How Life Cycle Assessment Supports Sustainability Reporting: Example from Clean Aviation †

Abstract

1. Introduction

2. Methods and Context

2.1. European Sustainability Reporting Standards (ESRSs)

- ESRS E1—Climate Change: Covers Greenhouse Gas (GHG) emissions, climate-related risks, mitigation strategies, and adaptation.

- ESRS E2—Pollution: Addresses emissions to air, water, and soil, including pollutants and harmful substances.

- ESRS E3—Water and Marine Resources: Covers water consumption, quality, and marine ecosystems.

- ESRS E4—Biodiversity and Ecosystems: Focuses on impacts on biodiversity, deforestation, and ecosystem restoration.

- ESRS E5—Resource Use and Circular Economy: Addresses resource efficiency, waste management, and circular practices.

2.2. Life Cycle Assessment (LCA)

2.3. Product Environmental Footprint (PEF)

2.4. Link Between ESRS, LCA, and EF

- ○

- Upstream stages (“cradle-to-gate”): Pre-manufacturing activities (extraction, processing, and transportation of raw material, energy production), i.e., supply chain impacts.

- ○

- Core stage: Direct operational emissions and resource use during product manufacturing.

- ○

- Downstream stages (“cradle-to-grave/cradle”): Activities after product manufacturing (product use, end-of-life treatment).

3. Example from Clean Aviation

3.1. Innovative Bio-Based Material

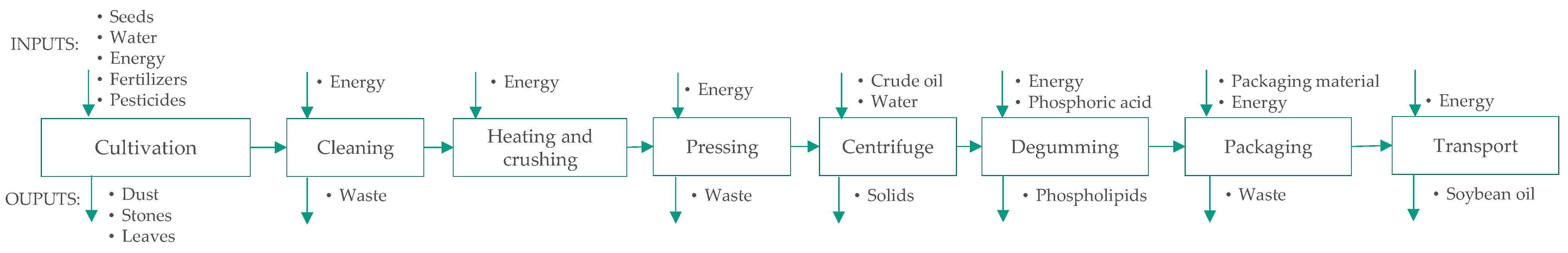

3.2. Scope Definition

3.2.1. System Boundary

3.2.2. LCA Dataset

3.3. Results

3.4. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. Corporate Sustainability Reporting. Available online: https://finance.ec.europa.eu/capital-markets-union-and-financial-markets/company-reporting-and-auditing/company-reporting/corporate-sustainability-reporting_en#:~:text=On%205%20January%202023%2C%20the,that%20companies%20have%20to%20report (accessed on 2 December 2024).

- Clean Aviation. Mission and Values. Available online: https://www.clean-aviation.eu/mission-and-values (accessed on 2 December 2024).

- Clean Sky 2. 2020 Consolidated Annual Activity Report. Available online: https://www.clean-aviation.eu/sites/default/files/2021-10/Consolidated-AAR-2020_en.pdf (accessed on 2 December 2024).

- SRIA, 2nd Revision of the Strategic Research and Innovation Agenda (SRIA) of the Clean Aviation Joint Undertaking. Towards Disruptive Technologies for New Generation Aircraft by 2035. Available online: https://clean-aviation.eu/sites/default/files/2024-09/2024-Clean-Aviation-SRIA.pdf (accessed on 2 December 2024).

- European Parliament and Council. Directive (EU) 2022/2464 of the European Parliament and of the Council of 14 December 2022 Amending Regulation (EU) No 537/2014, Directive 2004/109/EC, Directive 2006/43/EC and Directive 2013/34/EU, as Regards Corporate Sustainability Reporting. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32022L2464 (accessed on 2 December 2024).

- European Commission. 2050 Long-Term Strategy. Available online: https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 2 December 2024).

- EFRAG. [Draft] European Sustainability Reporting Standards. ESRS 1 General Requirements, 2022. Available online: https://www.efrag.org/sites/default/files/sites/webpublishing/SiteAssets/08%20Draft%20ESRS%20E1%20Climate%20Change%20November%202022.pdf (accessed on 2 December 2024).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- EU-Commission Recommendation. Commission Recommendation (EU) 2021/2279 of 15 December 2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organizations, Official Journal of the European Union. 2021. Available online: https://eur-lex.europa.eu/eli/reco/2021/2279/oj (accessed on 2 December 2024).

- European Platform on LCA (EPLCA). Product Environmental Footprint Category Rules Guidance. 2018. Available online: https://eplca.jrc.ec.europa.eu/permalink/PEFCR_guidance_v6.3-2.pdf (accessed on 2 December 2024).

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint (CFP) of Products—Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018.

