An Investigation of the Monotonic and Cyclic Behavior of Additively Manufactured TPU †

Abstract

1. Introduction

2. Materials and Methods

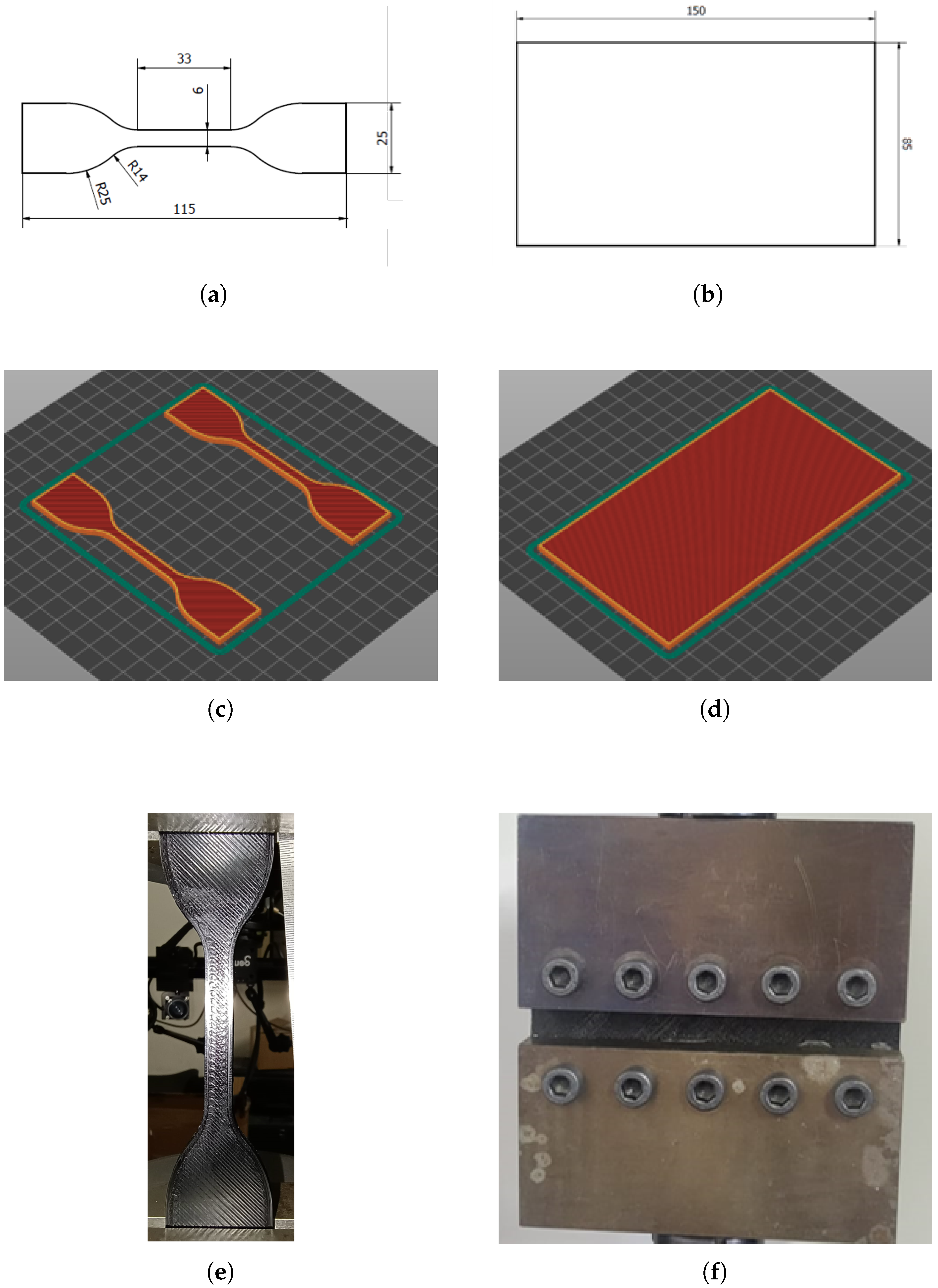

