An Aggregation Method for Evaluating the Performance of a Production Line Operating Under the Slowdown Policy †

Abstract

1. Introduction

2. Literature Review

2.1. Exact Methods

2.2. Decomposition Methods

2.3. Aggregation Methods

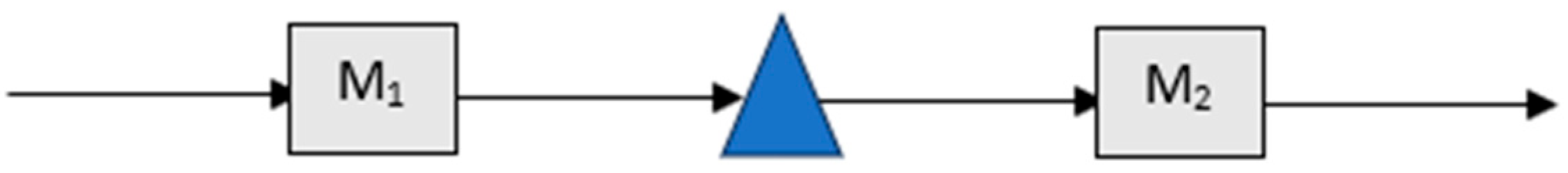

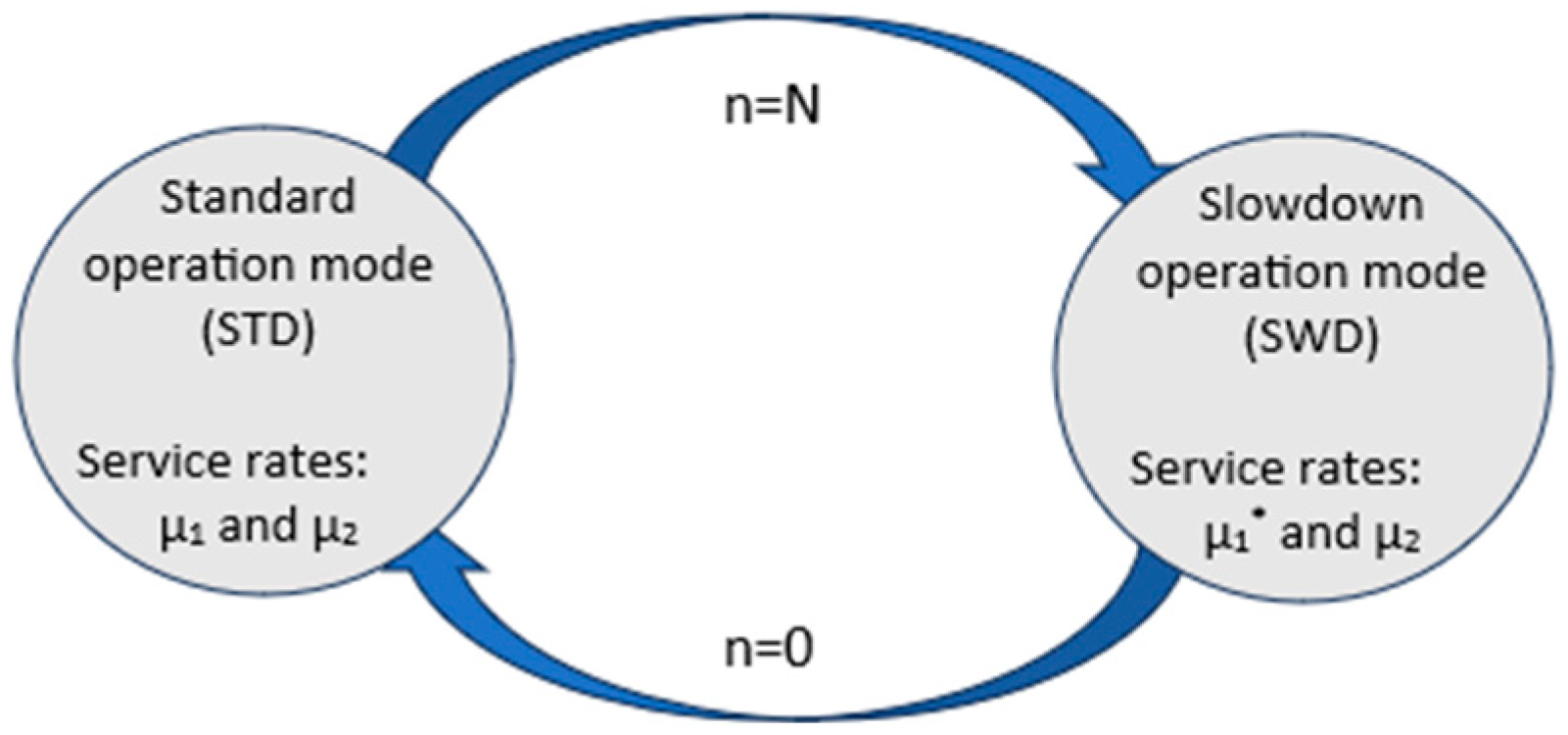

3. Slowdown Policy for a Two-Machine System

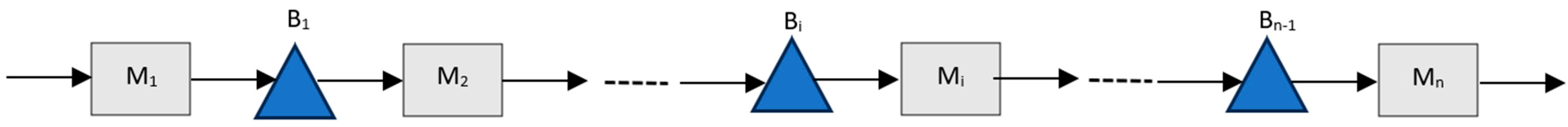

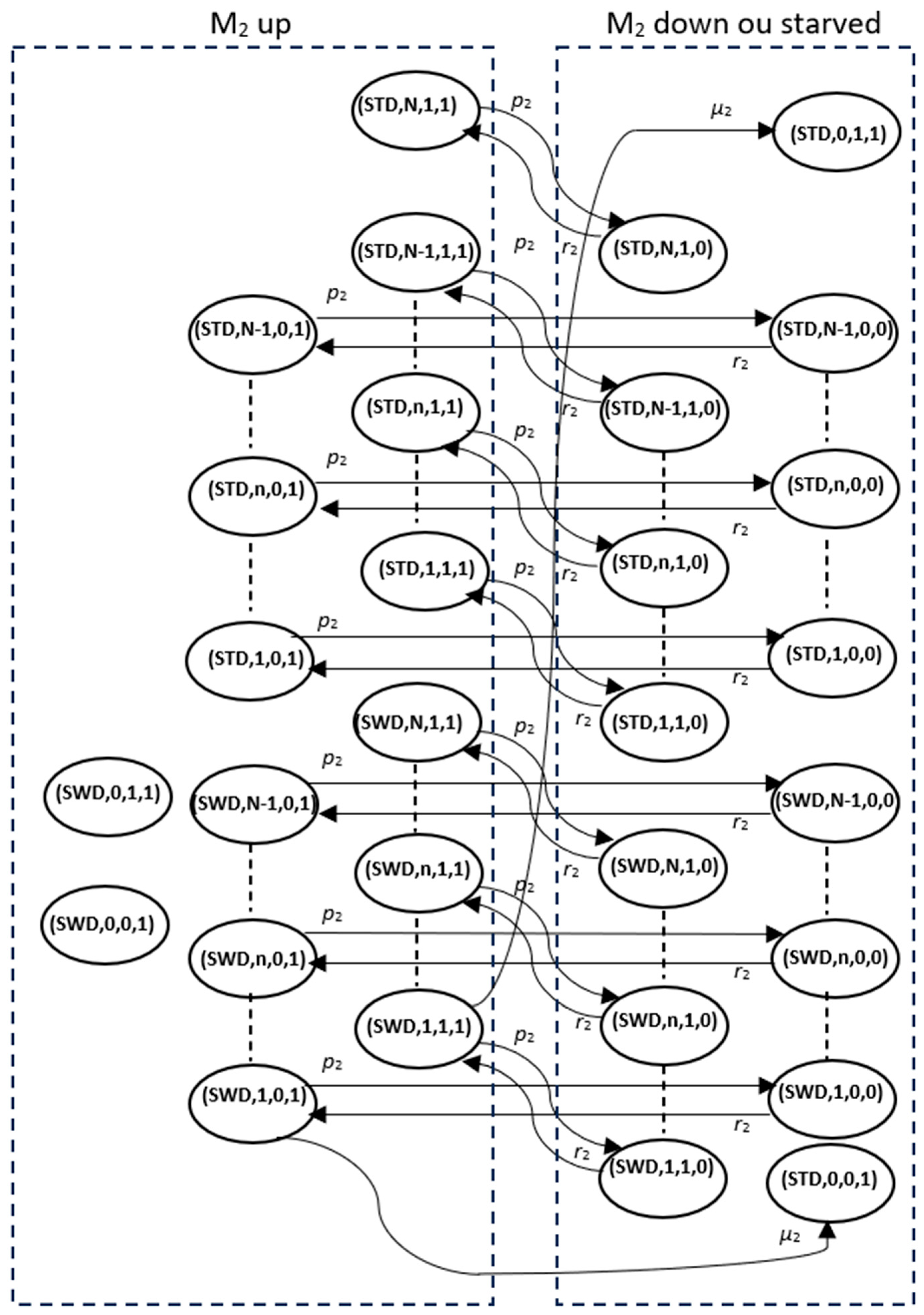

4. Aggregation Method for Multi-Machine Lines with the Slowdown Policy

- -

- M2 Up: This section includes all states where M2 is operational, either in Standard (STD) mode or Slowdown (SWD) mode.

- -

- M2 Down or starved: This section includes all states where M2 is down or starved, meaning it has failed and is undergoing repair or starved.

- -

- Equivalent Failure Rate

- -

- Equivalent Repair Rate

