Abstract

Lean manufacturing (LM) is one of the strongest tools used by manufacturing companies to improve and optimize their processes, making them more performant and agile. The current industrial revolution, or Industry 4.0, aims to give new momentum to manufacturing systems through various technologies, of which Blockchain is one of them. This technology has gained significant attention for its ability to enhance transparency, traceability, and data security within manufacturing and supply chain operations, representing a valuable opportunity to enhance lean manufacturing tools. Firstly, this paper presents what lean manufacturing is. After that, it explores how Industry 4.0 technologies influence LM. Then, it examines the impact of blockchain on LM, paving the way for lean 4.0 by presenting a case study concerning the Kanaban method in the automotive sector. Finally, the summary and future research direction will be presented.

1. Introduction

The fast advancement of Industry 4.0 allowed a new phase of digital transformation within manufacturing, Which is justified by the integration of a set of technologies including the Internet of Things (IoT), artificial intelligence (AI), big data, and blockchain technology [1]. The merging of these technologies has allowed unparalleled levels of automation, connectivity, and data sharing, fundamentally transforming the global industrial landscape. Central to this change is Lean manufacturing, a strategy aimed at enhancing value by removing waste and promoting ongoing improvement [2].

Although lean manufacturing has remained significant over the years, it encounters numerous challenges within the framework of Industry 4.0. Conventional lean methodologies like just-in-time (JIT), kanban systems, value stream mapping (VSM), and total productive maintenance (TPM) were not initially created to address the intricacies of today’s supply chains, which are becoming more global, fluid, and reliant on data [3]. The growing need for immediate data exchange, traceability, and operational clarity exposes the shortcomings of traditional lean methodologies. Problems like multiple information systems, a lack of visibility through supply chains, and data management inefficiencies have become major issues to achieving lean objectives in the digital age [4].

Blockchain technology, with its inherent qualities of decentralization, permanence, and openness, presents itself as a possible solution to these challenges [4]. Initially designed to enable secure financial transactions, blockchain technology has discovered a variety of uses in multiple sectors, especially in improving data dependability and building trust among partners in the supply chain. Within the manufacturing sector, blockchains can act as a strong digital framework to guarantee real-time transparency, enable safe data exchange, and streamline essential processes through the use of smart contracts [2].

This research examines how blockchain technology can be utilized to improve lean manufacturing tools within the context of Industry 4.0. By looking at the convergence of blockchains and lean practices, this study seeks to illustrate how blockchains can tackle significant issues encountered by lean manufacturing in a digitized setting. Specifically, it focuses on how blockchains can enhance traceability, improve data security, boost operational transparency, and enable real-time collaboration between stakeholders in the lean supply chain in the Industry 4.0 context. The outcomes of this research are expected to contribute to ongoing conversations regarding the adoption of blockchain technology in smart manufacturing environments, providing a resource for industries looking to improve their operational efficiency and maintain competitiveness in the digital age.

2. Literature Review

2.1. Lean Manufacturing

Lean manufacturing is a methodical and structured method used to improve production effectiveness by removing actions that do not add value. This concerns the minimization of various types of waste such as overproduction, delays, surplus inventory, defects, unnecessary transport, inefficient processing, and the underuse of human talent [5]. The concept of LM started with the Toyota Production System (TPS), which transformed industrial manufacturing by concentrating on continuous improvement (Kaizen), valuing employees, and reducing waste [6].

An important principle of lean manufacturing is the recognition and removal of waste, often called the seven types of waste (Muda), as identified by Taiichi Ohno. These encompass overproduction, surplus inventory, wasteful motion, idle time, excessive processing, defects, and unnecessary transportation [7]. The deployment of lean principles aims to optimize workflows, improve product quality, lower expenses, and boost overall efficiency [8].

Lean manufacturing allows the use of a set of tools and methods to enhance operational efficiency. Just-in-time (JIT) production guarantees that things are made only when required, which decries inventory expenses and boosts adaptability [3]. Kanban, a system that uses visual signals, encourages production efficiency by restricting work-in-progress and coordinating operations. Value stream mapping (VSM) allows organizations to evaluate and improve the total production workflow, pinpointing bottlenecks and zones of inefficiency [9]. Total productive maintenance (TPM) enhances the reliability of equipment by helping to reduce downtime with proactive maintenance methods [10]. Additional important lean tools are the 5Ss, which arrange work space for greater efficiency, Heijunka, which balances production schedules to anticipate demand variations, and Andon, a visual system that gives feedback for quality assurance [6].

Alongside minimizing waste, lean manufacturing favorites a culture centered on continuous improvement. The kaizen approach inspires workers at every level to participate in addressing challenges and improving processes, nurturing an atmosphere of innovation and efficiency [11]. The importance of leadership is vital in lean transformation, as leaders need to engage employees, drive cooperation across different functions, and maintain lean initiatives over the long term [12].

Lean manufacturing has been used by many industries outside of the automotive sector, such as the aerospace sector, healthcare, electronics, and services. Organizations that adopt lean principles often experience notable gains in productivity, decreased costs, lower lead times, and enhanced customer feedback [8]. Nonetheless, effectively implementing lean practices necessitates a change in culture, involvement from employees, and a dedication to ongoing learning and adaptation [13].

