Automatic Ladle Tracking with Object Detection and OCR in Steel Melting Shops †

Abstract

1. Introduction

- 1.

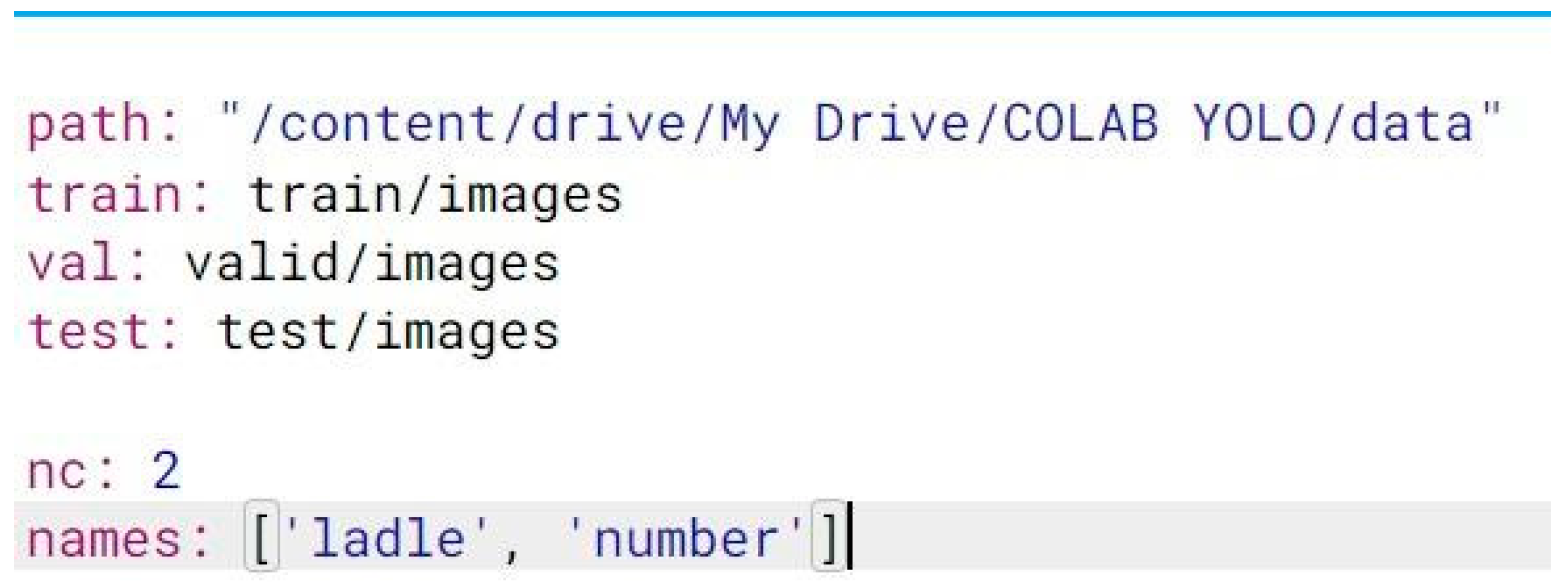

- A computer-vision-based ladle identification system that uses grayscale images of ladles to detect ladles in real time.

- 2.

