Design Challenges in the Development of a Hydrogen-Fueled Micro Gas Turbine Unit for Energy Generation †

Abstract

1. Introduction

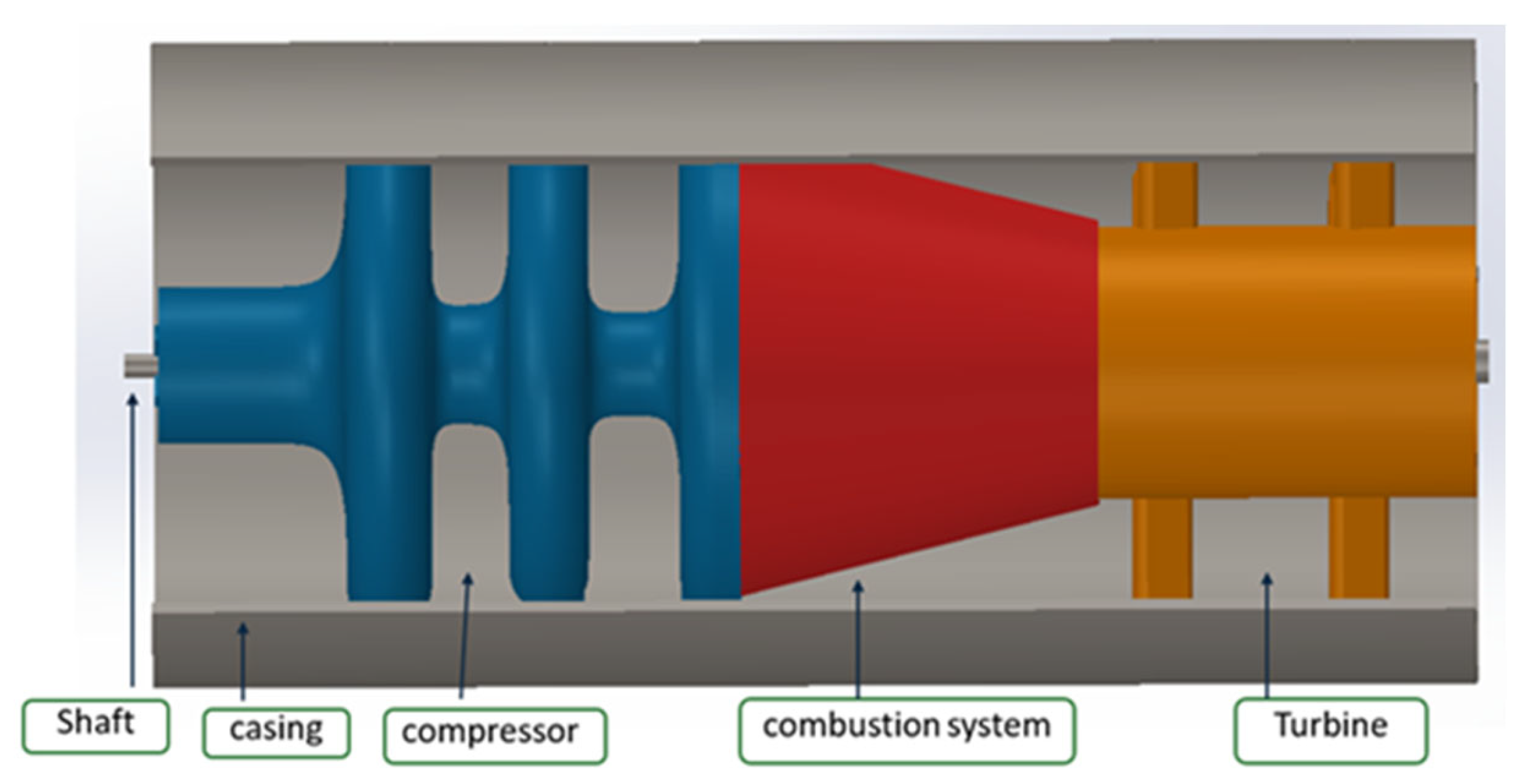

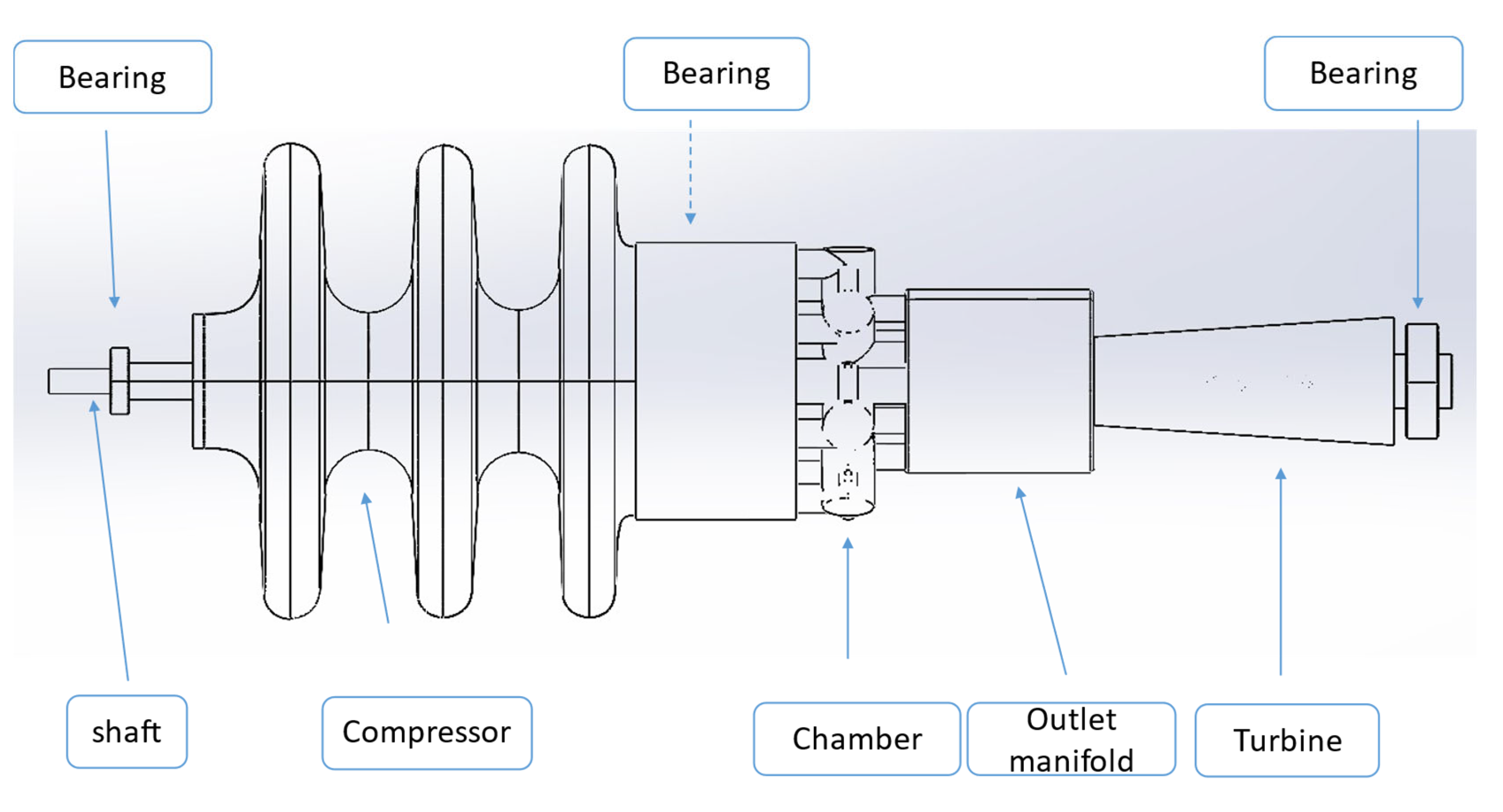