2.2. How Blockchain Can Enhance Lean Manufacturing Tools in an Industry 4.0 Context

Industry 4.0 is the integration of modern technologies, such as IoT, AI, and cyber-physical systems, focused on enhancing automation, connectivity, and data-informed decision-making all over the manufacturing process [1]. Blockchain, with its decentralized nature, transparency, and unchangeable ledger, improves these advancements by allowing secure and tamper-resistant data sharing through various networks [2]. Following that, blockchains enhance visibility in the supply chain, decrease differences in information, and demonstrate trust between stakeholders [3]. Blockchains boost transparency in the supply chain, reduce differences in information, and foster trust among stakeholders [4]. The combination of Industry 4.0 technologies and blockchains represents a strong basis for upgrading operational efficiency, enabling smooth data sharing, and promoting digital transformation in contemporary manufacturing environments.

Indeed, in the context of Industry 4.0, traditional lean methodologies face a set of challenges, especially in adjusting to the rising complexity of worldwide supply chains and the heightened need for real-time data transparency [2]. In this way, incorporating digital technologies gives a chance to strengthen lean systems by promoting better collaboration, transparency, and responsiveness in supply chain networks [14]. Blockchain technology, due to its decentralized nature and immutable ledger, offers solutions to these challenges by enhancing data transparency, reducing information discrepancies, and facilitating seamless collaboration among supply chain partners [4]. This integration not only improves lean methodologies but also paves the way for more agile and responsive manufacturing systems that align with the requirements of Industry 4.0 [15].

2.3. Challenges of Lean Manufacturing in Industry 4.0

Even though lean manufacturing represent an important tool, it faces various chanllenges when integrated with Industry 4.0. The classical lean methodologies like just-in-time (JIT), kanban systems, value stream mapping (VSM), and total productive maintenance (TPM) were not initially intended to tackle the intricacies of contemporary supply chains, which have evolved to be more global, dynamic, and reliant on data [3]. The rising demand for prompt data sharing, traceability, and operational transparency demonstrate the limitations of conventional lean practices. Problems such as separated information systems, lack of visibility across supply chains, and inefficiencies in data management have appeared as major obstacles to achieving lean objectives in the current digital environment [3].

Blockchain technology, known for its decentralization, unalterable nature, and transparency, offers a hopeful answer for addressing these issues [4]. Originally created to enable secure financial transactions, blockchains have discovered various uses across different sectors, especially in improving data integrity and building trust among supply chain collaborators. In the manufacturing industry, blockchains can serve as a robust digital infrastructure that ensure visibility in real-time, facilitate secure data exchange, and automate key processes through the use of smart contracts [2].

3. Research Methodology

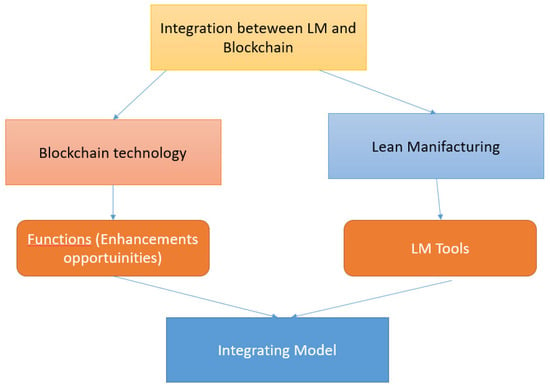

To identify enhancements that can add blockchains to lean manufacturing tools, we propose an integrated approach that leverages blockchain technology capabilities with the functional decomposition of LM tools.

In order to achieve our goal we have adopted the following stringent methodology:

- -

- Step 1: Identify enhancement capabilities of blockchain technology (functions);

- -

- Step 2: Identify enhancement opportuinities for the integration of blockchains with LM tools

- -

- Step 3: Proposition of an integrating model between LM tools and blockchains.

- -

- Step 4: Evaluation and comparaison of LM tools in both scenarios (classic and using blockchains).