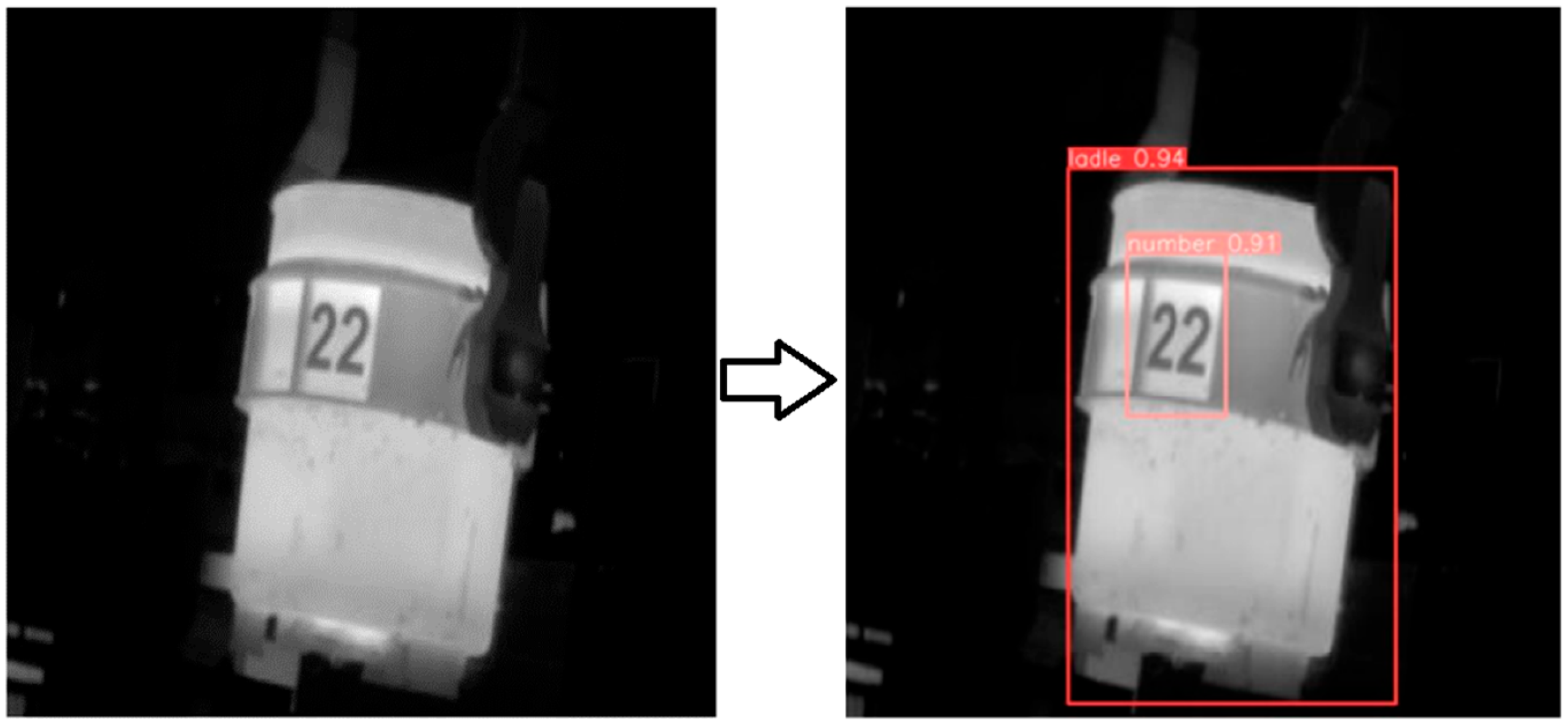

- A preprocessing-based OCR method that significantly improves the accuracy of ladle number extraction in challenging industrial environments.

- 3.

- A robust methodology for integrating object detection and OCR, which can further be used for any industrial process that requires real-time monitoring and tracking.

2. Proposed Methodology

2.1. Computer-Vision-Based Ladle Identification

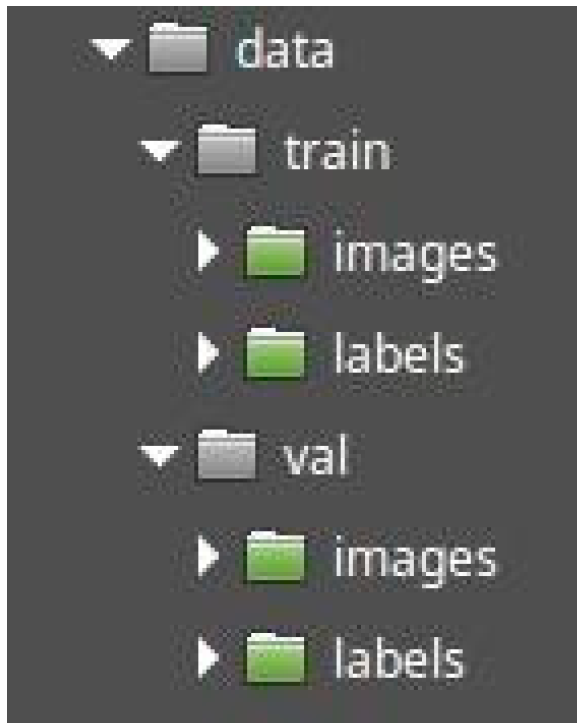

- path: root directory for storing dataset;

- train, validation, and test: pathways to the training, validation, and testing sets;

- nc: count of object classes (ladle and number);

- names: class names (“ladle”; “number”);

- batch_size: number of images trained per iteration;

- epochs: how many training steps to update model parameters.

- Learning rate: 0.001;

- Batch size: 16;

- Epochs: 100;

- Optimizer: Adam;

- Loss function: CIoU loss.

- YOLOv5 → YOLOv8 has a better backbone, better detection of small objects, and better computational efficiency.

- Faster R-CNN → It has very high accuracy but is computationally costly, though, and is not appropriate for application in real-time industrial scenarios.

- SSD (Single Shot MultiBox Detector) → Slightly faster than Faster R-CNN but not quite as good as YOLOv8.

