1. Introduction

Guided by the improvements in technology and dynamic market demands, the landscape of manufacturing and supply chain management has endured an important transformation in recent years [

1]. Characterized by mass production and long lead times, the classic centralized supply chain model is progressively being shifted by decentralized supply chains that leverage innovative manufacturing techniques [

2,

3]. The change, obviously shown in the use of 3D printing technologies, such as Fused Deposition Modeling (FDM), permits organizations to produce goods closer to the point of consumption [

4].

This path will not only increase responsiveness and flexibility but also facilitate mass customization, allowing businesses to meet the varied needs of their customers more definitely [

5].

Fused Deposition Modeling is a globally recognized 3D printing technology that works by extruding thermoplastic materials through a heated nozzle, layer by layer, to create three-dimensional objects [

6]. This approach has gained fame considering its cost-effectiveness, ease of use, and ability to produce complex geometries, things that are commonly difficult to achieve with traditional manufacturing methods [

4]. FDM is notably useful for decentralized supply chains, as it grants on-demand production, minimizing the need for extensive inventory and reducing waste [

7]. By approving localized manufacturing, FDM can actually shorten lead times and enhance supply chain agility, making it an engaging option for businesses seeking to adapt to quickly changing market conditions [

8].

The assimilation of machine learning (ML) into decentralized supply chains shows a critical improvement in optimizing operations and decision-making processes [

9]. Machine learning, a huge part of artificial intelligence, includes the development of algorithms that can learn from and make predictions based on data [

10]. In the world of supply chain management, ML can be used to analyze enormous amounts of data generated throughout the supply chain, giving the chance to organizations to enhance demand forecasting, increase inventory management, and improve overall operational efficiency [

11].

Various challenges must be analyzed to absolutely realize the huge advantage of the combination of FDM and machine learning in decentralized supply chains. First, one of the most important challenges is the complexity of implementing these technologies within existing supply chain frameworks [

12]. The outstanding combination of FDM and machine learning requires a comprehensive understanding of both the technical and operational aspects involved. Organizations must invest in the mandatory infrastructure, such as hardware, software, and skilled personnel, to effectively leverage these technologies. Also, the demand for interdisciplinary collaboration between software engineers, data scientists, and manufacturing experts is necessary to make sure that the solutions developed are practical and aligned with the specific needs of the organization [

11].

This systematic review will try to examine the actual situation of research and studies on decentralized supply chains using FDM, with a special focus on the application of machine learning techniques for improvement. By synthesizing findings from the existing literature, we intend to define the best practices, find key challenges, and provide a framework for future research directions in this field. The review will express a comprehensive analysis of the advantages and limitations of FDM and machine learning in decentralized supply chains, as well as their connection to operational performance and competitiveness [

1].

Ultimately, although numerous research has investigated the optimization of FDM production parameters through artificial intelligence, they predominantly concentrate on enhancing discrete manufacturing processes without considering the wider implications for decentralized supply chain management. So far, minimal research has explored how an integrated methodology that combines FDM, machine learning, and decentralized supply chains may improve production efficiency and supply chain coordination.

This research seeks to elucidate how decentralized supply chains might utilize innovative manufacturing and data-driven techniques to enhance operational performance and competitiveness. This study aims to elucidate the present state of research and identify gaps in the literature, thereby informing practitioners and academics to facilitate the effective application of FDM and machine learning in decentralized supply chain networks.

Finally, this review seeks to elucidate how decentralized supply chains might utilize innovative manufacturing and data-driven techniques to enhance operational performance and competitiveness. This study aims to elucidate the present research landscape and identify gaps in the literature, thereby informing practitioners and academics to facilitate the effective application of FDM and machine learning in decentralized supply chains.

2. Theoretical Background

Decentralized supply chains leveraging Fused Deposition Modeling (FDM) as a framework for optimization are studied from two main perspectives: their practical applicability in solving real-world challenges and their adoption by industries seeking to enhance operational efficiency [

13]. Both academia and industry have been actively working to develop and refine the body of literature and tools surrounding decentralized supply chains and FDM-based optimization frameworks. Over the past few years, there has been a notable increase in the number of frameworks addressing decentralized supply chains, driven by advancements in additive manufacturing and machine learning.

