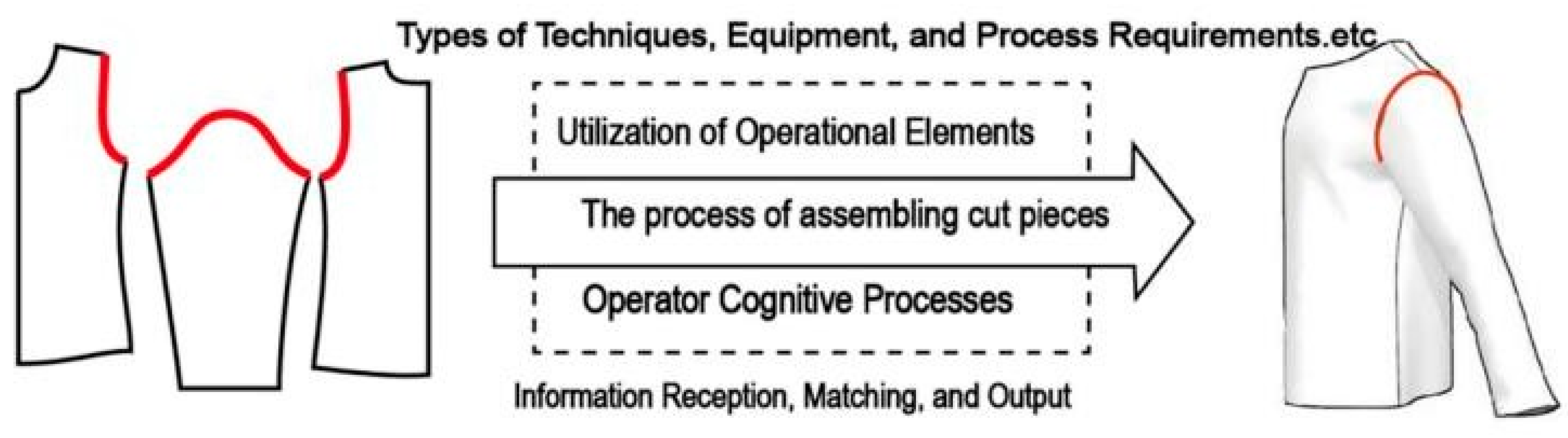

2. Methodology

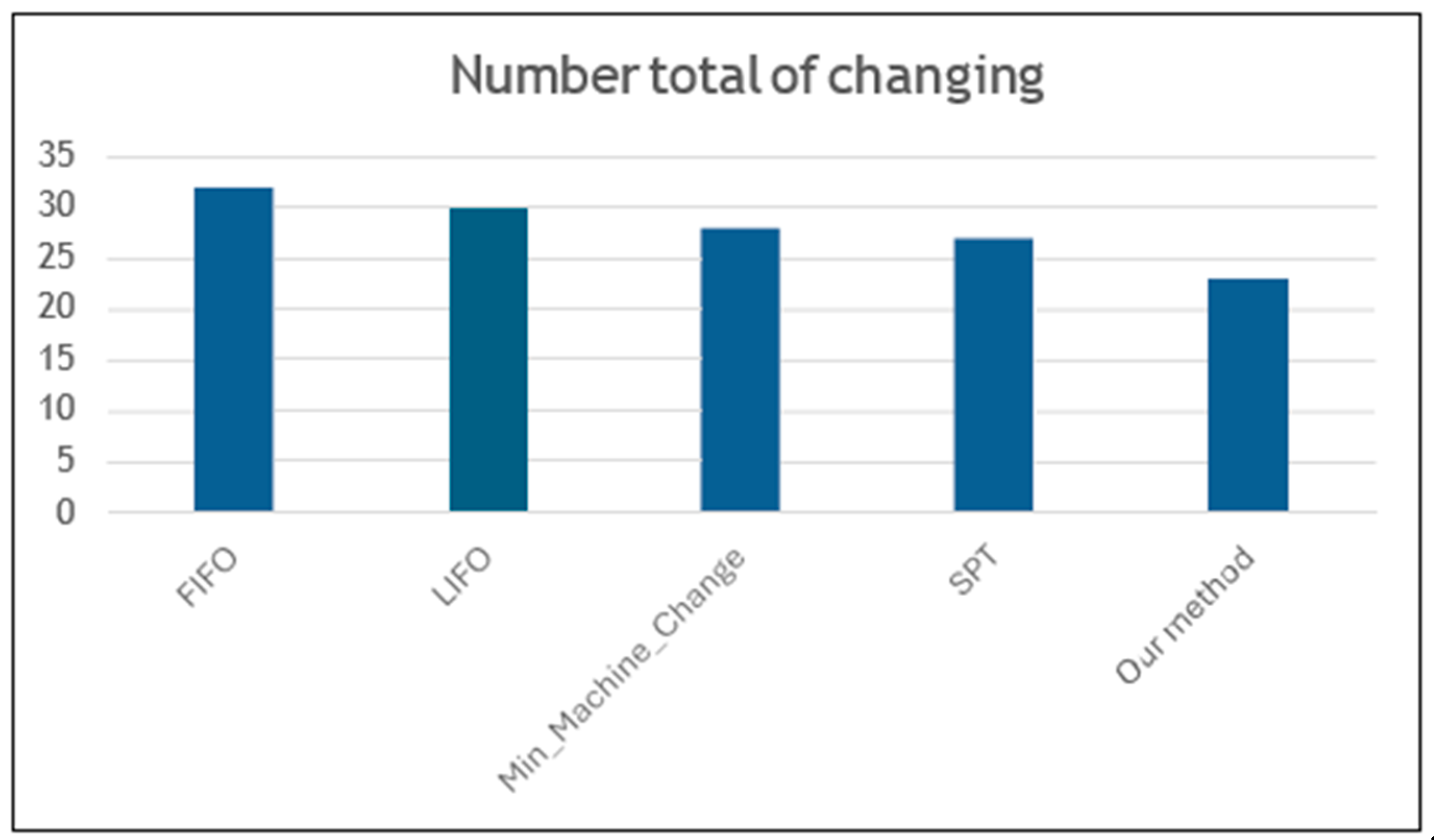

2.1. Subsect Proposed Clustering-Based Approach

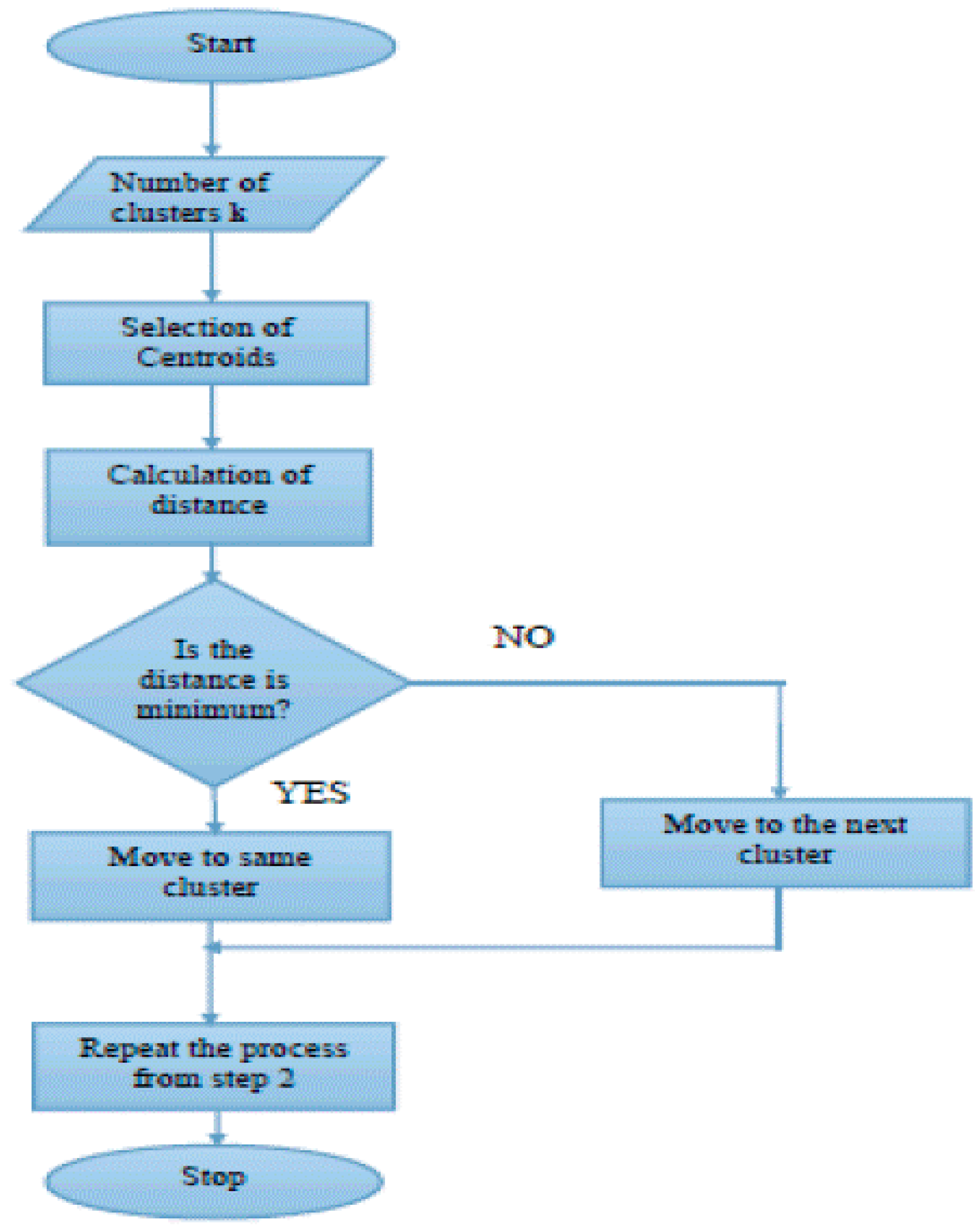

2.2. Clustering Algorithm

2.3. Cataloging of Homogeneous Clusters Using Dynamic K-Means

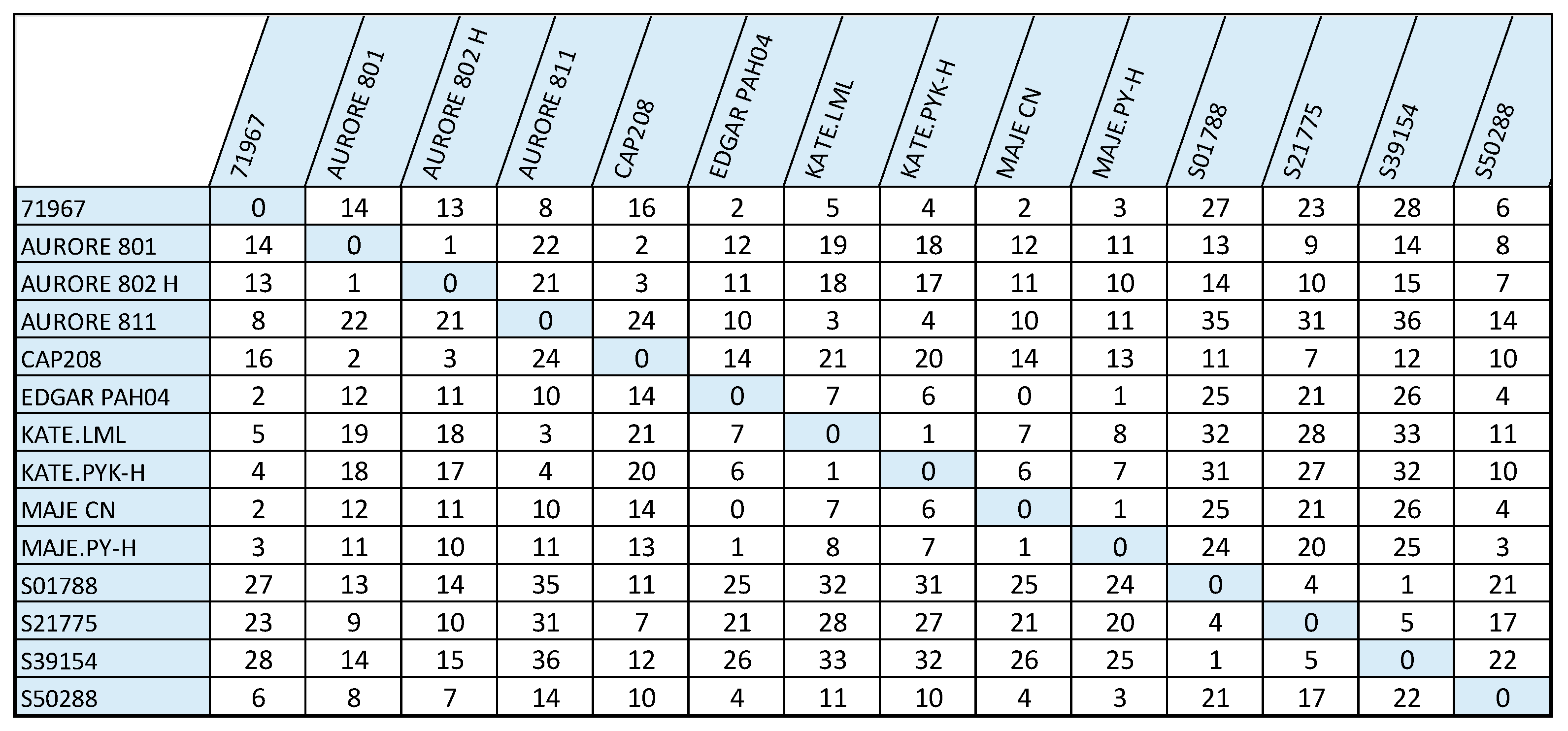

3. Analysis of the Company’s Order Book by Type of Operation and Creation of a Database

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ray, S.; Nayak, L. Marketing Sustainable Fashion: Trends and Future Directions. Sustainability 2023, 15, 6202. [Google Scholar] [CrossRef]

