Abstract

With the global emphasis on sustainable growth and development, the depletion of natural energy reserves due to reliance on fossil fuels and non-renewable sources remains a critical concern. Despite strides in transitioning to electrical mobility, rural and agricultural communities depend heavily on liquefied petroleum gas and firewood for cooking, lacking viable, sustainable alternatives. This study focuses on community-led efforts to advance biogas adoption, providing an eco-friendly and reliable energy alternative for rural and farming households. By designing and developing balloon-type anaerobic biodigesters, this initiative provides a robust, cost-effective, and scalable method to convert farm waste into biogas for household cooking. This approach reduces reliance on traditional fuels, mitigating deforestation and improving air quality, and generates organic biofertilizer as a byproduct, enhancing agricultural productivity through organic farming. The study focuses on optimizing critical parameters, including the input feed rate, gas production patterns, holding time, biodigester health, gas quality, and liquid manure yield. Statistical tools, such as descriptive analysis, regression analysis, and ANOVA, were employed to validate and predict biogas output data based on experimental and industrial-scale data. Artificial neural networks (ANNs) were also utilized to model and predict outputs, inspired by the information processing mechanisms of biological neural systems. A comprehensive database was developed from experimental and literary data to enhance model accuracy. The results demonstrate significant improvements in cooking practices, health outcomes, economic stability, and solid waste management among beneficiaries. The integration of statistical analysis and ANN modeling validated the biodigester system’s effectiveness and scalability. This research highlights the potential to harness renewable energy to address socio-economic challenges in rural areas, paving the way for a sustainable, equitable future by fostering environmentally conscious practices, clean energy access, and enhanced agricultural productivity.

1. Introduction

The growing concerns over environmental degradation, energy scarcity, and the socio-economic challenges faced by rural communities underscore the urgent need for sustainable energy solutions [1]. Rural and agricultural households in developing regions often struggle with inefficient energy practices, relying on firewood or liquefied petroleum gas (LPG) for cooking. These practices contribute to deforestation, indoor air pollution, and the dependency on non-renewable resources. Simultaneously, the improper disposal of agro-waste and cattle manure poses environmental and health risks [2]. Burning agricultural residues, for instance, is a widespread practice that not only wastes potential resources but also releases significant quantities of greenhouse gases and particulate matter into the atmosphere. Against this backdrop, sustainable biogas production through anaerobic digestion emerges as a holistic solution that addresses energy, waste management, and environmental sustainability challenges.

Anaerobic digestion is a natural process where microorganisms break down organic waste from farms and livestock, producing biogas, a renewable fuel mainly made up of methane and carbon dioxide. This process offers a dual benefit: it generates clean cooking fuel while simultaneously reducing the environmental burden associated with traditional waste disposal methods. According to studies, adopting biogas systems has shown significant potential to reduce dependency on firewood and fossil fuels, mitigate greenhouse gas emissions, and improve indoor air quality in rural households [1,2]. Moreover, the digestate, a byproduct of this process, can be used as an organic fertilizer, enhancing soil health and agricultural productivity, thus promoting a circular economy.

The intervention of biogas technology was chosen after a comprehensive analysis of the real-time challenges rural communities face. Key issues identified included the lack of effective disposal methods for agro-waste and cattle manure, the unavailability of firewood for cooking, and the harmful environmental consequences of field burning. Agricultural waste, which is often discarded or burned, represents a significant untapped resource that could be converted into energy through biogas systems [3]. Similarly, cattle manure, traditionally left to decompose in open spaces, not only contributes to methane emissions but also poses health hazards due to contamination of soil and water sources. By integrating these waste streams into a biogas system, rural households can derive sustainable energy while addressing critical environmental issues.

The adoption of biogas technology aligns with global and regional policy priorities aimed at fostering sustainable energy and waste management solutions. Initiatives such as the United Nations Sustainable Development Goals (SDGs), particularly Goal 7 on affordable and clean energy, Goal 13 on climate action, and Goal 15 on life on land, highlight the importance of adopting renewable energy and implementing responsible waste management practices (UN, 2015). Evidence from successful implementations worldwide demonstrates that small-scale biogas systems, tailored to local contexts, can significantly transform the lives of rural households by providing them with a steady energy supply, reducing their dependence on traditional fuels and fostering environmentally sustainable practices [4]. This study focuses on developing and optimizing balloon-type anaerobic biodigesters to harness these benefits, offering a scalable and cost-effective solution to empower rural communities.