- -

- Equivalent Processing Rate

5. Illustrative Example: A Five-Machine Line

6. Limitations

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nahas, Z.; El Hachemi, N.; Nahas, N. Performance Evaluation of an Unreliable Two-Machine System with Slowdown Policy. Comput. Ind. Eng. 2025, submitted.

- Diamantidis, A.C.; Lee, J.H.; Papadopoulos, C.T.; Li, J.; Heavy, C. Performance evaluation of flow lines with non-identical and unreliable parallel machines and finite buffers. Int. J. Prod. Res. 2020, 58, 3881–3904. [Google Scholar] [CrossRef]

- Bai, Y.; Tu, J.; Yang, M.; Zhang, L.; Denno, P. A new aggregation algorithm for performance metric calculation in serial production lines with exponential machines: Design, accuracy and robustness. Int. J. Prod. Res. 2021, 59, 4072–4089. [Google Scholar] [CrossRef]

- Tu, J.; Zhang, L. Performance analysis and optimisation of Bernoulli serial production lines with dynamic real-time bottleneck identification and mitigation. Int. J. Prod. Res. 2022, 60, 3989–4005. [Google Scholar] [CrossRef]

- Li, J.; Meerkov, S.M. Production Systems Engineering; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Gershwin, S.B. Manufacturing Systems Engineering; Prentice Hall: Hoboken, NJ, USA, 1994; pp. 76–93. [Google Scholar]

- Hunt, G.C. Sequential arrays of waiting lines. Oper. Res. 1956, 4, 674–683. [Google Scholar] [CrossRef]

- Muth, E.J. The production rate of a series of work stations with variable service times. Int. J. Prod. Res. 1973, 11, 155–169. [Google Scholar] [CrossRef]

- Buzacott, J.A. Prediction of the efficiency of production systems without internal storage. Int. J. Prod. Res. 1968, 6, 173–188. [Google Scholar] [CrossRef]

