Green Upgrading of Biodiesel Derived from Biomass Wastes †

Abstract

1. Introduction

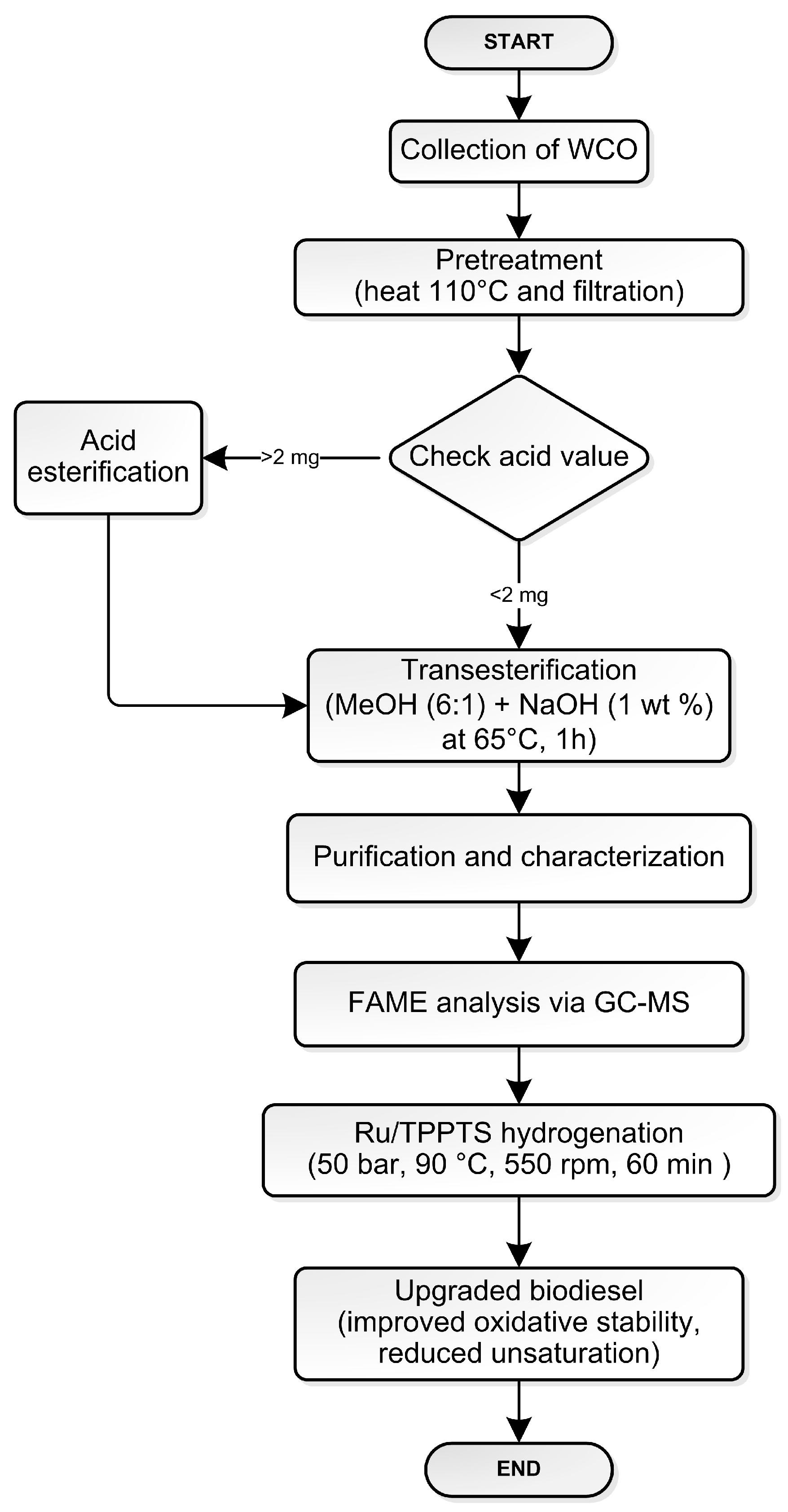

