Effect of FSW Parameters on Microstructure and Mechanical Properties of Dissimilar Aluminum Joints †

Abstract

1. Introduction

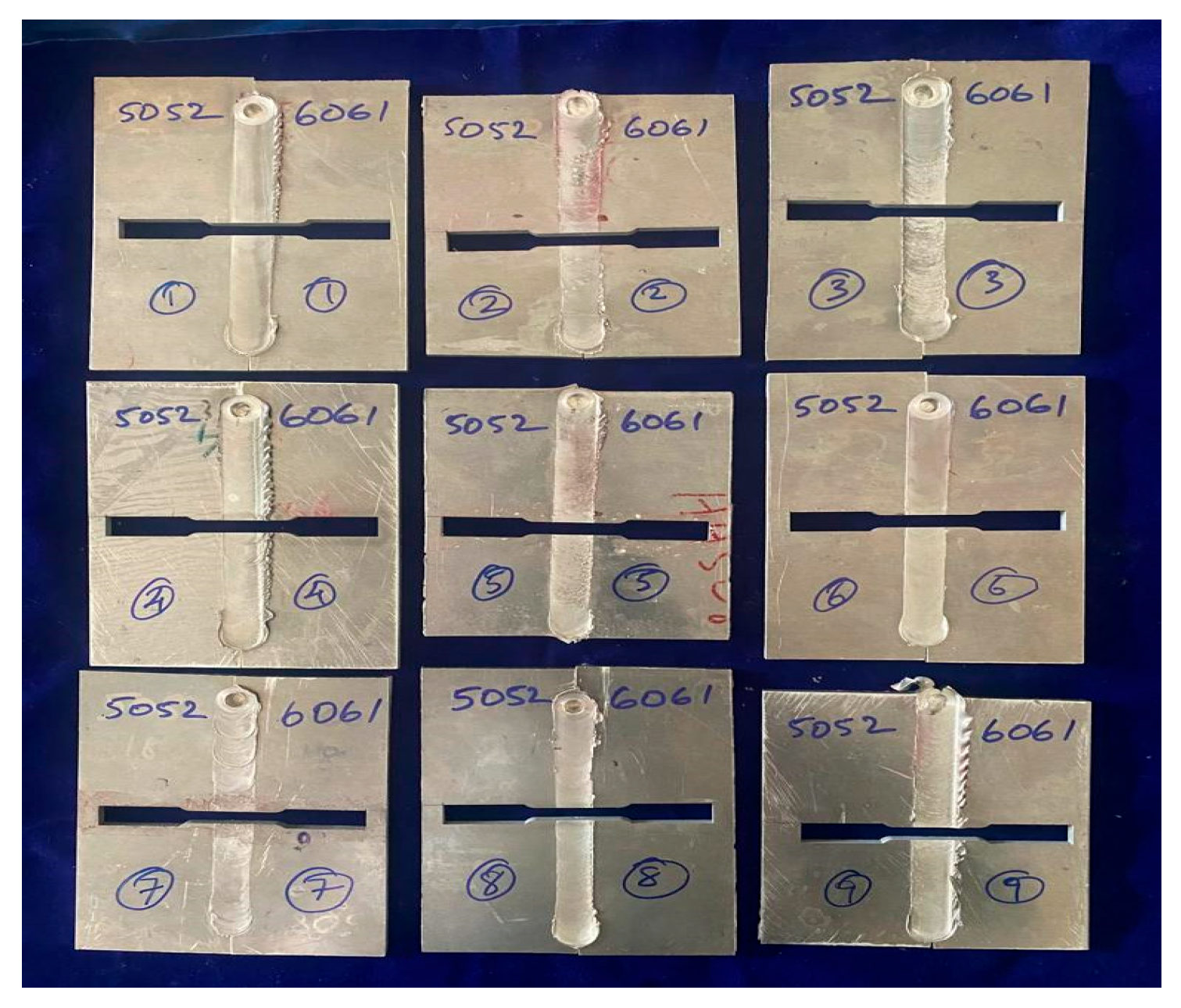

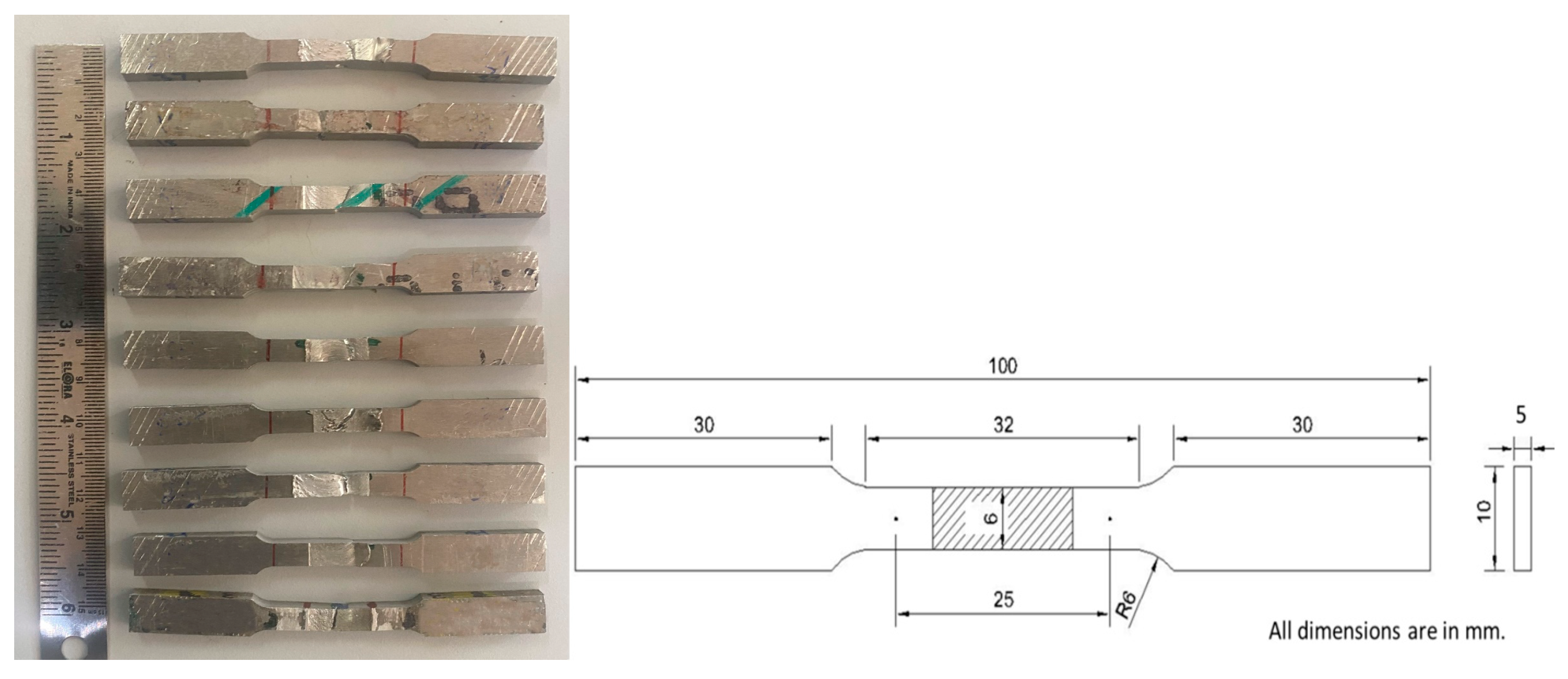

2. Experimental Details

3. Results and Discussion

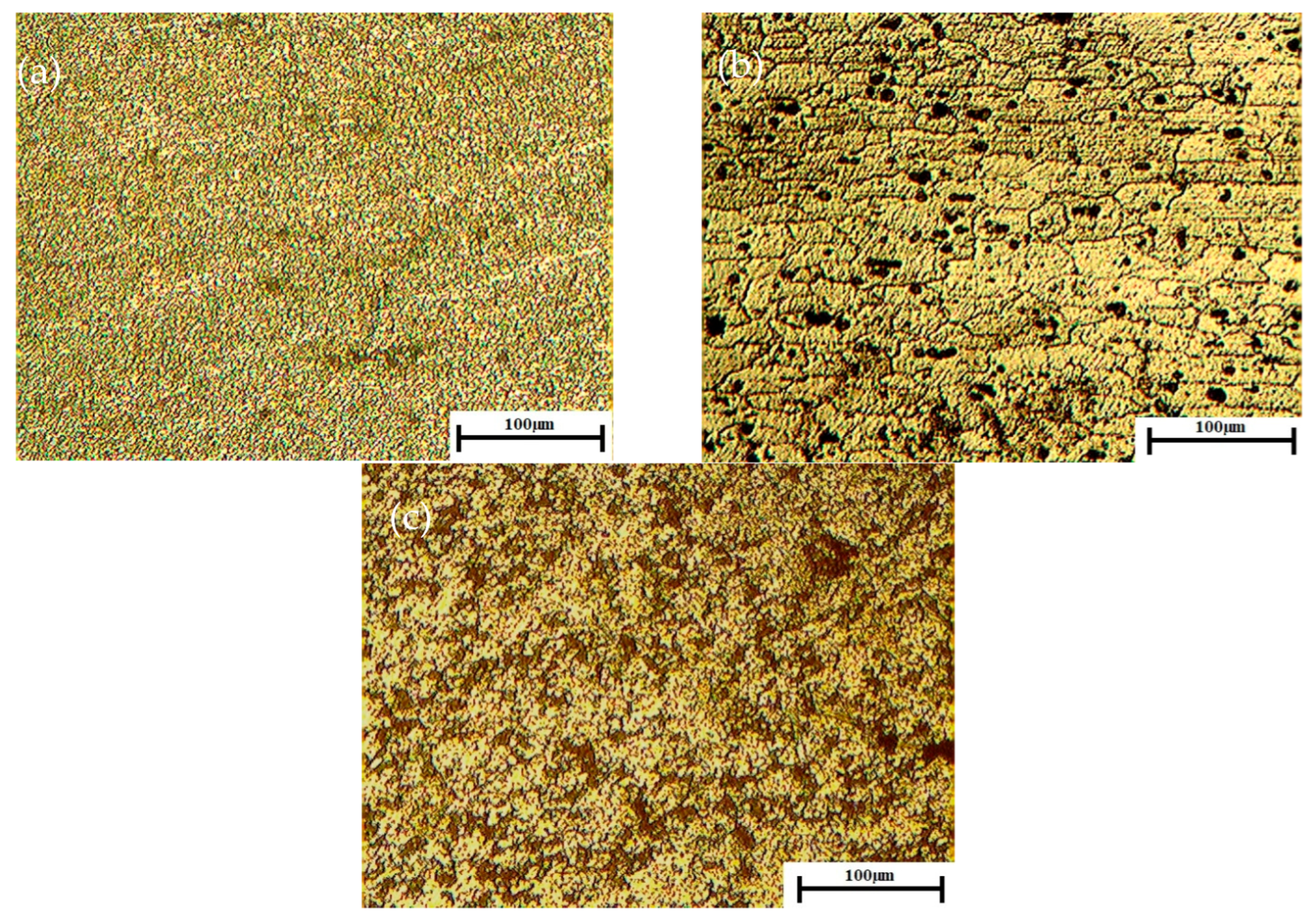

3.1. Microstructure Analysis

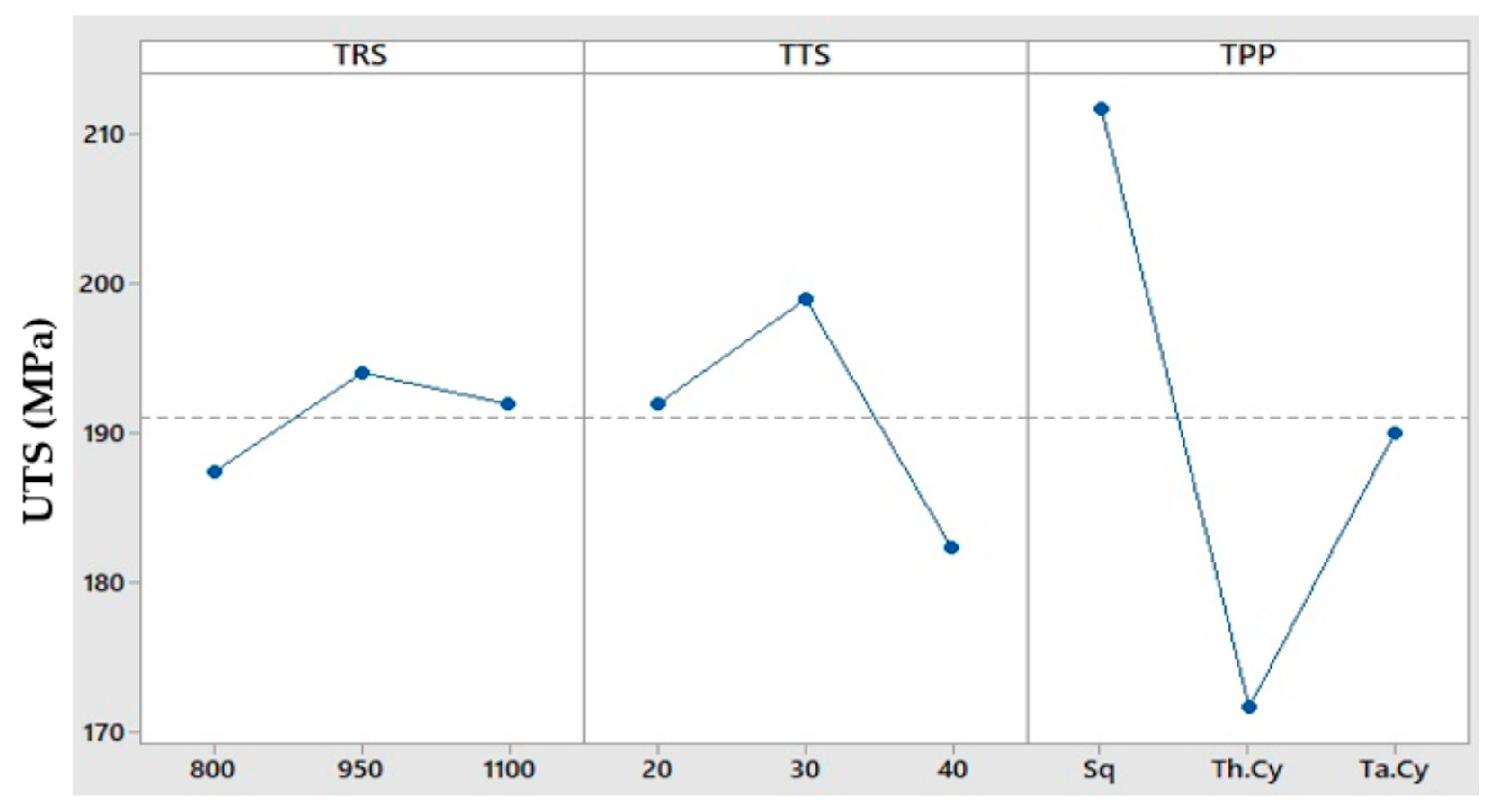

3.2. Analysis of Tensile Strength