- Gershwin, S.B.; Berman, O. Analysis of transfer lines consisting of two unreliable machines with random processing times and finite storage buffers. AIIE Trans. 1981, 13, 2–11. [Google Scholar] [CrossRef]

- Berman, O. Efficiency and production rate of a transfer line with two machines and a finite storage buffer. Eur. J. Oper. Res. 1982, 9, 295–308. [Google Scholar] [CrossRef][Green Version]

- Altıok, T. Approximate analysis of exponential tandem queues with blocking. Eur. J. Oper. Res. 1982, 11, 390–398. [Google Scholar] [CrossRef]

- Jafari, M.A.; Shanthikumar, J.G. An approximate model of multistage automatic transfer lines with possible scrapping of workpieces. IIE Trans. 1987, 19, 252–265. [Google Scholar] [CrossRef]

- Papadopoulos, H.T.; Heavey, C.; O’Kelly, M.E.J. Throughput rate of multistation reliable production lines with inter station buffers: (I) Exponential Case. Comput. Ind. 1989, 13, 229–244. [Google Scholar] [CrossRef]

- Jacobs, D.; Meerkov, S.M. Asymptotically reliable serial production lines with a quality control system. Comput. Math. Appl. 1991, 21, 85–90. [Google Scholar] [CrossRef]

- Cochran, J.K.; Erol, R. Performance modelling of serial production lines with inspection/repair stations. Int. J. Prod. Res. 2001, 39, 1707–1720. [Google Scholar] [CrossRef]

- Tolio, T.; Matta, A.; Gershwin, S.B. Analysis of two-machine lines with multiple failure modes. IIE Trans. 2002, 34, 51–62. [Google Scholar] [CrossRef]

- Tan, B. State-space modeling and analysis of pull-controlled production systems. In Analysis and Modeling of Manufacturing Systems; Springer: Boston, MA, USA, 2003; pp. 363–398. [Google Scholar]

- Kim, J.; Gershwin, S.B. Integrated quality and quantity modeling of a production line. OR Spectr. 2005, 27, 287–314. [Google Scholar] [CrossRef]

- Tancrez, J.S.; Chevalier, P.; Semal, P. Probability masses fitting in the analysis of manufacturing flow lines. Ann. Oper. Res. 2011, 182, 163–191. [Google Scholar] [CrossRef]

- Helber, S.; Schimmelpfeng, K.; Stolletz, R.; Lagershausen, S. Using linear programming to analyze and optimize stochastic flow lines. Ann. Oper. Res. 2011, 182, 193–211. [Google Scholar] [CrossRef]

- Göttlich, S.; Kühn, S.; Schwarz, J.A.; Stolletz, R. Approximations of time-dependent unreliable flow lines with finite buffers. Math. Methods Oper. Res. 2015, 83, 295–323. [Google Scholar] [CrossRef]

- Fernandes, P.; O’Kelly, M.E.J.; Papadopoulos, C.T.; Sales, A. Analysis of exponential reliable production lines using Kronecker descriptors. Int. J. Prod. Res. 2013, 51, 4240–4257. [Google Scholar] [CrossRef]

- Jia, Z.; Zhang, L.; Arinez, J.; Xiao, G. Performance analysis for serial production lines with Bernoulli machines and real-time WIP-based machine switch-on/off control. Int. J. Prod. Res. 2016, 54, 6285–6301. [Google Scholar] [CrossRef]

- Matta, A.; Simone, F. Analysis of two-machine lines with finite buffer, operation-dependent and time-dependent failure modes. Int. J. Prod. Res. 2016, 54, 1850–1862. [Google Scholar] [CrossRef]

- Huang, J.; Chang, Q.; Arinez, J. Deep reinforcement learning based preventive maintenance policy for serial production lines. Expert Syst. Appl. 2020, 160, 113701. [Google Scholar] [CrossRef]

- Scrivano, S.; Tolio, T. A Markov Chain model for the performance evaluation of manufacturing lines with general processing times. Procedia CIRP 2021, 103, 20–25. [Google Scholar] [CrossRef]