- DIN EN 15804:2022-03; Sustainability of Construction Works-Environmental Product Declarations-Core rules for the Product Category of Construction Products. DIN Deutsches Institut für Normung: Berlin, Germany, 2022.

- LANCA. LANCA® Characterization Factors for Life Cycle Assessment; Version 2.0; Fraunhofer Verlag: Stuttgart, Germany, 2016. [Google Scholar]

- SALCA. Recommended impact assessment method within Swiss Agricultural Life Cycle Assessment (SALCA): v2.01. Agroscope Sci. 2024, 183. [CrossRef]

- ISO 21930: 2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. International Organization for Standardization: Geneva, Switzerland, 2019.

- Höhne, C.-C.; Salles, A.; Brantsch, P.; Reichert, T.; Hanich-Spahn, R. Environmental Improvement Potential of Flexible Polyurethane Foam for Aviation Applications—A Case Example Analysis. J. Phys. Conf. Ser. 2023, 2526, 12053. [Google Scholar] [CrossRef]

- OpenLCA. Available online: https://www.openlca.org/lca-data/ (accessed on 2 December 2024).

- Sphera Managed LCA Content Databases (Website); Sphera Solutions GmbH: Stuttgart, Germany. Available online: https://lcadatabase.sphera.com/ (accessed on 2 December 2024).

| Report Standard | ESRS | LCA | EF 3.1 |

|---|---|---|---|

| ESRS E1: Climate Change | Requires reporting on greenhouse gas emissions across Scope 1, Scope 2, and Scope 3. |

| “EF 3.1 Climate Change”, including biogenic, fossil and land use and land use change emissions (based on IPCC 2021). |

| ESRS E2: Pollution | Requires reporting on emissions to air, water, and soil. |

| No specific indicator, but it can be assessed through other(s) indicator(s), such as “EF 3.1 Photochemical ozone formation, human health”; “EF 3.1 Particulate matter”, “EF 3.1 Acidification”; “EF 3.1 Eutrophication, freshwater”. |

| ESRS E3: Water and Marine Resources | Requires reporting on water usage and impacts on marine ecosystems. |

| “EF 3.1 Water use”; “EF 3.1 Eutrophication, marine”; “EF 3.1 Ecotoxicity, freshwater—total”. |

| ESRS E4: Biodiversity and Ecosystems | Requires reporting on activities causing harm (e.g., deforestation, pollution, habitat destruction). |

| “EF 3.1 Land Use”, which includes “Biodiversity Loss Potential (transformation and occupation)”. |

| ESRS E5: Resource Use and Circular Economy | Requires disclosures on resource efficiency and waste management. |

| “EF 3.1 Resource use, fossils”; “EF 3.1 Resource use, mineral and metals”. |

| Report Standard | EF 3.1 | Results from Bio-Oil (Unit/FU) | Results from Crude Oil (Unit/FU) |

|---|---|---|---|

| ESRS E1: Climate Change | Climate change—total | 9.03 × 10−1 kg CO2 eq. | 4.21 × 10−1 kg CO2 eq. |

| ESRS E2: Pollution | Photochemical ozone formation | 5.24 × 10−3 kg NMVOC eq. | 1.67 × 10−3 kg NMVOC eq. |

| Particulate matter | 1.12 × 10−7 Disease incidences | 2.24 × 10−8 Disease incidences | |

| Acidification | 1.18 × 10−2 Mole of H+ eq. | 1.33 × 10−3 Mole of H+ eq. | |

| Eutrophication, freshwater | 4.23 × 10−4 kg P eq. | 2.00 × 10−7 kg P eq. | |

| ESRS E3: Water and Marine Resources | Water use | 3.23 × 10+0 m3 world equiv. | 8.59 × 10−3 m3 world equiv. |

| Eutrophication, marine | 8.83 × 10−3 kg N eq. | 4.66 × 10−4 kg N eq. | |

| Ecotoxicity, freshwater—total | 1.88 × 10+0 CTUe | 3.58 × 10+1 CTUe | |

| ESRS E4: Biodiversity and Ecosystems | Land use | 3.36 × 10+2 Pt | 2.26 × 10−1 Pt |

| ESRS E5: Resource Use and Circular Economy | Resource use, fossils | 8.07 × 10+0 MJ | 4.50 × 10+1 MJ |

| Resource use, mineral and metals | 2.24 × 10−7 kg Sb eq. | 4.41 × 10−7 kg Sb eq. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Salles, A.C.N.; Brantsch, P. How Life Cycle Assessment Supports Sustainability Reporting: Example from Clean Aviation. Eng. Proc. 2025, 90, 56. https://doi.org/10.3390/engproc2025090056

de Salles ACN, Brantsch P. How Life Cycle Assessment Supports Sustainability Reporting: Example from Clean Aviation. Engineering Proceedings. 2025; 90(1):56. https://doi.org/10.3390/engproc2025090056

Chicago/Turabian Stylede Salles, Ana Claudia Nioac, and Peter Brantsch. 2025. "How Life Cycle Assessment Supports Sustainability Reporting: Example from Clean Aviation" Engineering Proceedings 90, no. 1: 56. https://doi.org/10.3390/engproc2025090056

APA Stylede Salles, A. C. N., & Brantsch, P. (2025). How Life Cycle Assessment Supports Sustainability Reporting: Example from Clean Aviation. Engineering Proceedings, 90(1), 56. https://doi.org/10.3390/engproc2025090056