Classification of Flavored Filipino Vinegars Using Electronic Nose †

Abstract

1. Introduction

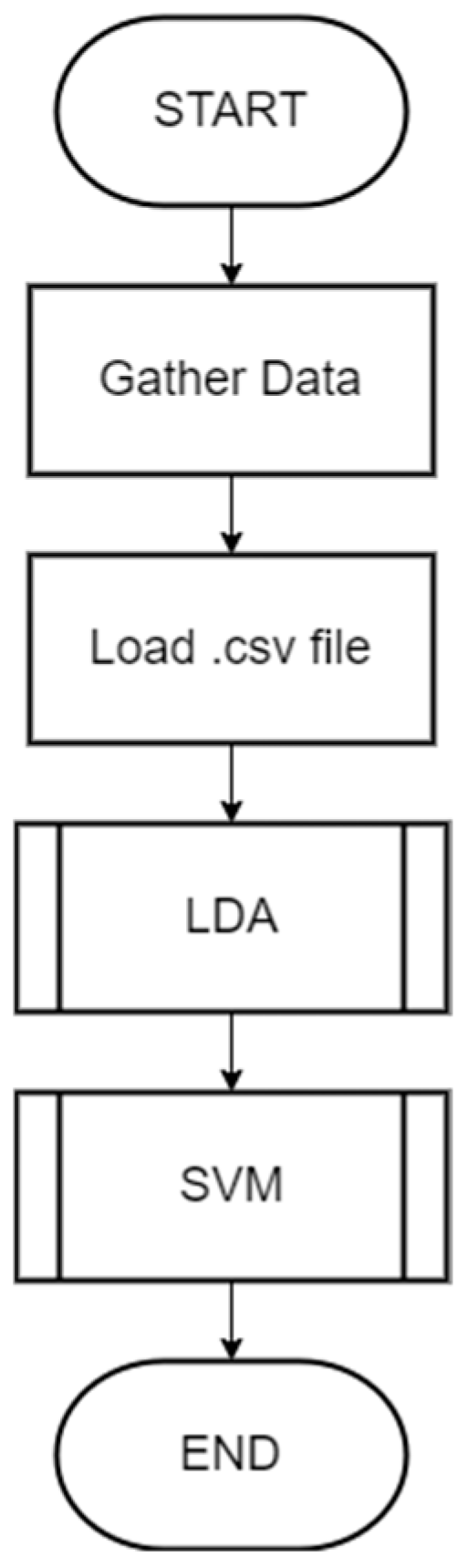

2. Methodology

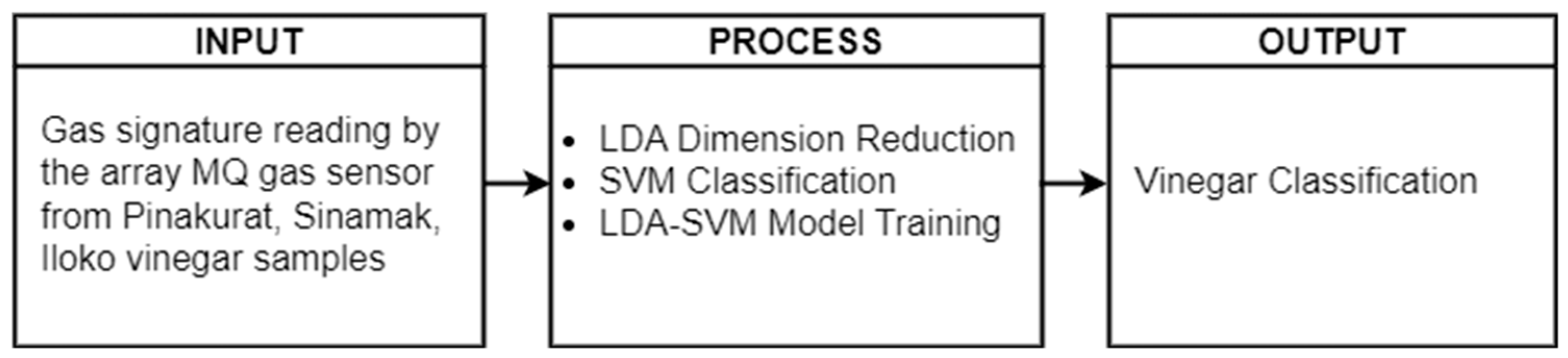

2.1. Conceptual Framework

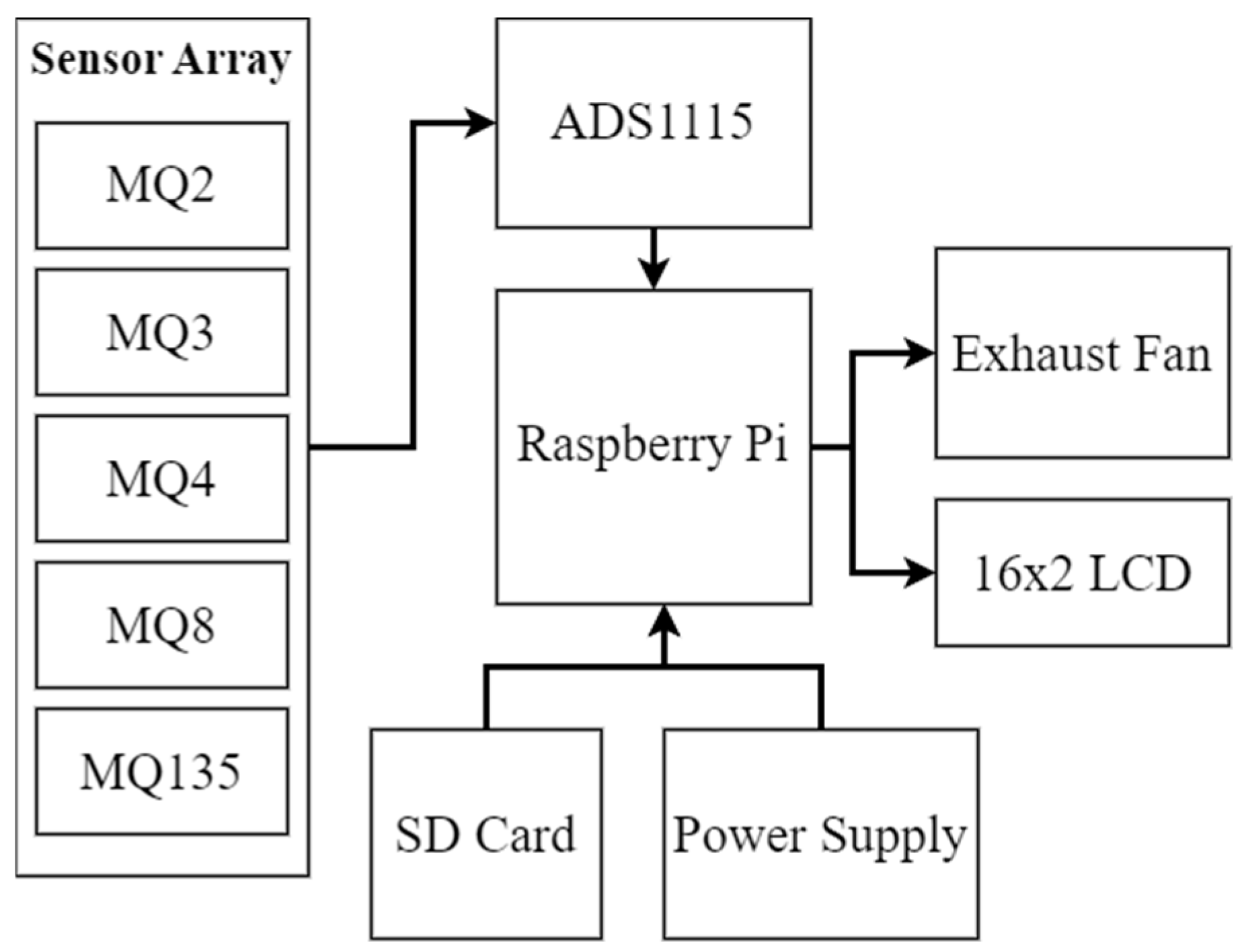

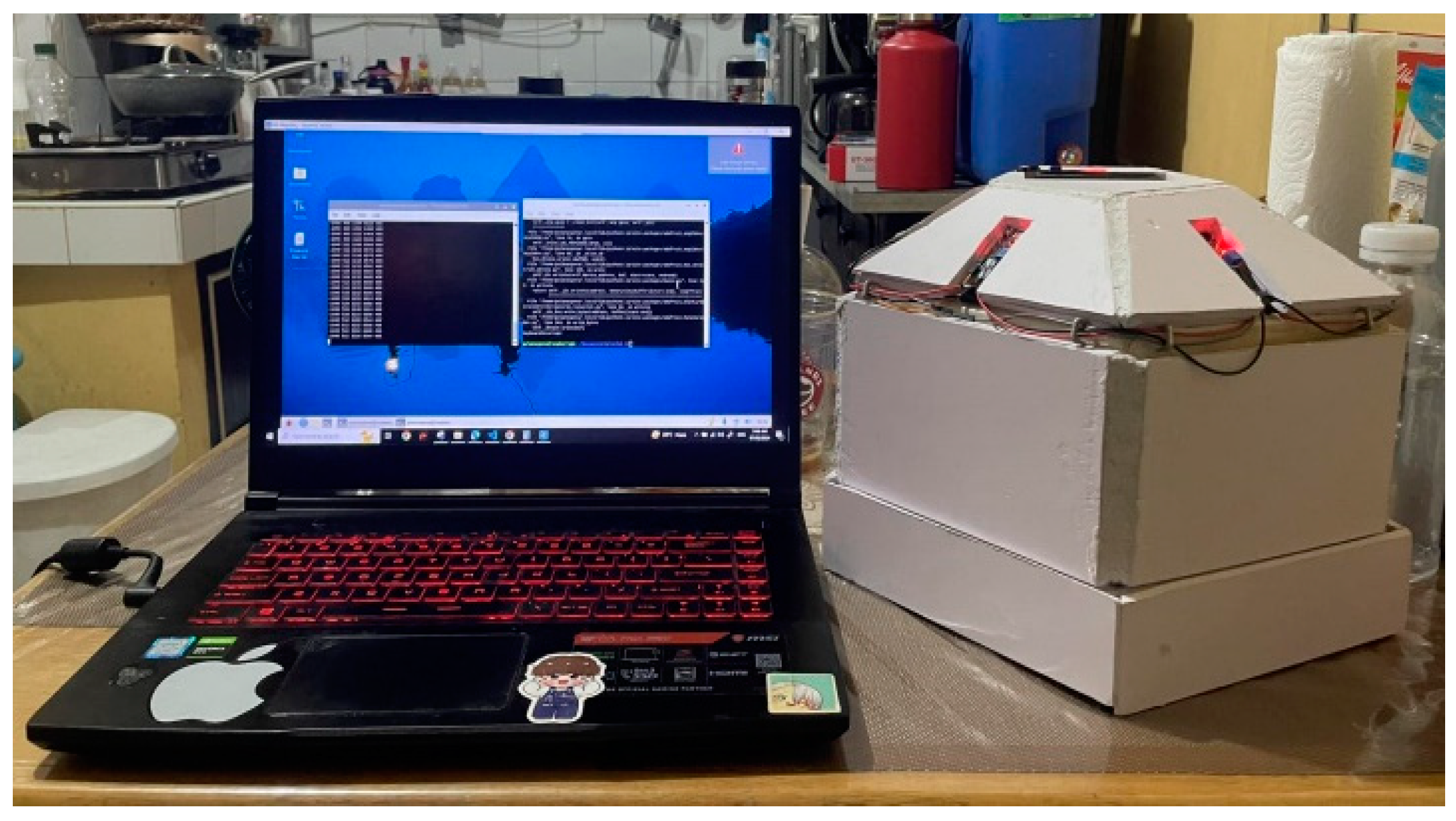