2.2. Enhanced Ladle Identification Through Preprocessing and OCR Integration

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Adediran, A.; Yliniemi, J.; Moukannaa, S.; Ramteke, D.; Perumal, P.; Illikainen, M. Enhancing the thermal stability of alkali-activated fe-rich fayalite slag-based mortars by incorporating ladle and blast furnace slags: Physical, mechanical and structural changes. Cem. Concr. Res. 2023, 166, 107098. [Google Scholar] [CrossRef]

- Ranjan, P.R.; Charan, M.P.; Alaka, S.; Duryodhan, J. Management of inventory for firms’ efficiency—A study on steel manufacturing industry. J. Adv. Manag. Res. 2024, 19, 443–463. [Google Scholar] [CrossRef]

- Burgmann, W.; Göhler, K. Modern vacuum pumps for the vacuum degassing of steel in small and large vacuum-degassing units. Metallurgist 2013, 57, 516–525. [Google Scholar] [CrossRef]

- Mutian, H.; Shuwang, W.; Yanfei, M.; Yusen, Z.; Zilin, C.; Imri, F.; Joseph, S.; Hua, Z.; Xinyuan, Z.; Ximin, H. Strong tough hydrogels via the synergy of freeze-casting and salting out. Nature 2021, 590, 594–599. [Google Scholar] [CrossRef]

- Qiang, L.; Christiaan, P.P. Large bubble-resolved direct numerical simulation for multiphase flow applied to gas-stirred ladles: Grid resolution and plug eccentricity effects. Metall. Mater. Trans. B 2023, 54, 1290–1313. [Google Scholar] [CrossRef]

- Červeňanská, Z.; Kotianová, J.; Važan, P.; Juhásová, B.; Juhás, M. Multi-objective optimization of production objectives based on surrogate model. Appl. Sci. 2020, 10, 7870. [Google Scholar] [CrossRef]

- Abidov, K.; Dadajanov, K.; Absoatov, U.; Sabitov, S. System of consistent rotation of speeds of drive electric motors of movement mechanisms of overhead cranes. E3S Web Conf. 2023, 383, 04053. [Google Scholar] [CrossRef]

- Jančar, D.; Machů, M.; Velička, M.; Tvardek, P.; Vlček, J. Use of numerical methods for the design of thermal protection of an rfid-based contactless identification system of ladles. Metals 2022, 12, 1163. [Google Scholar] [CrossRef]

- Zhou, J.; Niu, D.; Li, Q.; Liu, J. Iron and steel ladles tracking management system based on RFID and WLAN. J. Eng. 2019, 2019, 8310–8314. [Google Scholar] [CrossRef]

- Corna, N.; Dentella, F. Recent developments in the application of oxygen combustion to ladle preheating stations and steel reheating furnaces. La Metall. Ital. 2011, 103, 33–38. [Google Scholar]

- Zajec, P.; Rožanec, J.M.; Theodoropoulos, S.; Fontul, M.; Koehorst, E.; Fortuna, B.; Mladenić, D. Few-shot learning for defect detection in manufacturing. Int. J. Prod. Res. 2024, 62, 6979–6998. [Google Scholar] [CrossRef]

- Ördek, B.; Borgianni, Y.; Coatanea, E. Machine learning-supported manufacturing: A review and directions for future research. Prod. Manuf. Res. 2024, 12, 2326526. [Google Scholar] [CrossRef]

- Paranjape, A. Smart parking system using image detection algorithms optical character recognition (ocr). Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 1537–1541. [Google Scholar] [CrossRef]

| Class | Precision | Recall | mAP50 | mAP50-95 |

|---|---|---|---|---|

| Ladle | 0.992 | 1.000 | 0.995 | 0.937 |

| Number | 0.974 | 0.996 | 0.993 | 0.713 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murugan, K.; Senthilmurugan, M.; Senthilkumar, V.V.; Velusamy, H.; Sekar, K.; Buvanesan, V.; Venugopal, M. Automatic Ladle Tracking with Object Detection and OCR in Steel Melting Shops. Eng. Proc. 2025, 95, 11. https://doi.org/10.3390/engproc2025095011

Murugan K, Senthilmurugan M, Senthilkumar VV, Velusamy H, Sekar K, Buvanesan V, Venugopal M. Automatic Ladle Tracking with Object Detection and OCR in Steel Melting Shops. Engineering Proceedings. 2025; 95(1):11. https://doi.org/10.3390/engproc2025095011

Chicago/Turabian StyleMurugan, Kabil, Mahinas Senthilmurugan, Venbha V. Senthilkumar, Harshita Velusamy, Karthiga Sekar, Vasanthan Buvanesan, and Manikandan Venugopal. 2025. "Automatic Ladle Tracking with Object Detection and OCR in Steel Melting Shops" Engineering Proceedings 95, no. 1: 11. https://doi.org/10.3390/engproc2025095011

APA StyleMurugan, K., Senthilmurugan, M., Senthilkumar, V. V., Velusamy, H., Sekar, K., Buvanesan, V., & Venugopal, M. (2025). Automatic Ladle Tracking with Object Detection and OCR in Steel Melting Shops. Engineering Proceedings, 95(1), 11. https://doi.org/10.3390/engproc2025095011