Abstract

The present paper studies the degradation of an ethylene propylene diene monomer (EPDM) due to aging within an environment resembling the conditions inside the turbine stage of an electrically assisted turbocharger for fuel cell applications, with a special focus on the influence of the system resonance. Aging experiments were conducted on EPDM O-rings of different thicknesses and compression levels, evaluating their degradation and determining its impact on system functionality. The study also quantified changes in system resonance and created an Arrhenius law-based forecast model. The unique activation energy for the degradation processes was identified, providing insight into the optimal dimension and compression of EPDM O-rings.

1. Introduction

Hydrogen-based fuel cell systems can reduce carbon emissions in various applications, including aircraft propulsion [1,2]. To improve efficiency, pressurizing the oxygen supply can enhance fuel cell efficiency [3,4]. However, designing cost-effective and reliable rotor-bearing systems for this application remains a challenge. Air bearings, while ideal in terms of cleanliness for fuel cell applications, can be prohibitively expensive [5,6]. Thus, alternative bearing systems that include elastomer-based damping elements are explored to manage oscillations and control resonance frequencies in rotor dynamics.

Viscoelastic dampers, specifically those made from elastomers, play a crucial role in absorbing vibrations. In narrow temperature ranges, they are optimized for the transition phase at critical speeds to maximize efficiency. For broader ranges, the rubbery plateau region, less affected by temperature fluctuations, is preferred, requiring precise material and geometry optimization [7,8]. This study focuses on the use of ethylene-propylene-diene monomer rubber (EPDM) as a damping material, chosen for its resilience under fuel cell operating conditions, including extended temperature and mechanical stress exposure. Unlike existing research [9,10,11], which primarily investigated thermal degradation in standard test pieces, this study evaluates the degradation and dynamic behavior of compressed O-rings in conditions that mimic real-world fuel cell operation.

The aim is to assess aging’s impact on damping efficiency and develop a predictive model for elastomer degradation. The research involves finite element analysis for damping system design, experimental validation, and Arrhenius-based modeling to predict long-term degradation. This paper focuses on the experimental validation and predictive modeling phases.

2. Experimental Description

2.1. Material and Aging Process

This study utilized commercially available ethylene-propylene-diene rubber (E0540-80) O-rings, chosen for their durability and relevance to aging studies [12,13,14]. Departing from standard protocols (ISO 188, ISO 11346), the O-rings were compressed under controlled conditions to better replicate real-world operational stresses.

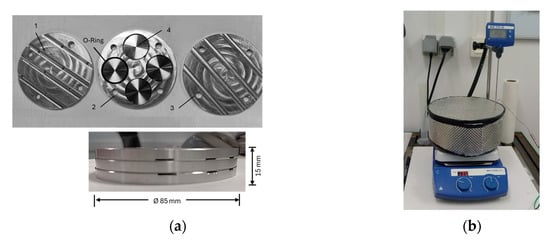

The O-rings were compressed between SS304 steel (inner hub) and AW-2007 aluminum (outer hub), as shown in Figure 1a. Each compression level and O-ring size was fitted precisely to ensure consistency across experimental trials. The aging setup exposed the O-rings to the surrounding medium to simulate fuel cell charging system conditions (Figure 1b). Based on research analyzing water samples from proton exchange membrane fuel cells (PEMFCs) [15], demineralized water (ISO 3696 Type 3) was selected as the aging medium. The system featured a closed-loop feedback mechanism with a heating source and thermocouple for precise temperature control (Figure 1b), achieving 0.1 K accuracy and a range of −10 °C to 400 °C. A total of 84 O-rings, with thicknesses of 1.5 mm and 2.0 mm, were tested at 10% and 20% compression across all temperatures. Six O-rings per combination were examined, with nine unaged specimens serving as controls for baseline comparisons.

Figure 1.

(a) Radial compression components for the O-rings: parts 1–3 are stainless steel 304, and part 4 is aluminum AW-2007. (b) The aging setup, housing the radial compression component, is immersed in the aging medium and operates within a thermally insulated, closed-loop feedback system to maintain a stable temperature.