- Dong, H.; Li, J. Energy and productivity analysis in serial production lines with setups. IEEE Robot. Autom. Lett. 2022, 7, 7108–7115. [Google Scholar] [CrossRef]

- Gebennini, E.; Grassi, A.; Fantuzzi, C. The two-machine one-buffer continuous time model with restart policy. Ann. Oper. Res. 2015, 230, 69–92. [Google Scholar] [CrossRef][Green Version]

- Gebennini, E.; Gershwin, S.B. Modeling waste production into two-machine-one-buffer transfer lines. IIE Trans. 2013, 45, 591–604. [Google Scholar] [CrossRef]

- Vladzievskiĭ, A.P. The probability law of operation of automatic lines and internal storage in them. Avtom. I Telemekhanika 1952, 13, 227–281. [Google Scholar]

- Hillier, F.S.; Boling, R.W. Finite queues in series with exponential or Erlang service times-a numerical approach. Oper. Res. 1967, 15, 286–303. [Google Scholar] [CrossRef]

- Takahashi, Y.; Miyahara, H.; Hasegawa, T. An approximation method for open restricted queueing networks. Oper. Res. 1980, 28, 594–602. [Google Scholar] [CrossRef]

- Boxma, O.J.; Konheim, A.G. Approximate analysis of exponential queueing systems with blocking. Acta Inform. 1981, 15, 19–66. [Google Scholar] [CrossRef]

- Altıok, T.; Perros, H.G. Approximate analysis of arbitrary configurations of open queueing networks with blocking. Ann. Oper. Res. 1987, 9, 481–509. [Google Scholar] [CrossRef]

- Choong, Y.F.; Gershwin, S.B. A decomposition method for the approximate evaluation of capacitated transfer lines with unreliable machines and random processing times. IIE Trans. 1987, 19, 150–159. [Google Scholar] [CrossRef]

- Dallery, Y.; David, R.; Xie, X.L. An efficient algorithm for analysis of transfer lines with unreliable machines and finite buffers. IIE Trans. 1988, 20, 280–283. [Google Scholar] [CrossRef]

- Dallery, Y.; David, R.; Xie, X.L. Approximate analysis of transfer lines with unreliable machines and finite buffers. IEEE Trans. Autom. Control 1989, 34, 943–953. [Google Scholar] [CrossRef]

- Jun, K.P.; Perros, H.G. An approximate analysis of open tandem queueing networks with blocking and general service times. Eur. J. Oper. Res. 1990, 46, 123–135. [Google Scholar] [CrossRef]

- Frein, Y.; Commault, C.; Dallery, Y. Modeling and analysis of closed-loop production lines with unreliable machines and finite buffers. IIE Trans. 1996, 28, 545–554. [Google Scholar] [CrossRef]

- Yeralan, S.; Tan, B. Analysis of multistation production systems with limited buffer capacity part 1: The subsystem model. Math. Comput. Model. 1997, 25, 109–122. [Google Scholar] [CrossRef]

- Tolio, T.; Matta, A.; Jovane, F. A method for performance evaluation of automated flow lines. CIRP Ann. 1998, 47, 373–376. [Google Scholar] [CrossRef]

- Han, M.S.; Lim, J.T.; Park, D.J. Performance analysis of serial production lines with quality inspection machines. Int. J. Syst. Sci. 1998, 29, 939–951. [Google Scholar] [CrossRef]

- Dallery, Y.; Bihan, L.H. An improved decomposition method for the analysis of production lines with unreliable machines and finite buffers. Int. J. Prod. Res. 1999, 37, 1093–1117. [Google Scholar] [CrossRef]

- Bihan, H.; Dallery, Y. A robust decomposition method for the analysis of production lines with unreliable machines and finite buffers. Ann. Oper. Res. 2000, 93, 265–297. [Google Scholar] [CrossRef]

- Tempelmeier, H.; Bürger, M. Performance evaluation of unbalanced flow lines with general distributed processing times, failures and imperfect production. IIE Trans. 2001, 33, 293–302. [Google Scholar] [CrossRef]

