Abstract

This paper tackles the logistics dilemma of how to meet customer expectations while at the same time respecting the internal processes and financial interests of the company and ensuring long-term sustainability. In this paper, integrated Quality Function Deployment (QFD) and Balanced Scorecard (BSC) techniques developed a method for the structured planning of logistics strategies. BSC, combined with QFD, gives the opportunity not only to “translate” the voice of the customer but also to focus on the company’s interests from four perspectives. For example, for products, we evaluated the interactions between different expectations, and the focus was on the disputes that arise during the expectations. The result of this paper is that Extended QFD provides a new method to formulate the various requirements. This method is suitable for creating a sustainable logistics strategy.

1. Introduction

The development of logistics strategies is a challenge for experts because a satisfactory logistics strategy is not only based on the customer’s perspective, but also the company’s point of view; that is, whether the customer requirements are feasible for the company in terms of internal processes and financials, and whether the company’s goals are sustainable in the long term [1,2].

The Quality Function Deployment (QFD) technique [3,4] and its adapted version for logistics applications [5] are excellent tools for “translating” the customer’s voice into technical parameters. However, for a logistics strategy to be predictable and sustainable in the long term, it is not sufficient to only use QFD—it is also necessary to examine the company’s performance indicators.

This research investigated which techniques are suitable for testing performance. After reviewing the Key Performance Indicator (KPI) [6] and Balanced Scorecard (BSC) [7] techniques, the Balanced Scorecard (BSC) technique [8] was finally chosen. The aim is to apply a corporate governance and performance measurement method that, in addition to customer expectations [9], also examines aspects of corporate, internal organizational business processes and learning and development expectations.

In the 1990s, Kaplan and Norton [10] developed the Balanced Scorecard (BSC) to break down corporate and business strategies by area, which can be used to monitor performance. The Balanced Scorecard [11] helps to create a basis for a common understanding of the company’s future. This will help all employees understand how they can contribute to the organization’s success, namely, the achievement of strategic goals.

A knowledge background study was also carried out to develop the methodology. The software used to visualize the literature analysis is VOSviewer 1.6.20 [12].

In this paper, a methodology to develop sustainable logistics strategies is presented.

2. Literature Review

The Quality Function Deployment (QFD) technique originated in Japan in 1972 [13]. Through QFD, a systematic method was developed to transform the voice of customers through various product planning, design, and manufacturing stages to achieve higher customer satisfaction [14].

This method can also be used as a design and problem-solving tool [15]. The QFD technique consists of a matrix of four consecutive stages that are used in many phases of the product design process [16]. A three-phase version of the technique, adapted for logistics applications, can also be used to develop and control logistics strategies [5].

The matrix used to design customer requirements is called the “House of Quality” (HOQ) [17] which is taken as a starting point for the joint applicability of QFD and BSC.

The Balanced Scorecard [18] is a strategic corporate governance and performance measurement method based on a balanced set of objectives and performance indicators. The basic premise of the BSC model [19] is that the performance of one business area has an impact on the results of other areas. It approaches organizational performance from four perspectives and organizes it into a coherent, logical system [20].

The four aspects are as follows:

- The corporate aspect relates to the company’s performance and profit orientation;

- The customer aspect—the product should be accessible and affordable;

- The internal organizational business process aspect refers to processes that support the achievement of strategic goals;

- The learning and development aspect, namely, how to maintain the company’s evolving capability to achieve future goals.

This method helps to highlight the interrelationship between the four aspects, making it accessible to different departments. The BSC system can be used to articulate the vision and strategy of the organization clearly and unambiguously and translate it into tangible and measurable objectives [21]. It has the advantage of helping with planning, setting priorities, and enabling continuous monitoring [22].

The Key Performance Indicator (KPI) is a metric [23] that measures a company’s performance and through which the company’s results can be compared with those of its competitors. The KPI is based on data measured in each department, with the main categories being financial, consumer, process, and other (human, etc.) performance indicators [24]. A brief comparison is presented to clarify which corporate performance measurement method can be used to develop sustainable logistics strategies.

As Table 1 shows, the BSC method [25] allows for a far more comprehensive analysis of the company’s objectives, as the interrelationships between the individual objectives of the company are much more emphasized in the application of BSC. This publication aims to support the development of logistics strategies for the company by considering not only customer expectations but also the company’s financial expectations and internal processes. It also aims at learning and development; that is, the sustainability of the company’s logistics strategy. Therefore, in this publication, the BSC method has been chosen as a complement to the QFD technique.

Table 1.

Comparison of KPI and BSC [25].

Knowledge Background Analyses

For the common use of QFD and BSC, the knowledge background in Science Direct, Scopus, and Web of Science databases was investigated. To narrow down the list of publications, the keywords QFD and BSC were used, supplemented with the keywords logistics and strategy to identify publications on the topic (Table 2).

Table 2.

Summary of the results of the keywords search based on Scopus, Science Direct, and Web of Science (27 November 2024).

The publications in the databases were examined for articles published in the last 5 years, namely 2019–2024. This covers 5 full years, as there are still very few publications in 2024. Then, the database of publications from the 15 years preceding 5 years, i.e., 2004–2018 (covering 15 full years), was also looked at to see the direction in which research on a topic has developed.

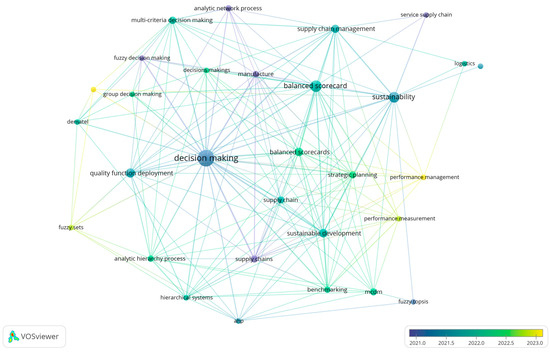

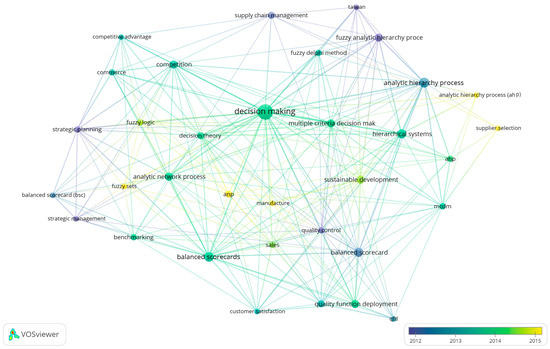

The resulting publications were analyzed using VOSviewer, a visualization text mining tool that draws different graphs and bibliometric maps of the keywords in the corpus using different statistical methods [12]. VOSviewer can be used to explore the relationship between the keywords in the corpus. The program scores keywords by relevance (relevance score) using statistical methods and visualizes the relationships between them based on their strength [26].

For the visualization with VOSviewer, only data imported from the Scopus database was used, as this is the database where most of the publication abstracts and keywords are available and, therefore, the most relevant scientific database for the analysis with VOSviewer.