The use of cattle manure for biogas production has been widely acknowledged as a sustainable and effective approach to meeting energy demands in rural communities. In the target villages, residents possess a foundational understanding of biogas technology, due to their past experiences with Gobar gas plants. These traditional systems were introduced decades ago and initially provided households with a renewable source of energy. However, over time, these plants fell into disrepair, primarily due to a lack of interest, increased maintenance demands, and insufficient labor for daily operations. The challenges associated with maintaining the health of these communal facilities, such as financial commitments for routine upkeep and the proper disposal of slurry byproducts, further contributed to their decline.

Despite the shortcomings of earlier initiatives, the target beneficiaries readily appreciated the potential of the proposed biogas digesters in this research, thanks to their historical knowledge of Gobar gas plants. This familiarity enabled them to quickly grasp the objectives, benefits, and operational advantages of the new biogas systems. Unlike the earlier communal setups, the modern biodigesters are designed to be installed near individual households, making them more convenient and user-friendly. The prospect of generating biogas locally for cooking purposes was especially appealing, as it eliminates the dependency on liquefied petroleum gas (LPG), alleviating financial burdens and promoting energy self-sufficiency.

The beneficiaries of the biogas initiative have expressed enthusiasm for its practicality and sustainability compared to traditional firewood and liquefied petroleum gas (LPG). By integrating biogas production into their daily routines, households meet their energy needs while contributing to environmental sustainability. The simplicity and efficiency of biodigesters have revived the interest in biogas technology and instilled a sense of ownership and empowerment among community members. This initiative exemplifies the value of blending modern technological advancements with traditional knowledge to create impactful, sustainable solutions.

In addition to community engagement, the study leverages advanced statistical techniques to optimize biogas production and evaluate large datasets. Tools such as regression analysis, analysis of variance (ANOVA), and artificial neural networks (ANNs) have been employed to analyze and predict biogas output. Regression analysis examines the relationship between input and output variables, facilitating the creation of predictive models for estimating energy values. ANOVA facilitates statistical testing of datasets containing multiple variables or groups, ensuring accurate predictions. ANNs, inspired by the biological neural system, model and optimize biogas or methane production through interconnected processing elements, learning, and adapting from data. The multilayer perceptron (MLP), a common ANN structure, provides exceptional accuracy by simulating the relationship between input and output variables [5,6].

By combining these statistical approaches with practical biodigester deployment, the initiative addresses the challenges of traditional biogas testing, which is often time-intensive and expensive. ANN models, supported by regression analysis and ANOVA, have shown high accuracy in correlating predicted and experimental data, making them invaluable for optimizing parameters such as feed type, microbial activity, and digestion efficiency. Studies demonstrate the applicability of ANN in various bioreactor setups, including floating drum anaerobic digesters and granular sludge bed reactors [7].

This integrated approach enhances biogas production efficiency and strengthens the socio-economic fabric of rural communities. It underscores the importance of data-driven decision-making alongside grassroots participation, paving the way for sustainable energy solutions that improve livelihoods, foster environmental conservation, and drive technological progress.

2. Proposed Methodology

This study focused on the design, construction, deployment, and operation of a small-scale anaerobic digester for sustainable biogas production using cattle manure. The primary materials used for the construction of the biodigester included high-quality polyethylene for the digester body, which was selected for its durability, flexibility, and resistance to anaerobic conditions. The biodigester was designed as a balloon-type system to ensure easy scalability and simple operation.

Feedstock for the digester primarily consisted of cattle manure, which was chosen due to its high organic content and availability in the target rural communities. The manure was mixed with water in a 1:1 ratio to form a slurry, ensuring the proper consistency for optimal biogas production [5,6]. This slurry was then fed into the biodigester, where anaerobic bacteria facilitated the breakdown of organic matter and the production of biogas. The digester was operated under controlled temperature conditions, ideally between 30 and 40 °C, to support the activity of mesophilic bacteria, which are most efficient at these temperatures.

Experimental data on biogas production were used for statistical analysis, such as regression analysis, ANN technology, and the ANOVA method. These studies help to correlate the input and output data of the experimental dataset. This also helps to predict the data by training and validating the given data for further analysis. To carry out these studies, some basic statistical analyses were performed to represent the collected data. They are descriptive analyses, plotting graphs between variables to correlate the values. The graphs used to represent the data included a scatterplot, a 3D scatterplot, a scatterplot along with a regression fit line, and a contour plot.