However, many academic frameworks for decentralized supply chains remain underutilized in industry, as they often lack the pragmatism required to meet the rapidly evolving demands of businesses. This gap highlights the challenge of bridging theoretical advancements with practical implementations [

14].

In this context, frameworks for decentralized supply chains serve as tools for companies to assess their current status and determine the changes needed to achieve greater flexibility and efficiency. However, these frameworks are not universally applicable; some are designed for specific sectors, while others adopt a broader scope. Regardless of their focus, they represent significant contributions to the understanding and application of FDM in decentralized supply chains. These frameworks can vary in their short-, medium-, and long-term goals, offering organizations tools for realignment, capacity building, and operational transformation [

15].

A key challenge in this area lies in the fact that many frameworks for decentralized supply chains and FDM are treated as proprietary knowledge by academic institutions and industry organizations. This limits public access to complete or final versions of these frameworks, contributing to existing research gaps in this continuously evolving field. Addressing these gaps requires greater collaboration between academia and industry, open sharing of insights, and a focus on the integration of emerging technologies such as machine learning to unlock the full potential of decentralized supply chains. In this purview, the first and the most important research question that this review paper aims to answer is the following:

Research Question 1: What are the key concepts and terminologies used in the context of decentralized supply chains and Fused Deposition Modeling?

Decentralized supply chains and additive manufacturing (AM), essentially, Fused Deposition Modeling (FDM), have transformed supply chain management by enabling localized production, minimizing lead times, and improving customization capabilities [

16]. Decentralized supply chains divide production and logistics processes across multiple actors, fostering flexibility and responsiveness to demand variability [

12]. Research explains that the assimilation of AM into supply chains minimizes inventory levels, improves material flows, and reduces waste, while also encouraging sustainability through energy efficiency and minimized material consumption [

12,

16].

FDM, a well-used AM technology, creates objects layer by layer using thermoplastic materials, making it slightly efficient for manufacturing small batches and customized products in industries including aerospace [

17], education [

18], electronics [

19], tool making [

20], automotive [

21], and medical industry [

22]. In addition, AM transformed traditional supply chain structures by introducing real-time demand forecasting, progressed inventory management, and decentralized production strategies, which enhance overall efficiency and responsiveness [

3].

The healthcare industry illustrates the potential of AM, where decentralized production of medical devices and implants minimizes logistical constraints and guarantees high levels of customization [

23]. Hence, the second research question of this study is the following:

Research Question 2: What machine learning approaches have been applied for optimizing FDM?

Blending machine learning (ML) into decentralized supply chains has shown notable potential in improving manufacturing efficiency and product quality. ML algorithms have been utilized to predict surface roughness, detect defects, and improve process parameters, leading to optimized manufacturing results. For example, supervised learning techniques have been used to predict surface finish quality, allowing real-time adaptation during the printing process [

24].

In addition, ML methods have been used to forecast feature dimensions in FDM-produced components, helping in maintaining dimensional accuracy and minimizing material waste [

4].

Additionally, the blending of ML in FDM processes has ensured the growth of predictive models for mechanical properties, improving the reliability and performance of manufactured parts [

4,

24].

Therefore, the third and final research question of this study is the following:

Research Question 3: What machine learning approaches have been applied for optimizing decentralized supply chains?