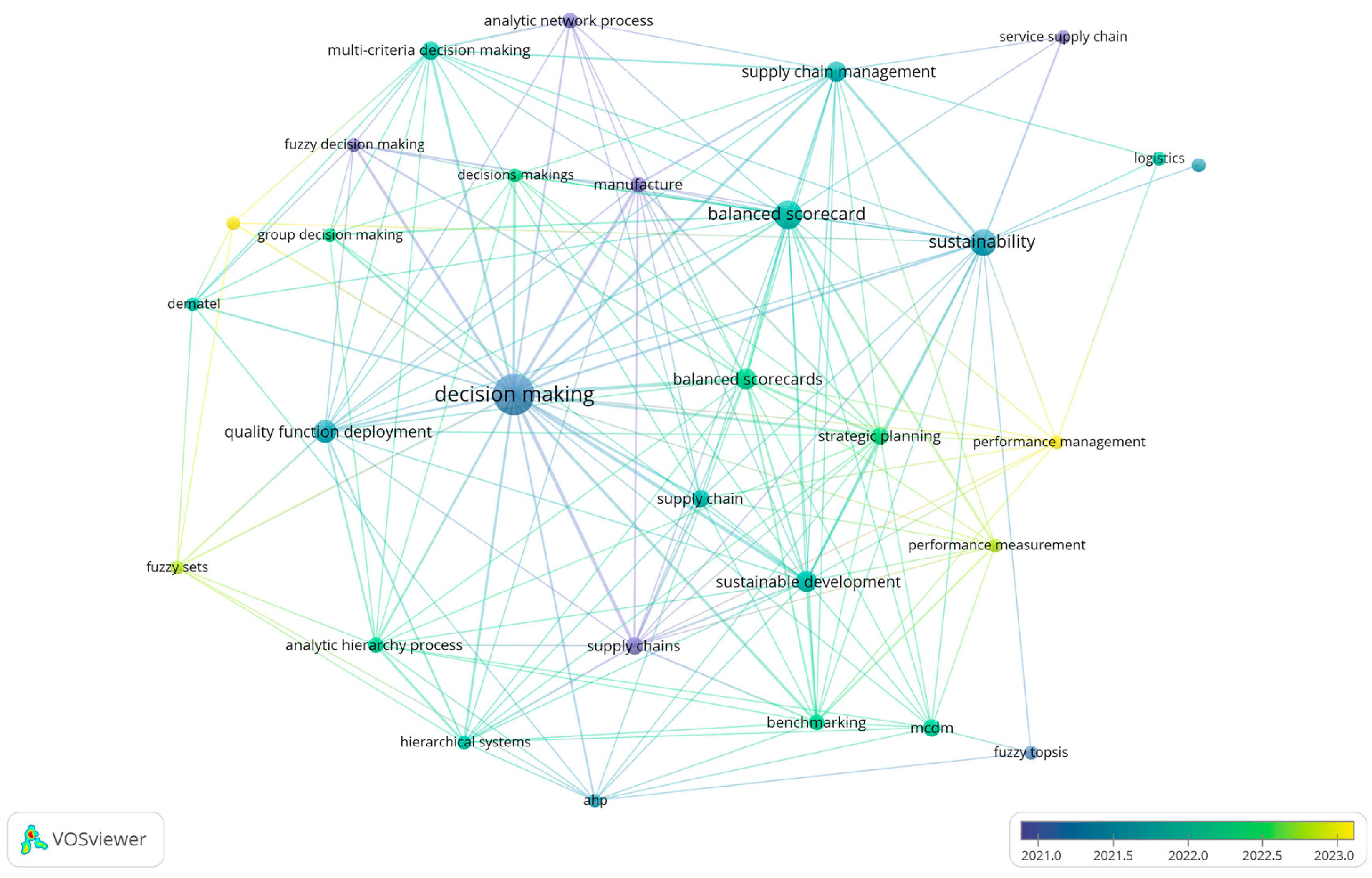

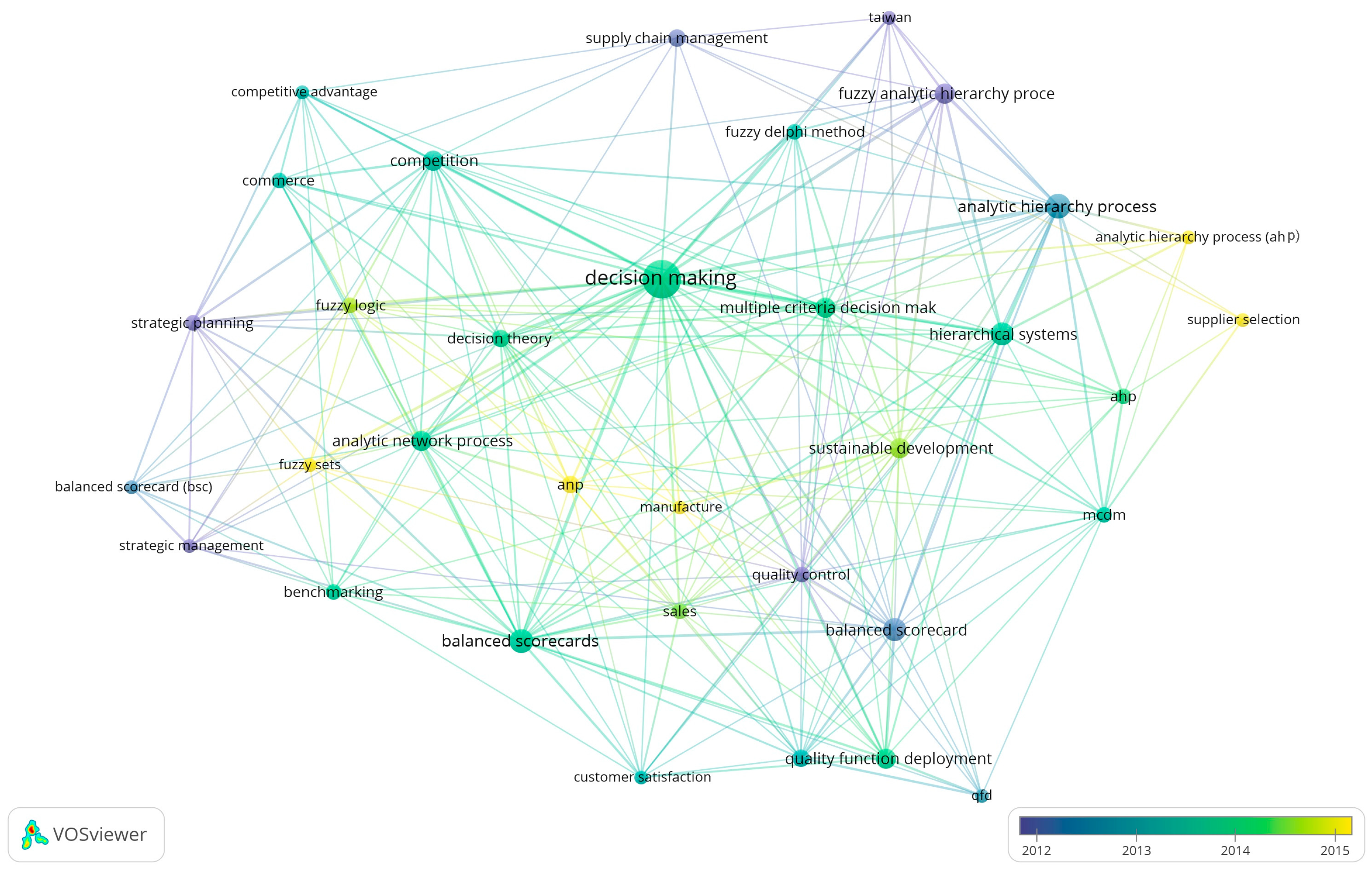

Both Figure 1 and Figure 2 focus on decision-making and several popular decision support methods (AHP, MCMD, QFD, Fuzzy) are also shown. However, Figure 1 shows that after 2020, sustainability and sustainable development have been introduced and supply chain management is directly linked to them, suggesting that practitioners have recognized that in order to achieve sustainability in logistics strategy, it is not only important to measure performance.

Figure 1.

Overlay visualization by VOSviewer from the research results of keywords: QFD AND BSC AND logistics AND strategy. From the last 5 years (on the 27 November 2024). Minimum number of occurrences: 4. Source: own compilation.

Figure 2.

Overlay visualization by VOSviewer from the research results of keywords: QFD AND BSC AND logistics AND strategy. From the 15 years preceding the last 5 years (on the 27 November 2024). Minimum number of occurrences: 4. Source: own compilation.

The topics for which publications have been written that are considered more relevant to this research are briefly described below:

- (a)

- Construction project management [27].

They propose a structure that can be used to manage construction projects efficiently and thus reduce delays. The Balanced Scorecard (BSC) and Quality Function Deployment (QFD) framework proposed in this study enabled the identification and prioritization of financial plan objectives and construction delay reduction.

- (b)

- Ranking of economic indicators [28].