2.1. Statistical Analysis

A statistical study, such as descriptive analysis, was performed to segregate the available data. To interpret the dataset, a scatterplot, a contour plot, and 3D scatterplot were plotted to check the segregated data. A scatterplot visually represents the correlation between two variables in a dataset by plotting data points on a Cartesian coordinate system. Along with a normal scatterplot, a regression fit line graph was also plotted, which shows a linear regression fit line along with the relationship between two variables in a dataset. A contour plot represents three-dimensional data on a two-dimensional plane, providing a visual interpretation of variations within the dataset. Similarly, a 3D scatterplot maps data points in three-dimensional space using Cartesian coordinates, serving as a fundamental method for illustrating relationships among three variables in a dataset.

2.2. Regression Analysis

Regression analysis comprises statistical techniques that estimate the relationship between a known variable and other variables within a dataset. It was utilized to assess the relationship between the variables in the data. It can produce a model equation for evaluating the data.

Yi = f (Xi, β) + ei

Yi = dependent variable; F = function; Xi = independent variable;

β = unknown parameters; ei = error terms

The linear regression equation: the equation has the form

where, Y = dependent variable

Y = a + bX

X = independent variable

b = slope of the line

a = y-intercept

2.3. ANOVA

Analysis of variance is a statistical method that separates the total variability in a dataset into two components: systematic factors, which significantly impact the data, and random factors, which do not contribute to meaningful variations. ANOVA is a conceptual way of performing statistical testing on a dataset that contains different variables or diverse groups of data [7,8,9]. The fundamental ANOVA model is the one-way model that evaluates the common mean values for given variables. In ANOVA, various tests are carried out to determine the hypothesis. If the factor ratio is equal to 1, there is no difference in the given group set, and the null hypothesis is accepted; if not, the alternative hypothesis is accepted. It also carries out some basic statistics such as mean, standard deviation, and class intervals based on the levels given in the dataset.

2.4. ANN

An artificial neural network mimics the functioning of the human brain by processing information through a network of interconnected units called neurons. These neurons collaborate to analyze data patterns and solve complex problems efficiently [10]. The ANN model was constructed based on input data and corresponding output results, followed by validation using experimental data. Throughout the training phase, the model identified relationships among input parameters that impact biogas yield. The acquired knowledge will subsequently be utilized to predict experimental outcomes.

2.5. Operational Parameters

Key parameters, such as the input feed rate, retention time, gas production rate, and slurry management, were monitored. The retention time in the digester was maintained at approximately 21 days (about 3 weeks) to allow for sufficient digestion and biogas production. The gas produced was captured using a gas holder connected to the digester through a gas pipe, with a pressure relief valve to prevent over-accumulation of gas. Biogas yield was measured by monitoring the volume of gas produced over a fixed period and was recorded regularly to assess the efficiency of the system.

2.6. Monitoring and Maintenance

The digester was continuously monitored to ensure optimal functioning. Parameters such as gas quality (methane content), temperature, and slurry consistency were checked daily. The bio-slurry produced as a byproduct of the digestion process was regularly removed and used as organic fertilizer, enhancing the nutrient content of the soil. The system was designed to require little maintenance and minimal technical expertise, and was monitored by local farmers to ensure smooth operation. This small-scale biodigester setup aimed to demonstrate the feasibility of using cattle manure as a sustainable feedstock for biogas production while offering practical benefits in terms of waste management, energy production, and soil enrichment for rural farming communities.

2.7. Sustainability Goals Addressal

The methodology for promoting biogas technology focuses on multiple benefits, encompassing ecological, health, financial, and social aspects. Ecologically, biogas technology helps maintain clean air and water by reducing greenhouse gas emissions and preventing soil and water pollution. It converts agricultural waste into biogas, producing organic fertilizers that enhance soil health. Health-wise, biogas eliminates the need for firewood, providing smoke-free cooking that significantly improves indoor air quality, thus promoting better health and lifestyle. The financial benefits are substantial, as biogas offers an affordable, sustainable alternative to fossil fuels and LPG, saving households up to INR 30,000 per year (USD 346.00), demonstrating its cost-effectiveness. Socially, biogas serves as a reliable and clean cooking fuel for farmers, while the byproduct, bio-slurry, acts as organic manure, which enhances agricultural productivity and supports sustainable farming practices. This approach fosters a circular economy by utilizing organic waste for energy and improving crop yields, making the technology both economically and environmentally beneficial [1,2].

