Abstract

This study aims to develop a real-time gas leak detection system for application in gas cylinder filling machines. To promptly recover gas during leakage incidents, the efficiency of the gas filling process was improved by reducing resource wastage. The system utilized a Raspberry Pi with a camera for image-based detection and employed the dark channel prior method to detect the presence of gas. The message queue system was used for the real-time data transmission of gas leak status, temperature, and humidity data. The system sent data to a central server via message queuing telemetry transport (MTQQ). Node-RED was used for data visualization and anomaly alerts. Machine learning methods such as support vector machines (SVMs) and decision trees were applied to analyze the correlation between gas leaks and other environmental parameters to predict leak incidents. This system effectively detected gas leakage and transmitted and analyzed the data, significantly improving the operational efficiency of the gas cylinder filling process.

1. Introduction

In the gas cylinder filling process, detecting gas leaks is critical for ensuring operational safety and resource efficiency. Leaks pose potential safety risks such as explosions or fires and cause resource waste. To address these challenges, real-time monitoring and prompt responses to leaks are essential technical requirements. Therefore, this research aims to develop a real-time gas leak detection system applied to gas cylinder filling machines.

The system uses a Raspberry Pi with a camera for image detection and employs the dark channel prior (DCP) method to detect gas leaks. In addition to image detection, the system integrates temperature and humidity sensors to monitor environmental conditions. Data collected by these sensors are transmitted in real time using the message queuing telemetry transport (MQTT) protocol. Once the data are sent to a central server, Node-RED is used for data visualization and anomaly alerts. Machine learning algorithms such as support vector machines (SVMs) and decision trees are used to predict gas leaks and explore their relationships with environmental parameters. This system combines image analysis, data transmission, and machine learning techniques to offer more precise and efficient solutions than traditional leak detection methods and significantly enhance the efficiency and safety of gas filling operations.