3. Methodology

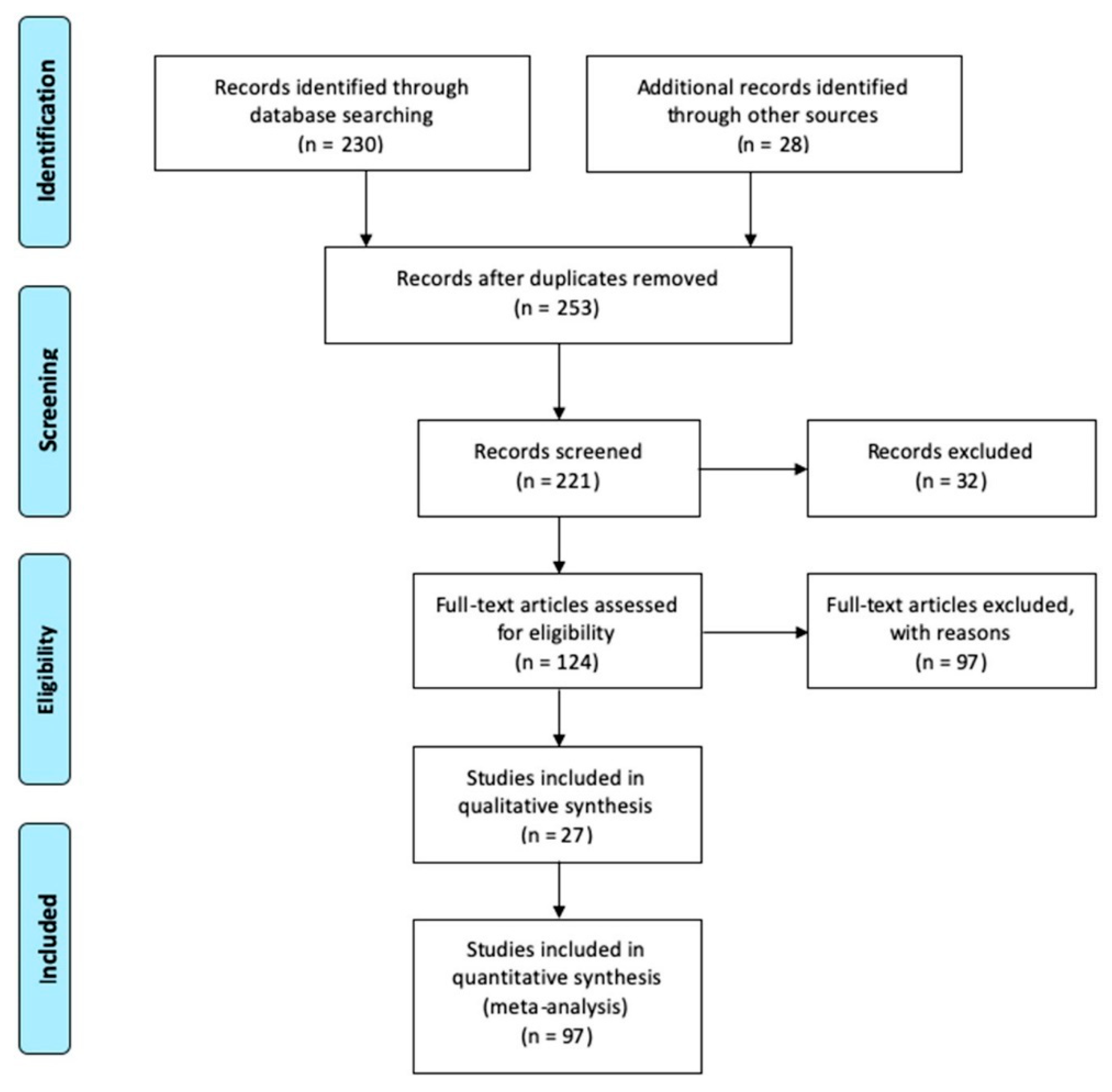

As this paper aims at specific results through three independent research questions, the systematic literature review is more appropriate than the broad traditional literature review. Thereon, to contribute to the existing body of knowledge on decentralized supply chains using Fused Deposition Modeling (FDM), a systematic literature review (SLR) methodology of Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) by Moher and Liberati was deployed [

25]. PRISMA is an evidence-based reporting standard that is effective for critical appraisal. The technique of SLR methodology is particularly helpful as it meticulously summarizes the available research in response to research questions [

26]. Furthermore, the inclusion and exclusion criteria, with two attempts at the reduction in articles as per this technique lead to a targeted list of articles. In this paper, this review technique has helped considerably in exploring the various readiness models available and then narrowing down the choices to merely Industry 4.0 readiness models and 4.0 readiness dimensions. Overall, the steps of systematic methodology adapted for this review article are shown in

Figure 1. By definition, a systematic review is an examination of a clearly formulated question that uses explicit methods to critically appraise research. This can be performed with or without statistical procedures [

27]. This literature review has been designed in a structured and rigorous manner. It is replicable, and, hence, it can be updated in the future with the state-of-the-art findings on Industry 4.0 readiness.