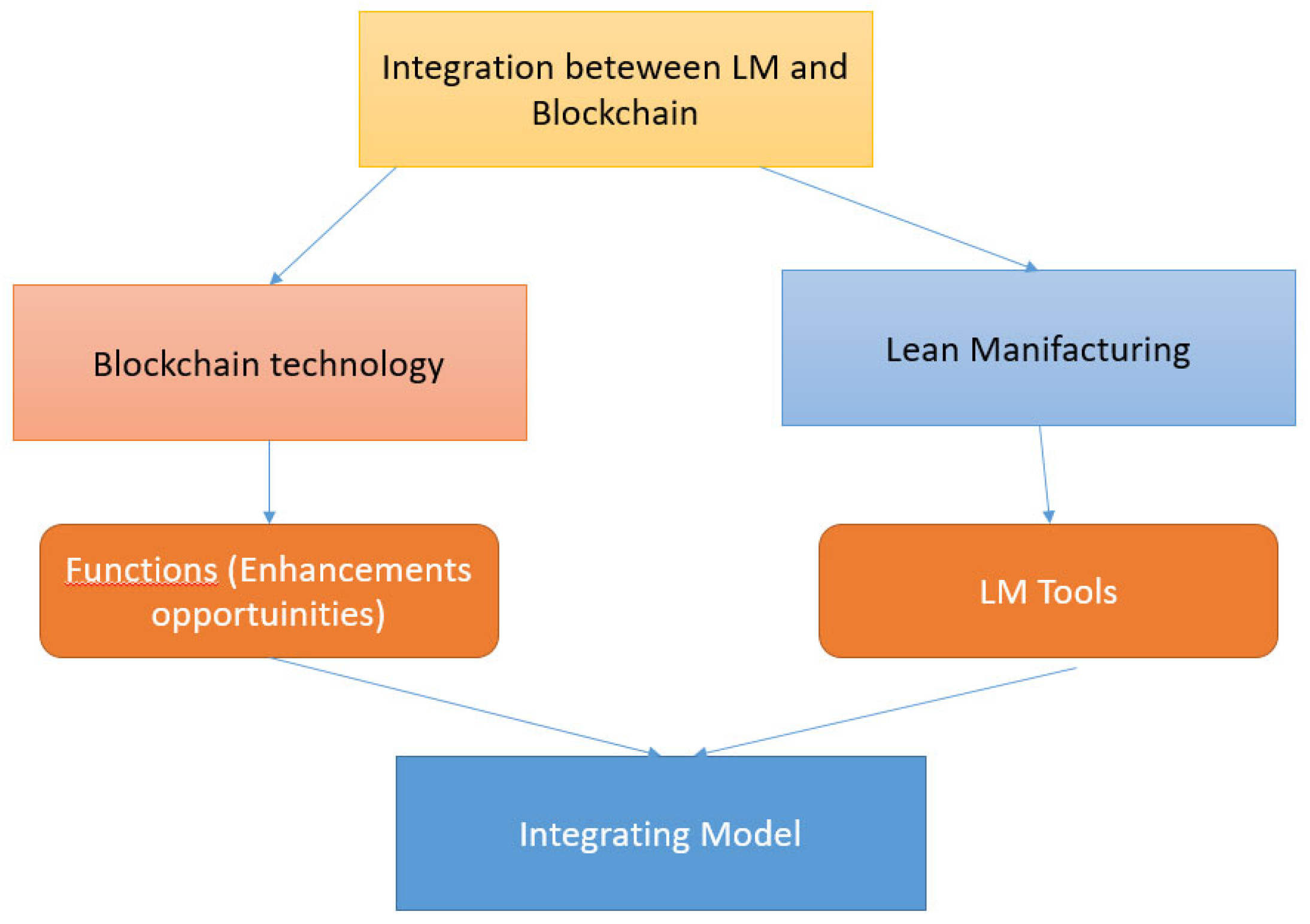

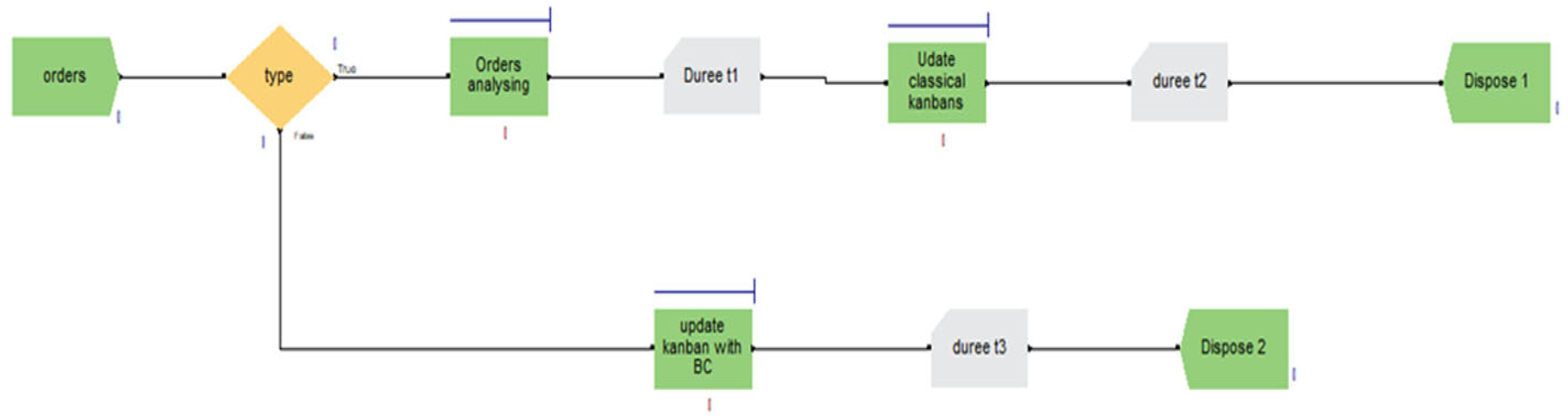

Figure 1 below presents the proposed integration model structure.

Figure 1.

Integration between lean manufacturing and a blockchain.

3.1. How Can Blockchains Improve LM Tools

Identify Enhancement Capabilities for Blockchain Technology (Function)

Through our review of the literature regarding companies implementing Industry 4.0 technologies, we have compiled a list of the most frequently recognized functions in Table 1 below.

Table 1.

Blockchain capabilities.

3.2. Identify Enhancements Opportunities of Integrating Blockchains with LM Tools

In this part we present a set of models demonstrating the integration between kanban, the purpose of which is to demonstrate the improvement.