- Aggour, A.; Moussaid, A.; Abou El Hassan, A. Fast fashion in the Moroccan apparel supply chain: A case study. Int. J. Manag. Value Supply Chain. 2016, 7, 17–24. [Google Scholar] [CrossRef]

- Karacapilidis, N.I.; Pappis, C.P. Production planning and control in textile industry: A case study. Comput. Ind. 1996, 30, 127–144. [Google Scholar] [CrossRef]

- Aggour, A.; Moussaid, A.; El Hassan, A.A. Fast fashion assessment tool: A case study of a moroccan apparel supply chain. Int. J Sup. Chain. Mgt 2018, 7, 213–220. [Google Scholar]

- Spahija, S.; Dumishllari, E.; Leti, A.; Dhoska, K. The influence of line balance on efficiency in garment production. J. Integr. Eng. Appl. Sci. 2024, 2, 40–47. [Google Scholar] [CrossRef]

- Marzouk, Y.M.; Ghoniem, A.F. K-means clustering for optimal partitioning and dynamic load balancing of parallel hierarchical N-body simulations. J. Comput. Phys. 2005, 207, 493–528. [Google Scholar] [CrossRef]

- Wong, W.K. Optimisation of apparel manufacturing resource allocation using a generic optimised table-planning model. Int. J. Adv. Manuf. Technol. 2023, 21, 935–944. [Google Scholar] [CrossRef]

- Astanti, R.D.; Ai, T.J. Clustering-based heuristics for aligning master production schedule and delivery schedule. Manag. Syst. Prod. Eng. 2024, 32, 401–408. [Google Scholar] [CrossRef]

- Rahman, S.; Baten, A.; Hoque, M.; Mahmud, M.I. Impact of lean manufacturing on productivity and layout design in sewing section of a garment industry. Int. J. Ind. Manag. 2023, 17, 152–161. [Google Scholar] [CrossRef]

- Cevallos Bravo, M.V. Textile companies and the factors involved in their competitiveness: A bibliographic review. Open J. Bus. Manag. 2022, 10, 1013–1025. [Google Scholar] [CrossRef]

- Barde, P.S.; Jadhao, R.R. Advance manufacturing process for convenient & optimize production. J. Emerg. Technol. Innov. Res. 2019, 6, 393–398. [Google Scholar]