2. Conceptual Design

3. Design Challenges

3.1. Component Level

3.1.1. Chamber

3.1.2. Outlet Manifold

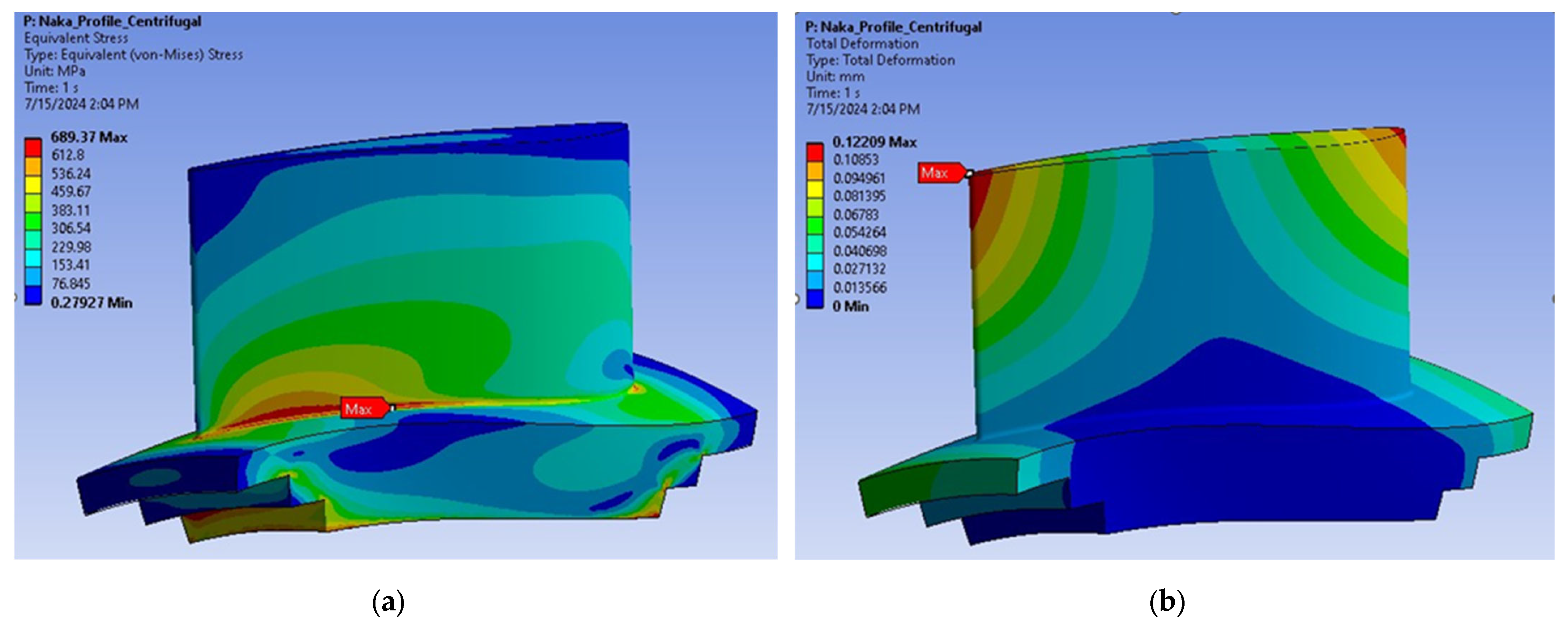

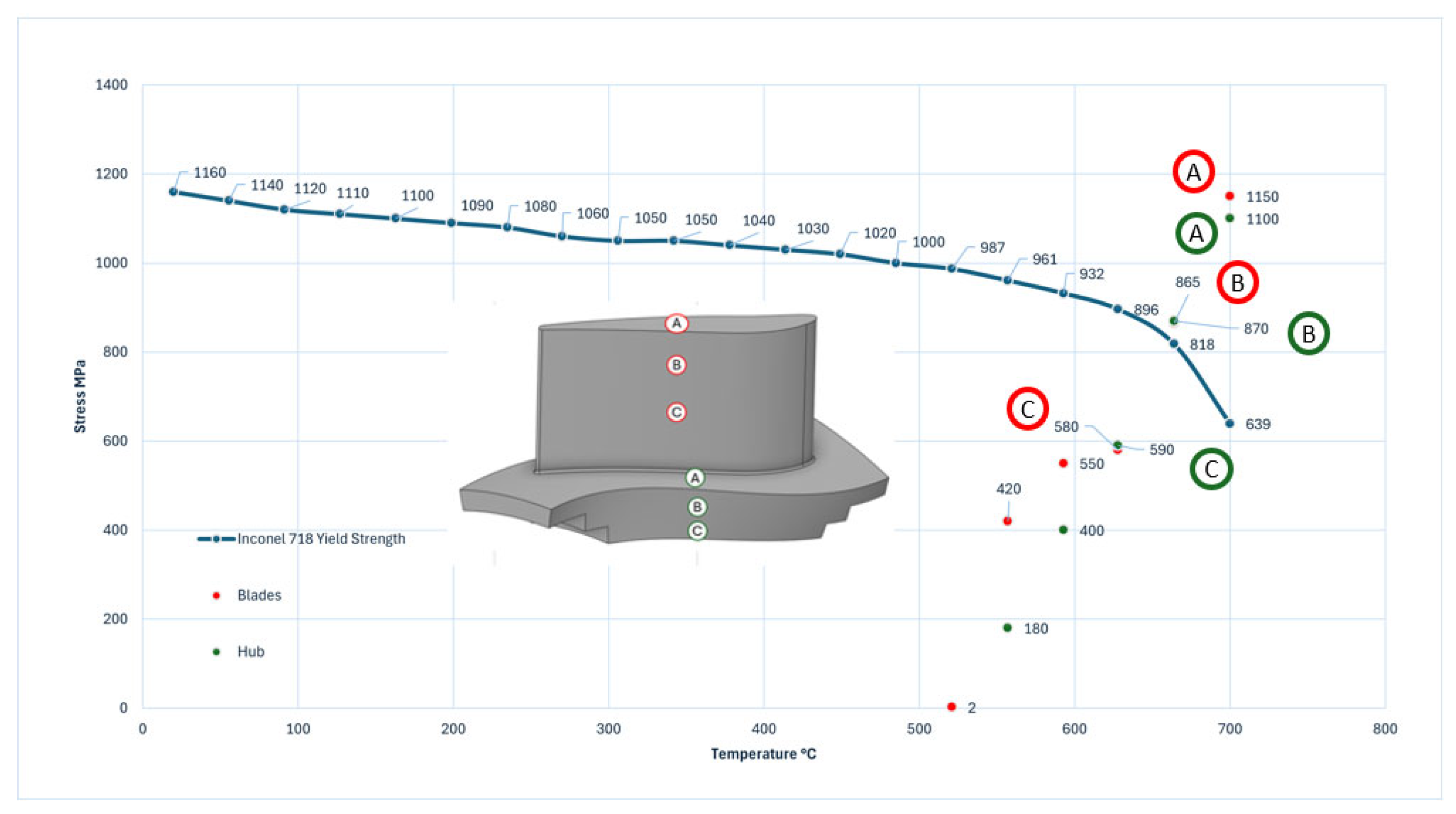

3.1.3. Turbine

3.1.4. Bearings

3.1.5. Shaft

3.2. MGT System Level

3.2.1. Temperature Management

3.2.2. Operating Speed

4. Pathway to Solutions

4.1. System Level

4.1.1. Equivalence Ratio

4.1.2. Vibrational Management

4.1.3. Temperature Management

4.2. Component Level

4.2.1. Bearing

- Q = quantity in mm3/h;

- w = numerical coefficient = 0.01 mm/h;

- d = internal bearing diameter;

- B = bearing width in mm.