2.2. Hardware

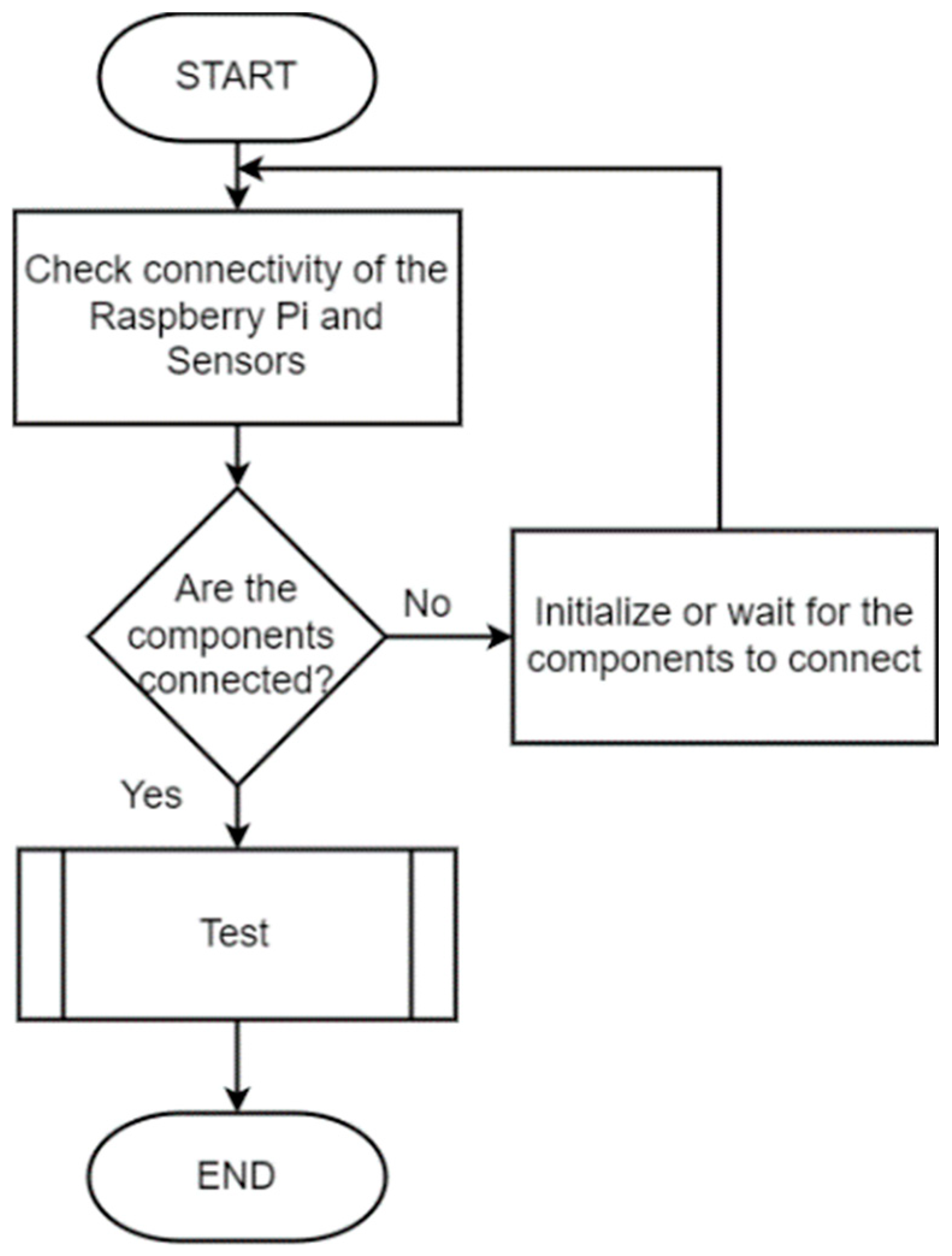

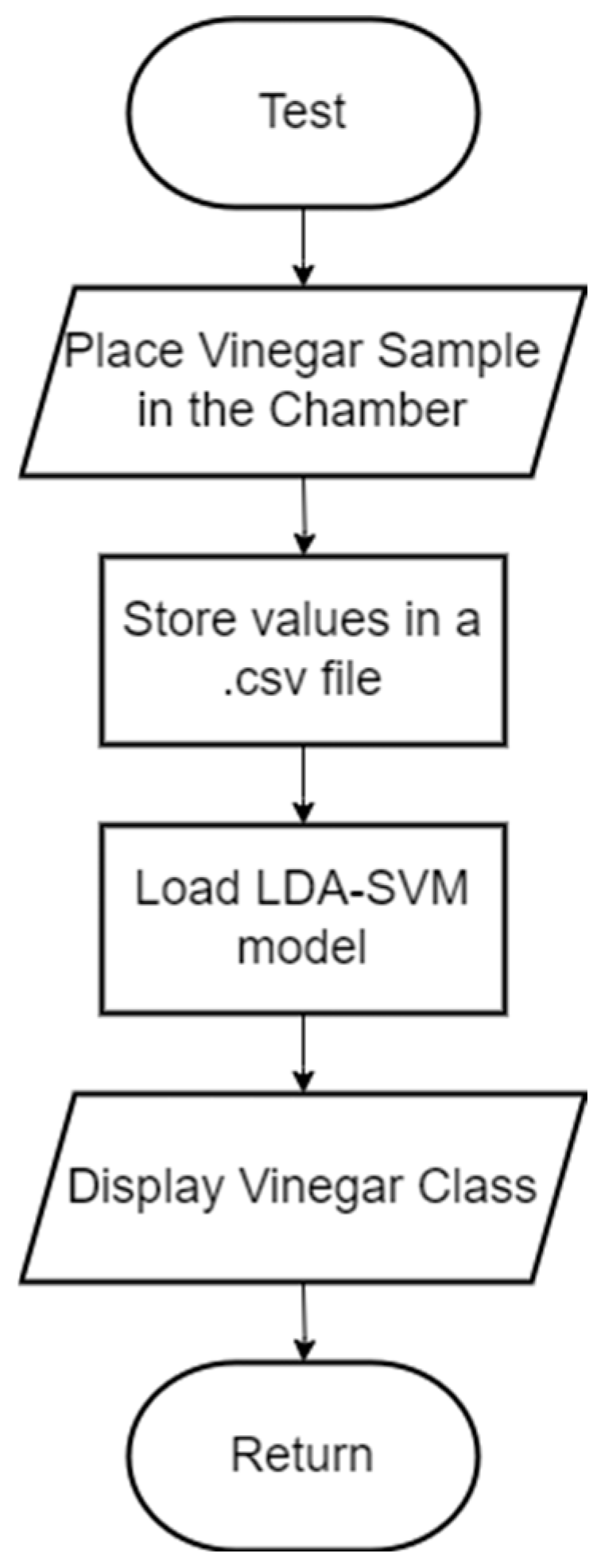

2.3. Software Development

2.4. Experimental Setup

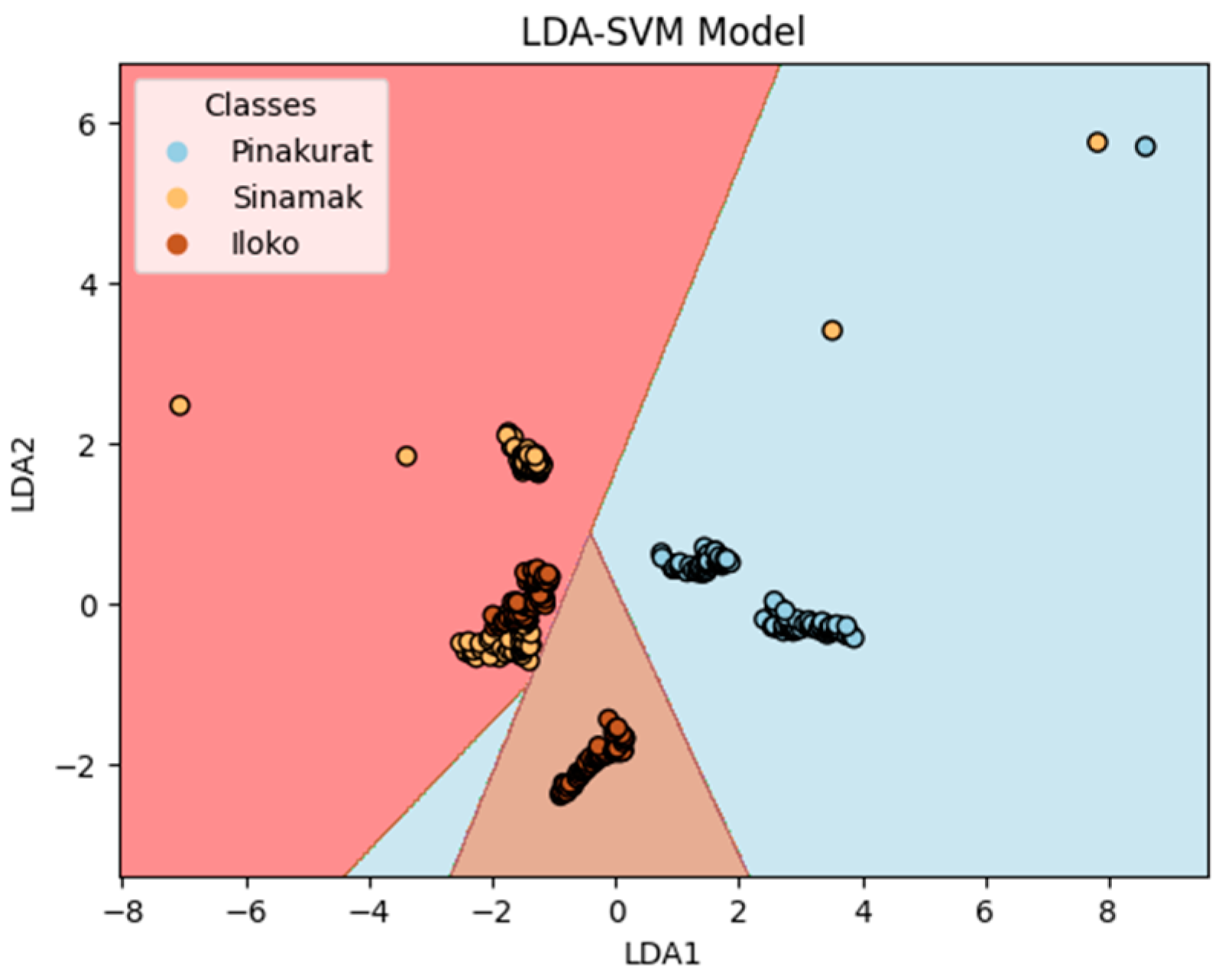

3. Results and Discussion

3.1. Data

3.2. Statistical Analysis

4. Conclusions and Recommendations