The maximum aging temperature was set at 80 °C, replicating real-world aging mechanisms. The lower temperature was set at 24 °C, and an intermediate temperature of 60 °C was chosen for model development. Thus, the experiments were conducted at various temperatures and intervals at 1, 3, 4, 9, 18, and 29 days to ensure adequate data for analysis.

2.2. Dynamic Measurements

Dynamic testing was performed to evaluate the system’s response to harmonic excitation under controlled compression. Accelerometers and an eddy current displacement sensor captured dynamic parameters, such as resonance frequency (ω0), and maximum deflection amplitude (x0). The tests involved harmonic oscillations at a constant 1 g acceleration, sweeping from 100 Hz to 1800 Hz at 400 Hz/min, with a secondary scan at 100 Hz/min for higher resolution.

Data were filtered using a low-pass filter to remove high-frequency noise, followed by fast Fourier transform (FFT) for frequency response analysis. Instrumentation included two PCB accelerometers (356A66 and 352C23), with an accuracy of ±1% FSO, and a MICRO-EPSILON ES08 sensor for deflection measurements, with a resolution of 0.04 μm and accuracy of ±1.6 μm across the range from 25 Hz to 2.5 kHz. The modal vibration test system, TV 51110-M, was equipped with an analog amplifier, ensuring a distortion of less than 0.05%. All measurements were taken in a thermally stable, air-conditioned environment.

2.3. Arrhenius Model and Degradation Rate

The Arrhenius model was applied to assess the degradation rate of EPDM O-rings under varying test temperatures. The model assumes consistent degradation mechanisms within the examined temperature range, providing efficient lifespan predictions based on prior studies [16,17,18]. The rate constant k(T) is temperature dependent and is expressed as shown in Equation (1).

Here, A is the pre-exponential factor, Ea is the activation energy, and R is the gas constant. Using a graphical approach, the pre-exponential factor A and activation energy Ea were estimated from experimental data at three aging temperatures. The resonance frequency shift over time is represented in Equation (2).

This model is valid up to a maximum operational temperature of 120 °C, beyond which EPDM behavior deviates from the Arrhenius predictions [19,20].

To determine the best degradation model, statistical regression was performed on the resonance frequency shifts over aging time. Models were evaluated based on their coefficient of determination (R2), standard error of estimation (SEE), and mean absolute error (MAE). Several regression models were explored.

3. Results

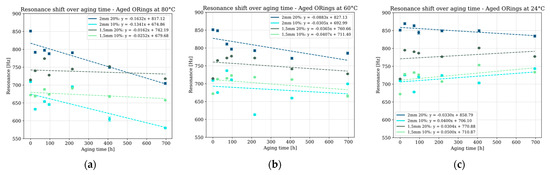

3.1. Effect of Aging on Resonance

The resonance frequency shift due to elastomer aging at 80 °C (Figure 2a) shows a notable decrease over time for 2.0 mm O-rings, while that for 1.5 mm O-rings first increases slightly before decreasing at higher aging times. The 2.0 mm O-ring with 20% compression exhibits the highest frequency change rate. At 60 °C (Figure 2b), the frequency reduction is more gradual, but similar trends to 80 °C aging are observed. At 24 °C (Figure 2c), the 1.5 mm O-rings show an increase in resonance frequency, peaking at 9.5%, while the 2.0 mm O-ring frequency increases by about 5%, with minimal change for the 20% compression O-ring. As the temperature decreases, the 1.5 mm O-rings show a pronounced initial frequency increase that stabilizes, while the 2.0 mm O-rings exhibit a consistent frequency decrease, suggesting that degradation moves the system’s resonance out of its operational range.

Figure 2.

Shift in system resonance frequency due to aging effects on O-rings at different temperatures: (a) 80 °C, (b) 60 °C, and (c) 24 °C.