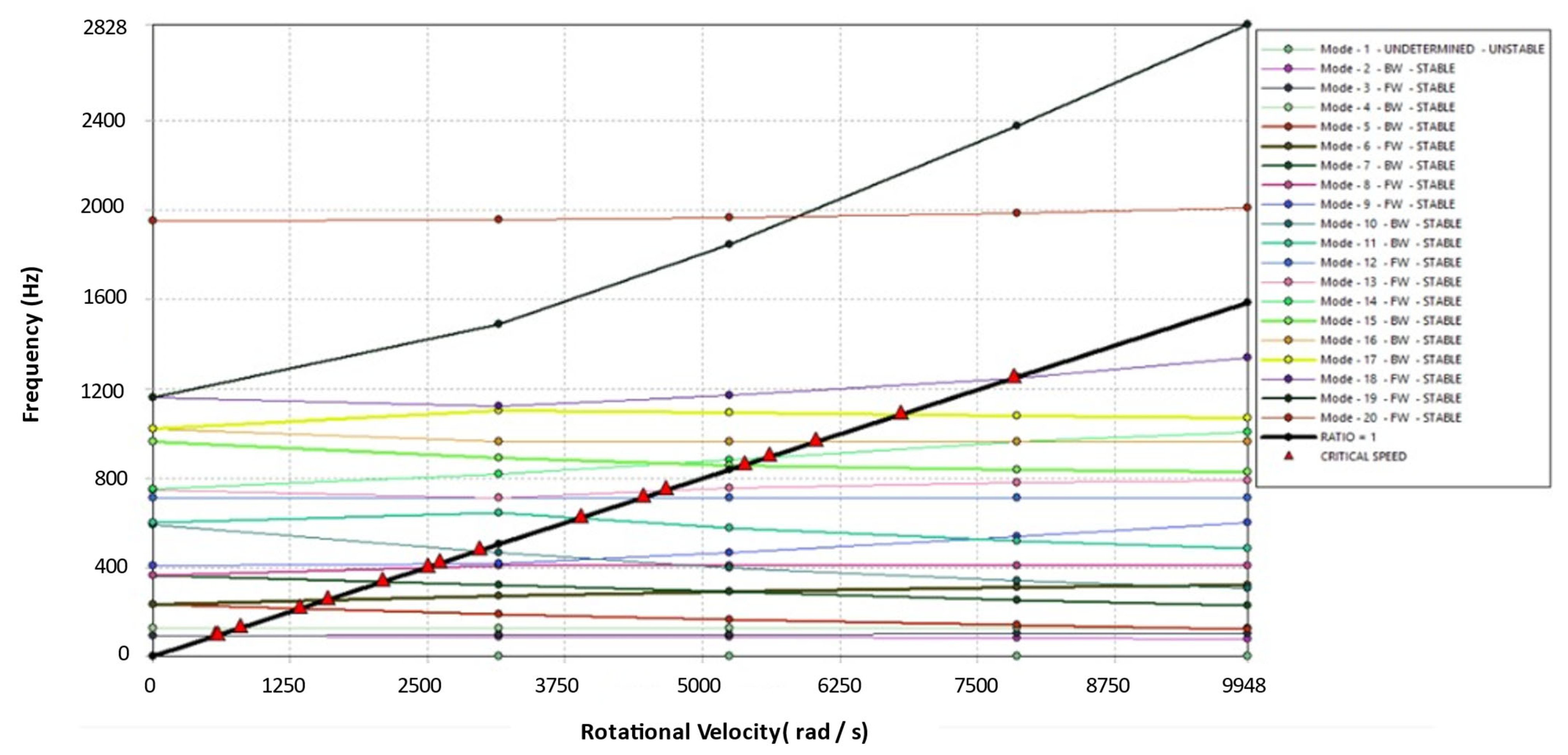

4.2.2. Shaft

- K = stiffness matrix;

- S = stress stiffening matrix;

- M = mass matrix;

- ωi2 = n eigen values;

- {φ}i = n eigen vectors;

- n = number of degrees of freedom (DOF).

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The Future of Hydrogen—Analysis—IEA. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 12 September 2024).

- Aliberti, D.; Ortenzi, F.; La Battaglia, V.; Marini, S.; Vellucci, F. Evaluation of the Efficiency of a Hybrid ICE Vehicle Fuelled with Hydrogen Compared with a Fuel Cell Vehicle, Based on a Simulation Model. J. Phys. Conf. Ser. 2023, 2648, 012082. [Google Scholar] [CrossRef]

- Statista Largest Operational Coal Power Plants in the EU by Capacity 2021. Available online: https://www.statista.com/statistics/1264199/largest-operational-coal-power-plants-by-capacity-in-the-eu-27/ (accessed on 12 September 2024).

- European Turbine Network (ETN Global); ETN Secretariat. The Path Towards a Zero-Carbon Gas Turbine. 2019. Available online: https://api.semanticscholar.org/CorpusID:211166022 (accessed on 12 September 2024).