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pizarro, C.; Esteban-Díez, I.; Sáenz-González, C.; González-Sáiz, J.M. Vinegar classification based on feature extraction and selection from headspace solid-phase microextraction/gas chromatography volatile analyses: A feasibility study. Anal. Chim. Acta 2008, 608, 38–47. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.H.; Zhu, J.; Wu, B.; Huang, D.P.; Sun, J.; Dai, C.X. Classification of Chinese vinegar varieties using electronic nose and fuzzy Foley–Sammon transformation. J. Food Sci. Technol. 2020, 57, 1310–1319. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.O.; Moon, D.S.; Lee, D.S.; Kim, J.H.; Park, I.S.; Yoon, H.J.; Shin, D.H.; Park, S.S.; Lee, J.H. A Case of Chemical Pneumonitis Caused by Acetic Acid Fume Inhalation. Tuberc. Respir. Dis. 1994, 41, 424. [Google Scholar] [CrossRef][Green Version]

- Padilla, D.A.; Krystine, M.; Directo, R. An Electronic Nose Approach in Identifying Ripe Tomato Fruit Using LeNet-5 Structure. In Proceedings of the 2024 7th International Conference on Information and Computer Technologies (ICICT), Honolulu, HI, USA, 15–17 March 2024. [Google Scholar] [CrossRef]