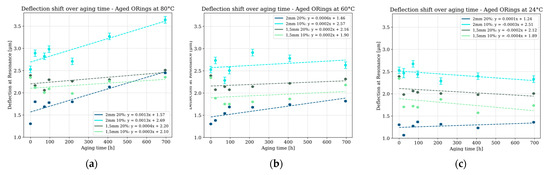

Deflection at resonance increases for all O-rings at 80 °C (Figure 3a), with 2.0 mm O-rings showing a faster increase. At 60 °C (Figure 3b), the deflections for the 1.5 mm O-rings decrease initially, then increase, while the 2.0 mm O-rings show a continuous increase. At 24 °C (Figure 3c), the 1.5 mm O-rings decrease sharply in deflection within the first 24 h, then stabilize, while the 2.0 mm O-rings show minimal change. The maximum deflection observed was 3.6 μm in the 2.0 mm O-ring at 10% compression after 696 h at 80 °C, with other O-rings remaining below 2.5 μm, far below the system’s critical threshold of 80 μm.

Figure 3.

Changes in deflection amplitude during system resonance due to aging effects on O-rings at different temperatures: (a) 80 °C, (b) 60 °C, and (c) 24 °C.

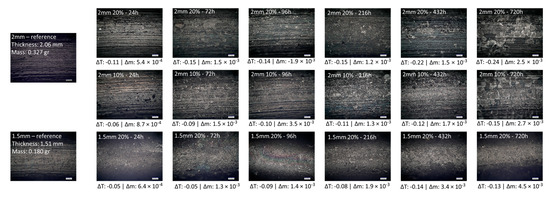

3.2. Effect of Aging on Surface Morphology of O-Rings

The study investigated surface morphology changes in O-rings during aging, revealing more pronounced degradation at higher temperatures. Consequently, only the O-ring aged at 80 °C is presented in this analysis. For each O-ring, both mass differences and thickness changes were evaluated. While the mass remained relatively stable throughout aging, significant shrinkage was observed. This shrinkage is more pronounced under higher compression and in O-rings with a greater surface-to-volume ratio [21].

In the 2.0 mm-thick O-ring, external morphology changes gradually, with horizontal lines from the reference O-ring remaining visible throughout the aging process. After 696 h, surface alterations are mainly due to oxide formation, with the 10% compressed O-ring showing more uniform coverage than the 20% compressed one. For the 1.5 mm-thick O-ring, the outer surface changes after just 24 h as the horizontal lines disappear. The surface then stabilizes, with glossy, spot-like areas emerging at 216 h and spreading to cover the entire surface. These results highlight the distinct degradation patterns between the two O-ring thicknesses. For the 2.0 mm O-ring, higher compression significantly affects surface morphology after 432 h, leading to the formation of oxide deposits, visible as white spots. These deposits, identified as aluminum oxide, are more uniformly distributed at the highest compression and are likely a result of the O-ring’s positioning between the aluminum and stainless steel casings. The oxide layer was analyzed using EDX microscopy, with a detailed explanation available in the referenced thesis [21].

3.3. Activation Energy Determination for Degradation Analysis

This analysis focused on 2.0 mm O-rings, as no satisfactory model was found for 1.5 mm O-rings, highlighting the difficulty of modeling thinner configurations. For 20% compression, a logarithmic transformation of Y against the square root of X provided the best fit, while a square root transformation of both Y and X was optimal for 10% compression. The models revealed variations in responses between 10% and 20% compression, possibly due to compression effects or sample limitations, highlighting the need for more refined predictive models.

Table 1 presents the regression analysis for 2.0 mm O-rings at 20% compression, and Table 2 for 10% compression. As the aging temperature decreases, R2 also decreases, indicating a more linear trend at lower temperatures. While dynamic experiments were conducted only once, the reduced degradation rate at lower temperatures likely explains this effect, suggesting the need for more complex regression models to better assess aging dynamics.

Table 1.

Statistical analysis of logarithmic regression for resonance frequency extrapolation in 2.0 mm O-rings at 10% compression and three temperatures (80 °C, 60 °C, and 24 °C).

Table 2.

Statistical analysis of square root regression for resonance frequency extrapolation in 2.0 mm O-rings at 10% compression and three temperatures (80 °C, 60 °C, and 24 °C).

The Arrhenius equations for the EPDM O-rings under the investigated conditions were derived by determining the rate constant (kT) and pre-exponential factor (A), as summarized in Table 3. With the Arrhenius equation established, long-term predictions of frequency variation during resonance can now be made.

Table 3.

Arrhenius parameters for 2.0 mm EPDM O-rings with 10% and 20% compression ratios in demineralized water.