2. Proposed System

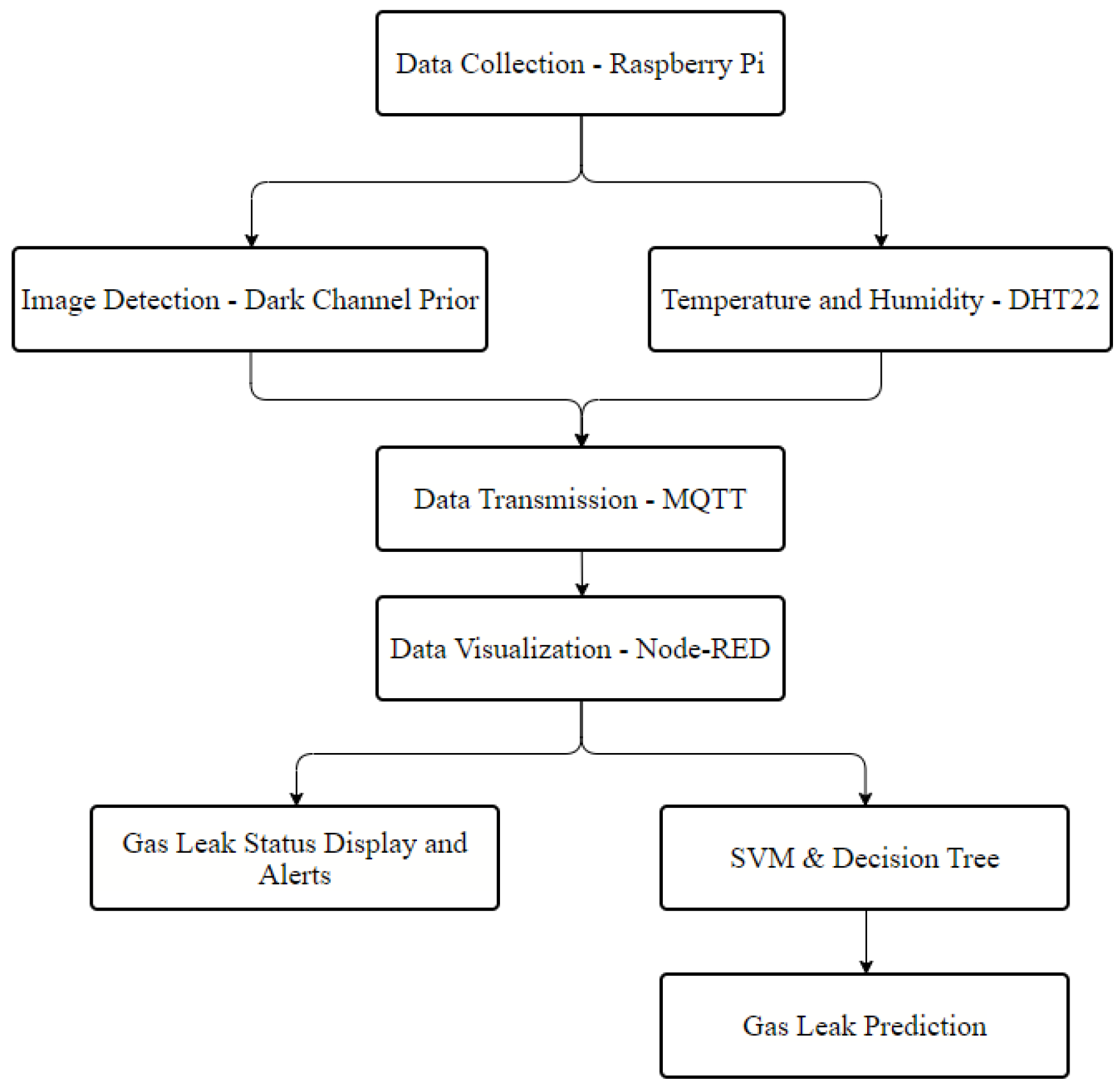

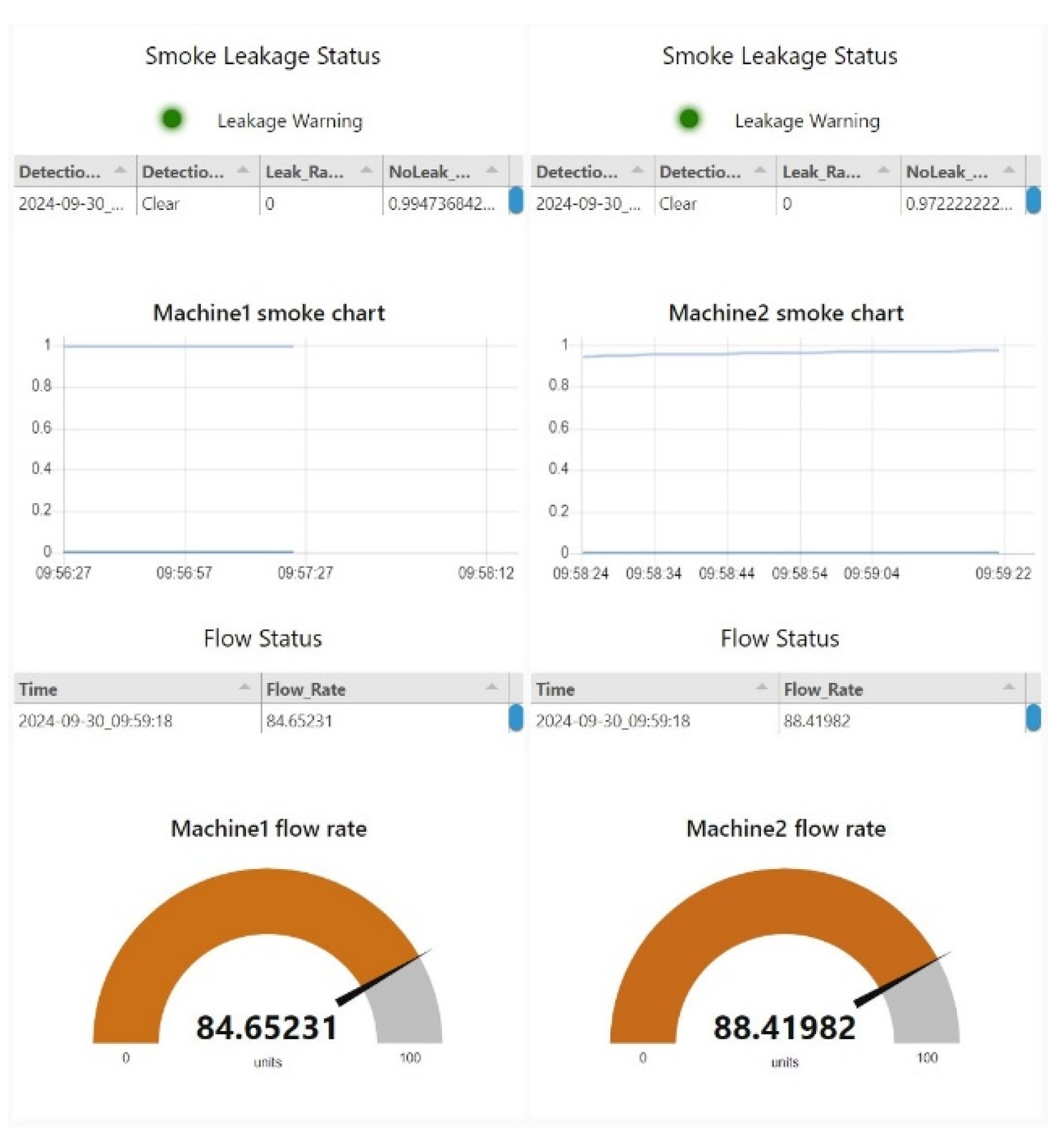

The real-time gas leak detection system developed in this study consists of hardware and software components. The hardware includes a Raspberry Pi (Raspberry Pi Foundation, Cambridge, UK) as the central processing unit, coupled with a camera module and temperature and humidity sensors to enable image detection and multi-parameter data collection. The software integrates image processing techniques, communication protocols, and machine learning algorithms to perform full-process analysis, from data collection to leak prediction (Figure 1).

Figure 1.

System flowchart.

2.1. Hardware

2.1.1. Raspberry Pi 3 Model B

As the core processing unit of the system, Raspberry Pi 3 Model B integrated images and sensor data and performed preliminary processing (Figure 2). It has sufficient processing power to execute image analysis algorithms and network connectivity for real-time data transmission [1].

Figure 2.

Raspberry Pi 3 Model B.

2.1.2. Raspberry Pi Camera Module 3

The camera module was used to capture the images of the gas filling operation and gas leak detection (Figure 3).

Figure 3.

Raspberry Pi camera module 3.

2.1.3. DHT22 Temperature and Humidity Sensor

The sensor was integrated to monitor temperature and humidity during the filling process (Figure 4). The data served as auxiliary parameters for gas leak determination and prediction.

Figure 4.

DHT22 temperature and humidity sensor.