- Krieg, G.N.; Kuhn, H. A decomposition method for multi-product kanban systems with setup times and lost sales. IIE Trans. 2002, 34, 613–625. [Google Scholar] [CrossRef]

- Colledani, M.; Matta, A.; Tolio, T. Performance evaluation of production lines with finite buffer capacity producing two different products. OR Spectr. 2005, 27, 243–263. [Google Scholar] [CrossRef]

- Li, J. Throughput analysis in automotive paint shops: A case study. IEEE Trans. Autom. Sci. Eng. 2004, 1, 90–98. [Google Scholar] [CrossRef]

- Alden, J.M.; Burns, L.D.; Costy, T.; Hutton, R.D.; Jackson, C.A.; Kim, D.S.; Kohls, K.A.; Owen, J.H.; Turnquist, M.A.; Veen, D.J.V. General motor increases its production throughput. Interfaces 2006, 36, 6–25. [Google Scholar] [CrossRef]

- Kim, J.; Gershwin, S.B. Analysis of long flow lines with quality and operational failures. IIE Trans. 2008, 40, 284–296. [Google Scholar] [CrossRef]

- Xia, B.; Xi, L.; Zhou, B. An improved decomposition method for evaluating the performance of transfer lines with unreliable machines and finite buffers. Int. J. Prod. Res. 2012, 50, 4009–4024. [Google Scholar] [CrossRef]

- Shin, Y.W.; Moon, D.H. Approximation of throughput in tandem queues with multiple servers and blocking. Appl. Math. Model. 2014, 38, 6122–6132. [Google Scholar] [CrossRef]

- Liberopoulos, G. Performance evaluation of a production line operated under an echelon buffer policy. IISE Trans. 2018, 50, 161–177. [Google Scholar] [CrossRef]

- Wang, X.; Dai, Y.; Jia, Z. Energy-efficient on/off control in serial production lines with Bernoulli machines. Flex. Serv. Manuf. J. 2022, 36, 103–128. [Google Scholar] [CrossRef]

- Helber, S.; Kellenbrink, C.; Südbeck, I. Evaluation of stochastic flow lines with provisioning of auxiliary material. OR Spectr. 2023, 46, 669–708. [Google Scholar] [CrossRef]

- De Koster, M.B.M. Estimation of line efficiency by aggregation. Int. J. Prod. Res. 1987, 25, 615–626. [Google Scholar] [CrossRef]

- Wijngaard, J. The effect of interstage buffer storage on the output of two unreliable production units in series, with different production rates. AIIE Trans. 1979, 11, 42–47. [Google Scholar] [CrossRef]

- de Koster, R.; Wijngaard, J. A continuous flow model for three production units in series with buffers. In DGOR, 14th Annual Meeting/Vorträge der 14. Jahrestagung; Springer: Berlin/Heidelberg, Germany, 1986; pp. 253–264. [Google Scholar]

- Liu, C.M.; Lin, C.L. Performance evaluation of unbalanced serial production lines. Int. J. Prod. Res. 1994, 32, 2897–2914. [Google Scholar] [CrossRef]

- Lim, J.T.; Meerkov, S.M.; Top, F. Homogeneous, asymptotically reliable serial production lines: Theory and a case study. IEEE Trans. Autom. Control 1990, 35, 524–534. [Google Scholar] [CrossRef]

- Chiang, S.Y.; Kuo, C.T.; Meerkov, S.M. DT-bottlenecks in serial production lines: Theory and application. IEEE Trans. Robot. Autom. 2000, 16, 567–580. [Google Scholar] [CrossRef]

- Colledani, M.; Gandola, F.; Matta, A.; Tolio, T. Performance evaluation of linear and non-linear multi-product multi-stage lines with unreliable machines and finite homogeneous buffers. IIE Trans. 2008, 40, 612–626. [Google Scholar] [CrossRef]