2. Materials and Methods

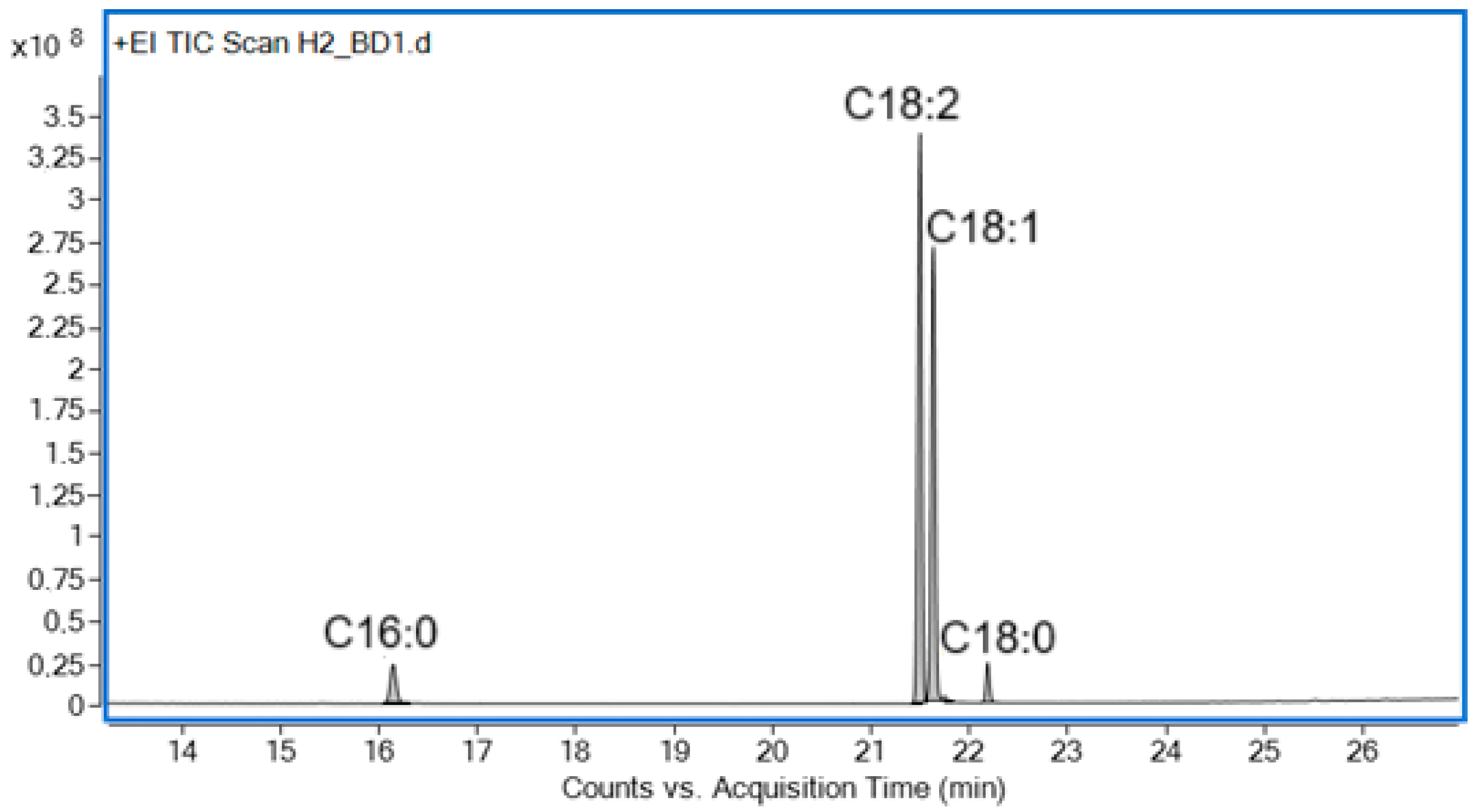

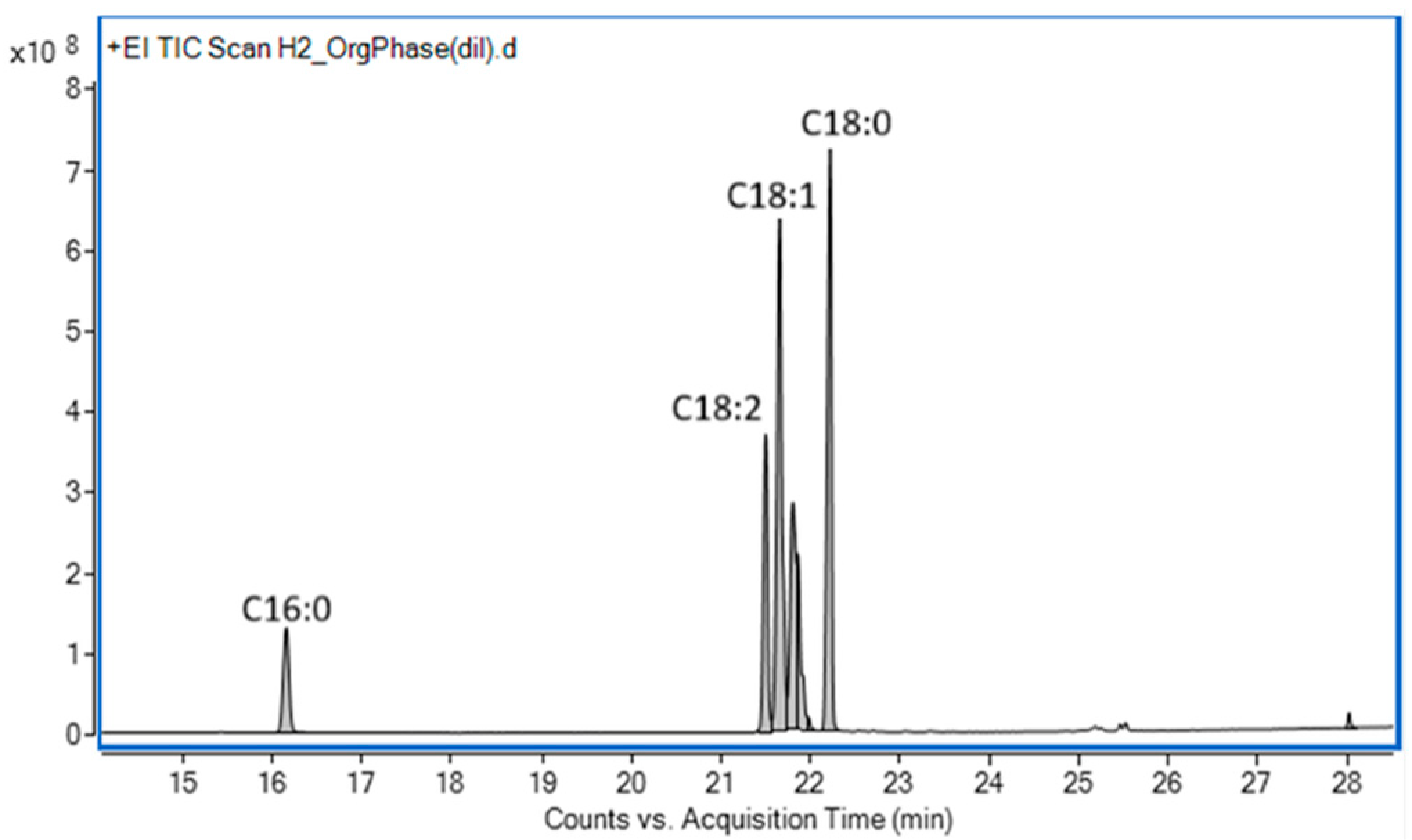

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFPP | Cold Filter Plugging Point |