2.2. Software

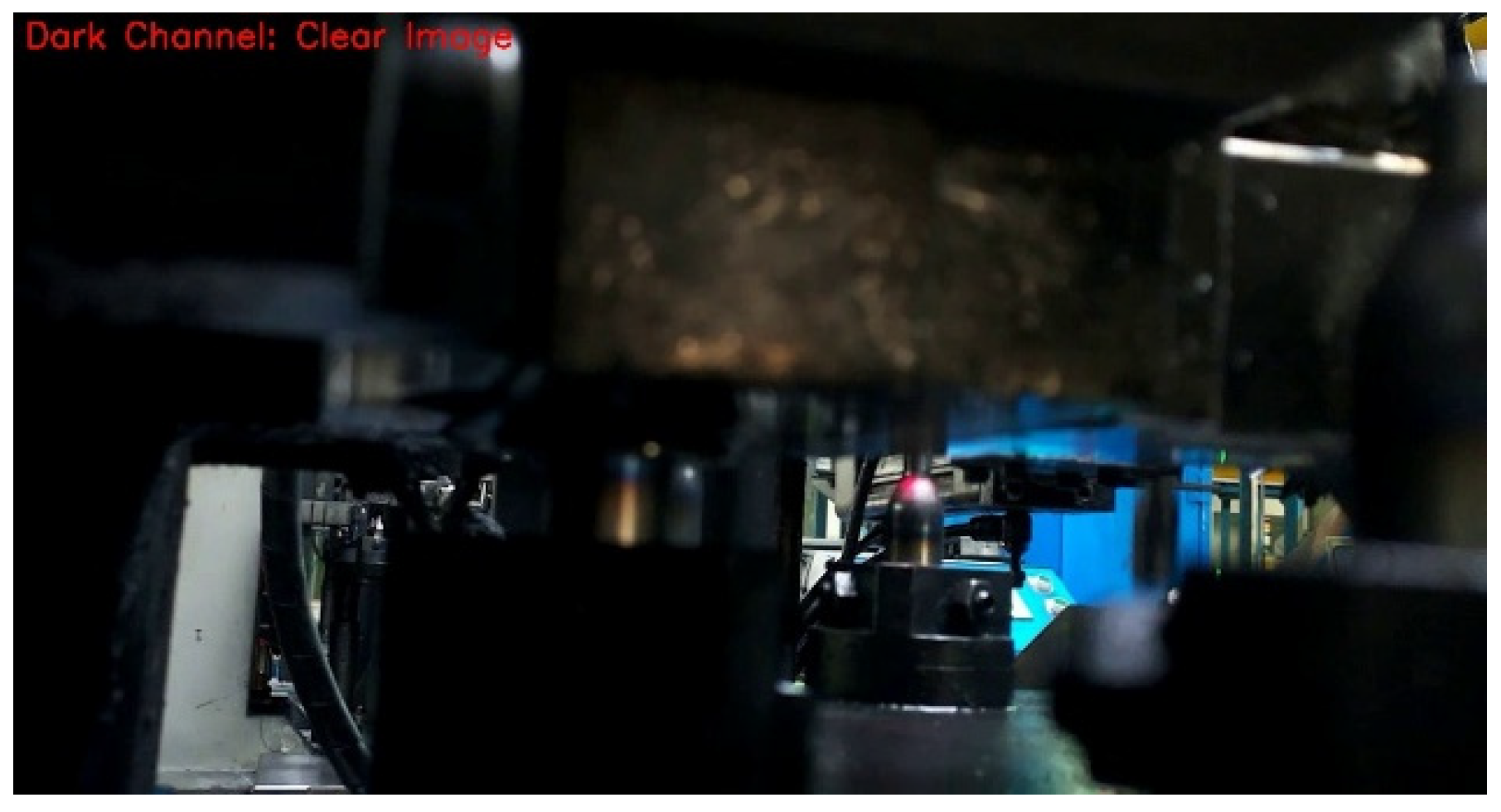

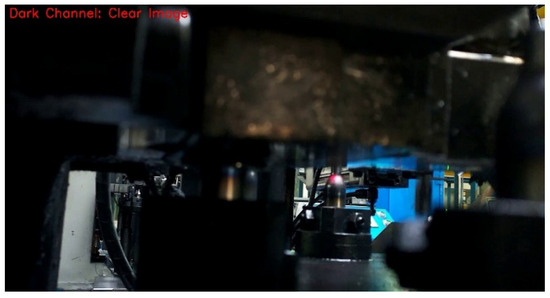

2.2.1. DCP

To achieve real-time gas leak detection, we employed the DCP method for image dehazing [2]. This method assumes non-sky regions in an image containing pixels with near-zero intensity in at least one color channel, making it highly effective for handling images with scattering properties such as gas or fog. In this study, the input RGB image was processed by taking the minimum value across all three color channels to obtain a dark channel image. Morphological erosion was then used to enhance dark channel features. The average brightness of the dark channel image was computed and compared with a pre-defined threshold to determine the presence of gas leaks. If the average brightness exceeded the threshold, a gas leak was detected.

2.2.2. MQTT

For real-time transmission of sensor data and image recognition results, MTQQ was used. As a lightweight messaging protocol, MQTT is well suited for IoT applications, particularly for real-time responses and large-scale data transmission [3]. The collected data were encapsulated as messages and transmitted via MQTT to the central server for visualization and further analysis.

2.2.3. Node-RED

On the server, the Node-RED platform was used for data visualization. Operators viewed the environmental parameters and gas leak status in real time through a web interface. If anomalies were detected, an alert was triggered, prompting operators to take appropriate action.

2.2.4. Machine Learning Module

SVM and decision tree algorithms were applied to analyze collected environmental parameters and gas leak status and the correlation between leaks and environmental factors. These algorithms improve the accuracy of gas leak detection and predict future leaks, helping operators take preventive measures.

3. Result and Discussion

3.1. Gas Leak Detection

The system uses the DCP method for gas leak image detection (Figure 5 and Figure 6). The method demonstrated high accuracy in detecting gas leaks. Experiment results using different concentrations of transparent gases confirm the DCP method’s ability to effectively capture optical changes caused by gas leaking. The detection accuracy of the system exceeds 90%, proving DCP’s effectiveness in industrial real-time gas leak detection.

Figure 5.

Gas leakage.

Figure 6.

No gas leakage.