3. Results and Discussion

3.1. Scatterplot

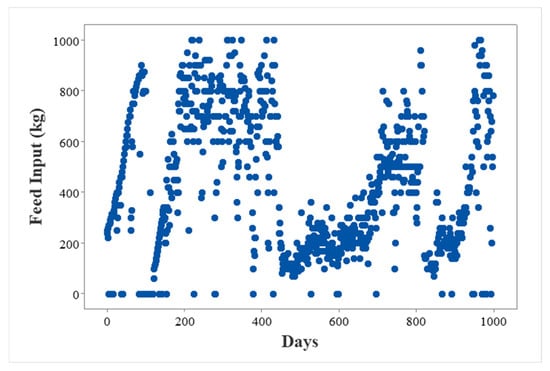

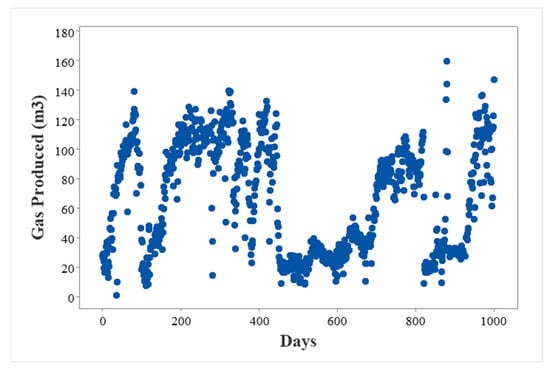

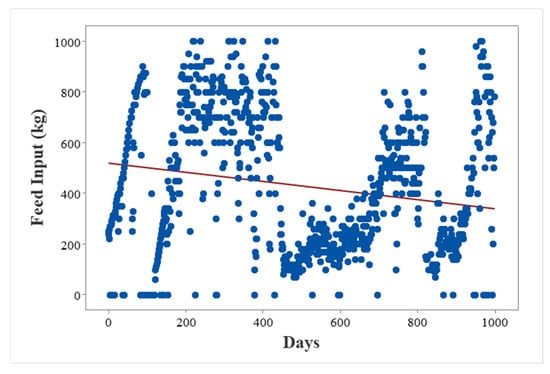

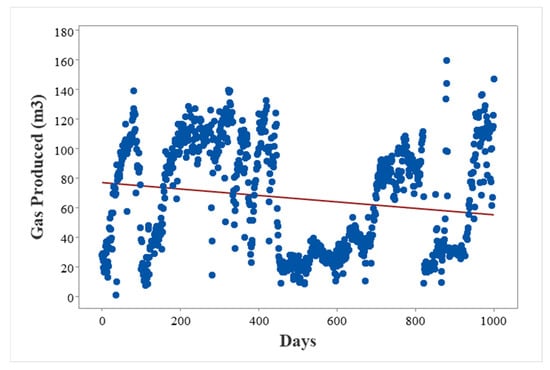

A scatterplot is used to represent the correlation between two variables. Figure 1 and Figure 2 represent the scatterplot between Days vs. Feed Input (kg) and Days vs. Gas Produced (m3). A scatterplot with a regression fit line represents the linear regression by plotting a fit line for two variables. Figure 3 and Figure 4 represent the scatterplot with a regression fit line between Days vs. Feed Input (kg) and Days vs. Gas Produced (m3).

Figure 1.

Scatterplot between Days vs. Feed Input (kg).

Figure 2.

Scatterplot between Days vs. Gas Produced (m3).

Figure 3.

Scatterplot with Regression Fit Line between Days vs. Feed Input (kg).

Figure 4.

Scatterplot with Regression Fit Line between Days and Gas Produced (m3).