- Barati, S.; De Santoli, L.; Lo Basso, G. Modeling and Analysis of a Micro Gas Turbine Fuelled with Hydrogen and Natural Gas Blends. E3S Web Conf. 2021, 312, 08012. [Google Scholar] [CrossRef]

- Banihabib, R.; Lingstädt, T.; Wersland, M.; Kutne, P.; Assadi, M. Development and Testing of a 100 kW Fuel-Flexible Micro Gas Turbine Running on 100% Hydrogen. Int. J. Hydrogen Energy 2024, 49, 92–111. [Google Scholar] [CrossRef]

- Banihabib, R.; Assadi, M. A Hydrogen-Fueled Micro Gas Turbine Unit for Carbon-Free Heat and Power Generation. Sustainability 2022, 14, 13305. [Google Scholar] [CrossRef]

- Zhou, H.; Xue, J.; Gao, H.; Ma, N. Hydrogen-Fueled Gas Turbines in Future Energy System. Int. J. Hydrogen Energy 2024, 64, 569–582. [Google Scholar] [CrossRef]

- Gas Factsheet|Www.Acer.Europa.Eu. Available online: https://www.acer.europa.eu/gas-factsheet (accessed on 12 September 2024).

- Renewable Energy. Available online: https://www.eea.europa.eu/en/topics/in-depth/renewable-energy (accessed on 12 September 2024).

- Minotti, A. Electrical Energy Generator Device PCT/IB2018/05203. Available online: https://patents.google.com/patent/WO2018173012A1/en?oq=PCT%2fIB2018%2f052036 (accessed on 12 September 2024).

- Baldi, N.; Giorgetti, A.; Palladino, M.; Giovannetti, I.; Arcidiacono, G.; Citti, P. Study on the Effect of Inter-Layer Cooling Time on Porosity and Melt Pool in Inconel 718 Components Processed by Laser Powder Bed Fusion. Materials 2023, 16, 3920. [Google Scholar] [CrossRef] [PubMed]

- Ciappi, A.; Giorgetti, A.; Ceccanti, F.; Canegallo, G. Technological and Economical Consideration for Turbine Blade Tip Restoration through Metal Deposition Technologies. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1741–1758. [Google Scholar] [CrossRef]

- Sun, J.; Liu, Q.; Gu, M.; Wang, Y. Effect of Equivalence Ratio on Pollutant Formation in CH4O/H2/NH3 Blend Combustion. Molecules 2023, 29, 176. [Google Scholar] [CrossRef] [PubMed]

- Moroshkina, A.; Ponomareva, A.; Mislavskii, V.; Sereshchenko, E.; Gubernov, V.; Bykov, V.; Minaev, S. Activation Energy of Hydrogen–Methane Mixtures. Fire 2024, 7, 42. [Google Scholar] [CrossRef]

- Makaryan, I.A.; Sedov, I.V.; Salgansky, E.A.; Arutyunov, A.V.; Arutyunov, V.S. A Comprehensive Review on the Prospects of Using Hydrogen–Methane Blends: Challenges and Opportunities. Energies 2022, 15, 2265. [Google Scholar] [CrossRef]

- Luo, Q.-H.; Hu, J.-B.; Sun, B.-G.; Liu, F.-S.; Wang, X.; Li, C.; Bao, L.-Z. Effect of Equivalence Ratios on the Power, Combustion Stability and NOx Controlling Strategy for the Turbocharged Hydrogen Engine at Low Engine Speeds. Int. J. Hydrogen Energy 2019, 44, 17095–17102. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Z.; Peng, S.; Liu, C.; Liu, C.; Liu, L.; Zhou, R.; Zhi, S.; Fan, T.; Li, P. Effects of Hydrogen Blending Ratio and Equivalence Ratio on the Dynamic Characteristics of Deflagration Shock Waves of CH4/H2 Mixtures. ACS Omega 2024, 9, 23853–23863. [Google Scholar] [CrossRef] [PubMed]

- Kanti, R.M.; Kawahara, N.; Tomita, E.; Fujitani, T. Effect of Equivalence Ratio on Combustion Characteristics in a Hydrogen Direct-Injection SI Engine; Springer eBooks: Berlin/Heidelberg, Germany, 2012; pp. 97–102. [Google Scholar]

