1. Introduction

The worldwide plastic waste crisis highlights major flaws in our traditional linear economic model, often described as the “take–make–dispose” system [

1]. Although this approach once supported industrial growth, it relies heavily on finite fossil fuel resources. As a result, it contributes to resource depletion, increases greenhouse gas emissions, and accelerates environmental degradation [

1,

2]. Additionally, weak supply chains and inadequate waste management systems have led to large amounts of plastic waste accumulating in landfills and natural environments, causing serious ecological damage [

3].

In contrast, the circular economy offers a real solution. It focuses on using resources efficiently through strategies like recycling, remanufacturing, and eco-design [

4]. A central concept within this model is Design for Recycling (DfR), which ensures that products are designed from the outset to be durable and easy to recycle. This way, we can recover high-quality materials, rely less on new resources, and move towards systems where nothing goes to waste [

5].

This paper lays the foundation for a DfR knowledge system that links design strategies with recycling processes. The goal is to support better decision-making during product development. The study examines the limitations of the linear economy, explores the main principles of circular design, and identifies pathways for more sustainable plastic management.

2. Limitations of the Linear Model and the Plastic Waste Crisis

2.1. Linear Model Challenges in Plastic Waste

The traditional “take–make–dispose” economic model powered industrial and economic growth throughout the 20th century. However, its limitations have become increasingly evident, particularly in the context of plastic production and waste management [

1,

2]. This model simply assumes that natural resources are unlimited and that the environment can absorb waste indefinitely.

Plastics are a prime example of this problem. Made mostly from petrochemicals, they highlight how much we unsustainably rely on limited fossil fuels. This reliance drains our resources, boosts greenhouse gas emissions, and damages the environment [

1]. When products are made under this linear system, the focus is often just on efficiency and making things in large quantities, often overlooking what happens to a product after its useful life. This means many products, especially plastics, cannot be recycled easily, or at all [

6]. The disposal stage typically involving landfilling, incineration, or environmental littering leads to growing pollution and a significant loss of valuable materials [

3].

Another major flaw in the linear model is the lack of integration between its stages, with minimal feedback or coordination among them [

2]. This disconnection exacerbates issues like resource overuse, ineffective waste management, and environmental harm. These problems are particularly evident with our dependence on single-use plastics and the insufficient development of recycling facilities [

5]. Addressing these challenges necessitates a shift toward circular economy that emphasizes resource efficiency, product longevity, and waste reduction [

4].

2.2. Plastics: Resource Dependency and Waste Challenges

Our plastic habit relies heavily on finite fossil fuels, which are crucial for making common polymers like polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Global production surpasses 400 million tons annually, pushed by industrial growth and consumer demand [

7]. This dependence drains limited reserves and creates environmental and economic risks. We urgently need new material options [

8].

Plastic use also reflects global inequality. Wealthy nations, despite their smaller populations, consume over 70% of all plastics. Yet, the resources are often taken from poorer regions, leaving behind local environmental damage and inadequate recycling systems [

8]. Single-use plastics, commonly designed without sustainability in mind, reinforce the linear economy by ignoring opportunities for reuse and recovery [

4].

Plastic waste has hit alarming levels. We generate over 300 million tons annually, but less than 20% gets properly recycled. Mixed materials, chemical additives, and poor product design make recycling complex and inefficient [

9]. Often, this waste leaks into our environment, polluting land and marine ecosystems. Just in 2015, China’s Yangtze River alone dumped about 330,000 tons of plastic into the ocean [

10]. Such pollution disrupts ecosystems, introduces microplastics into the food chain, and poses risks to human health [

6]. On land, plastics block waterways and degrade soil. In oceans, they form huge patches like the Great Pacific Garbage Patch. And microplastics make everything worse by soaking up toxic pollutants and releasing harmful chemicals, putting marine animals and our food systems at risk [

6].

Solving these problems demands a fundamental shift. We need to design products for easy recyclability, use fewer hazardous materials, and set up better waste collection and sorting systems [

5]. And vitally, governments, industries, and consumers must work together to turn plastic waste into valuable resources, truly embracing circular economy goals [

4].