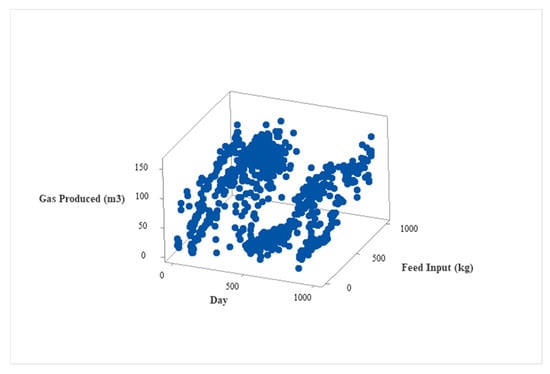

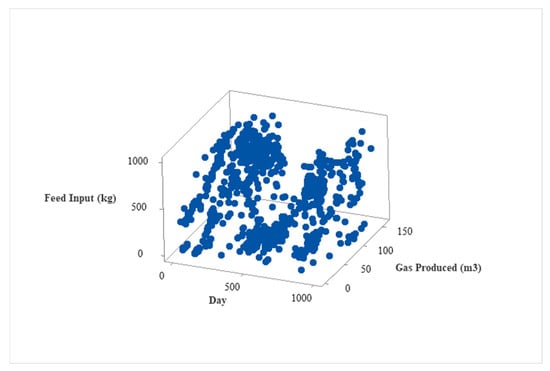

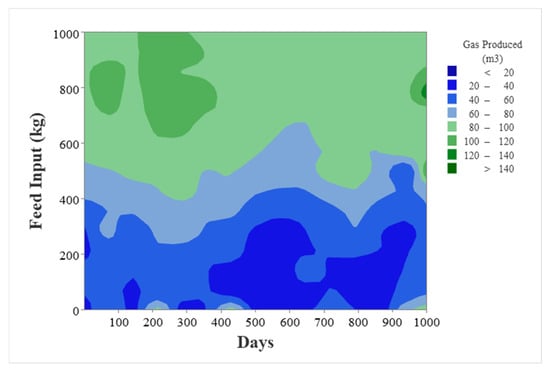

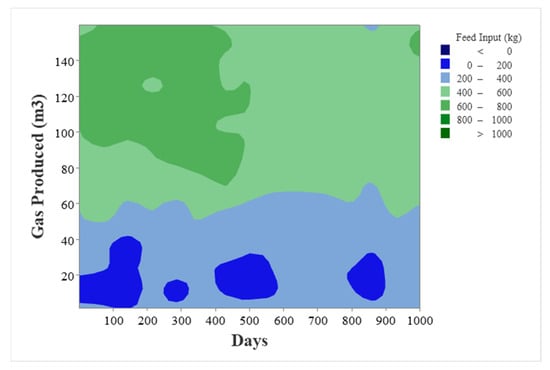

3.2. D Scatterplot and Contour Plot

Along with the scatterplot, two more plots, a 3D scatterplot and a contour plot, represent the correlation between two or three variables. A 3D scatterplot represents the plot between three variables Days, Feed Input (kg), and Gas Produced (m3). Figure 5 and Figure 6 represent the 3D scatterplot between Days, Feed Input (kg), and Gas Produced (m3). It helps to represent the data in the three-dimensional view, which helps us to analyze the data quickly. Figure 7 and Figure 8 represent the contour plot between Days, Feed Input (kg), and Gas Produced (m3).

Figure 5.

3D scatterplot between Days, Feed Input (kg), and Gas Produced (m3).

Figure 6.

3D scatterplot between Days, Gas Produced (m3) and Feed Input (kg).

Figure 7.

Contour plot between Days, Feed Input (kg), and Gas Produced (m3).

Figure 8.

Contour plot between Days, Gas Produced (m3), and Feed Input (kg).

3.3. ANN Modeling and Prediction

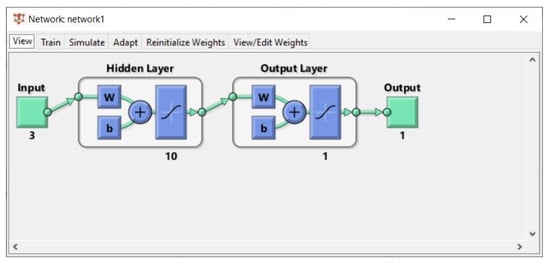

MATLAB R2014 v8.3 is used to predict gas production using the ANN tool. The variables present in the dataset are used as input and target data to predict the output based on the given data. The Feed Input (kg), Digester pH, and Digester Temperature (°C) variables are used as input data, whereas Gas Produced (m3) is used as target data. Both input and target data are used to produce an output network. A Feed-Forward Backpropagation ANN is employed to predict gas production using the Levenberg–Marquardt (trainlm) training algorithm and the Mean Squared Error (MSE) method. The ANN divides the input and target data into three subsets: 60% for training, 20% for testing, and 20% for validation. The neural network's performance depends on several hidden layers, with some neurons, as shown in Figure 9. Here, for analysis purposes, the 3-10-10-1 (three inputs with two hidden layers, each one containing ten neurons, which gives a single output) algorithm is used [11,12].

Figure 9.

Neural Network Diagram.