The BSC core framework has an added supplier aspect, a four-phase Quality Function Deployment (QFD), and economic GRI priorities. Finally, the results of the QFD were used in the TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution) technique to rank the economic indicators.

- (c)

- Examination of employee expectations [29].

This study attempts to explore the factual expectations of employees using the Balance Scorecard (BSC) approach. Furthermore, the relationship between employers’ expectations and the requirements needed to meet those expectations is also determined using Quality Function Deployment (QFD).

- (d)

- Financial targets for the pavement management sector [30].

The results of the QFD-BSC analysis are studied using the fishbone diagram and causal analysis to graphically illustrate how the four perspectives’ significant factors lead to better financial targets in the pavement management industry.

- (e)

- Healthcare model [31].

This publication developed a comprehensive healthcare model using the Kano model, Quality Function Deployment (QFD), and the Balanced Scorecard (BSC) to simultaneously reduce costs, improve quality, improve patient satisfaction, and increase hospital profitability.

- (f)

- Extended PPHOQ [32].

An extended Product Planning House of Quality (PPHOQ) using the Least Deviation Based Approach (LDBA) and the Balanced Scorecard (BSC) was proposed. They develop a comprehensive and systematic approach to determine the aggregate PR of engineering characteristics in the extended PPHOQ.

- (g)

- Strategic map for business development [33].

To identify and prioritize the business’s development needs, a strategic map is drawn up that combines the BSC’s management principles with quality principles from the Malcolm Baldridge National Quality Award and the European Foundation for Quality Management. An implementation methodology to support its application in a specific enterprise is implemented using the Quality Function Deployment (QFD) quality planning tool.

- (h)

- For performance measures based on financial management [34].

It proposes a structured methodological approach based on the Quality Function Deployment (QFD) methodology to improve the implementation of the Balanced Scorecard methodology in individual organizations, based on traditional financial management performance measures.

- (i)

- Analysis of educational criteria [35].

This publication analyses the educational criteria for strategy development in vocational education and training. The methodology of the proposed framework is to combine the SWOT matrix and the Balanced Scorecard (BSC) by identifying the four critical success perspectives using the quality function development (QFD) methodology.

This list shows some publications that have been written suggesting the joint use of BSC and QFD. However, no publication was found that specifically advocated the structured planning of logistics strategies.

3. Methodology: Extended QFD with BSC Methodology

BSC was chosen because it examines expectations from 4 different perspectives [7]. Combined with QFD [36], it provides the opportunity to not only “translate” the voice of the customer, but also to keep the interests of the company in mind, at the same time allowing for the examination of internal process expectations and sustainability.

In other words, the development of Extended QFD provides a methodology to formulate the different requirements in a structured way; that is, to define how strategic directions, as expectations of customers, companies, internal organizational business processes, and learning and development objectives, vary for each product range produced by each company. The methodology will be used to show that, unlike basic QFD, different aspects can be examined here. This is because the methodology, using QFD and BSC together, can be used to draw up a corporate strategy, which can help visualize the relationships between the expectations expressed by the different aspects and the contrasts. These contradictions may not be resolved, but they can help in the decision-making process.

Using the Extended QFD method, we did not consider the sustainability in the classical context [37], but the long-term sustainability of a company. However, all three dimensions of sustainability [37] are included in this methodology:

- Economic: concerns about the economy often cause conflict between disciplines, which requires a “trade-off” [38]. This means, for example, trying to find a balance between the requirements of the economic department and the logistics services [39].

- Social: a reliable, resilient company with long-term planning provides its employees with security and predictability [40].

- Environmental: if a company is sustainable, it can plan for the long term with equipment, machinery, etc., the replacement of which mostly generates waste [41]. A learning and growth approach also means innovative solutions, which often means energy efficiency and purchasing sustainable equipment.

Thus, sustainability has been used in interpreting companies’ logistics strategies, but its dimension is more emergent in the methodology. After all, having a predictable, reliable, and sustainable strategy supports both economic and environmental goals as well as overall social goals. Thus, each of the three dimensions of sustainability is included in developing a sustainable logistics strategy.

To use BSC and QFD together, Table 3 has been created, in which the parameters that appear in the field of logistics strategy have been added to the BSC 4 approach, the list of which reflects our own opinion and may vary depending on the company culture and product area.

Table 3.

Logistics parameters with balance scorecard perspectives.

As the developed Extended QFD is a methodology, the technical and organizational elements that may arise in the logistics strategy of a product and may have similar importance have been added to the list of logistics parameters in this publication.

For the logistics parameters in Table 3 and Table 4, some information is provided for clarity. There is an obvious conflict of interest regarding order quantity, since the company is basically interested in switching production to another product as few times as possible, while the customer wants to be able to order as much as they need.

Table 4.

Legend for the relevance values between BSC expectations and logistics parameters.

Therefore, economic batch sizes can be presented differently from the customer’s and the financial (company) point of view, as the importance of economic batch sizes for both parties differs. It is suitable for the customer to order a lot of units, but, in this case, the company needs to keep stock or produce smaller units, so it has to readjust the machines each time. For the company, it is better to have larger orders, which it can deliver to the customer immediately after production, so it does not need to hold stock and the number of changeovers can be kept low.

The degree of customer focus of the communicated, ordered unit of measure depends on several factors. For example, whether the customer is either ‘dictated’ by the market, meaning that a product is produced where there are several competing firms to compete with, or whether the product is so specialized that quantity requirements can be imposed on the customer in terms of order. Therefore, in Extended QFD, the customer’s aspect is called free defined order size, which means that the customer can order 1 piece and several pieces at the same time. Financial (company) in terms of LOT size designation is used in this article since the batch size has a significant impact on inventory and also on changeovers.

The internal processes perspective includes logistics parameters that have an impact on the internal processes of the company, such as keeping lead time, constant supply, and quality.

Learning and growth refer to the long-term development and sustainability of the company, which means that the aim is to develop a logistics strategy that enables the company to stay in the market. These parameters can be defined in the Extended QFD diagram with the indicators expansion, productivity improvement, contract time (long term), and constant customer base. Productivity improvement can be measured year by year. In addition, the contract’s length determines the company’s ability to be present in the market. This can be measured by the percentage of capacity that is linked to long-term contracts. Constant customer base, on the other hand, is measured by the percentage of customers that change in 1 year. It is also a predictor of how loyal customers are, as a secure customer base makes a company sustainable.