3. Towards a Circular Economy for Sustainable Plastics Management

3.1. Sustainability Through the Circular Economy

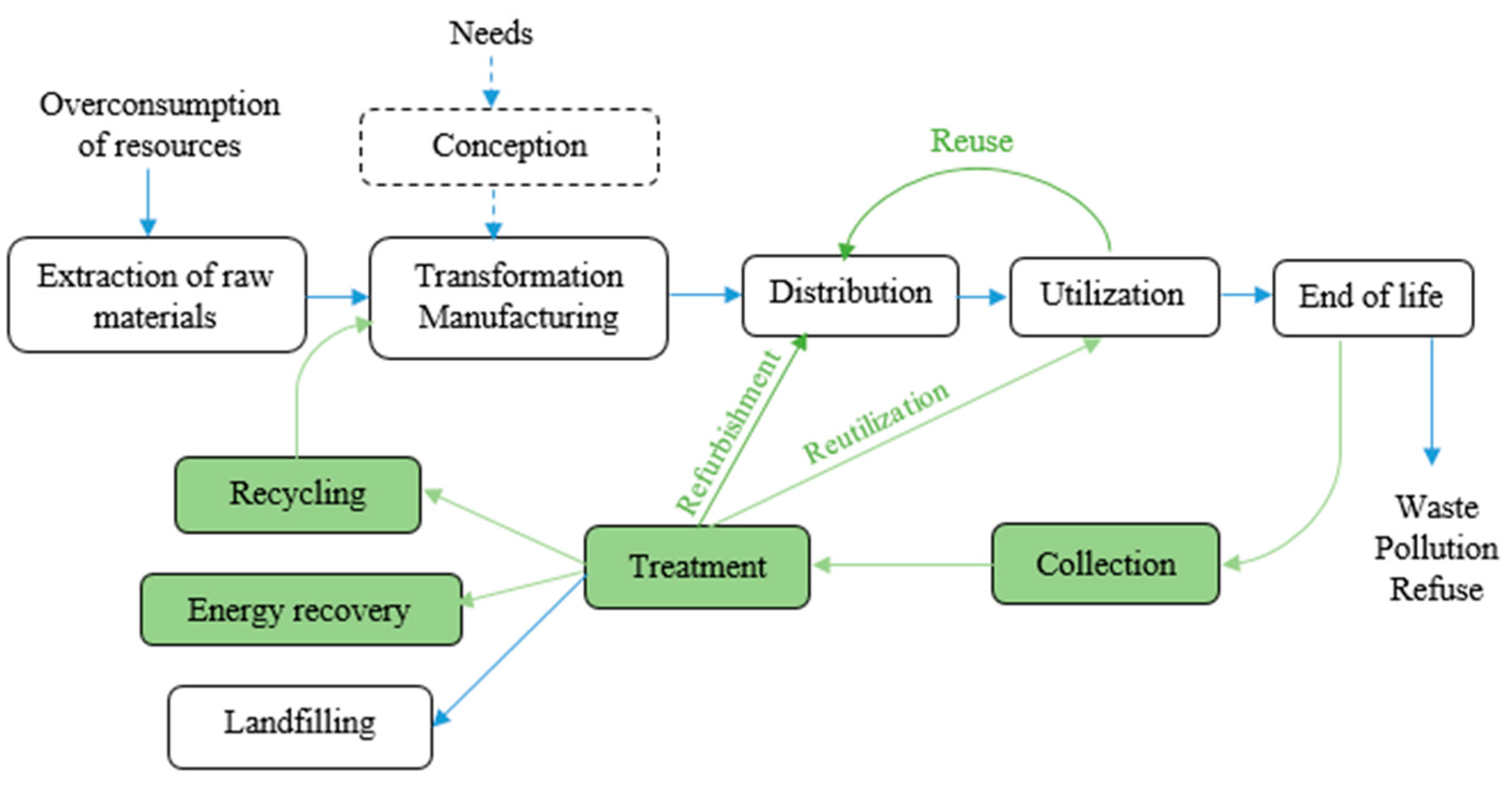

The circular economy transforms how we manage resources. It aims to minimize waste and maximize resource efficiency throughout a product’s life. Unlike the linear “take–make–dispose” model, it emphasizes resource recirculation, keeping materials and products in circulation for an extended period [

11]. By fostering regenerative systems, the circular economy reduces dependency on finite resources and mitigates environmental impacts. It integrates processes such as resource extraction, manufacturing, distribution, and end-of-life recovery through recycling, reuse, and resource regeneration [

12]. This transition is visually represented in

Figure 1.

A central tenet of this framework is the establishment of closed-loop systems, which treat waste as a resource to be reused, remanufactured, or recycled. These systems operate through two main cycles: biological and technical. Biological cycles involve renewable resources like biodegradable plastics or organic waste, which decompose naturally and return nutrients to the environment, supporting ecosystem health [

7]. In contrast, technical cycles manage finite resources, such as synthetic plastics and metals, by enabling repair, refurbishment, and recycling to preserve material utility and minimize degradation [

11].

Adopting circular economy principles comes with challenges—especially the gap between the long-lasting nature of plastics and the short life of many products. Plastics often outlive their use, contributing to waste build-up. Solutions like eco-design and modular manufacturing help by extending product life and improving recyclability [

13,

14]. Overall, the circular economy offers a sustainable alternative to the linear model by reducing waste and promoting efficient resource use through closed-loop systems and well-managed material cycles.