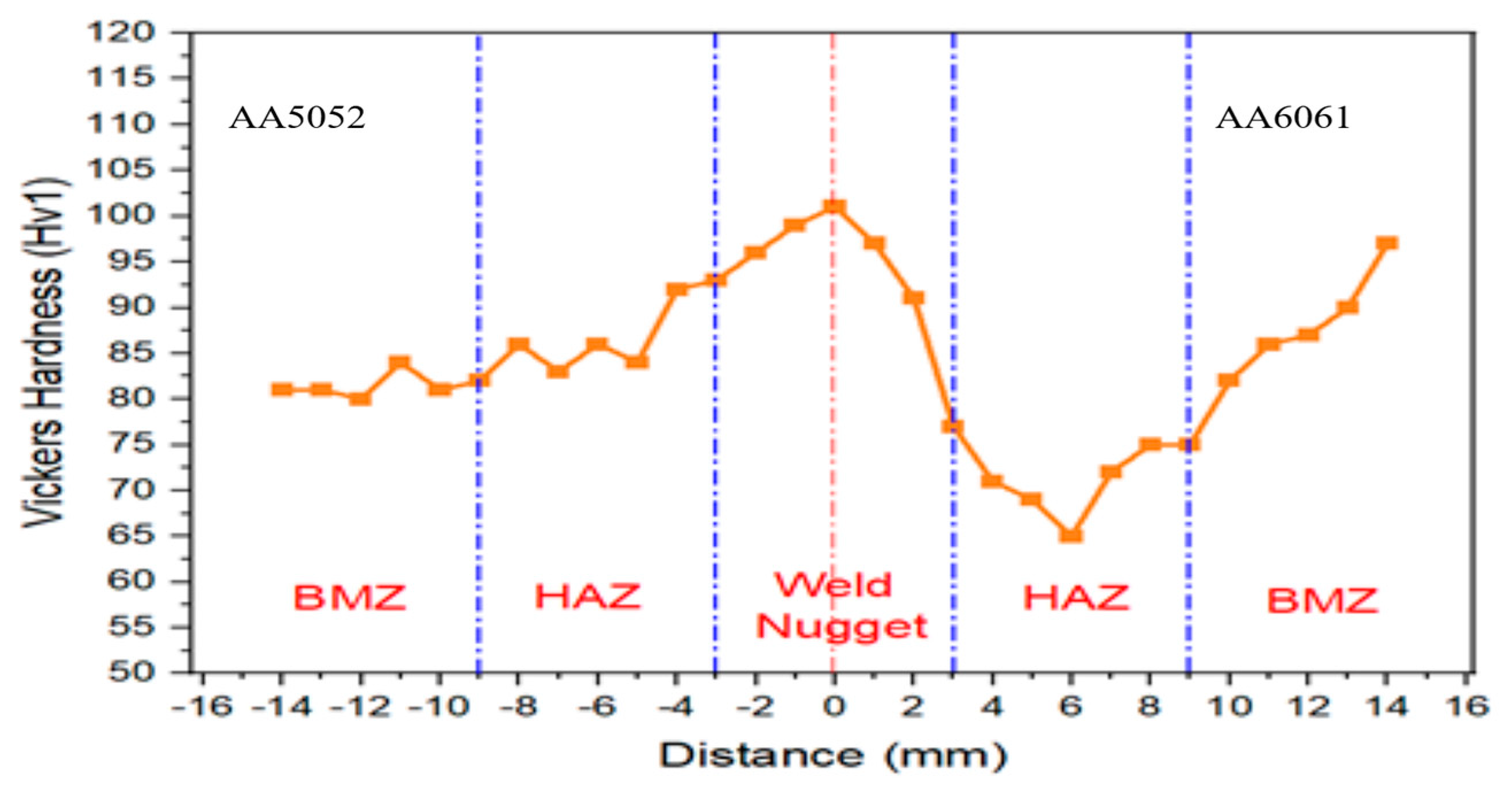

3.3. Hardness Survey

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yazidipour, A.R.; Shafiei, M.; Jamshidi Aval, H. An investigation of the microstructures and properties of metal inert gas and friction stir welds in aluminum alloy 5083. Sadhana 2011, 36, 505–514. [Google Scholar] [CrossRef]