Kanban 4.0 and Blockchains

The kanban approach relies on the pull production system, which triggers manufacturing only upon receiving customer orders. This technique promotes a consistent production flow, preserving a set stock level to ensure a reliable supply chain process [12].

The integration of Industry 4.0 technologies enhances kanban by improving its efficiency, adaptability, and flexibility in dynamic manufacturing environments. By utilizing simulation methods and real-time digital representations of physical objects (digital twins), kanban loops can be optimized with greater accuracy. Additionally, digital twins enable manufacturers to anticipate fluctuations in demand and adjust kanban configurations, such as lot sizes, inventory amounts, and delivery timelines, while effortlessly integrating external changes into production schedules [16].

Moreover, technologies provide ongoing monitoring of work-in-progress, improving the ability to track material movement and aiding in the decrease in excess inventory by allowing real-time comparisons between intended and actual figures [17]. The advent of cyber–physical systems (CPSs) greatly enhances kanban automation by reducing the necessity for human participation. Intelligent storage systems operate through self-regulation, facilitating the collection and transmission of data while paving the way for fully autonomous robotic systems that handle monitoring and control [18].

The success of implementing kanban relies on the accuracy and availability of input data, such as customer orders and forecasts of demand. Blockchain technology provides a secure and transparent framework for data exchange, allowing supply chain participants to access synchronized, real-time demand information, which helps reduce information asymmetry. In a private or consortium blockchain, access permissions can be managed to protect data privacy and enhance collaboration within the supply chain [19].

Through the use of blockchain-powered smart contracts, kanban could evolve into a fully demand-driven system, where customers order details are automatically accessed rather than transmitted, ensuring seamless coordination with production scheduling. This facilitates precise modifications of lot sizes, inventory quantities, and delivery timelines in real-time [20].

Additionally, blockchains reduce the administrative workload involved in sharing and verifying orders, decreasing dependence on email communication and providing constant, real-time access to supply chain information. This enhances visibility throughout the entire process, improving both horizontal and vertical integration within the supply chain [21].

Blockchains can reinforce kanban systems by automating the pull signal with smart contracts and allowing for tamper-proof visibility of stock levels across tiers. While the current literature offers limited direct implementations, the integration between kanban principles and blockchain capabilities—such as traceability and real-time synchronization—has been acknowledged as a promising area for lean digitalization [2,10].

For this reason, we can say that blockchain technology will allow manufacturers to improve their ability to manage their kanban loops. Accordingly, this will increase their capability of avoiding over-production and over-stocks, provide higher availability of materials, support a reduction in planning effort and production control effort, and lead to less required storage space all over the supply chain network.