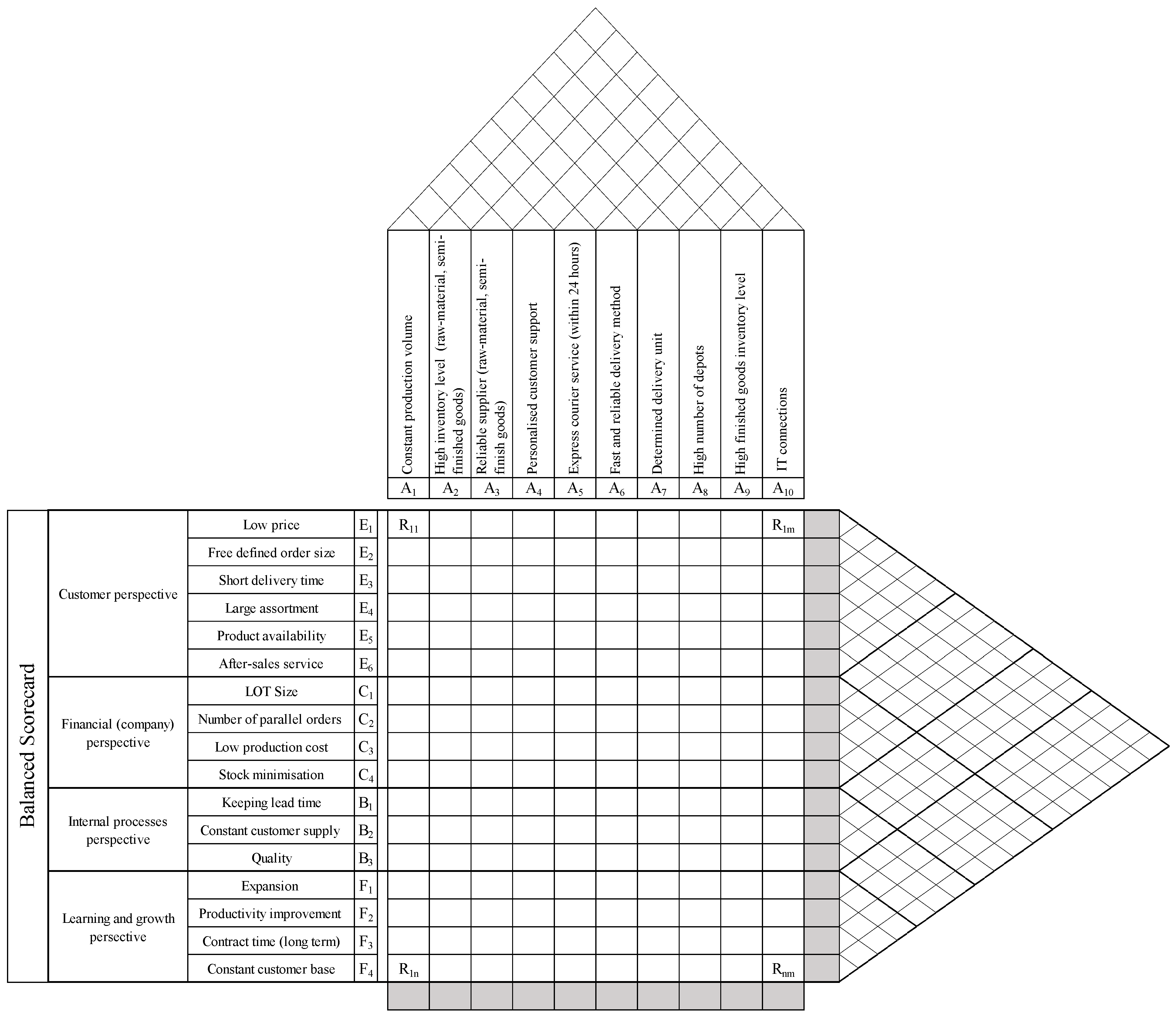

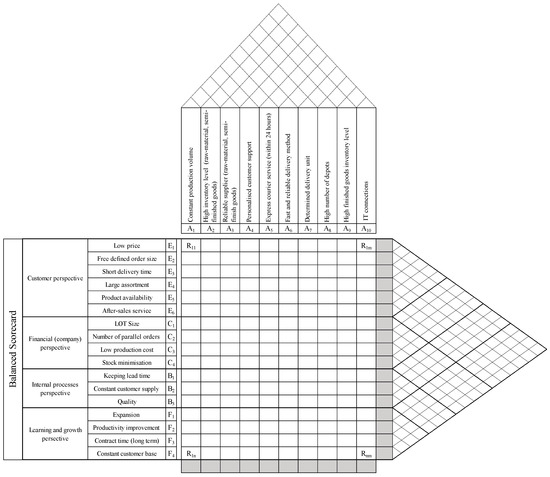

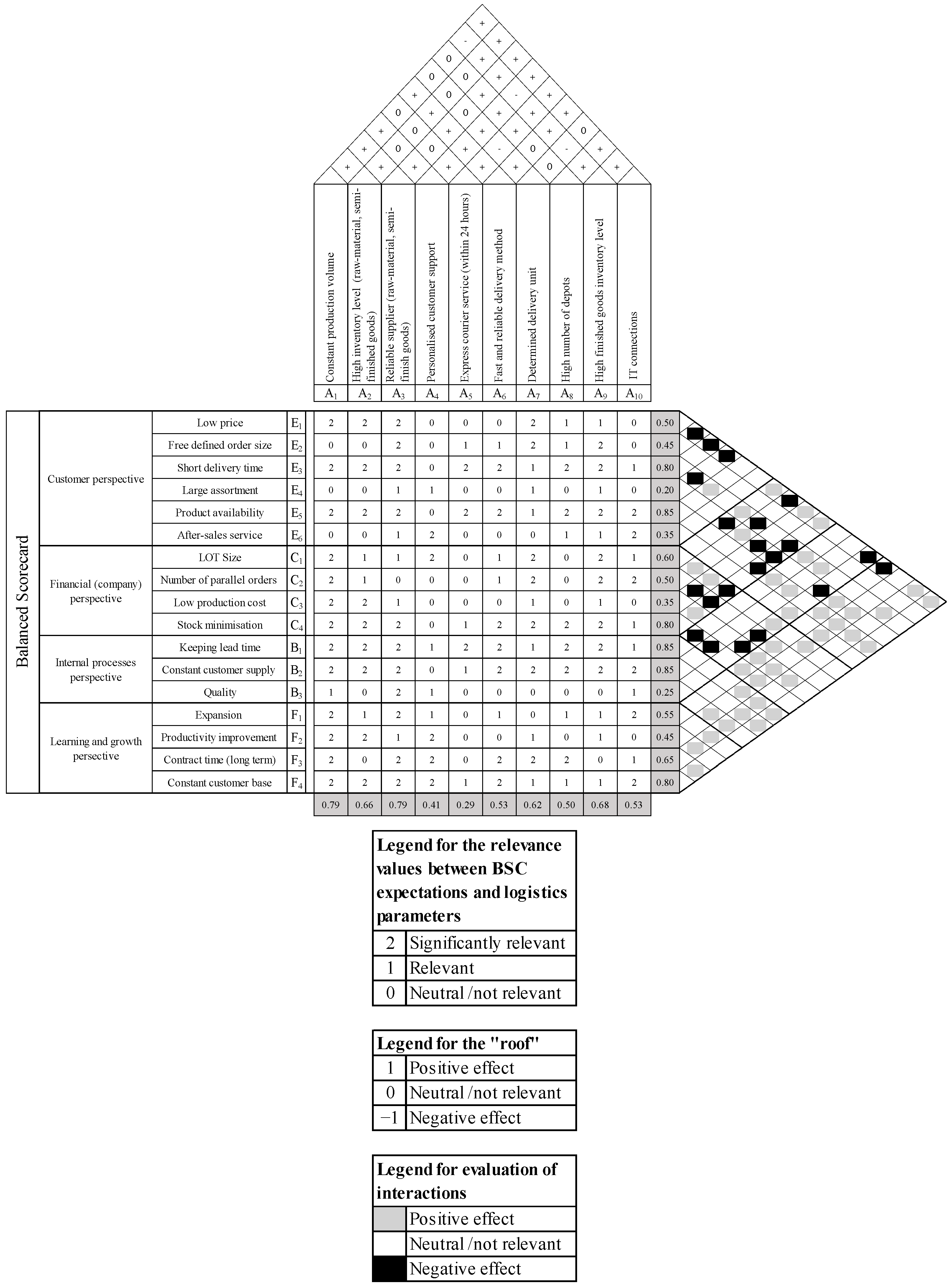

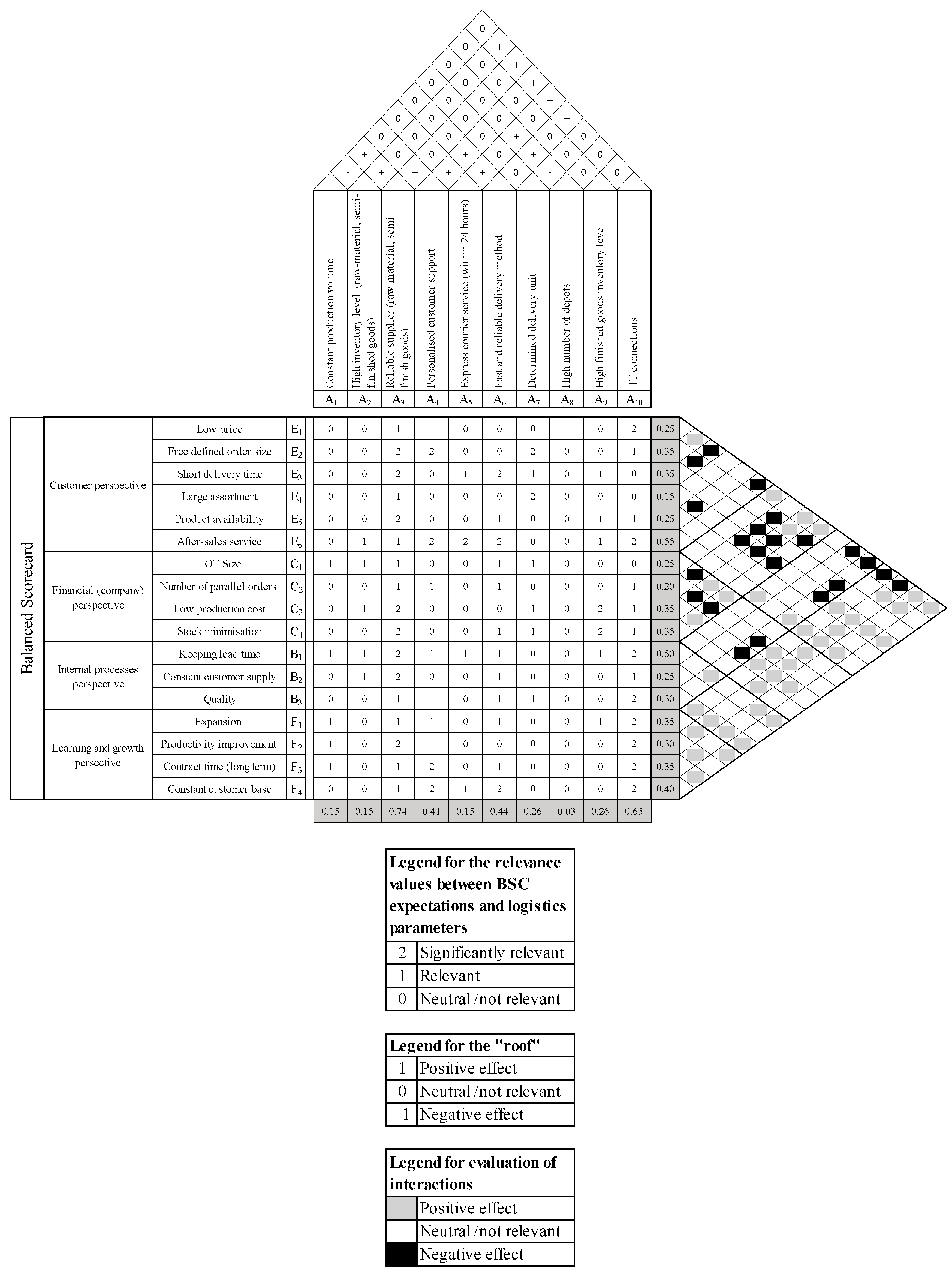

In connection with the joint use of the Balanced Scorecard and Quality Function Deployment, we created a diagram called Extended QFD (Figure 3 and Table 5), which was used to combine the strategic indicator system represented in BSC with the QFD technique.

Figure 3.

Extended QFD. Source: own compilation.

Table 5.

Legend for the matrix.

The BSC technique separately examines customer expectations, the company’s approach to financial and internal processes, and the activities that promote the company’s development, which means it strives for balance. The Extended QFD methodology developed combines the BSC technique with QFD to show where there are inconsistencies. For this purpose, the logistic requirements that can be defined according to the BSC structure are shown on the right-hand side of the matrix. For this example, general logistics-related expectations have been collected that are common to the expectations of customers and the company; they may vary depending on the product and the company culture.

In the legend of Table 6, it can be seen that in the Extended QFD, the relevance of the expectations collected from the BSC is first investigated with the logistic parameters. The values 0,1, and 2 have been used in the analysis, where 2 means that the expectation and the logistic parameter have a significant impact on one another for the product under consideration, 1 means that they have a moderate impact on each other, and 0 is neutral; that is, not relevant for the present product. In the present examples, with regard to the interaction effects, the logistic parameter has not been examined to determine whether it has a positive or negative impact on the expectation.

Table 6.

Legend for the effect of logistics parameters.

In the triangle at the top of the House of Quality, the interaction between the available logistical technical and service elements has been examined, with the legend in Table 5.

In this paper, the analysis of the values in the roof has not been performed, as the relevance of the expectations set by the BSC is focused on the logistic parameters, and therefore, the “inside” of the QFD provides the basis for the analysis.

Example products have been produced for the use of the Extended QFD system developed (Appendix A and Appendix B). The symbol explanation in Table 7 relates to the analysis of the interrelationship between the logistics-related requirements in BSC.

Table 7.

Legend for evaluation of interaction.

The example products show that if a logistics strategy is developed and then BSC is to be introduced, it becomes clear that the same indicators cannot be set by the corporate leadership towards the management because of the different nature of the product. The chosen products are as follows: Example 1—toothpaste (Appendix A); Example 2—mainframe computer (Appendix B).

3.1. Example 1

To demonstrate the methodology, the first example product (Appendix A) is toothpaste, a mass-produced product that should be available to consumers anywhere, anytime. It requires a push logistics strategy with a short lead time.

In terms of toothpaste, price (E1) and constant production volume (A1) take a value of 2. This means that price has a significant influence on production volume. For example, if there is a sudden price increase, demand is likely to fall, so continuous production will only increase the inventory. Conversely, if there is a price decrease, this is likely to generate higher demand.