- Kozinski, O.; Kotyrba, M.; Volna, E. Improving the Production Efficiency Based on Algorithmization of the Planning Process. Appl. Syst. Innov. 2023, 6, 77. [Google Scholar] [CrossRef]

- Tsai, W.-H.; Chen, H.-C.; Chang, S.-C.; Chan, K.-C. Revolutionizing Textile Manufacturing: Sustainable and Profitable Production by Integrating Industry 4.0, Activity-Based Costing, and the Theory of Constraints. Processes 2024, 12, 2311. [Google Scholar] [CrossRef]

- Rossi, A. Does Economic Upgrading Lead to Social Upgrading in Global Production Networks? Evidence from Morocco. World Dev. 2013, 46, 223–233. [Google Scholar] [CrossRef]

- Kentli, A.; Dal, V.; Alkaya, A.F. Minimizing Machine Changeover Time in Product Line in an Apparel Industry. TEKSTİL Ve KONFEKSİYON 2013, 23, 159–167. [Google Scholar]

- Choi, H.; Yu, S.; Lee, D.; Noh, S.D.; Ji, S.; Kim, H.; Yoon, H.; Kwon, M.; Han, J. Optimization of the Factory Layout and Production Flow Using Production-Simulation-Based Reinforcement Learning. Machines 2024, 12, 390. [Google Scholar] [CrossRef]

- Ali, S.M.; Haque, M.N.; Sarker, M.R.; Kandasamy, J.; Vlachos, I. Improving Changeover Techniques in Apparel Manufacturing through Single Minute Exchange of Die: Implications for Benchmarking. Benchmarking: Int. J. 2025, 32, 1207–1223. [Google Scholar] [CrossRef]

- Al Naqbi, H.; Bahroun, Z.; Ahmed, V. Enhancing Work Productivity through Generative Artificial Intelligence: A Comprehensive Literature Review. Sustainability 2024, 16, 1166. [Google Scholar] [CrossRef]

| Garment | Operation | Product Family | Equipment | Skill | Standard Allocated Munite |

|---|---|---|---|---|---|

| AUR 802 H | Measure and cut neckline band | PYJ_ | Manual | Manual | 0.4 |

| AUR 802 H | Assemble neckline band | PYJ_ | Sewing machine | Assembly | 0.4 |

| AUR 802 H | Attach front neckline tape | PYJ_ | Sewing machine | Collar assembly | 1.5 |

| AUR 802 H | Notch | PYJ_ | Manual | Manual | 0.2 |

| AUR 802 H | Overlock neckline band | PYJ_ | 3-thread overlocker | Overlocking | 0.6 |

| AUR 802 H | Secure overlock edge | PYJ_ | Sewing machine | Securing | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mouloud, A.; El Belghiti, Y.; Tetouani, S.; Cherkaoui, O.; Soulhi, A. Optimizing Order Scheduling in Morocco’s Garment Industry for Fast Fashion: A K-Means Clustering-Driven Approach. Eng. Proc. 2025, 97, 50. https://doi.org/10.3390/engproc2025097050

Mouloud A, El Belghiti Y, Tetouani S, Cherkaoui O, Soulhi A. Optimizing Order Scheduling in Morocco’s Garment Industry for Fast Fashion: A K-Means Clustering-Driven Approach. Engineering Proceedings. 2025; 97(1):50. https://doi.org/10.3390/engproc2025097050

Chicago/Turabian StyleMouloud, Abdelfattah, Yasmine El Belghiti, Samir Tetouani, Omar Cherkaoui, and Aziz Soulhi. 2025. "Optimizing Order Scheduling in Morocco’s Garment Industry for Fast Fashion: A K-Means Clustering-Driven Approach" Engineering Proceedings 97, no. 1: 50. https://doi.org/10.3390/engproc2025097050

APA StyleMouloud, A., El Belghiti, Y., Tetouani, S., Cherkaoui, O., & Soulhi, A. (2025). Optimizing Order Scheduling in Morocco’s Garment Industry for Fast Fashion: A K-Means Clustering-Driven Approach. Engineering Proceedings, 97(1), 50. https://doi.org/10.3390/engproc2025097050