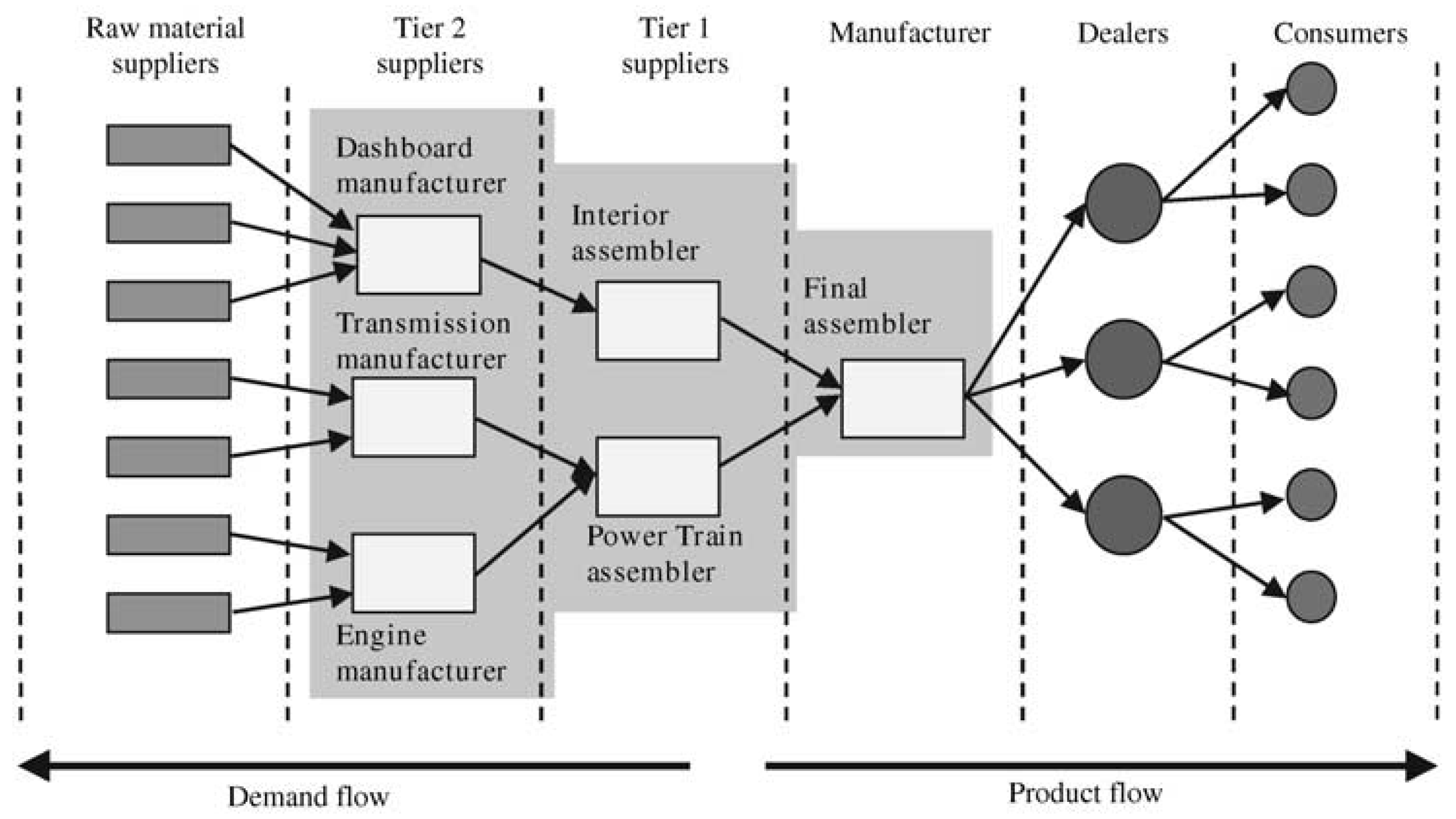

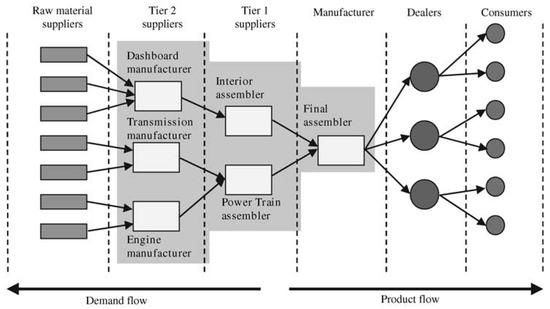

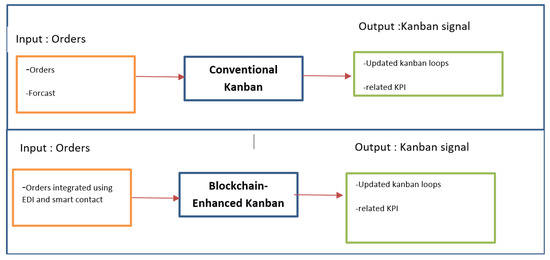

To illustrate the importance of blockchain technology in improving the kanban method, we consider the simplified diagram in Figure 2 of the automotive supply chain below.

Figure 2.

A generic supply chain sheme (illustration an automotive supply chain) [21].