Where most 1s are included, the parameters have a moderate impact on each other. For example, after-sales service (E6) and reliable raw materials and semi-finished goods suppliers (A3) influence each other. This is because the after-sales service can handle a customer complaint and quickly provide another product if it knows that the supply of raw materials and semi-finished goods is dynamic, i.e., it will not affect the constant production volume.

Where they take a value of 0, the elements do not affect each other, so no particular change is necessary for this product. For toothpaste, both free defined order size (E2) and personalized customer support (A4) are set to 0 because, for a mass product, it is possible to purchase both small and large quantities, and the product is available in a wide range, eliminating the need for personalized customer support.

3.2. Example 2

The example product (Appendix B) is the mainframe computer, a custom-built, high-end product. It requires a pull logistics strategy and, because of its specificity, usually has a long lead time.

In the case of Example 2, it can be seen that the parameters take on a completely different value during the relevance test than in the case of the product in Example 1. The values are determined, taking into account the specificity of the product in each case. For example, the price (E1) and the constant production volume (A1) for the mainframe computer take the value 0. As this is a unique product with a high price range, constant production is not usually a feature and, therefore, does not affect the price.

The after-sales service (E6) and the reliable raw-material, semi-finished goods supplier (A3) also have an impact here, taking the value 1. For this product, the relationship between after-sales service (E6) and reliable raw-material, semi-finished goods supplier (A3) is significant because, in the event of a failure of a high-price category product, the supply of spare parts must be ensured, and this is only possible if the firm has a reliable supplier.

For the mainframe computer, free defined order size (E2) and personalized customer support (A4) took 2 values. As it is a product with unique specializations, usually with an order unit of 1, the customer’s desire to buy, for example, 6 products at a time, is likely to require personalized customer support. This is because, in order to ensure that all 6 products have the same specifications in terms of hardware and software, it is also necessary to agree on how long it will take to produce this quantity, given the expected requirements, and how it will be installed.

3.3. Comparison of Example 1 and Example 2

After the relevance examination, the results of the columns (n) and the rows (m) should also be examined.

- = Relevance of BSC expectation and logistics parameters.

- n = The number of expectations established in BSC.

For columns (n), the current analysis is based on the importance of a given logistical technical parameter for the realization of the expectations set by BSC.

For Example, with 1, which is toothpaste, the constant production volume (A1) shows a value of 0.79. This means that this logistical parameter is very important for each of our desires in BSC because, as a mass product, the expectations of the customer and the company in terms of financial, process, and development can only be met if the company can produce continuously. If a mass-produced product is not available continuously, the customer will not be satisfied because they will not be able to buy the product anywhere. In addition, the company will not be able to stick to its targets, e.g., low production cost, keeping lead time, etc.