- Barwinska, I.; Kopec, M.; Kukla, D.; Senderowski, C.; Kowalewski, Z.L. Thermal Barrier Coatings for High-Temperature Performance of Nickel-Based Superalloys: A Synthetic Review. Coatings 2023, 13, 769. [Google Scholar] [CrossRef]

- Boissonnet, G.; Chalk, C.; Nicholls, J.R.; Bonnet, G.; Pedraza, F. Thermal Insulation of YSZ and Erbia-Doped Yttria-Stabilised Zirconia EB-PVD Thermal Barrier Coating Systems after CMAS Attack. Materials 2020, 13, 4382. [Google Scholar] [CrossRef] [PubMed]

- Mondal, K.; Nuñez, L.; Downey, C.M.; Van Rooyen, I.J. Recent Advances in the Thermal Barrier Coatings for Extreme Environments. Mater. Sci. Energy Technol. 2021, 4, 208–210. [Google Scholar] [CrossRef]

- Bogdan, M.; Peter, I. A Comprehensive Understanding of Thermal Barrier Coatings (TBCs): Applications, Materials, Coating Design and Failure Mechanisms. Metals 2024, 14, 575. [Google Scholar] [CrossRef]

- Xiao, S.; Li, J.; Huang, P.; Zhang, A.; Tian, Y.; Zhang, X.; Zhang, J.; Ryu, J.; Han, G. Evaluation of Environmental Barrier Coatings: A Review. Int. J. Appl. Ceram. Technol. 2023, 20, 2055–2076. [Google Scholar] [CrossRef]

- Lü, K.; Huang, Y.; Xu, M.; Xie, Y.; Deng, L.; Dong, S.; Jiang, J.; Chen, W.; Cao, X. Multi-Layered Environmental Barrier Coatings Designed on Basis of YbTaO4-Ta2O5 Composites for Protecting SiCf/SiC Composites. J. Eur. Ceram. Soc. 2024, 44, 3525–3536. [Google Scholar] [CrossRef]

- Lee, K.; Zhu, D.; Wiesner, V.L.; Mark, V.R.; Kashyap, T.; Wiesner, V. Environmental Barrier Coatings for Ceramic Matrix Composites—An Overview. Available online: https://ntrs.nasa.gov/citations/20170004751 (accessed on 12 September 2024).

- Vaßen, R.; Bakan, E.; Gatzen, C.; Kim, S.; Mack, D.E.; Guillon, O. Environmental Barrier Coatings Made by Different Thermal Spray Technologies. Coatings 2019, 9, 784. [Google Scholar] [CrossRef]

- SKF Air-Oil Lubrication Units and Mixing Valves Product Series OLA, MV and 161. Available online: https://www.skf.com/uk/products/lubrication-management/system-components/supply-units/oil-and-air-lubrication/ola (accessed on 7 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gottipati, U.N.; Minotti, A.; La Battaglia, V.; Giorgetti, A. Design Challenges in the Development of a Hydrogen-Fueled Micro Gas Turbine Unit for Energy Generation. Eng. Proc. 2025, 85, 45. https://doi.org/10.3390/engproc2025085045

Gottipati UN, Minotti A, La Battaglia V, Giorgetti A. Design Challenges in the Development of a Hydrogen-Fueled Micro Gas Turbine Unit for Energy Generation. Engineering Proceedings. 2025; 85(1):45. https://doi.org/10.3390/engproc2025085045

Chicago/Turabian StyleGottipati, Uma Nataraj, Angelo Minotti, Vincenzo La Battaglia, and Alessandro Giorgetti. 2025. "Design Challenges in the Development of a Hydrogen-Fueled Micro Gas Turbine Unit for Energy Generation" Engineering Proceedings 85, no. 1: 45. https://doi.org/10.3390/engproc2025085045

APA StyleGottipati, U. N., Minotti, A., La Battaglia, V., & Giorgetti, A. (2025). Design Challenges in the Development of a Hydrogen-Fueled Micro Gas Turbine Unit for Energy Generation. Engineering Proceedings, 85(1), 45. https://doi.org/10.3390/engproc2025085045