3.2. Benefits of a Circular Economy for Plastics

Shifting to a circular economy for plastics brings a wide range of environmental, economic, and social benefits. It offers a way to move beyond the limitations of the linear “take–make–dispose” model and supports the goals set out in the United Nations Sustainable Development Goals (SDGs) [

15]. By fostering reuse, recycling, and recovery, it cuts reliance on virgin raw materials, mitigating volatile fossil fuel costs and boosting economic resilience [

6].

Recycling lowers production costs by recovering secondary materials that can replace virgin inputs, making better use of local resources and supporting regional economies [

16]. Thanks to advances in recycling technology, high-quality recycled plastics are now being produced, opening new opportunities across various industries.

From an environmental perspective, the circular economy reduces greenhouse gas emissions by limiting the need for energy-intensive extraction and processing of raw materials [

4]. Effective waste management also prevents plastic leakage into ecosystems, reducing harm to wildlife and human health [

6]. Eco-design and better recyclability, such as mono-material designs and reduced additive use, boost resource efficiency by making recycling easier and cutting waste [

13].

On the social side, a circular economy creates jobs and boosts social inclusion. In Morocco, for example, the recycling sector provides livelihoods for many people, from informal waste pickers to organized businesses [

17]. It also raises public awareness and participation, promoting responsible consumption, waste sorting, and environmental stewardship. Overall, by reducing waste and supporting more efficient resource use, the circular economy helps address plastic pollution while promoting sustainability, economic opportunity, and social well-being. Through coordinated efforts by governments, businesses, and communities, it also helps advance the SDGs and build a more equitable future [

15].

3.3. Recycling the Foundation of Circular Economy

Recycling plays a central role in advancing the circular economy, especially for plastics. By converting used materials into valuable resources, it helps reduce environmental impact and supports more sustainable production systems in line with global goals for resource efficiency [

4].

Recent developments have significantly improved how plastics are processed. Mechanical recycling, the most widely used method, involves sorting, cleaning, and remanufacturing plastics into new raw materials. Improved sorting technologies, such as near-infrared (NIR) spectroscopy, have made it easier to accurately identify different polymers, resulting in better-quality recycled materials [

13,

18]. Chemical recycling offers an alternative by breaking plastics down into their basic building blocks through methods like pyrolysis and solvolysis. However, these techniques often require a lot of energy and still face challenges in becoming economically viable [

19]. Digital technologies, including machine-readable markers and embedded tracers, further boost recycling efficiency, helping identify materials precisely, reducing contamination, and improving complex product recyclability [

18]. Still, these advances highlight technology’s potential to address existing barriers.

Despite progress, recycling faces limits. Polymer degradation often reduces recycled plastic quality, restricting high-value reuse (downcycling) [

11]. Economic factors also hinder recycling, with low oil prices making virgin plastics more cost competitive and high collection and sorting costs reducing profitability. Additionally, the complexity of modern plastic products, including multi-material packaging and embedded additives, complicates recycling processes. Addressing these issues requires advanced separation technologies and standardized design practices to ensure compatibility with recycling systems [

6,

19].

4. Eco-Design and DfR: Advancing Sustainability Through Lifecycle Integration

4.1. Eco-Design: Driving Sustainability in Product Development

Eco-design, or Design for Environment (DfE), integrates environmental considerations into the product development process by addressing impacts across the entire lifecycle, from resource extraction to end-of-life management. By aligning design decisions with sustainability principles, eco-design optimizes resource use, reduces waste, and promotes environmentally responsible products [

20]. This lifecycle approach ensures that all phases, including resource conservation, energy efficiency, and waste reduction, contribute to sustainability goals.

Key principles of eco-design include selecting recyclable materials, minimizing energy use, and facilitating reuse, repair, or recycling. These principles support circular economy objectives by keeping materials within technical cycles for as long as possible [

13]. Strategies such as modular design enhance product durability, reparability, and upgradability, enabling component replacement instead of full disposal. For instance, modular design can make products more durable and easier to repair or upgrade. In plastics, this could mean using standard parts and detachable joints to extend product life and reduce waste [

20].

Material selection is a key part of eco-design. Opting for widely recyclable plastics like PE, PP, and PET helps lower environmental impact and simplifies recycling. Designs using a single type of plastic (mono-material) and fewer additives such as pigments make sorting and recycling easier and improve the quality of recycled materials [

19]. Eco-design also explores alternatives like biodegradable or bio-based plastics, weighing their environmental benefits against performance needs and potential lifecycle trade-offs [

21].