- Kundu, J.; Singh, H. Friction stir welding of AA5083 aluminium alloy: Multi-response optimization using Taguchi-based grey relational analysis. Adv. Mech. Eng. 2016, 8, 1–10. [Google Scholar] [CrossRef]

- Tronci, A.; McKenzie, R.; Leal, R.M.; Rodriigues, D.M. Microstructural and mechanical characterization of 5xxx-H111 friction stir welded tailored blanks. Sci. Technol. Weld. Join. 2011, 16, 433–439. [Google Scholar] [CrossRef]

- Birol, Y.; Kasman, S. Effect of welding parameters on microstructure and mechanical properties of friction stir welded EN AW 5083 H111 plats. Mater. Sci. Technol. 2013, 29, 1354–1362. [Google Scholar] [CrossRef]

- Fahimpour, V.; Sadrnezhaad, S.K.; Karimzadeh, F. Microstructure and mechanical property change during FSW and GTAW of Al6061 alloy. Metall. Mater. Trans. A 2013, 44, 2187–2195. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.R.; Bajpai, A.K. Mechanical properties of friction stir welded 6061 aluminium alloy. Int. J. Eng. Res. Technol. 2013, 2, 74–80. [Google Scholar]

- Jamshidi Aval, H.; Serajzadeh, S. A study on natural aging behavior and mechanical properties of friction stir welded AA6061-T6 plates. Int. J. Adv. Manuf. Technol. 2014, 71, 933–941. [Google Scholar] [CrossRef]