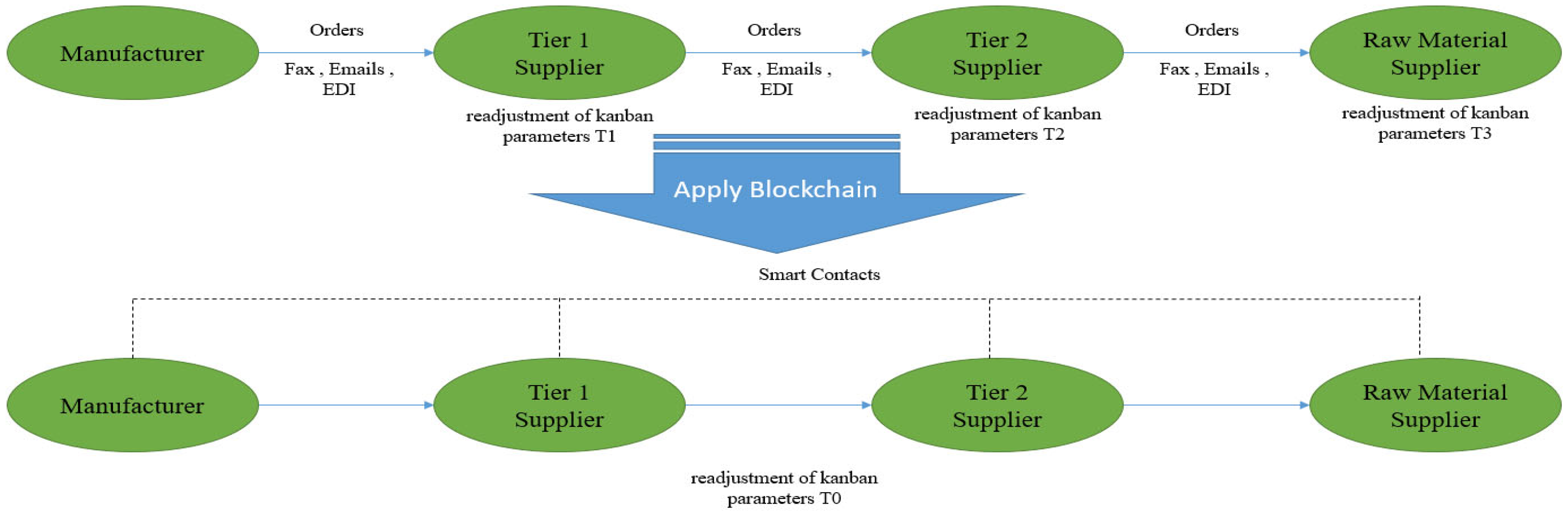

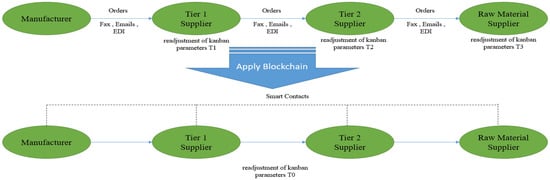

This automotive supply chain model demonstrates the movement of demand (on the left) and products (on the right) through various levels, beginning with raw material suppliers and ending with consumers. The multi-layered supplier framework facilitates just-in-time (JIT) manufacturing, allowing for effective inventory control. The inclusion of blockchain technology may improve transparency, traceability, and real-time cooperation throughout all levels of the supply chain. It can allow a total broadcast of orders and forecasts from the manufacturer into their suppliers’ network (tier 1, tier 2…). The Figure 3 below show a model of integrating a blockchain into the automotive supply chain. This can give an important enhancement to kanban loops management as all suppliers can update in real time their inventory needs and their kanban loops at the same moment when a manufacturers order changes.

Figure 3.

Model of integration blockchain into kanban.

4. Case Study: Evaluation and Comparison of Classical Kanban and Blockchain-Integrated Kanban Systems

To evaluate the importance of integration of blockchains into kanban systems and demonstrate the added value offered by this technology, we developed an approach to address the challenges encountered in the daily life of industrial companies. By drawing inspiration from existing approaches, we propose the following:

- Mapping of the process in both scenarios: a classical kanban and a blockchain-integrated kanban system.

- Simulation of processes using Arena.

- Evaluation and comparison of the time of treatment in both scenarios.

4.1. Case Study: Company in the Automotive Sector in Morocco

One of the international leaders in its field (plastics injection), the company works three shifts, with 800 staff and a schedule that changes each week following orders from clients. The company should be constantly efficient. To achieve the following objectives, the company should be aware of its production planification system, which concerns the following:

- -

- Constantly verify the quality of data related to customer orders;

- -

- Integration of data into information systems;

- -

- Updating planification maps following orders and forecasts of customers (kanban card, production schedule);

- -

- Ensure real-time operation of the information system through real-time updates.

To meet these objectives, the company has opted for a study on a blockchain-integrated kanban system to see how this technology can improve the quality of data and reactivity in internal logistics, ensuring the real-time operation of the information system through real-time updates.

- Objective

This study presents a simulation model developed in Arena to compare the performance of a traditional kanban system versus a blockchain-enhanced kanban system, using data of a company working in the automotive sector in Morocco. The simulation evaluates key performance metrics, specifically including order processing delays.

- Mapping of kanban process scenarios:

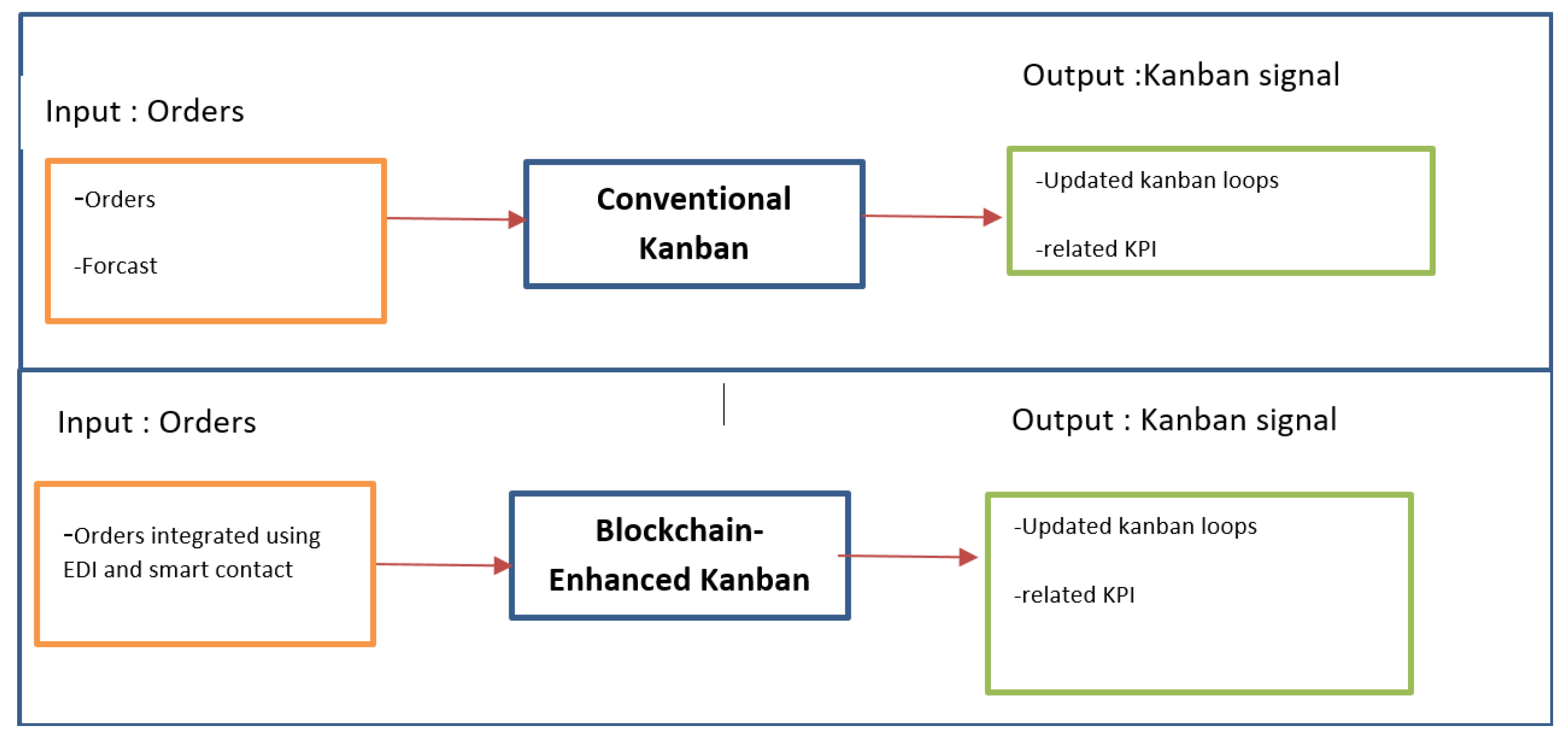

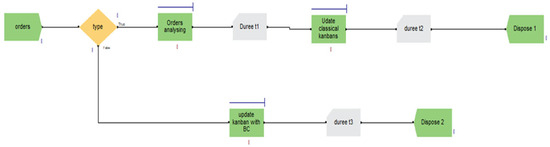

To compare the classic kanban process and the blockchain-enhanced kanban process, the Figure 4 below shows processes for both scenarios.

Figure 4.

Mapping of kanban process scenario.

- Simulation of processes using Arena

The purpose of this section is to model and analyze the workflow of a traditional kanban system and a blockchain-integrated kanban system, and then to compare performance indicators and order processing delays. By conducting a discrete-event simulation in Arena, the goal here is to provide quantitative insights into the effectiveness of blockchain technology when applied to the kanban method. The findings contribute to the ongoing discourse on digital transformation in supply chain management and offer practical insights for industries seeking to optimize their lean practices in the context of Industry 4.0. The figure below shows the modeling of two scenarios in Arena.

In this way, we can see that the traditional kanban model includes three manual steps: order analysis (4 h), kanban signal update (8 h), and system validation. These delays reflect the real-life processes executed in the studied automotive company. Indeed, the blockchain-enhanced kanban system replaces these steps with automated processes: smart contracts verify and validate the order in 0.5 h and the kanban signal is updated in real time. Both models start with an incoming order entity and follow a decision node that assigns the process path. The simulation compares the two workflows over a one-year period, focusing on average processing time and order response delays. Figure 5 below shows the simulation model using Arena Simulation.

Figure 5.

Model in Arena of kanban process scenario.

This Arena simulation model represents the order processing flow in a traditional kanban system and a blockchain-enhanced kanban system.

- ✓

- Entry Point: The system receives incoming orders (orders entity). For the company this operation is performed one time per week.

- ✓

- Decision Node (type): A decision determines whether the order is processed using traditional kanban (50% True) or blockchain kanban (50% False).

Traditional Kanban Process:

- ✓

- Order analyzing—Initial order analysis (4 h).

- ✓

- Duration t1—Processing time for analysis.

- ✓

- Update classical kanban—Manual update of kanban signals (8 h).

- ✓

- Duration t2—Delay in signal propagation and validation.

- ✓

- Dispose 1—The order exits the system after processing.

Blockchain Kanban Process:

- ✓

- Update kanban with BC—Automated update and verification using blockchain smart contracts (0.5 h).

- ✓

- Duration t3—Reduced processing time due to automation (0 h).

- ✓

- Dispose 2—The order exits the system after blockchain-based processing.

This simulation demonstrates that in one year, order processing delays in kanban using the blockchain scenario represent only 8% of the same indicator measured in the classic kanban process. The Table 2 below represents a synthesis of comparison between the two scenarios:

Table 2.

Comparison between the two scenarios.

4.2. Comparaison Between E-Kanban Approch and Kanban Integrating a Blockchain and Challenges

In contrast to e-Kanban systems, which ensure the management of kanban loops using a digital tool and depend on centralized databases and client-server setups, kanban systems integrated with blockchains present enhanced data integrity, decentralization, and increased trust among supply chain partners. Although e-Kanban solutions facilitate electronic signal transmission and ensure its integration with ERP systems, they are always susceptible to single points of failure and lack of transparency in multi-tier networks. On the other hand, blockchains allow for the real-time and tamper-proof dissemination of kanban signals via smart contracts and distributed ledgers, which can decrease the dependence on intermediaries and the need for manual reconciliation. This demonstrates that blockchains are a more resilient option, particularly for supply chains that are globally distributed and collaborative.

Due to its potential, implementing blockchains in lean manufacturing tools presents several practical challenges. First, integrating blockchain into deployed IT infrastructure in companies requires additional investment, both financially and in system compatibility. Also, small and medium enterprises (SMEs) do not possess the necessary digital maturity or in-house expertise required to implement distributed ledger technologies.