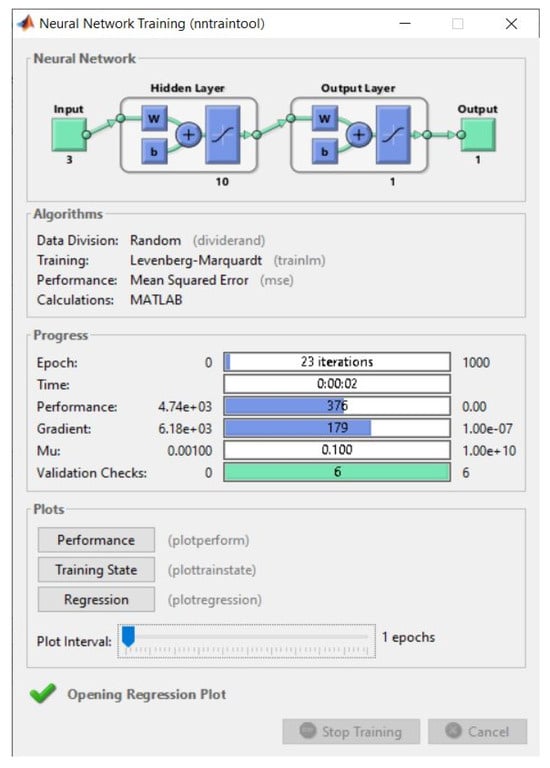

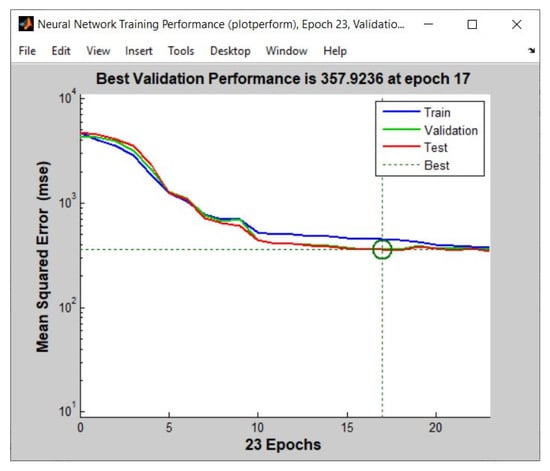

The ANN summary interface provides real-time updates on training progress and includes an option for users to halt the process at any stage by selecting “Stop Training”. Within the performance section, the regression analysis evaluates the linear correlation between the network’s predicted outputs and the actual target values [13,14]. For this study, all the ANN tool parameters remained at their default settings, and the network underwent training for 1000 iterations. Figure 10 illustrates the performance plot, highlighting the point of optimal validation performance.

Figure 10.

Summary of ANN modeling.

Performance validation and regression analysis were assessed once the iteration process achieved the lowest gradient value. The results indicated that both the validation and the test values aligned closely with the best-fit line. This alignment suggests a minimal discrepancy between the actual and theoretical outcomes, with the gradient reaching its lowest point of 102.5 at the 17th epoch, as shown in Figure 11.

Figure 11.

Performance Evaluation Plot of the Artificial Neural Network (ANN).

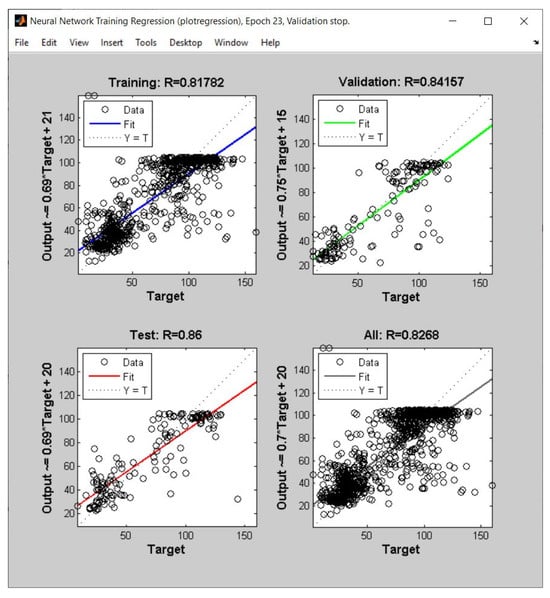

As illustrated in Figure 12, the parity plot reveals that the fit data line and the cluster line are nearly overlapping, with R-values of 0.81782, 0.84157, and 0.86 for training, validation, and testing, respectively. Collectively, these values correspond to an overall response of R = 0.8268. These findings indicate that the neural network model effectively replicates the gas yield data based on the selected input parameters used for model training and fitting [15]. An R-value above 81% suggests minimal experimental error, demonstrating a high level of agreement between the experimental data and the model’s predictions.