3.4. Accuracy of the Measurments and Validation Test

Dynamic tests were conducted on new (non-aged) O-rings under harmonic acceleration (1 g) to assess measurement precision and variability. Three O-rings per configuration were tested. The 95% confidence intervals (CIs) for resonance frequency and deflection were calculated using the t-distribution (n = 4). Welch’s ANOVA revealed statistically significant differences (p < 0.05) across groups, indicating substantial variability in resonance frequencies due to O-ring differences. High F-values highlighted the dominant influence of O-ring variation over measurement variability. Table 4 and Table 5 show the mean values, CIs, and Welch’s ANOVA results (F-values, p-values) for each configuration.

Table 4.

Measurement accuracy and statistical analysis for resonance frequency.

Table 5.

Measurement accuracy and statistical analysis for deflection at resonance frequency.

Measurement uncertainty was estimated using Gaussian error propagation (GEP), considering sensor and amplifier errors. The uncertainty for resonance frequency was 2.003%, and for deflection, it was 2.006%, with 67% uniform distribution.

The exceptionally high F-value for the 1.5 mm/20% configuration (F3,4 = 1847.66) underscores the considerable influence of O-ring-to-O-ring variability on resonance frequency. A similar trend is observed in the deflection at resonance. The elevated F-values in this configuration compared to the rest suggest that thinner O-rings with a high compression ratio exhibit heightened sensitivity to O-ring-to-O-ring variations, since minor manufacturing deviations in diameter can lead to differences in the compression-induced surface stiffening, which may explain the pronounced variability between O-rings.

A validation test was performed one month after the initial tests to assess repeatability and determine whether changes in resonance frequency were due to material aging or system stiffness alterations. The O-rings were stored at room temperature (~24 °C) and 33% relative humidity, with Table 6 showing the differences in mean resonance frequencies and deflection amplitudes between the tests.

Table 6.

Difference in the mean value of resonance frequency and deflection amplitude between initial and repetition dynamic tests after completing the test campaign.

The shifts in resonance frequency and deflection observed during the experimental campaign were primarily attributed to material aging, as the validation test results fell within the measurement uncertainty. However, the 1.5 mm/20% configuration showed significant deviations, indicating that it is particularly sensitive to aging. Since only this configuration exhibited notable deviations, it is unlikely that system changes influenced the observed differences in resonance frequency. Nonetheless, the limited sample size in this study provides preliminary insights into O-ring variability and measurement trends, serving as an exploratory analysis rather than as definitive statistical evidence.

4. Discussion

Aging generally reduces resonance frequency by affecting the volume, particularly at higher temperatures. Alterations in the material’s surface properties may mitigate these effects, potentially even increasing the resonance frequency. This becomes evident in the above-mentioned case (see Figure 2a) due to the higher surface-to-volume ratio of small O-rings, making the surface more influential in determining material properties. In addition, as can be seen in Figure 4, thicker O-rings exhibit a more stable surface morphology during aging, suggesting that thinner O-rings experience even faster surface degradation. In particular, the changes observed in the first 24 h indicate faster surface degradation of small O-rings. These findings support the hypothesis that the surface-to-volume ratio significantly affects elastomer aging, although further research is needed for confirmation.

Figure 4.

Morphological evolution of 2.0 mm O-rings (10% and 20% compression) and 1.5 mm O-rings (20% compression) across tested intervals during aging at 80 °C. ΔΤ = tinitial − taged: thickness difference [gr] and Δm = minitial − maged: mass difference [gr].

Frequency and deflection analyses (see Figure 3) reveal that as system frequency decreases, deflection amplitude increases, with the maximum deflection reaching 3.6 μm in 2.0 mm O-rings with 10% compression after 696 h, still below the threshold. Although degradation increases deflection, it does not pose a significant issue, as the increase is small. However, the resonance frequency shifts, gradually moving the system’s resonance outside its operational range. While the system’s resonance may fall below the operating range during aging, excitation can still occur during startup and shutdown. During startup, the system can bypass the undesired frequency range with a large inrush of current to flow through the e-motor. Despite the O-rings’ ability to reduce deflection and shift resonance frequency, aging necessitates careful management of the rundown process. Henceforth, implementing a forced shutdown via the e-motor should be considered to avoid potential damage to the rotor or vibration compensation system.