- Dehghani, K.; Ghorbani, R.; Soltanipoor, A.R. Microstructural evolution and mechanical properties during the friction stir welding of 7075-O aluminum alloy. Int. J. Adv. Manuf. Technol. 2015, 77, 1671–1679. [Google Scholar] [CrossRef]

- Moradi, M.M.; Aval, H.J.; Jamaati, R.; Amirkhanlou, S.; Ji, S. Microstructure and texture evaluation of friction stir welded dissimilar aluminum alloys: AA2024 and AA6061. J. Manuf. Process. 2018, 32, 1–10. [Google Scholar] [CrossRef]

- Kasman, S. Multi-response optimization using the Taguchi-based grey relational analysis: A case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111. Int. J. Adv. Manuf. Technol. 2013, 68, 795–804. [Google Scholar] [CrossRef]

- ASTM E8/E8M–24; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2024.

- Hajiha, M.R.; Farzadi, A.; Samadani Agdam, S.A.; Shabanzadeh, A.; Ramezani, S. Microstructural and mechanical properties of dissimilar joining of AA5052 and AA6061 by friction stir welding. J. Weld. Sci. Technol. Iran 2024, 9, 39–51. [Google Scholar]

- Khalafe, W.H.; Sheng, E.L.; Bin Isa, M.R.; Shamsudin, S.B. Enhancing Mechanical Characteristics of 6061-T6 with 5083-H111 Aluminum Alloy Dissimilar Weldments: A New Pin Tool Design for Friction Stir Welding (FSW). Metals 2024, 14, 534. [Google Scholar] [CrossRef]

- Yelamasetti, B.; Sridevi, M.; Sree, N.S.; Geetha, N.K.; Bridjesh, P.; Shelare, S.D.; Prakash, C. Comparative studies on Mechanical properties and Microstructural changes of AA5052 and AA6082 dissimilar weldments developed by TIG, MIG, and FSW techniques. J. Mater. Eng. Perform. 2025, 34, 9972–9985. [Google Scholar] [CrossRef]

| Welding Parameters | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| TRS (rpm) | 800 | 950 | 1100 |

| TTS (mm/min.) | 20 | 30 | 40 |

| TPP | Square | Threaded cylinder | Tapered cylinder |

| Sample No. | TRS (RPM) | TTS (mm/min) | TPP | Tensile Strength (MPa) |

|---|---|---|---|---|

| 1 | 800 | 20 | Square | 206 |

| 2 | 800 | 30 | Th. Cyl. | 170 |

| 3 | 800 | 40 | Tap. Cyl. | 186 |

| 4 | 950 | 20 | Th. Cyl. | 184 |

| 5 | 950 | 30 | Tap. Cyl. | 200 |

| 6 | 950 | 40 | Square | 202 |

| 7 | 1100 | 20 | Tap. Cyl. | 189 |

| 8 | 1100 | 30 | Square | 227 |

| 9 | 1100 | 40 | Th. Cyl. | 166 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krishnamoorthy, J.; Murugesan, S.K.; Nagappan, S.; Prithiviraj, S.P. Effect of FSW Parameters on Microstructure and Mechanical Properties of Dissimilar Aluminum Joints. Eng. Proc. 2025, 93, 12. https://doi.org/10.3390/engproc2025093012

Krishnamoorthy J, Murugesan SK, Nagappan S, Prithiviraj SP. Effect of FSW Parameters on Microstructure and Mechanical Properties of Dissimilar Aluminum Joints. Engineering Proceedings. 2025; 93(1):12. https://doi.org/10.3390/engproc2025093012

Chicago/Turabian StyleKrishnamoorthy, Jayakumar, Saran Kumar Murugesan, Sanjuvigasini Nagappan, and Sanjay Prakash Prithiviraj. 2025. "Effect of FSW Parameters on Microstructure and Mechanical Properties of Dissimilar Aluminum Joints" Engineering Proceedings 93, no. 1: 12. https://doi.org/10.3390/engproc2025093012

APA StyleKrishnamoorthy, J., Murugesan, S. K., Nagappan, S., & Prithiviraj, S. P. (2025). Effect of FSW Parameters on Microstructure and Mechanical Properties of Dissimilar Aluminum Joints. Engineering Proceedings, 93(1), 12. https://doi.org/10.3390/engproc2025093012