- Li, J. Continuous improvement at Toyota manufacturing plant: Applications of production systems engineering methods. Int. J. Prod. Res. 2013, 51, 7235–7249. [Google Scholar] [CrossRef]

- Chen, G.; Wang, C.; Zhang, L.; Arinez, J.; Xiao, G. Transient performance analysis of serial production lines with geometric machines. IEEE Trans. Autom. Control 2016, 61, 877–891. [Google Scholar] [CrossRef]

- Meerkov, S.M.; Shimkin, N.; Zhang, L. Transient behavior of two-machine geometric production lines. IEEE Trans. Autom. Control 2010, 55, 453–458. [Google Scholar] [CrossRef]

- Wang, F.; Ju, F.; Kang, N. Transient analysis and real-time control of geometric serial lines with residence time constraints. IISE Trans. 2019, 51, 709–728. [Google Scholar] [CrossRef]

- Liu, L.; Yan, C.B.; Li, J. Modeling, analysis, and improvement of batch-discrete manufacturing systems: A systems approach. IEEE Trans. Autom. Sci. Eng. 2021, 19, 1567–1585. [Google Scholar] [CrossRef]

- Wang, X.; Dai, Y.; Jia, Z.; Wang, G. Transient analysis of production performance and energy consumption in geometric flexible production systems. Expert Syst. Appl. 2024, 245, 123065. [Google Scholar] [CrossRef]

- Belmansour, A.-T. Contribution à la Modélisation, L’Analyse et L’Optimisation de Lignes de Production en Série Peu Fiables. Master’s Thesis, Université du Québec en Abitibi-Témiscamingue, Rouyn_Noranda, QC, Canada, 2007. [Google Scholar]

- Ouazene, Y. Méthodologie D’aide à la Conception Des Lignes de Production en Série: Application à L’Industrie Automobile. Ph.D. Thesis, Université de Technologie de Troyes, Troyes, France, 2013. [Google Scholar]

| Machine 1 | Machine 2 | Machine 3 | Machine 4 | Machine 5 |

|---|---|---|---|---|

| {µ1, µ1*, r1, p1, p1*} | {µ2, µ2*, r2, p2, p2*} | {µ3, µ3*, r3, p3, p3*} | {µ4, µ4*, r4, p4, p4*} | {µ5, r5, p5} |

| {1.63,1.3,0.0222,0.00148,0.00118} | {1.81,1.21,0.129,0.0236,0.0158} | {1.69,0.782,0.046,0.002,0.00095} | {1.78,1.6,0.027,0.0082,0.0074} | {1.82,0.027,0.0011} |

| Scenario | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Bi | 10 | 15 | 20 | 25 | 30 |

| Aggregation method | 0.94 | 1.01 | 1.06 | 1.12 | 1.14 |

| Simulation | 0.9767 | 0.9861 | 1.0837 | 1.0803 | 1.0809 |

| Error (%) | 3.9 | 2.36 | 2.23 | 3.54 | 5.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nahas, Z.; El-Hachemi, N.; Nahas, N. An Aggregation Method for Evaluating the Performance of a Production Line Operating Under the Slowdown Policy. Eng. Proc. 2025, 97, 14. https://doi.org/10.3390/engproc2025097014

Nahas Z, El-Hachemi N, Nahas N. An Aggregation Method for Evaluating the Performance of a Production Line Operating Under the Slowdown Policy. Engineering Proceedings. 2025; 97(1):14. https://doi.org/10.3390/engproc2025097014

Chicago/Turabian StyleNahas, Zouheir, Nizar El-Hachemi, and Nabil Nahas. 2025. "An Aggregation Method for Evaluating the Performance of a Production Line Operating Under the Slowdown Policy" Engineering Proceedings 97, no. 1: 14. https://doi.org/10.3390/engproc2025097014

APA StyleNahas, Z., El-Hachemi, N., & Nahas, N. (2025). An Aggregation Method for Evaluating the Performance of a Production Line Operating Under the Slowdown Policy. Engineering Proceedings, 97(1), 14. https://doi.org/10.3390/engproc2025097014