The Arrhenius model offers valuable insights, but its long-term accuracy is limited due to its assumption of consistent degradation mechanisms. As pre-tension decreases with aging, deflection may increase, especially near zero due to elastomer relaxation. Therefore, forecasts should be conservative, with the lowest 90% confidence interval.

5. Conclusions

This study investigates the degradation of EPDM O-rings used as dampers in electrically assisted turbochargers for fuel cell applications, focusing on key aging factors such as temperature, aging time, compression, and surface-to-volume ratio. The temperature was found to have the most significant impact, particularly at 80 °C for 2.0 mm O-rings, with lesser effects observed at 60 °C and at room temperature. The surface-to-volume ratio also played a role, with 1.5 mm O-rings exhibiting minimal changes after 24 h of aging. However, due to the limited sample size, caution is advised in attributing observed changes solely to aging, as inherent variability between individual O-rings may also influence the results. This highlights the need for a larger dataset to draw statistically reliable conclusions.

The study suggests analyzing system response changes in two main components: alterations in the outer surface and changes in the core structure of the O-ring. This approach provides insights into the aging mechanisms affecting elastomer behavior and helps isolate the effects of surface degradation.

A predictive model was developed to reveal the complex nonlinear effects of EPDM aging on its properties, using nonlinear regression techniques to estimate the activation energy of degradation and to provide insights into optimal compression for minimizing degradation. The unique activation energy associated with degradation was identified, offering guidance on selecting optimal O-ring dimensions and compression for our application.

Author Contributions

Conceptualization, A.G. and M.T.; methodology, A.G.; validation, A.G., M.T., and R.D.; formal analysis, A.G. and M.T.; investigation, A.G.; data curation, A.G.; writing—original draft preparation, A.G.; review and editing, G.I., R.D., T.E. and A.K.; supervision, A.K., G.I. and T.E. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the financial support under research grant 19/21046A provided by the Federal Ministry for Economic Affairs and Climate Action on the basis of a decision by the German Bundestag. The authors are responsible for the content of this publication.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Restrictions apply to the availability of these data. The data presented in this study are available on request from the corresponding author (due to privacy restrictions) with the permission of IHI Charging Systems International.

Acknowledgments

The authors express gratitude to D. Just for insightful discussions; to M. Rode, S. Slavic, and D. Filsinger for insightful discussions; to I. Banegas, T. Alles, and G. Karakasis for technical assistance; and to V. Gkoutzamanis for manuscript preparation guidance.

Conflicts of Interest

Authors Mario Tränkner, Georgios Iosifidis and Roberto DeSantis were employed by the company IHI Charging Systems International GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Antivachis, M.; Dietz, F.; Zwyssig, C.; Bortis, D.; Kolar, J.W. Novel High-Speed Turbo Compressor with Integrated Inverter for Fuel Cell Air Supply. Front. Mech. Eng. 2020, 6, 612301. [Google Scholar] [CrossRef]

- Schmelcher, M.; Häßy, J. Hydrogen fuel cells for aviation? A potential analysis comparing different thrust categories. In Proceedings of the ISABE 2022, Ottawa, ON, Canada, 25 September 2022. [Google Scholar]

- Yan, Q.; Toghiani, H.; Causey, H. Steady state and dynamic performance of PEMFCs under various operating conditions and load changes. J. Power Sources 2006, 161, 492–502. [Google Scholar] [CrossRef]

- Filsinger, D.; Kuwata, G.; Ikeya, N. Tailored Centrifugal Turbomachinery for Electric Fuel Cell Turbocharger. Int. J. Rotating Mach. 2021, 2021, 3972387. [Google Scholar] [CrossRef]

- Wang, P.; Lusardi, C. Leveraging Air System Technology for Fuel Cell System Cost Reduction. In Proceedings of the DOE Hydrogen Program, Virtual, 6 June 2022. [Google Scholar]

- Frohlich, P. Development of an oil free turbo compressor for mobile fuel cell applications—Challenges and results. In Proceedings of the Fuel Cell Conference FC3, Chemnitz, Germany, 26–27 November 2019. [Google Scholar]

- Darlow, M.; Zorzi, E. Mechanical Design Handbook for Elastomers; NASA Contractor Reports; No. 3423; NASA: Washington, DC, USA, 1981.