For Example 2, the mainframe computer, the constant production volume (A1) shows a value of 0.21. This means that the constant production volume is not relevant for a product made to order since it is not continuously produced; production starts after the order is received.

The number of rows (m) shows how useful a given technical element is in general, meaning how intensively it supports a ‘desire’:

- = Relevance of BSC expectation and logistics parameters.

- m = The number of logistics parameters.

In Example 1, toothpaste, the stated expectation is a short delivery time (E3), which is evaluated at 0.80. This means that it is supported by most of the logistic technical parameters, i.e., it is a feasible expectation for toothpaste.

For product No. 2—the mainframe computer—the short delivery time (E3) expectation is assessed at 0,35, which means that this expectation is not feasible for a custom-made product using the present logistical technology and service elements.

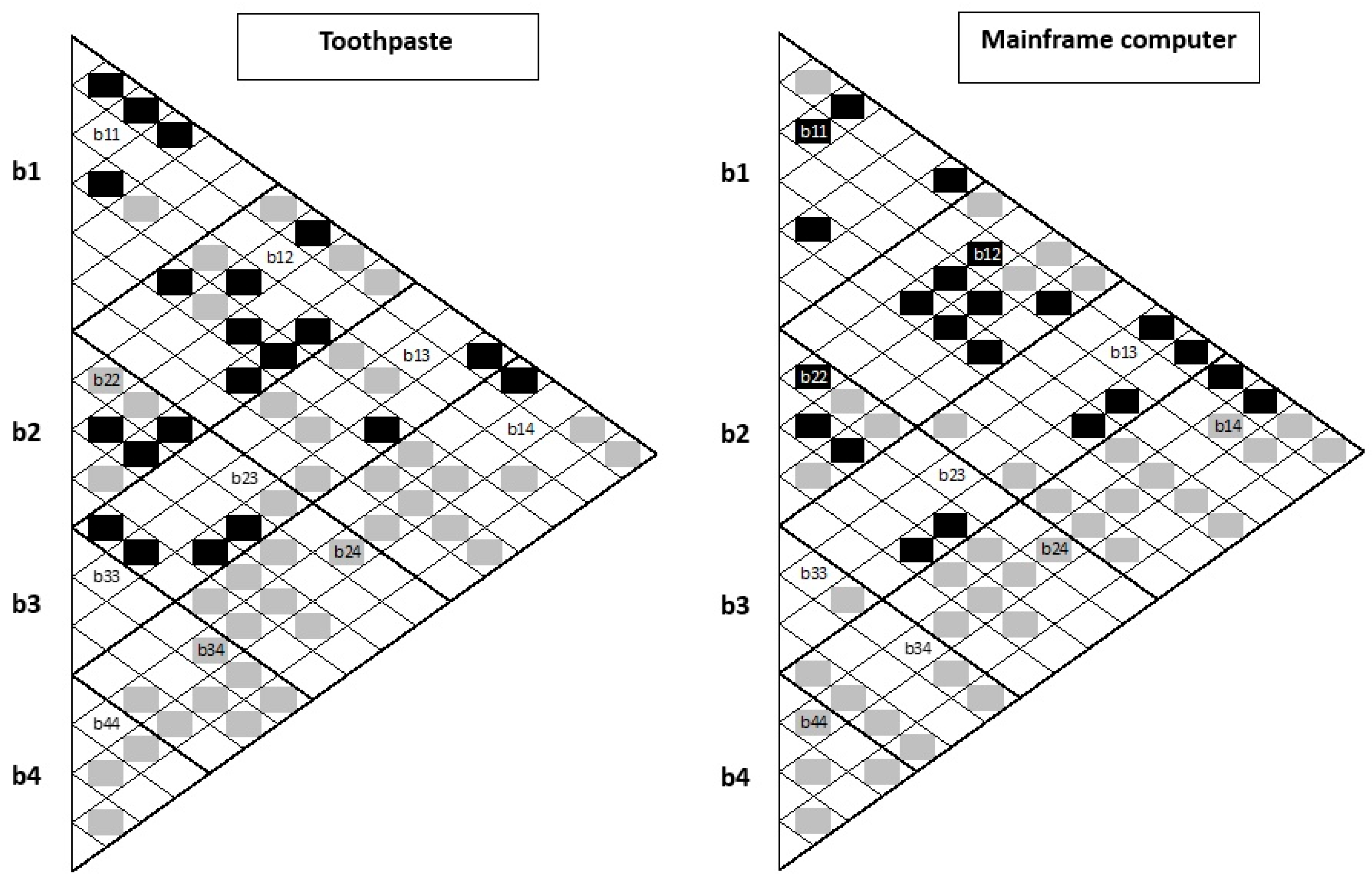

3.4. Examining the Relevance Between BSC Requirements in Example Products

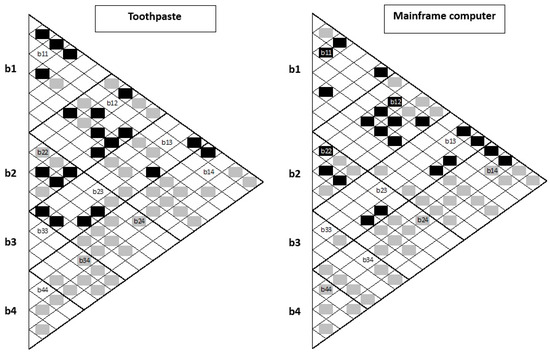

In BSC, the four perspectives (customer, financial, internal processes, learning, and growth) were linked to the formulated logistics-related expectations, and the relevance between them was also evaluated separately based on Examples 1 and 2 (Appendix A and Appendix B) and Table 7. Following the legend in Table 8, expectations that have a positive impact on each other are marked in gray, negative impacts are marked in black, and those that have no effect or are not relevant for the product in question are marked in white. Once the assessment was completed, the impacts were analyzed, and the results are presented in Table 8.

Table 8.

Data for the analysis for evaluation of BSC interactions (Appendix A and Appendix B).

As illustrated in Appendix A and Appendix B and Table 8, the positive and negative effects proportions show similar results. However, for the sample products in the appendix, it is clear that the evaluated expectations defined in BSC show positive and negative interactions in different places.