| FAME | Fatty Acid Methyl Ester |

| GC-MS | Gas Chromatography–Mass Spectrometry |

| OS | Oxidative Stability |

| WCO | Waste Cooking Oil |

| TPPTS | Trisodium Triphenylphosphine-3,3’, 3’-Tri Sulfonate |

References

- Kokkinos, N.; Emmanouilidou, E.; Sharma, S. Waste-To-Biofuel Production for the Transportation Sector; Springer: Berlin/Heidelberg, Germany, 2024; pp. 99–122. [Google Scholar]

- Ramos, M.; Dias, A.P.S.; Puna, J.F.; Gomes, J.; Bordado, J.C. Biodiesel Production Processes and Sustainable Raw Materials. Energies 2019, 12, 4408. [Google Scholar] [CrossRef]

- Suzihaque, M.U.H.; Alwi, H.; Kalthum Ibrahim, U.; Abdullah, S.; Haron, N. Biodiesel production from waste cooking oil: A brief review. Mater. Today Proc. 2022, 63, S490–S495. [Google Scholar] [CrossRef]

- Cerón Ferrusca, M.; Romero, R.; Martínez, S.L.; Ramírez-Serrano, A.; Natividad, R. Biodiesel Production from Waste Cooking Oil: A Perspective on Catalytic Processes. Processes 2023, 11, 1952. [Google Scholar] [CrossRef]

- Shin, H.-Y.; Ryu, J.-H.; Bae, S.-Y.; Kim, Y.C. Biodiesel production from highly unsaturated feedstock via simultaneous transesterification and partial hydrogenation in supercritical methanol. J. Supercrit. Fluids 2013, 82, 251–255. [Google Scholar] [CrossRef]

- Lin, C.-Y. Effects of the Degree of Unsaturation of Fatty Acid Esters on Engine Performance and Emission Characteristics. Processes 2022, 10, 2161. [Google Scholar] [CrossRef]

- Knothe, G. Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process. Technol. 2005, 86, 1059–1070. [Google Scholar] [CrossRef]

- Wan Osman, W.N.A.; Rosli, M.H.; Mazli, W.N.A.; Samsuri, S. Comparative review of biodiesel production and purification. Carbon Capture Sci. Technol. 2024, 13, 100264. [Google Scholar] [CrossRef]

- Stathis, P.; Stavroulaki, D.; Kaika, N.; Krommyda, K.; Papadogianakis, G. Low trans-isomers formation in the aqueous-phase Pt/TPPTS-catalyzed partial hydrogenation of methyl esters of linseed oil. Appl. Catal. B Environ. 2017, 209, 579–590. [Google Scholar] [CrossRef]

- Bouriazos, A.; Vasiliou, C.; Tsichla, A.; Papadogianakis, G. Catalytic conversions in green aqueous media. Part 8: Partial and full hydrogenation of renewable methyl esters of vegetable oils. Catal. Today 2015, 247, 20–32. [Google Scholar] [CrossRef]

- Zuo, L.; Wang, J.; Mei, D.; Adu-Mensah, D.; Gao, Y. Ultrasonic-assisted catalytic transfer hydrogenation of cottonseed biodiesel using Raney-Ni catalyst in aqueous environment. Chem. Eng. J. 2022, 437, 135193. [Google Scholar] [CrossRef]

- Psalidas, A.; Emmanouilidou, E.; Kokkinos, N. Catalytic Upgrading of Biodiesel by Partial Hydrogenation of Its FAME Composition: A Systematic Review. Energies 2023, 17, 561. [Google Scholar] [CrossRef]

- Kokkinos, N.C. Modeling and simulation of biphasic catalytic hydrogenation of a hydroformylated fuel. Int. J. Hydrog. Energy 2021, 46, 19731–19736. [Google Scholar] [CrossRef]

- Wieselburg, B. Review on Bioidiesel Standardization World-Wide. 2004. Available online: https://task39.ieabioenergy.com/wp-content/uploads/sites/37/2013/05/Review-on-Biodiesel-Standardization.pdf. (accessed on 10 March 2024).