- Borman, A. Elastomerringe zur Schwingungsberuhigung in der Rotordynamik Theorie, Messungen und Optimierte Auslegung. Doctoral Thesis, Technische Universität Berlin, Berlin, Germany, 2005. [Google Scholar]

- Lin, C.W.; Chien, C.H.; Tan, J.; Chao, Y.J.; Van Zee, J.W. Dynamic mechanical characteristics of five elastomeric gasket materials aged in a simulated and an accelerated PEM fuel cell environment. Int. J. Hydrogen Energy 2010, 36, 6756–6767. [Google Scholar] [CrossRef]

- Lin, C.W.; Chien, C.H.; Tan, J.; Chao, Y.J.; Van Zee, J.W. Chemical degradation of five elastomeric seal materials in a simulated and an accelerated PEM fuel cell environment. J. Power Sources 2011, 196, 1955–1966. [Google Scholar] [CrossRef]

- Tan, J.; Chao, Y.J.; Wang, H.; Gong, J.; Van Zee, J.W. Chemical and mechanical stability of EPDM in a PEM fuel cell environment. Polym. Degrad. Stab. 2009, 94, 2072–2078. [Google Scholar] [CrossRef]

- Kömmling, A.; Jaunich, M.; Goral, M.; Wolff, D. Insights for lifetime predictions of O-Ring seals from five-year long-term aging tests. Polym. Degrad. Stab. 2020, 179, 109278. [Google Scholar] [CrossRef]

- Im, H.; Jeoung, S. Mechanical Aging Test and Sealing Performance of Thermoplastic Vulcanizate as Sealing Gasket in Automotive Fuel Cell Applications. Polymers 2023, 15, 1872. [Google Scholar] [CrossRef] [PubMed]

- Zaghdoudi, M.; Kömmling, A.; Jaunich, M.; Wolff, D. Scission, cross-linking, and physical relaxation during thermal degradation of elastomers. Polymers 2019, 11, 1280. [Google Scholar] [CrossRef] [PubMed]

- Tibaquirá, J.E.; Hristovski, K.D.; Westerhoff, P.; Posner, J.D. Recovery and quality of water produced by commercial fuel cells. Int. J. Hydrogen Energy 2011, 36, 4022–4028. [Google Scholar] [CrossRef]

- Lui, J.; Li, X.; Xu, L.; He, T. Service Lifetime Estimation of EPDM Rubber Based on Accelerated Aging Tests. J. Mater. Eng. Perform. 2017, 26, 1735–1740. [Google Scholar]

- Veiga, J.C.; Junger, D.F.; Sousa, A.M.F. Compressed Non-Asbestos Gaskets Shelf Life Prediction. In Proceedings of the ASME 2010 Pressure Vessels and Piping Division/K-PVP Conference. ASME 2010 Pressure Vessels and Piping Conference: Volume 2, Bellevue, DC, USA, 18–22 July 2010; pp. 21–30. [Google Scholar]

- Woo, C.S.; Park, H.S. Useful lifetime prediction of rubber component. Eng. Fail. Anal. 2011, 18, 1645–1651. [Google Scholar] [CrossRef]

- Cui, Z.; Liu, W.; Tan, L.; Sun, G.; Hu, X. Evidence for non-Arrhenius behavior of EPDM rubber by combining Arrhenius and time-temperature superposition (TTS) extrapolations. RSC Adv. 2024, 14, 5216–5221. [Google Scholar] [CrossRef] [PubMed]

- Zaghdoudi, M.; Kömmling, A.; Jaunich, M.; Wolff, D. Erroneous or arrhenius: A degradation rate-based model for EPDM during homogeneous ageing. Polymers 2020, 12, 2152. [Google Scholar] [CrossRef] [PubMed]

- Gaitanidou, A. Experimental Investigation of Dynamical Behavior on Aged Elastomer Components in Hydrogen Fuel Cell Charging Systems. Master’s Thesis, Aristotle University of Thessaloniki, Thessaloniki, Greece, 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).