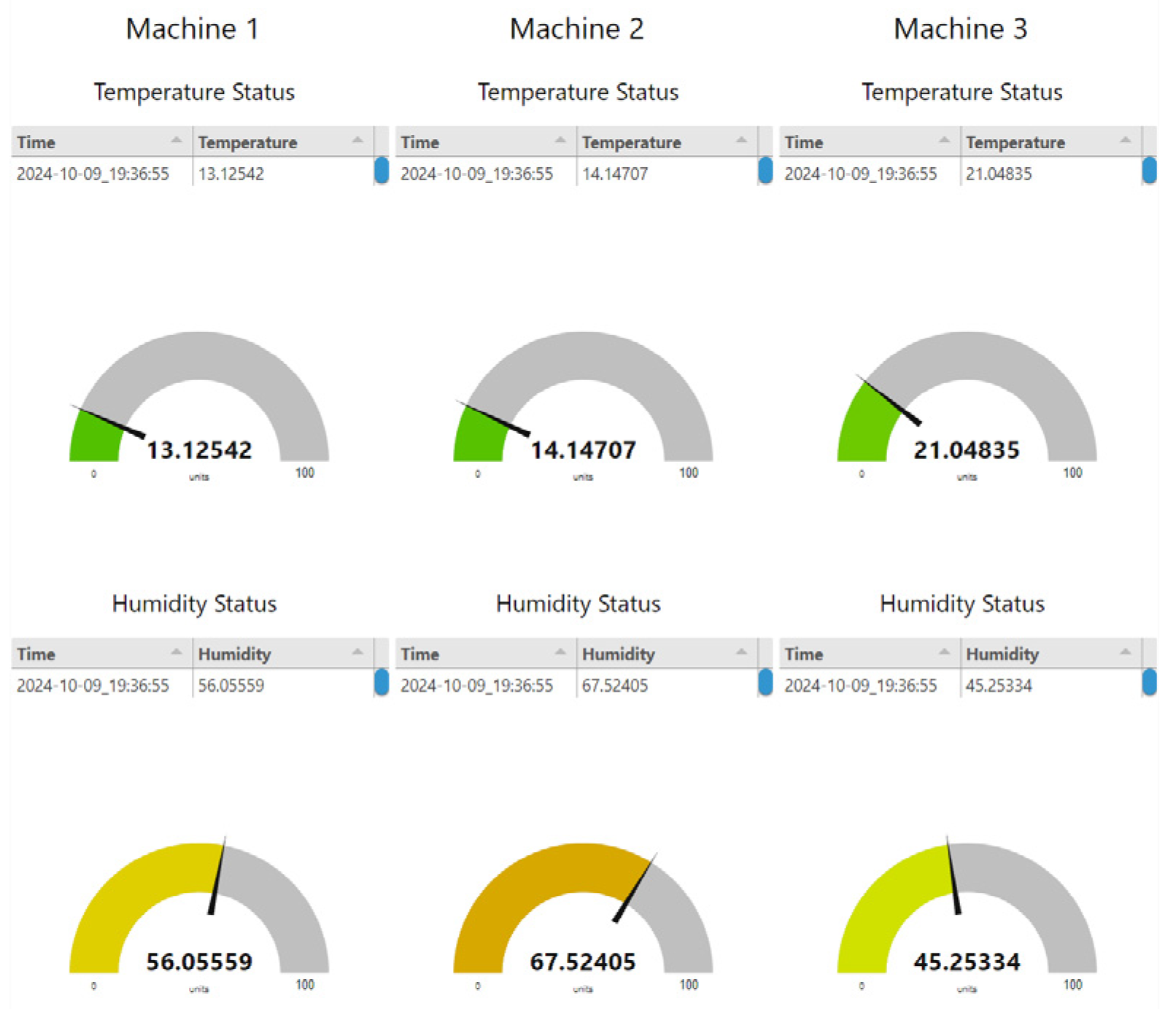

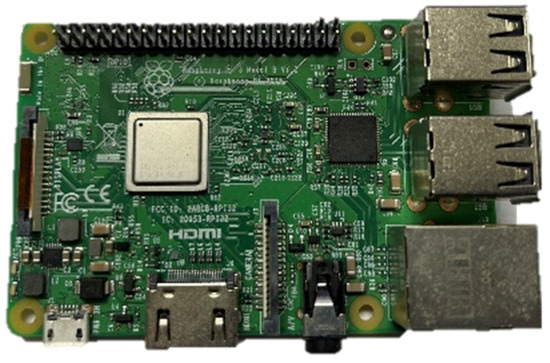

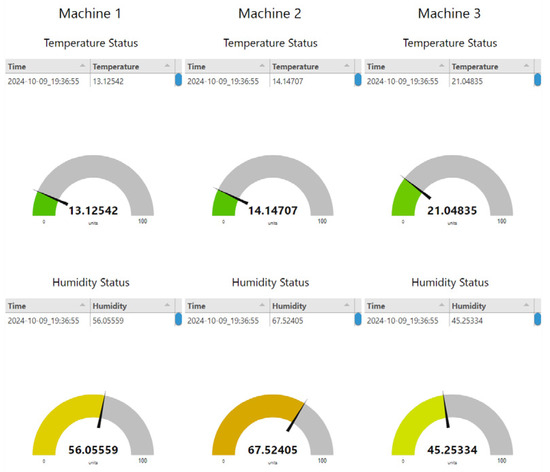

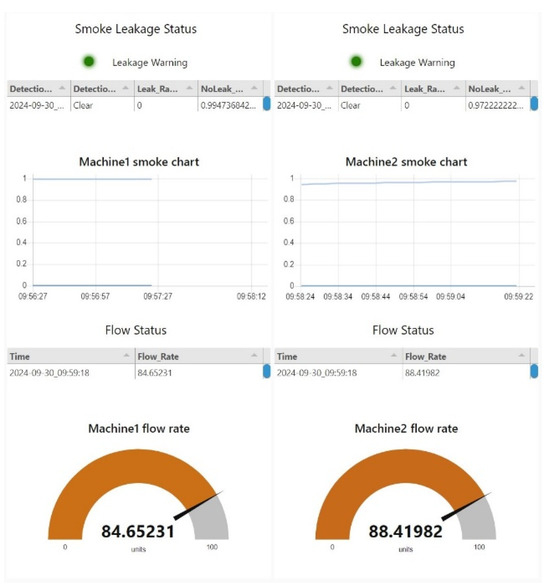

3.2. Node-RED Visualization

Node-RED is used to display the gas leak status and sensor data. Once data are transmitted to the central server via MQTT, the Node-RED interface updates and shows the latest data from all sensors visualizing the gas leak rate. When a gas leak is detected, an alert icon is immediately shown on the Node-RED interface (Figure 7 and Figure 8). This functionality is crucial for real-time monitoring in industrial applications.

Figure 7.

Sensor data visualization.

Figure 8.

Gas leak data visualization.

3.3. Machine Learning Analysis

3.3.1. SVM Analysis

SVM is mainly used to classify leak and non-leak conditions. The SVM model shows an accuracy rate of 92% in predicting gas leaks. By using the RBF kernel function, the model’s adaptability to non-linear data improved, enhancing the accuracy of leak predictions.

3.3.2. Decision Tree

The decision tree is used to reveal the specific relationships between gas leaks and environmental parameters. The model shows that temperature and humidity are the two primary factors influencing gas leaks. The prediction accuracy of the decision tree reaches 88%, proving leak detection ability under different environmental conditions.