- Jayson, P.; Armada, E.G.; Manlises, C.O. Identification of Various Genus mentha L. with Electronic Nose Using Fuzzy Logic Algorithm. In Proceedings of the 2024 7th International Conference on Information and Computer Technologies (ICICT), Honolulu, HI, USA, 15–17 March 2024. [Google Scholar] [CrossRef]

- Zambotti, G.; Soprani, M.; Gobbi, E.; Capuano, R.; Pasqualetti, V.; Di Natale, C.; Ponzoni, A. Early detection of fish degradation by an electronic nose. In Proceedings of the 2019 IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Fukuoka, Japan, 26–29 May 2019. [Google Scholar] [CrossRef]

- Wang, S.H.; Chou, T.I.; Chiu, S.W.; Tang, K.T. Using a Hybrid Deep Neural Network for Gas Classification. IEEE Sens. J. 2021, 21, 6401–6407. [Google Scholar] [CrossRef]

- Caya, M.V.C.; Cruz, F.R.G.; Blas, P.J.R.; Cagalingan, M.M.; Malbas, R.G.L.; Chung, W.-Y. Determining spoilage level against time and temperature of tomato-based Filipino cuisines using electronic nose. In Proceedings of the 2017IEEE 9th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Manila, Philippines, 1–3 December 2017. [Google Scholar] [CrossRef]

- Caya, M.V.; Maramba, R.G.; Mendoza, J.S.; Suman, P.S. Characterization and classification of coffee bean types using support vector machine. In Proceedings of the 2020 IEEE 12th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 3–7 December 2020. [Google Scholar] [CrossRef]

- Anticuando, M.K.D.; Directo, C.K.R.; Padilla, D.A. Electronic Nose and Deep Learning Approach in Identifying Ripe Lycopersicum esculentum L. TomatoFruit. In Proceedings of the 2022 13th International Conference on Computing Communication and Networking Technologies, ICCCNT 2022, Kharagpur, India, 3–5 October 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Ibarra, M.A.; Patajo, S.J.G.; Caya, M.V.C. Characterization and Classification of Mangifera Indica Ripeness with Electronic Nose using Fuzzy Logic Algorithm. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management, HNICEM 2022, Boracay Island, Philippines, 1–4 December 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022. [Google Scholar] [CrossRef]

- MacAtangay, C.; Cruz, C.A.C.D.; Villaverde, J.F. Determination of Tomato Fruit Stages Using Principal Component Analysis and Fuzzy Logic Algorithm. In Proceedings of the 4th IEEE International Conference on Artificial Intelligence in Engineering and Technology, IICAIET 2022, Kota Kinabalu, Malaysia, 13–15 September 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Cerenio, W.; Custodio, A.; Perez, N.; Villaverde, J.F. Shopping Cart Following Robot through Computer Vision and Object Tracking Method. In Proceedings of the 2022 IEEE Region 10 Symposium (TENSYMP), Mumbai, India, 1–3 July 2022. [Google Scholar] [CrossRef]

- Balangue, R.D.; Christ; Linsangan, N.B.; Paul, J.; Juanatas, R.A.; Juanatas, I.C. Ear Recognition for Ear Biometrics Using Integrated Image Processing Techniques via Raspberry Pi. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Boracay Island, Philippines, 1–4 December 2022. [Google Scholar] [CrossRef]

- Gonzales, J.C.; Ron, J.; Villaverde, J.F. BMI Estimation from 2D Face Images Using Support Vector Machine. In Proceedings of the 2022 6th International Conference on Communication and Information Systems (ICCIS), Chongqing, China, 14–16 October 2022. [Google Scholar] [CrossRef]

- Evangelista, G.; Paglinawan, A.C.; Paglinawan, C.C. Design of breath acetone detection for diabetes detection and classification using electronic nose. In Proceedings of the 2024 16th International Conference on Computer and Automation Engineering (ICCAE), Melbourne, Australia, 14–16 March 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Pellegrino, R.V.; Tarrobago, A.C.; Zulueta, D.L. Development of anemia cells recognition system using Raspberry Pi. In Proceedings of the 2023 15th International Conference on Computer and Automation Engineering (ICCAE), Sydney, Australia, 3–5 March 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Caya, M.V.; Romero, D.K.R.; Castro, P.A. E-nose Based Classification of Drying Method Using Local Tea Leaves Gas Signature. In Proceedings of the 2021 IEEE 13th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management, HNICEM 2021, Manila, Philippines, 28–30 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Gabrielle, S.; Jose, J.C.; Villaverde, J.F.; Ann, M. Detection of Common Types of Eczema Using Gray Level Co-occurrence Matrix and Support Vector Machine. In Proceedings of the 2023 15th International Conference on Computer and Automation Engineering (ICCAE), Sydney, Australia, 3–5 March 2023. [Google Scholar] [CrossRef]