For data analysis, the methodology was further supported by content analysis, as it is often preferred in the social sciences. Content analysis can be described as a systematic technique in which certain words (codes) in a text are summarized within categories [

28]. Likewise, for this review paper, themes were constructed based on similar contexts and meanings, which led to the findings that are depicted in the next section of this paper [

29].

A thorough review of the existing literature on topics related to decentralized supply chains using Fused Deposition Modeling (FDM) was conducted, resulting in 97 articles identified within a timeline spanning from 2009 to 2024. The literature search utilized four main keywords, covering 18 publishers and databases, as shown in

Table 1. This systematic review applied both inclusion and exclusion criteria, as detailed in

Table 2. The criteria were based on three main factors: the type of literature, language, and timeline.

Given that the majority of relevant literature is published in English, this review provides a comprehensive overview of available resources. Informal sources such as magazine articles, often lacking academic rigor, were excluded. However, industry reports and whitepapers from credible consultancy firms were included due to their relevance and practical insights. Of the 102 full-text articles initially screened, 28 (27%) were qualitative, while 74 (73%) were quantitative.

Two elimination rounds were conducted, following the PRISMA approach, which ultimately identified 97 articles for detailed review and discussion. These articles spanned a timeline from 2009 to 2024. The first elimination round categorized the literature into conceptual, theoretical, and empirical studies. The second elimination round involved extensive full-text analysis to retain only studies that directly aligned with the research objectives. Papers that did not provide frameworks for decentralized supply chains, optimization approaches, or integration of FDM with machine learning techniques were excluded.

The findings from this systematic review form the basis for the next section, focusing on the role of FDM in decentralized supply chains and the optimization potential offered by machine learning techniques.

4. Results

This review paper’s research aims to entail a comprehensive literature assessment of 97 selected publications on Fused Deposition Modeling (FDM) concerning the application of machine learning (ML) in dematerialized transportation, revealing two primary findings: a compilation of current FDM optimization models utilizing AI and the delineation of critical factors influencing AI-driven progress in FDM-based logistics systems.

An exhaustive examination of 30 established decentralized supply chain readiness models utilizing Fused Deposition Modeling (FDM) identifies six principal dimensions frequently employed in these models: technology, infrastructure, process efficiency, data-driven decision making, sustainability, and innovation. These dimensions signify the essential elements required for enhancing decentralized supply networks through the FDM architecture.

Table 3 below classifies and aggregates distinct dimensions derived from these models. The initial column enumerates the precise terminology of dimensions identified in the current decentralized supply chain preparedness models. The second column presents the tally of these dimensions, categorized according to semantic and functional similarities. The third column delineates the proposed pooled dimensions, amalgamating analogous features into overarching categories.

Table 3 illustrates that the predominant individual dimensions are associated with technology, underscoring the essential significance of technology breakthroughs, including automation, IoT, and digital integration, in the optimization of decentralized supply chains. The second most cited feature is Infrastructure, highlighting the significance of distributed manufacturing facilities, logistics networks, and digital platforms in facilitating decentralized supply chains.

Other dimensions, such as process efficiency, data-driven decision making, and sustainability, exhibit roughly similar representation, underscoring their importance in improving the adaptability, precision, and environmental effect of decentralized supply chains. The dimension least usually cited is Innovation, indicating that although it contributes to supply chain change, it is typically integrated within larger technological and strategic contexts.

Numerous research has investigated the use of machine learning (ML) to optimize additive manufacturing (AM) parameters; however, they often lack a thorough quantitative assessment of the model’s efficacy. Metrics like Mean Squared Error (MSE) and coefficient of determination (R²) are crucial for assessing the accuracy of predictive models, whereas precision, recall, and F1-score are typically employed for evaluating classification models. A comprehensive examination of these measures within the framework of distributed manufacturing and decentralized supply chains is still a domain to be investigated. Consequently, we advise that subsequent studies integrate these variables to guarantee a comprehensive assessment of machine learning methodologies utilized in optimizing additive manufacturing supply chains.

Consequently, the amalgamation of these six fundamental characteristics offers a systematic viewpoint on the essential elements required for evaluating and enhancing decentralized supply chains through FDM and machine learning methodologies.