SVM outperforms the decision tree in terms of prediction accuracy. However, the decision tree offers better interpretability, particularly in showing the environmental parameters affecting gas leaks. Decision trees are more effective in helping operators understand the underlying causes of leaks, allowing them to take more targeted preventive measures.

4. Conclusions

The developed system provides an efficient and accurate solution for gas leak detection and significantly improves the safety and efficiency of the gas filling process. It is still necessary to optimize the stability of the image recognition algorithm, especially in high-pressure environments. The accuracy of machine learning models can be increased by incorporating more environmental parameters.

Author Contributions

Conceptualization, N.-Z.H.; methodology, N.-Z.H.; software, H.-L.H.; validation, C.-M.T. and Y.-Y.W.; formal analysis, Y.-X.L.; investigation, C.-C.L.; resources, P.-H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original data are unavailable due to privacy or ethical restrictions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Richardson, M.; Wallace, S. Getting Started with Raspberry Pi, 3rd ed.; O’Reilly Media: Sebastopol, CA, USA, 2014. [Google Scholar]

- He, K.; Sun, J.; Tang, X. Single image haze removal using dark channel prior. IEEE Trans. Pattern Anal. Mach. Intell. 2011, 33, 2341–2353. [Google Scholar] [CrossRef] [PubMed]

- Banks, A.; Gupta, R. MQTT, Version 3.1.1; OASIS Standard: Woburn, MA, USA, 2014.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).