5. Conclusions and Perspectives

Integrating blockchain technology into lean manufacturing in the context of Industry 4.0 presents significant opportunities for enhancing efficiency, transparency, and collaboration through supply chain networks. While lean manufacturing is recognized by its effectiveness in reducing waste and enhancing processes, its traditional tools find it challenging to adapt to the more complex, data-centric, and worldwide production environments. The characteristics of blockchain technology, including its decentralization, immutability, and transparency, offer an innovative way to enhance lean principles by enabling real-time data sharing, secure transactions, and automated process execution using smart contracts.

This paper has illustrated how blockchain technology can enhance lean methodologies like kanban by boosting traceability and facilitating greater collaboration among stakeholders. In addition, the use of smart contracts and decentralized ledgers enhances the resilience of supply chains, reduces operational inefficiencies, and promotes increased trust among supply chain partners. This was demonstrated by a simple simulation comparing the performance obtained in a classic kanban case and also in a kanban integrating a blockchain scenario.

Future studies should investigate other lean manufacturing tools to confirm the effect of blockchains on enhancing LM efficiency, as well as explore how blockchains can be integrated with AI and IoT to develop a more holistic Industry 4.0 framework. Tackling these issues will be essential for promoting widespread adoption and ensuring the long-term viability of blockchain-enabled lean manufacturing systems.

In the end, the merging of blockchains, lean manufacturing, and Industry 4.0 has the capacity to propel the next stage of smart manufacturing, providing businesses with a competitive edge in an increasingly digital and interconnected industrial environment.

Author Contributions

Conceptualization, R.I. and S.D.; methodology, R.I.; software, R.I.; validation, R.I., S.D. and L.I.; formal analysis, R.I.; investigation, R.I.; resources, S.D.; data curation, R.I.; writing—original draft preparation, R.I.; writing—review and editing, S.D. and L.I.; visualization, R.I.; supervision, S.D.; project administration, S.D.; funding acquisition, L.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding, and no funding was provided for the Article Processing Charges (APC).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting this study are available from the corresponding author through a reasonable request. The simulation models implemented in this research were developed in Arena software based on a case study from the Moroccan automotive sector. Due to company confidentiality agreements, raw operational data cannot be shared publicly. However, a generalized version of the simulation model and associated parameters can be provided for academic or research purposes.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes Metab. Syndr. Clin. Res. Rev. 2021, 15, 621–627. [Google Scholar] [CrossRef] [PubMed]

- Treiblmaier, H. The impact of the blockchain on the supply chain: A theory-based research framework and a call for action. Supply Chain. Manag. Int. J. 2018, 23, 545–559. [Google Scholar] [CrossRef]

- Obeidat, R.; Ispas, A.; Aleodor, B.; Bendic, V. Blockchain Technology—Applicability in the Traceability of a Product Throughout the Supply Chain. Macromol. Symp. 2021, 395, 2100270. [Google Scholar] [CrossRef]

- Sheel, A.; Nath, V. Effect of blockchain technology adoption on supply chain adaptability, agility, alignment and performance. Manag. Res. Rev. 2019, 42, 1353–1374. [Google Scholar] [CrossRef]

- Ghode, D.; Yadav, V.S.; Jain, R.; Soni, G. Blockchain adoption in the supply chain: An appraisal on challenges. J. Manuf. Technol. Manag. 2020, 32, 42–62. [Google Scholar] [CrossRef]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Shingo, S. A Study of the Toyota Production System: From an Industrial Engineering Viewpoint; CRC Press: Boca Raton, FL, USA, 1989. [Google Scholar]

- Rother, M.; Shook, J. Learning to See: Value Stream Mapping to Create Value and Eliminate Muda; Lean Enterprise Institute: Boston, MA, USA, 1999. [Google Scholar]

- Nakajima, S. Introduction to TPM: Total Productive Maintenance; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Imai, M. Kaizen: The Key to Japan’s Competitive Success; McGraw-Hill Education: New York, NY, USA, 1986. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Simon & Schuster: New York, NY, USA, 1996. [Google Scholar]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve: A review of contemporary lean thinking. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Supranee, S.; Rotchanakitumnuai, S. The acceptance of the application of blockchain technology in the supply chain process of the Thai automotive industry. In Proceedings of the 17th International Conference on Electronic Business, Dubai, United Arab Emirates, 4–8 December 2017; pp. 252–257. [Google Scholar]

- Sharma, P.K.; Kumar, N.; Park, J.H. Blockchain-based distributed framework for automotive industry in a smart city. IEEE Trans. Ind. Inform. 2018, 15, 3157–3165. [Google Scholar] [CrossRef]

- Bitcoin: A Peer-to-Peer Electronic Cash System. 2008. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 23 April 2025).

- Schuh, G.; Potente, T.; Wesch-Potente, C.; Weber, A.R.; Prote, J.-P. Collaboration Mechanisms to Increase Productivity in the Context of Industrie 4.0. Procedia CIRP 2014, 19, 51–56. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature Review and a Proposed Framework for Future Research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Monostori, L. Cyber-physical production systems: Roots, expectations and R&D challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain. Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Chandra, C.; Kamrani, A.K. Collaborative Engineering: Theory and Practice; Springer: Boston, MA, USA, 2004. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).