- Hortinela, C.; Balbin, J.R.; Fausto, J.C.; Divina, P.D.; Felices, J.P.T. Identification of Abnormal Red Blood Cells and Diagnosing Specific Types of Anemia Using Image Processing and Support Vector Machine. In Proceedings of the 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November–1 December 2019. [Google Scholar] [CrossRef]

| Sensors | Sensitivity | Gas Present in Vinegar |

|---|---|---|

| MQ2 | Methane, Butane, LPG, Smoke Detection | Isobutanol, Methane Carboxylic Acid |

| MQ3 | Alcohol, Ethanol, Smoke Detection | Ethyl Lactate, Ethyl Acetate |

| MQ4 | Methane, CNG Gas Detection | Methane Carboxylic Acid |

| MQ8 | Hydrogen Gas Detection | Acetic Acid |

| MQ135 | CO, Ammonia, Benzene, Alcohol, Smoke Detection | Benzyl Alcohol, Ethyl Lactate, Ethyl Acetate |

| Vinegar Flavor | MQ135 | MQ8 | MQ3 | MQ4 | MQ2 |

|---|---|---|---|---|---|

| Pinakurat | 881 | 5433 | 4748 | 5267 | 1425 |

| Pinakurat | 817 | 5449 | 4828 | 5395 | 1441 |

| Iloko | 1337 | 4534 | 3327 | 4227 | 1314 |

| Pinakurat | 881 | 5433 | 4748 | 5267 | 1425 |

| Iloko | 1353 | 4454 | 3151 | 4179 | 1346 |

| Sinamak | 127 | 1035 | 1603 | 1020 | 207 |

| Sinamak | 1934 | 5595 | 3629 | 5131 | 1771 |

| Vinegar Flavor | LDA1 Values | LDA2 Values |

|---|---|---|

| Pinakurat | −14.17041487 | −0.570621815 |

| Pinakurat | −16.22063184 | 0.46116660216968114 |

| Iloko | 5.371439689865838 | −0.389170779 |

| Iloko | 6.710915978916585 | 1.2452827362266632 |

| Sinamak | 9.178909891882189 | −1.125653828 |

| Sinamak | 9.129781152 | 0.37899708410468125 |

| Predicted | |||||

|---|---|---|---|---|---|

| Actual | Sinamak | Iloko | Pinakurat | Total | |

| Sinamak | 13 | 0 | 23 | ||

| Iloko | 0 | 36 | 0 | ||

| Pinakurat | 0 | 0 | 36 | ||

| Total | 85 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palanas, J.L.; Peña, M.I.C.; Caya, M.V.C. Classification of Flavored Filipino Vinegars Using Electronic Nose. Eng. Proc. 2025, 92, 16. https://doi.org/10.3390/engproc2025092016

Palanas JL, Peña MIC, Caya MVC. Classification of Flavored Filipino Vinegars Using Electronic Nose. Engineering Proceedings. 2025; 92(1):16. https://doi.org/10.3390/engproc2025092016

Chicago/Turabian StylePalanas, Jon Laurman, Michael Irvin C. Peña, and Meo Vincent C. Caya. 2025. "Classification of Flavored Filipino Vinegars Using Electronic Nose" Engineering Proceedings 92, no. 1: 16. https://doi.org/10.3390/engproc2025092016

APA StylePalanas, J. L., Peña, M. I. C., & Caya, M. V. C. (2025). Classification of Flavored Filipino Vinegars Using Electronic Nose. Engineering Proceedings, 92(1), 16. https://doi.org/10.3390/engproc2025092016