- Emmanouilidou, E.; Lazaridou, A.; Mitkidou, S.; Kokkinos, N. A comparative study on biodiesel production from edible and non-edible biomasses. J. Mol. Struct. 2024, 1306, 137870. [Google Scholar] [CrossRef]

- Lopresto, C.G.; De Paola, M.G.; Calabrò, V. Importance of the properties, collection, and storage of waste cooking oils to produce high-quality biodiesel—An overview. Biomass Bioenergy 2024, 189, 107363. [Google Scholar] [CrossRef]

- Dwivedi, G.; Jain, S.; Sharma, M.P. Impact analysis of biodiesel on engine performance—A review. Renew. Sustain. Energy Rev. 2011, 15, 4633–4641. [Google Scholar] [CrossRef]

- Pullen, J.; Saeed, K. An overview of biodiesel oxidation stability. Renew. Sustain. Energy Rev. 2012, 16, 5924–5950. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.; Li, F.; Wang, H.; Ma, X.; Li, J.; Zhou, L.; Xiao, Q. Effects of unsaturated fatty acid methyl esters on the oxidation stability of biodiesel determined by gas chromatography-mass spectrometry and information entropy methods. Renew. Energy 2021, 175, 880–886. [Google Scholar] [CrossRef]

- Masudi, A.; Muraza, O.; Jusoh, N.W.C.; Ubaidillah, U. Improvements in the stability of biodiesel fuels: Recent progress and challenges. Environ. Sci. Pollut. Res. 2023, 30, 14104–14125. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N. Oxidative stability of biodiesel: Causes, effects and prevention. Fuel 2017, 190, 328–350. [Google Scholar] [CrossRef]

| Property | Measured Value | Specs EN 14214 | Test Method |

|---|---|---|---|

| Density at 15 °C, g·cm−3 | 0.8868 | 0.86–0.91 | EN ISO 12185 |

| Acid number, mg KOH·g−1 | 0.40 | <0.5 | EN ISO 14104 [14] |

| CFPP, °C | −2.0 | Country Specific Max. +5 °C | ΕΝ 116 [14] |

| Oxidative stability at 110 °C, h | 0.34 | >6 | EN 14112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emmanouilidou, E.; Psalidas, A.; Lazaridou, A.; Mitkidou, S.; Kokkinos, N.C. Green Upgrading of Biodiesel Derived from Biomass Wastes. Eng. Proc. 2025, 87, 14. https://doi.org/10.3390/engproc2025087014

Emmanouilidou E, Psalidas A, Lazaridou A, Mitkidou S, Kokkinos NC. Green Upgrading of Biodiesel Derived from Biomass Wastes. Engineering Proceedings. 2025; 87(1):14. https://doi.org/10.3390/engproc2025087014

Chicago/Turabian StyleEmmanouilidou, Elissavet, Alexandros Psalidas, Anastasia Lazaridou, Sophia Mitkidou, and Nikolaos C. Kokkinos. 2025. "Green Upgrading of Biodiesel Derived from Biomass Wastes" Engineering Proceedings 87, no. 1: 14. https://doi.org/10.3390/engproc2025087014

APA StyleEmmanouilidou, E., Psalidas, A., Lazaridou, A., Mitkidou, S., & Kokkinos, N. C. (2025). Green Upgrading of Biodiesel Derived from Biomass Wastes. Engineering Proceedings, 87(1), 14. https://doi.org/10.3390/engproc2025087014