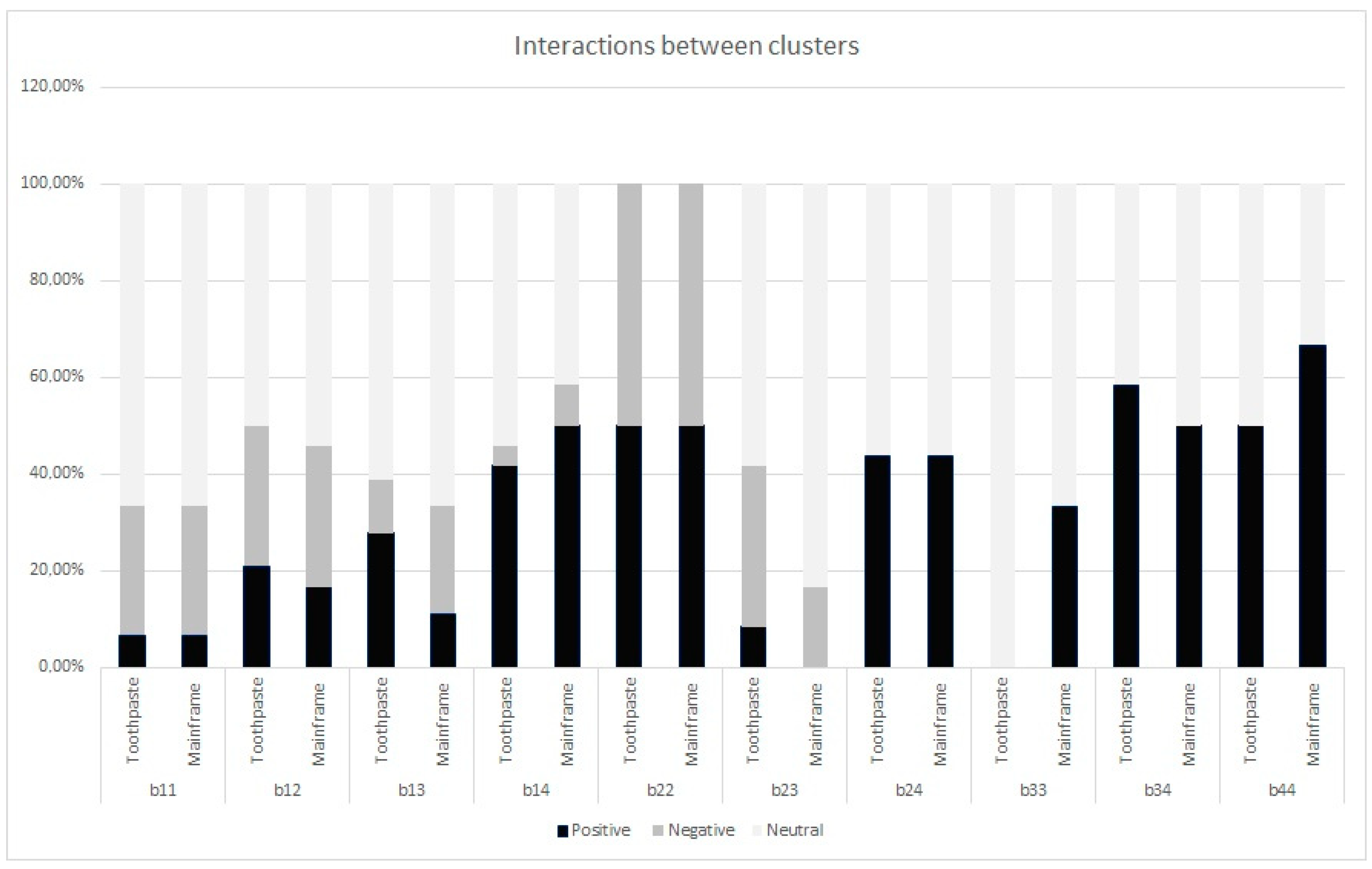

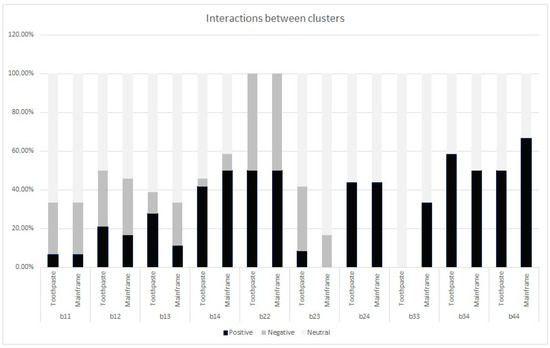

To see this, the interactions are also examined by cluster (Figure 4), and for each cluster, the proportion of positive and negative values associated with the interactions is calculated (Table 8).

Figure 4.

The interaction of BSC parameters. b = Clusters in the interaction of BSC parameters.

Table 9 demonstrated that the percentages of interactions of positive and negative effects are very similar for the toothpaste and mainframe computer; however, Figure 4 and Table 9 apparently show the same % value, but the distribution and location of positive interactions are not the same, and the location of the contrasts are different. This means that the focus should be placed elsewhere on different products. Within this, the clusters b11, b22, b33, and b44 should also be examined separately, where the expectations within BSC, defined from one perspective, can be seen. If many negative contradictions can be identified within clusters b11, b22, b33, and b44, it means that in that particular area, where the expectations come from, it is not clear exactly what is wanted from the product. In other words, these areas need to be focused on because internal controversies have an impact on customer service through logistics processes.

Table 9.

Distribution of positive and negative interactions within clusters.

Figure 5 illustrates the interactions within clusters. It shows the differences within each cluster for the product evaluated in Appendix A and Appendix B, with the percentages also shown in Table 9.

Figure 5.

Interaction of clusters.

It is clearly visualized in Figure 5 that although the same expectations are formulated for products requiring different logistics strategies and lead times, completely different technical and service elements are prioritized to fulfill the expectations formulated in the Balanced Scorecard. In other words, they may show very similar percentages on the overall average, but the inconsistencies in each cluster show in which areas the percentage of controversies is high and where the focus needs to be placed in order to ensure that the logistics strategy is sustainable in the context of the performance indicators defined in the Balanced Scorecard.

Certain limitations may affect the performance of the analysis. The precise definition of expectations and indicators is important in this area, and the method’s effectiveness depends on it. In some cases, however, the expectations themselves may be weakly defined, uncertain, subjective, or potentially subject to cognitive bias [42]. On the other hand, the interpretation and quantification of indicators may also cause difficulties, such as what counts as ‘fast’, what unit of measurement is used, etc. In this sense, the practical application of the proposed methodology will only lead to the right result if it is based on sound professional principles.

This publication aims to present a useful methodology for investigating the interdisciplinary nature of logistics by analyzing the expectations of different disciplines based on the parameters of the services provided by logistics and the logistics environment. This methodology can be used as a “first step in conflict resolution” to make inconsistencies visible. In the process of using this methodology, expectations can be transformed into fuzzy sets [43,44] that help companies to quantify the discrepancies between the expectations of the different disciplines.

4. Conclusions

Planning logistics strategies is a significant challenge for experts, for which a methodology has long been sought. The COVID-19 epidemic highlighted the vulnerability of the supply chain, and today, the adequacy of logistics processes, including strategies, is even more critical.

In this publication, the Extended QFD methodology was presented, which is a combination of QFD and BSC techniques, designed to meet customer requirements and to serve the company’s interests. The methodology developed has been represented by examples. For the example products, the interactions between the different expectations have been evaluated and the focus has been on the controversies during the expectations.

BSC, combined with QFD, not only allows the voice of the customer to be ‘translated’ but also long-term development in the company’s internal processes while keeping in mind its financial interests, which means that the sustainability of the corporate strategy can be achieved.

The future plan is to explore research directions such as the scalability of the Extended QFD methodology using fuzzy sets, thus quantifying uncertainties in the logistics field.

Author Contributions

Conceptualization, E.S. and P.F.; methodology, E.S. and P.F.; formal analysis, E.S.; investigation, E.S.; resources, E.S. and P.F.; writing—original draft preparation, E.S.; writing—review and editing, E.S. and P.F.; visualization, P.F.; supervision, P.F.; project administration, P.F.; funding acquisition, E.S. and P.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A. Example 1: Toothpaste

Appendix B. Example 2: Mainframe Computer

References

- Long, L.N.B.; Cuong, T.N.; Kim, H.-S.; You, S.-S. Sustainability and robust decision-support strategy for multi-echelon supply chain system against disruptions. Int. J. Logist. Res. Appl. 2023, 27, 1953–1983. [Google Scholar] [CrossRef]

- Prataviera, L.B.; Creazza, A.; Perotti, S.; Rodrigues, V.S. How to align logistics environmental sustainability with corporate strategy? An Italian perspective. Int. J. Logist. Res. Appl. 2023. [Google Scholar] [CrossRef]

- QFD: Past, Present, and Future. 1997. Available online: http://www.las.inpe.br/~perondi/19.10.2009/Akao_1997_QFD_History.pdf (accessed on 9 February 2024).