Another important approach is Design for Disassembly (DfD), which ensures that products can be easily taken apart at the end of their life. Features like removable adhesives or wash-off labels reduce contamination in plastic recycling, improving the recovery of high-quality materials [

19]. As industries move toward more sustainable production, eco-design becomes essential. It not only reduces environmental impact but also helps companies meet regulatory requirements and the rising consumer demand for greener products. This makes eco-design both an environmental and economic priority [

20].

4.2. Design for Recycling: Integrating Sustainability at End-of-Life

While eco-design considers environmental impacts across a product’s entire lifecycle, its effectiveness increases when combined with Design for Recycling (DfR). DfR focuses specifically on making products easier to recycle at the end of their life, ensuring materials can be recovered and reused efficiently [

22]. In the case of plastics, where recycling rates remain low, DfR plays a vital role by incorporating recyclability directly into product design. Key DfR strategies include using recyclable polymers such as PE, PP, and PET and avoiding complex composites or problematic additives that hinder recycling [

13]. Features like detachable joints and removable labels, as well as avoiding pigments like carbon black (which disrupts automated sorting), improve the quality and purity of recycled materials. These design choices make plastics more suitable for reuse in products like packaging and automotive parts [

13].

However, several challenges limit the widespread adoption of DfR. These include weak collaboration among stakeholders, a lack of industry standards, and heavy reliance on informal recycling systems—particularly in low- and middle-income countries [

23]. Another barrier is the knowledge gap: many designers lack tools and data to align design decisions with recycling processes, material behavior, and market demands. This highlights the need for structured systems to capture and share DfR knowledge, enabling better integration of recycling-friendly practices in product development [

24].

Emerging technologies such as chemical recycling and tracer-based sorting offer new possibilities, but high costs and scalability issues remain [

18]. Moreover, the growing complexity of plastic products due to multi-material constructions and embedded additives continues to challenge recycling efforts.

5. Discussion

Design for Recycling (DfR) has become a key strategy for addressing the end-of-life challenges of plastic products. By aligning product design with recycling capabilities, DfR supports the circular economy goals, improving resource efficiency and reducing environmental impact. However, realizing its full potential requires closing current gaps in collaboration, knowledge sharing, and access to tools and standards.

Effective collaboration between designers, recyclers, and policymakers is essential for advancing DfR practices. Designers incorporate recyclability into product concepts; recyclers provide insights on processing challenges and opportunities; and policymakers create regulations that support sustainable design. Working together helps integrate DfR into product lifecycles, reduce waste, and improve material recovery rates [

25].

To support this collaboration, shared digital platforms and centralized knowledge databases are critical. These tools can provide up-to-date information on material properties, recycling guidelines, and market demands. For instance, a database linking material choices to recyclability standards would help designers create products that are compatible with current recycling systems. It is also important to make such resources available to small- and medium-sized enterprises (SMEs), which often lack the capacity to develop sustainable practices on their own. Offering training, online tools, and localized guidance can help SMEs contribute to sustainability goals while staying competitive.

Standardized DfR frameworks are also vital. Consistent design guidelines ensure that products are developed with recyclability in mind, supporting the use of both current and emerging recycling technologies. These standards can also improve international cooperation by harmonizing recycling systems across regions. In summary, DfR plays a crucial role in making plastic use more sustainable. Its success depends on stronger collaboration, better access to digital tools, and the widespread sharing of knowledge especially with smaller industry players. Addressing these needs will help DfR drive the transition to a circular economy, supporting both environmental sustainability and long-term economic resilience.

6. Conclusions

This study underscores the urgent need to move away from the linear model of plastic production and toward a circular economy that emphasizes resource efficiency and environmental sustainability. Continued reliance on fossil fuels, weak recycling infrastructure, and fragmented value chains are not sustainable. Eco-design and Design for Recycling (DfR) are essential to addressing end-of-life challenges by embedding recyclability and durability at the design stage.

The success of these strategies depends on strong collaboration across the value chain—among designers, manufacturers, recyclers, policymakers, and consumers. Shared knowledge platforms and clear design standards are crucial to support the development and scaling of innovative recycling technologies such as advanced sorting systems and chemical recycling. At the same time, supportive policies and economic incentives are needed to make circular alternatives more viable than single-use plastics.

Looking forward, integrated digital tools and knowledge systems that combine DfR principles with material data will empower designers to create more sustainable products. Expanding advanced recycling methods will also require policy support that encourages the use of recycled polymers. Public engagement through awareness campaigns and local initiatives can further enhance participation and promote social inclusion through recycling-related employment.

Ultimately, embedding eco-design and DfR into circular economy frameworks can help reduce waste, preserve natural resources, generate economic value, and protect environmental health. By addressing sustainability at the design phase, industries and communities can work together to build a more resilient and sustainable future for plastics.