Table 3 gives a summary of the different aspects that have been found in current digital readiness models for decentralized supply chains. The proposed pooled dimensions are shown in bold in the third column. They are made up of individual elements that are similar in terms of their ideas and how they work. These combined groups—Technology, Infrastructure, Process Efficiency, Data-Driven Decision Making, Sustainability, and Innovation—make it easier to judge how ready a decentralized supply chain is. The bold formatting shows how important these categories are for optimizing decentralized systems through additive manufacturing and machine learning methods.

This systematic research underscores the transformational impact of Fused Deposition Modeling (FDM) on decentralized supply chains, especially when combined with machine learning (ML). The expanding corpus of academic and practical implementations demonstrates that AI-driven optimization is progressively transforming FDM-based manufacturing and logistics. This progression presents a series of obstacles that must be resolved for extensive application.

5. Discussion

This review paper was conceived based on three research questions, as stated in the Introduction Section. This section will lead a discussion on those three questions in the same order.

Research Question 1: What are the key concepts and terminologies used in the context of decentralized supply chains and Fused Deposition Modeling?

Research on decentralized supply networks and Fused Deposition Modeling (FDM) has garnered considerable attention in the existing literature and relevant knowledge base. This analysis concentrates on two domains to investigate the confluence between decentralized supply networks and additive manufacturing.

Our examination of keyword co-occurrence networks identified the correlation of decentralized supply chains with several fundamental ideas, including blockchain technology, smart contracts, distributed ledger systems, traceability, transparency, resilience, and supply chain autonomy. These features are essential for facilitating decentralized networks, wherein decision making is dispersed instead of centralized, hence providing security, trust, and operational efficiency.

In the realm of FDM, often, referenced terms in the literature encompass material extrusion, thermoplastic filaments, layer-by-layer deposition, print resolution, infill density, topology optimization, and process parameters. The significance of FDM in decentralized supply chains arises from its capacity to facilitate on-demand manufacturing, diminish lead times, and improve supply chain flexibility.

The fundamental connection between decentralized supply chains and FDM is their mutual focus on autonomy, adaptability, and data-informed decision making. The incorporation of AI methodologies further fortifies this connection by improving process optimization, predictive maintenance, defect identification, and supply chain coordination. Decentralized supply chain models utilizing FDM have garnered heightened academic interest from an operational standpoint, especially in tackling issues associated with customization, digital inventory management, and remote production networks.

The integration of dispersed supply chains and FDM underscores the increasing significance of digital technologies, intelligent manufacturing, and AI-enhanced decision support in the evolution of supply chain management. The variety of these technologies offers decision-makers numerous alternatives to optimize resource use, guarantee sustainability, and improve the adaptability of supply chain networks in a complex and dynamic environment.

Research Question 2: What machine learning approaches have been applied for optimizing FDM?

The incorporation of machine learning (ML) in Fused Deposition Modeling (FDM) has shown considerable promise in improving production efficiency, product quality, and process dependability. Diverse machine learning strategies have been utilized to boost critical elements of Fused Deposition Modeling, encompassing process parameter optimization, surface quality prediction, defect identification, mechanical property improvement, and material utilization optimization.

A significant problem in FDM is the selection of ideal process parameters, including extrusion temperature, layer height, print speed, and infill density, which directly influence part quality. Machine learning algorithms, especially supervised learning methods such as regression models and artificial neural networks (ANNs), have been trained on historical printing data to forecast optimal parameters, thereby enhancing surface smoothness and dimensional accuracy while reducing defects and material waste.

Machine learning-based predictive models have been utilized to anticipate surface roughness and identify printing problems in real time. Algorithms like Support Vector Machines (SVM) and Random Forests categorize defective prints, facilitating real-time modifications and enhancing uniformity. Deep learning models, such as Convolutional Neural Networks (CNNs), have been utilized in computer vision applications to evaluate layer adhesion quality and detect anomalies throughout the printing process.

Ensuring the mechanical stability of FDM-printed components is a significant task in which machine learning is instrumental. Supervised learning techniques, including artificial neural networks and ensemble learning methods, have been employed to forecast mechanical performance based on material characteristics, processing conditions, and environmental variables. These prediction models assist producers in refining print parameters to attain optimal strength, toughness, and durability.