Figure 12.

Parity plots comparing predicted values with experimental values for training, testing, and validation.

The economic implications of biogas adoption are equally notable. By transforming cattle waste into a valuable resource, households can generate wealth from what was previously considered a burdensome waste product. This shift in perspective has the potential to improve the economic stability of rural families, particularly in areas where agriculture is the primary livelihood. The use of biogas for cooking eliminates the financial strain of purchasing LPG, which has become increasingly expensive, and provides a more stable and predictable energy source [16]. This economic empowerment fosters greater self-reliance, which is crucial in rural communities where access to external financial support can be limited.

Overall, the adoption of biogas systems in rural households has proven to be a highly effective intervention, not only for energy generation but also for improving environmental sustainability and public health. The benefits of biogas production extend far beyond cooking and waste management, offering economic advantages, promoting sustainable agriculture, and improving overall quality of life. These findings support the broader implementation of biogas technology as a key component of rural development strategies, particularly in areas facing challenges related to energy access, environmental degradation, and poverty [17,18].

4. Conclusions

This study combines statistical analysis and community-focused interventions to enhance biogas production and utilization, providing transformative benefits to economically unprivileged communities. By employing readily available resources, such as cattle manure and open land, self-sustaining biogas units have enabled households to generate their own cooking gas. This initiative reduces reliance on costly liquefied petroleum gas (LPG) and the physically demanding task of collecting firewood, ensuring access to clean and sustainable energy. Alongside addressing energy scarcity and environmental degradation, the intervention promotes cost-effective and eco-friendly solutions tailored to the needs of rural communities [19].

The statistical analysis performed in this study evaluates biogas production data using advanced techniques, such as basic and descriptive analysis, regression analysis, ANOVA, and artificial neural networks. These methods enable data segregation for experimental and industrial-scale applications, providing insights into input–output relationships. Additionally, graphical interpretations, including scatterplots, scatterplots with regression fit lines, contour plots, and 3D scatterplots, were utilized to develop predictive models for biogas production. These tools aid in optimizing parameters to estimate the required input and expected output for industrial-scale operations, improving efficiency and scalability.

The biogas units introduced in this initiative are designed to be simple, user-friendly, and adaptable, requiring minimal technical expertise and labor. Continuous monitoring ensures consistent operation, maximizing biogas yields while empowering beneficiaries with a sense of ownership and confidence. The adoption of biogas technology has significantly improved household convenience, reduced indoor air pollution, and mitigated environmental impacts. Moreover, the byproduct of the biodigesters—organic biofertilizer—enhances agricultural productivity, adding economic value for farming households.

Unlike traditional energy interventions, this research has taken a comprehensive approach to rural development [20]. By integrating advanced statistical analysis with community-focused implementation, it offers a replicable model for sustainable energy solutions. More than just an energy alternative, this initiative lowers household expenses, reduces indoor air pollution, and mitigates environmental degradation, all while promoting resilience in drought-prone regions. This study reinforces the viability of biogas technology by setting a new standard for data-driven, community-centered sustainability efforts, demonstrating how targeted innovations can drive long-term socio-economic and environmental change.

Author Contributions

Conceptualization C.D. and V.K.K.K.; methodology, C.D.; software, V.K.K.K.; validation, C.D., V.K.K.K. and K.A.; formal analysis, C.D.; investigation, V.K.K.K.; resources, K.A.; data curation, C.D.; writing—original draft preparation, C.D.; writing—review and editing, C.D.; visualization, V.K.K.K.; supervision, V.K.K.K.; project administration, V.K.K.K.; funding acquisition, V.K.K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Department of Science and Technology (DST), Government of India, grant number: DST/SEED/SCSP/STI/2020/354; Dated 27 March 2021.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors sincerely express their heartfelt gratitude to the Department of Science and Technology (DST), Government of India, for generously funding this project titled “STI Hub for Income Generation and Livelihood Improvement of Scheduled Caste Community of Guntur District, Andhra Pradesh [File No.: DST/SEED/SCSP/STI/2020/354; Dated 27 March 2021]. Deep appreciation extended to the authorities of VFSTR, Guntur, Andhra Pradesh, for their invaluable support throughout the project. Furthermore, the authors are immensely grateful to all the target beneficiaries of the STI Hub’s Intervention 3, “Sustainable Biogas Production by Anaerobic Digestion of Farm Wastes and Cattle Manure,” for their cooperation, encouragement, and unwavering support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354. [Google Scholar] [CrossRef]