- Buics, L.; Horváth, Z.C.; Földesi, P.; Eisinger, B.B. An assessment of traffic education and its examination system—An extended House of Quality approach. Humanit. Soc. Sci. Commun. 2024, 11, 91. [Google Scholar] [CrossRef]

- Sós, E.; Földesi, P. Application of the QFD Technique Method in Logistics Strategy. Acta Polytech. Hung. 2023, 20, 145–164. [Google Scholar] [CrossRef]

- Nelson, J.; Ding, A.; Mann, S.; Parsons, M.; Samei, E. Key Performance Indicators for Quality Imaging Practice: Why, What, and How. J. Am. Coll. Radiol. 2022, 19, 4–12. [Google Scholar] [CrossRef]

- Suárez-Gargallo, C.; Zaragoza-Sáez, P. A comprehensive bibliometric study of the balanced scorecard. Eval. Program Plan. 2023, 97, 102256. [Google Scholar] [CrossRef]

- de Souza Machado, A.C.C.; Filho, G.L.T.; de Abreu, T.M.; Facchini, F.; da Silva, R.F.; Pinto, L.F.R. Use of Balanced Scorecard (BSC) Performance Indicators for Small-Scale Hydropower Project Attractiveness Analysis. Energies 2023, 16, 6615. [Google Scholar] [CrossRef]

- Hossain, M.S.; Zhou, X.; Rahman, M.F. Customer satisfaction under heterogeneous services of different self-service technologies. Manag. Mark. 2019, 14, 90–107. [Google Scholar] [CrossRef]

- Kaplan, R.S.; Norton, D.P. The balanced scorecard--measures that drive performance. Harv. Bus. Rev. 1992, 70, 71–79. [Google Scholar]

- Trudel, J. The Balanced Scorecard: Translating Strategy into Action; Kaplin, R.S., Norton, D.P., Eds.; Harvard Business School Press: Boston, MA, USA, 1996; p. 336. [Google Scholar]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Akao, Y. The Method for Motivation by Quality Function Deployment (QFD). Nang Yan Bus. J. 2014, 1, 1–9. [Google Scholar] [CrossRef]

- Chan, L.K.; Wu, M.L. A systematic approach to quality function deployment with a full illustrative example. Omega (Westport) 2005, 33, 119–139. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A.; Gazda, A. A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy. Energies 2023, 16, 2474. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.A. A multi-phased QFD based optimization approach to sustainable service design. Int. J. Prod. Econ. 2016, 171, 165–178. [Google Scholar] [CrossRef]

- Bottani, E.; Rizzi, A. Strategic management of logistics service: A fuzzy QFD approach. Int. J. Prod. Econ. 2006, 103, 585–599. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, R.; Alfaro-Saiz, J.J.; Carot, J.M. A dynamic supply chain BSC-based methodology to improve operations efficiency. Comput. Ind. 2020, 122, 103294. [Google Scholar] [CrossRef]

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Borucki, C.; Karaca, F. Performance assessment of construction companies for the circular economy: A balanced scorecard approach. Sustain. Prod. Consum. 2022, 33, 991–1004. [Google Scholar] [CrossRef]

- Fabac, R. Digital Balanced Scorecard System as a Supporting Strategy for Digital Transformation. Sustainability 2022, 14, 9690. [Google Scholar] [CrossRef]

- Chytas, P.; Glykas, M.; Valiris, G. A proactive balanced scorecard. Int. J. Inf. Manag. 2011, 31, 460–468. [Google Scholar] [CrossRef]

- Asosheh, A.; Nalchigar, S.; Jamporazmey, M. Information technology project evaluation: An integrated data envelopment analysis and balanced scorecard approach. Expert Syst. Appl. 2010, 37, 5931–5938. [Google Scholar] [CrossRef]

- Banu, G.S. Measuring innovation using key performance indicators. Procedia Manuf. 2018, 22, 906–911. [Google Scholar] [CrossRef]

- Crotts, J.C.; Magnini, V.P.; Calvert, E. Key performance indicators for destination management in developed economies: A four pillar approach. Ann. Tour. Res. Empir. Insights 2022, 3, 100053. [Google Scholar] [CrossRef]

- BSC Designer. 2019. Available online: https://bscdesigner.com/bsc-vs-kpi-software.htm (accessed on 16 June 2023).

- Orbán, Z. E-Learning Projekek Sikertényezői: Az E-Learning Megoldások Actor-Network Theory Elemzése. PhD. Thesis, Budapesti Corvinus Egyetem Közgazdasági, Budapest, Hungary, 2021. [Google Scholar]

- Gunduz, M.; Al-Naimi, N.H. Construction projects delay mitigation using integrated balanced scorecard and quality function deployment. Eng. Constr. Archit. Manag. 2022, 29, 2073–2105. [Google Scholar] [CrossRef]

- Goharshenasan, A.; Sheikh Aboumasoudi, A.; Shahin, A.; Ansari, A. Prioritizing the economic indicators of SSC: An integrative QFD approach of performance prism and BSC. Benchmarking 2022, 29, 522–550. [Google Scholar] [CrossRef]

- Agarwal, A. Investigating design targets for effective performance management system: An application of balance scorecard using QFD. J. Adv. Manag. Res. 2020, 18, 353–367. [Google Scholar] [CrossRef]

- Sirin, O.; Gunduz, M.; Moussa, A. Application of Tools of Quality Function Deployment and Modified Balanced Scorecard for Optimal Allocation of Pavement Management Resources. IEEE Access 2020, 8, 76399–76410. [Google Scholar] [CrossRef]

- Jonny, J.; Zagloed, T.Y.M. The development of an integrated Indonesian health care model using Kano’s model, quality function deployment and balanced scorecard. AIP Conf. Proc. 2017, 1902, 020031. [Google Scholar]

- Li, Y.L.; Huang, M.; Chin, K.S.; Luo, X.G.; Han, Y. Integrating preference analysis and balanced scorecard to product planning house of quality. Comput. Ind. Eng. 2011, 60, 256–268. [Google Scholar] [CrossRef]

- Barad, M.; Dror, S. Strategy maps as improvement paths of enterprises. Int. J. Prod. Res. 2008, 46, 6627–6647. [Google Scholar] [CrossRef]

- Dror, S. The Balanced Scorecard versus quality award models as strategic frameworks. Total Qual. Manag. Bus. Excell. 2008, 19, 583–593. [Google Scholar] [CrossRef]

- Lee, S.F.; Lo, K.K. E-enterprise and management course development using strategy formulation framework for vocational education. J. Mater. Process. Technol. 2003, 139, 604–612. [Google Scholar] [CrossRef]

- Kiran, D.R. Quality Function Deployment. Total Qual. Manag. 2017, 425–437. [Google Scholar] [CrossRef]

- Mangukiya, R.D.; Sklarew, D.M. Analyzing three pillars of sustainable development goals at sub-national scales within the USA. World Dev. Sustain. 2023, 2, 100058. [Google Scholar] [CrossRef]

- Liu, L.; Xu, H.; Zhu, S.X. Push verse pull: Inventory-leadtime tradeoff for managing system variability. Eur. J. Oper. Res. 2020, 287, 119–132. [Google Scholar] [CrossRef]

- Ozili, P.K. Sustainability accounting. Contemp. Stud. Econ. Financ. Anal. 2022, 108A, 171–180. [Google Scholar]

- Rodríguez-Fernández, M.; Gaspar-González, A.I.; Sánchez-Teba, E.M. Sustainable social responsibility through stakeholders engagement. Corp. Soc. Responsible Environ. Manag. 2020, 27, 2425–2436. [Google Scholar] [CrossRef]

- Elg, U.; Welinder, A. Sustainabilty and retail marketing: Corporate, product and store perspectives. J. Retail. Consum. Serv. 2022, 64, 102810. [Google Scholar] [CrossRef]

- Földesi, P.; Botzheim, J.; Süle, E. Representation of loss aversion and impatience concerning time utility in supply chains. Smart Innov. Syst. Technol. 2011, 10, 273–282. [Google Scholar]

- Földesi, P.; Sós, E. Assessing logistics strategy issues under cognitive biases. In Proceedings of the 14th IEEE International Conference on Cognitive Infocommunications, Budapest, Hungary, 22–23 September 2023; pp. 141–146. [Google Scholar]

- Földesi, P.; Botzheim, J.; Süle, E. Fuzzy approach to utility of time factor. In Proceedings of the 2009 4th International Symposium on Computational Intelligence and Intelligent Informatics, Luxor, Egypt, 21–25 October 2009; pp. 23–29. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).