Minimizing material waste while preserving part integrity is another domain where machine learning has been effectively applied. Reinforcement learning and optimization algorithms evaluate historical print jobs to identify optimal infill patterns and density levels, balancing material usage and structural integrity. By utilizing these insights, machine learning facilitates effective material utilization and improves sustainability in additive manufacturing.

Furthermore, machine learning-based predictive maintenance methods have been utilized to detect probable faults in FDM printers prior to their occurrence. Anomaly detection systems examine sensor data from the printing process, including temperature variations, extrusion rates, and motor vibrations, to anticipate wear and tear. This proactive strategy minimizes downtime, guarantees uniform print quality, and improves overall machine dependability.

Machine learning is emerging as a disruptive technology for FDM, providing robust solutions for process optimization, defect reduction, and enhancement of mechanical properties. Utilizing supervised learning, deep learning, and reinforcement learning methodologies, machine learning empowers producers to optimize print settings, elevate quality control, and augment the overall efficiency of additive manufacturing operations. With the progression of research, machine learning is anticipated to assume a more pivotal position in the evolution of intelligent and adaptive FDM systems, underscoring its potential as a transformative force in decentralized manufacturing and digital fabrication.

6. Conclusions

Decentralized supply chains leveraging Fused Deposition Modeling (FDM) for optimization are an emerging focus in supply chain and production research. This systematic literature review identifies 30 frameworks and models related to decentralized supply chains and FDM, addressing the first research question of this study. Furthermore, the review examines 41 unique dimensions proposed by researchers and industry practitioners for evaluating and optimizing decentralized supply chains, thus answering the second and third research questions of this study.

From a theoretical perspective, this study offers two primary contributions. First, it consolidates 6 key dimensions from the 41 unique dimensions found in the 30 frameworks: technology, process, scalability, data-driven optimization, logistics, and innovation. These dimensions are essential for implementing FDM-based decentralized supply chains and are applicable across various industries and organization sizes. Second, the review reveals the prominence of machine learning and data analytics, with 8 of the 41 dimensions specifically focusing on their role in optimizing decentralized supply chains. This finding emphasizes the need for organizations to prioritize advanced technologies to fully exploit the potential of decentralized frameworks [

30].

The growing academic and industrial interest in decentralized supply chains and FDM integration is evident, as reflected in the increasing number of studies in this field. However, this review also has limitations. First, it is based on historical data, providing a snapshot of the state of the literature at a specific point in time. Second, the methodology was constrained by selected databases and keywords, as detailed in the methodology section. These limitations highlight the need for ongoing research to keep pace with rapid advancements in this field.

The findings of this review set a solid foundation for future research. The six dimensions identified can be further explored through semi-structured interviews and case studies to uncover deeper insights. Additionally, empirical research through quantitative methods could establish interdependencies between these dimensions, enhancing the understanding of their collective

7. Limitations of Current Research

Although numerous studies investigate the implementation of blockchain in decentralized supply chains, there is a paucity of studies about its application in machine learning (ML)-driven Finite Difference Method (FDM) models within dematerialized logistics. The current literature predominantly emphasizes blockchain’s contribution to enhancing transparency and security in supply chain operations. Nonetheless, its capacity to improve traceability, data integrity, and secure transactions in AI-optimized Fused Deposition Modeling and machine learning-driven prediction models is predominantly unexamined. Furthermore, the incorporation of machine learning approaches to enhance FDM-based simulations is extensively researched; nevertheless, the security and dependability of these AI-generated decisions, especially inside decentralized supply chains, are deficient in thorough blockchain-based validation.

8. Future Research Directions

Future research should investigate the integration of blockchain technology, specifically smart contracts, to enhance the security and traceability of ML-driven FDM processes. Blockchain could provide a decentralized, immutable, and transparent mechanism for tracking data transactions, ensuring the integrity of AI-optimized manufacturing workflows. Additionally, the combination of machine learning models with blockchain-based authentication could enable more secure, auditable, and efficient predictive analytics in dematerialized logistics. This could include developing intelligent smart contracts that dynamically validate and optimize FDM-based simulations using real-time ML predictions, ensuring a secure and adaptive decision-making framework in decentralized manufacturing environments.