- Surendra, K.; Takara, D.; Hashimoto, A.G.; Khanal, S.K. Biogas as a sustainable energy source for developing countries: Opportunities and challenges. Renew. Sustain. Energy Rev. 2014, 31, 846–859. [Google Scholar] [CrossRef]

- Kusmiyati, U.; Wijaya, D.K.; Hartono, B.J.R.; Shidik, G.F.; Fudholi, A. Harnessing the power of cow dung: Exploring the environmental, energy, and economic potential of biogas production in Indonesia. Results Eng. 2023, 20, 101431. [Google Scholar] [CrossRef]

- Kampman, B.; Leguijt, C.; Scholten, T.; Tallan-Kelpsaite, J.; Brückmann, R.; Maroulis, G.; Lesschen, J.P.; Meesters, K.; Sikirica, N.; Elbersen, B. Optimal Use of Biogas from Waste Streams: An Assessment of the Potential of Biogas from Digestion in the EU Beyond 2020; European Commission: Brussel, Belgium, 2017. [Google Scholar]

- Rittmann, B.E.; McCarty, P.L. Environmental Biotechnology: Principles and Applications; McGraw Hill: Singapore, 2001. [Google Scholar]

- Rowse, L.E. Design of Small Scale Anaerobic Digesters for Application in Rural Developing Countries. Scholar Commons. Available online: https://scholarcommons.usf.edu/etd/ (accessed on 1 September 2024).

- Weisberg, S. Applied Linear Regression, 4th ed.; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Janczak, D.; Marczuk, A.; Dach, J. Energy value estimation of silages for substrate in biogas plants using an artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

- King, B.M. Analysis of variance. In International Encyclopedia of Education, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2010; pp. 32–36. [Google Scholar] [CrossRef]

- Almomani, F. Prediction of biogas production from chemically treated co-digested agricultural waste using artificial neural network. Fuel 2020, 280, 118573. [Google Scholar] [CrossRef]

- Sewsynker-Sukai, Y.; Faloye, F.; Kana, E.B.G. Artificial neural networks: An efficient tool for modelling and optimization of biofuel production (a mini review). Biotechnol. Biotechnol. Equip. 2016, 31, 221–235. [Google Scholar] [CrossRef]

- Şenol, H. Methane yield prediction of ultrasonic pretreated sewage sludge by means of an artificial neural network. Energy 2021, 215, 119173. [Google Scholar] [CrossRef]

- Sathish, S.; Vivekanandan, S. Parametric optimization for floating drum anaerobic bio-digester using Response Surface Methodology and Artificial Neural Network. Alex. Eng. J. 2016, 55, 3297–3307. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.-C.; Lim, J.W.; Zhang, J. Bioinformatics analysis of metagenomics data of biogas-producing microbial communities in anaerobic digesters: A review. Renew. Sustain. Energy Rev. 2019, 100, 110–126. [Google Scholar] [CrossRef]

- Yi-Fan, H.; Chang-Zhu, Y.; Jin-Feng, D.; Wen-Hong, P.; Jia-Kuang, Y. Modeling of expanded granular sludge bed reactor using artificial neural network. J. Environ. Chem. Eng. 2017, 5, 2142–2150. [Google Scholar] [CrossRef]

- Ghimire, P.C. SNV supported domestic biogas programmes in Asia and Africa. Renew. Energy 2013, 49, 90–94. [Google Scholar] [CrossRef]

- United Nations (UN). Transforming Our World: The 2030 Agenda for Sustainable Development; UN: New York, NY, USA, 2015. [Google Scholar]

- Kossmann, W.; Kossmann, W.; Pönitz, U. Biogas Digest Volume I: Biogas Basics; Information and Advisory Service on Appropriate Technology (ISAT), Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ): Eschborn, Germany, 1999. [Google Scholar]

- Singh, K.J.; Sooch, S.S. Comparative study of economics and environmental impact of biogas plants in rural areas of Punjab, India. Energy Convers. Manag. 2004, 45, 1329–1341. [Google Scholar] [CrossRef]

- United Nations Development Programme (UNDP). Biogas Technology for Rural Development: Lessons Learned from Successful Case Studies; UNDP: New York, NY, USA, 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).