Integrating Ambient Intelligence Technologies for Empowering Agriculture †

Abstract

:1. Introduction

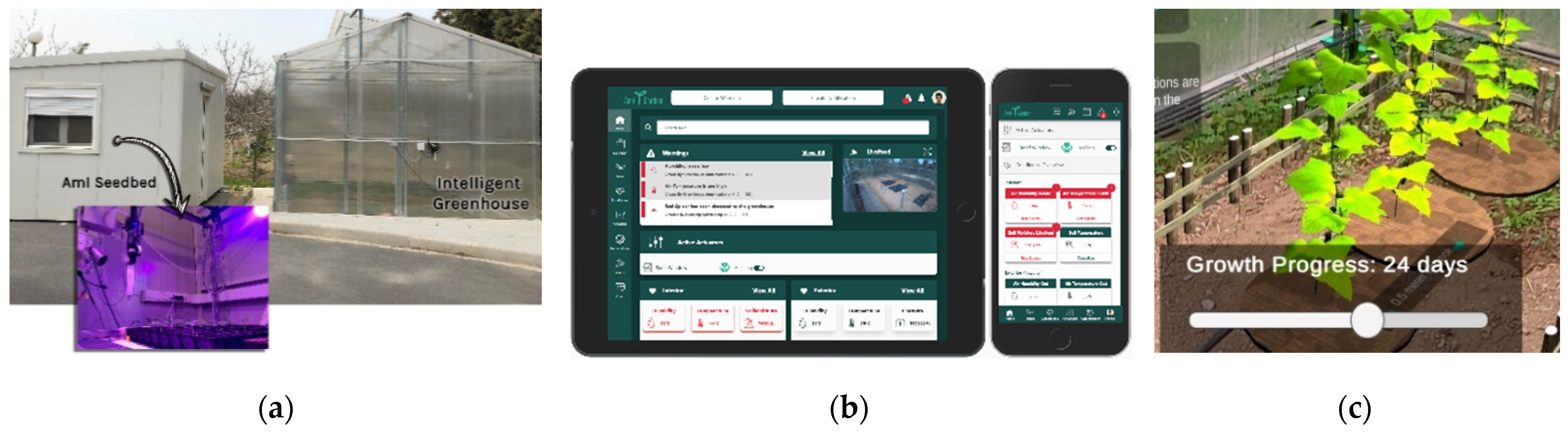

2. Design Process

3. AmI Seedbed and Intelligent Greenhouse

4. End-User Applications

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aubert, B.A.; Schroeder, A.; Grimaudo, J. IT as Enabler of Sustainable Farming: An Empirical Analysis of Farmers’ Adoption Decision of Precision Agriculture Technology. Decis. Support Syst. 2012, 54, 510–520. [Google Scholar] [CrossRef] [Green Version]

- Atherton, B.C.; Morgan, M.; Shearer, S.A.; Stombaugh, T.S.; Ward, A.D. Site-Specific Farming: A Perspective on Information Needs, Benefits and Limitations. J. Soil Water Conserv. 1999, 54, 455–461. [Google Scholar]

- Council, N.R. Precision Agriculture in the 21st Century: Geospatial and Information Technologies in Crop Management; The National Academies Press: Washington, DC, USA, 1997; ISBN 0-309-05893-7. [Google Scholar]

- McBratney, A.; Whelan, B.; Ancev, T.; Bouma, J. Future Directions of Precision Agriculture. Precis. Agric. 2005, 6, 7–23. [Google Scholar] [CrossRef]

- Muñoz, A.; Park, J. Agriculture and Environment Perspectives in Intelligent Systems; IOS Press: Amsterdam, The Netherlands, 2019; Volume 24, ISBN 1-61499-969-4. [Google Scholar]

- Smart Greenhouse. Available online: https://myfood.eu/our-technology/smart-greenhouse/ (accessed on 8 March 2021).

- Belgibaev, B.; Nikulin, V.; Umarov, A. Designing Smart Greenhouses, Satisfactory Price-Quality. J. Math. Mech. Comput. Sci. 2020, 105, 174–190. [Google Scholar] [CrossRef]

- Mirabella, O.; Brischetto, M. A Hybrid Wired/Wireless Networking Infrastructure for Greenhouse Management. IEEE Trans. Instrum. Meas. 2010, 60, 398–407. [Google Scholar] [CrossRef]

- FarmBot | Open-Source CNC Farming. Available online: https://farm.bot/ (accessed on 27 November 2020).

- Aarts, E.; Wichert, R. Ambient intelligence. In Technology Guide; Springer: Berlin/Heidelberg, Germany, 2009; pp. 244–249. [Google Scholar]

- Stephanidis, C. Human Factors in Ambient Intelligence Environments. Handb. Hum. Factors Ergon. 2012, 1354–1373. [Google Scholar]

- Plattner, H.; Meinel, C.; Weinberg, U. Design-Thinking; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 3-86880-013-1. [Google Scholar]

- Bekiaris, I.; Leonidis, A.; Korozi, M.; Stratakis, C.; Zidianakis, E.; Doxastaki, M.; Stephanidis, C. GRETA: Pervasive and AR Interfaces for Controlling Intelligent Greenhouses. In Proceedings of the 2021 17th International Conference on Intelligent Environments (IE), Dubai, United Arab Emirates, 21–24 June 2021. [Google Scholar]

- Leonidis, A.; Korozi, M.; Kouroumalis, V.; Poutouris, E.; Stefanidi, E.; Arampatzis, D.; Sykianaki, E.; Anyfantis, N.; Kalligiannakis, E.; Nicodemou, V.C. Ambient Intelligence in the Living Room. Sensors 2019, 19, 5011. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Intelligent Greenhouse | AmI Seedbed | Common |

|---|---|---|

|

|

|

| Sensors | Actuators | Custom-Made Artefacts |

|---|---|---|

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stratakis, C.; Stivaktakis, N.M.; Bouloukakis, M.; Leonidis, A.; Doxastaki, M.; Kapnas, G.; Evdaimon, T.; Korozi, M.; Kalligiannakis, E.; Stephanidis, C. Integrating Ambient Intelligence Technologies for Empowering Agriculture. Eng. Proc. 2021, 9, 41. https://doi.org/10.3390/engproc2021009041

Stratakis C, Stivaktakis NM, Bouloukakis M, Leonidis A, Doxastaki M, Kapnas G, Evdaimon T, Korozi M, Kalligiannakis E, Stephanidis C. Integrating Ambient Intelligence Technologies for Empowering Agriculture. Engineering Proceedings. 2021; 9(1):41. https://doi.org/10.3390/engproc2021009041

Chicago/Turabian StyleStratakis, Christos, Nikolaos Menelaos Stivaktakis, Manousos Bouloukakis, Asterios Leonidis, Maria Doxastaki, George Kapnas, Theodoros Evdaimon, Maria Korozi, Evangelos Kalligiannakis, and Constantine Stephanidis. 2021. "Integrating Ambient Intelligence Technologies for Empowering Agriculture" Engineering Proceedings 9, no. 1: 41. https://doi.org/10.3390/engproc2021009041

APA StyleStratakis, C., Stivaktakis, N. M., Bouloukakis, M., Leonidis, A., Doxastaki, M., Kapnas, G., Evdaimon, T., Korozi, M., Kalligiannakis, E., & Stephanidis, C. (2021). Integrating Ambient Intelligence Technologies for Empowering Agriculture. Engineering Proceedings, 9(1), 41. https://doi.org/10.3390/engproc2021009041