2.1. Samples Manufacturing

2.2. Mechanical Testing

3. Results

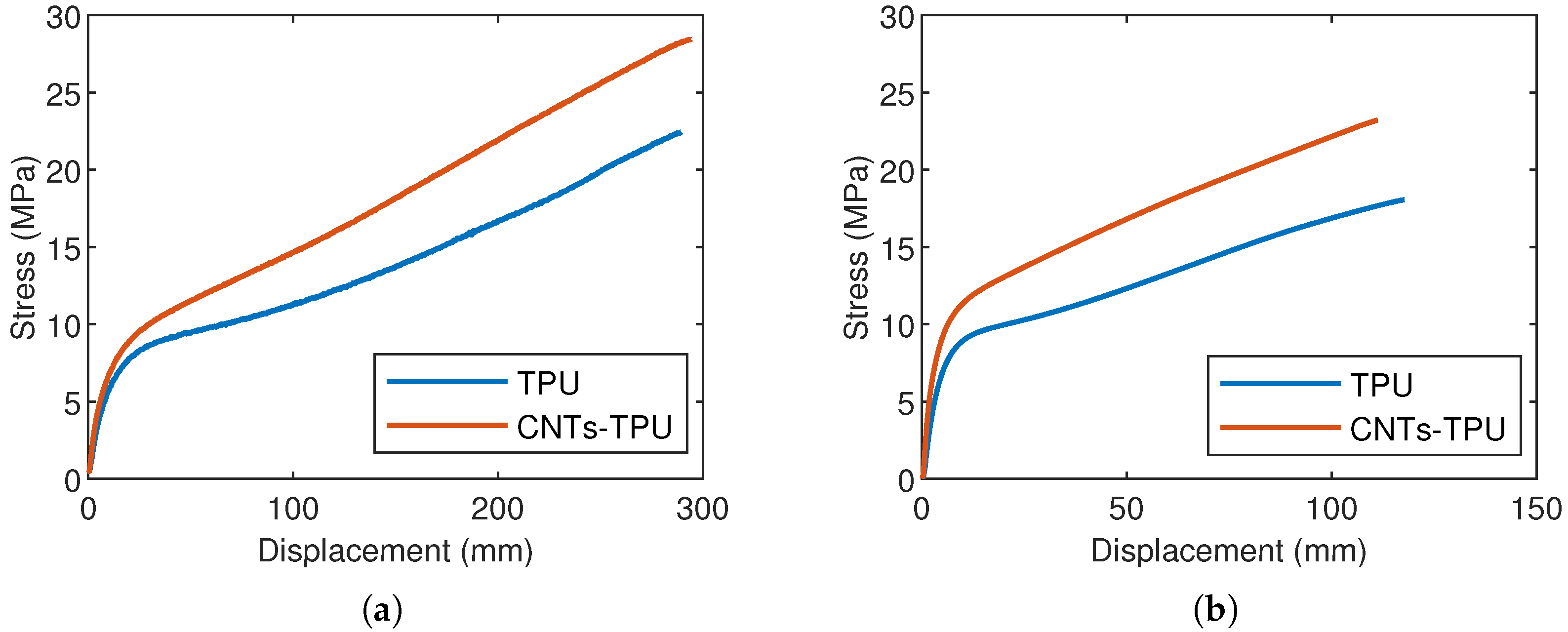

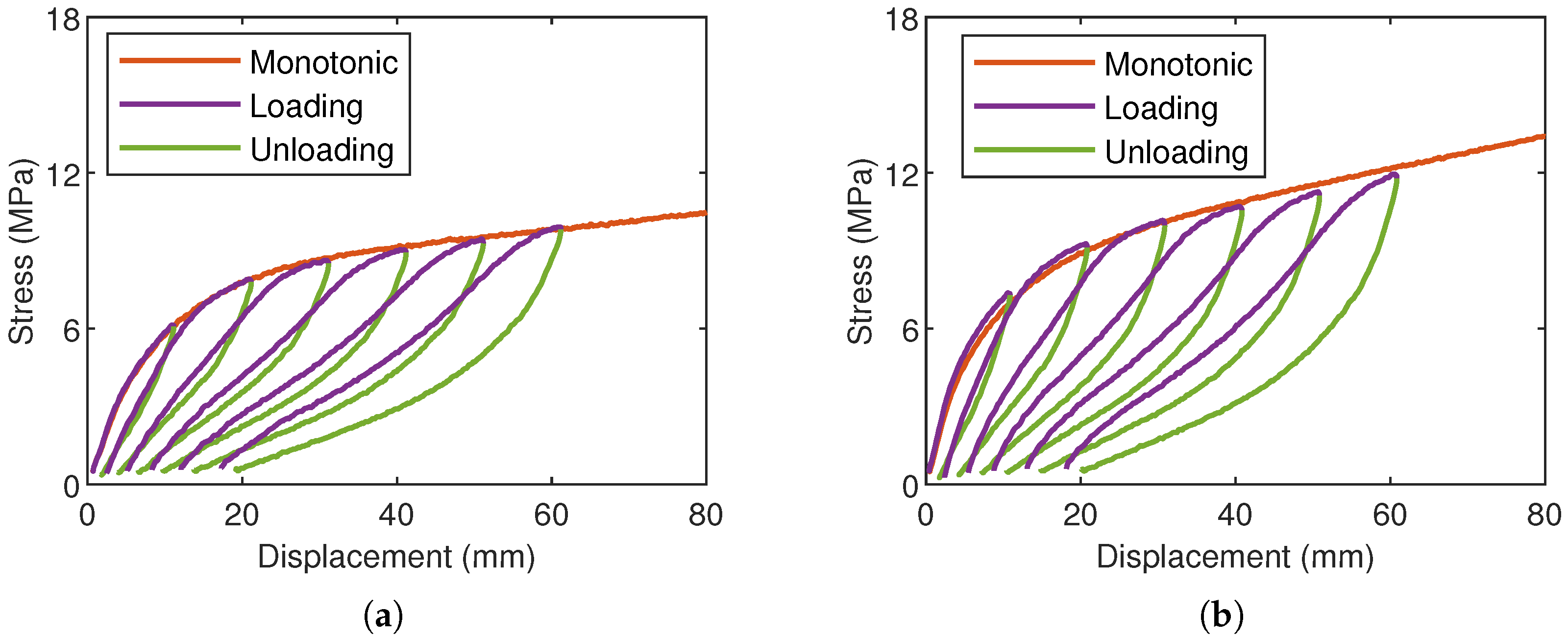

3.1. Monotonic Loadings

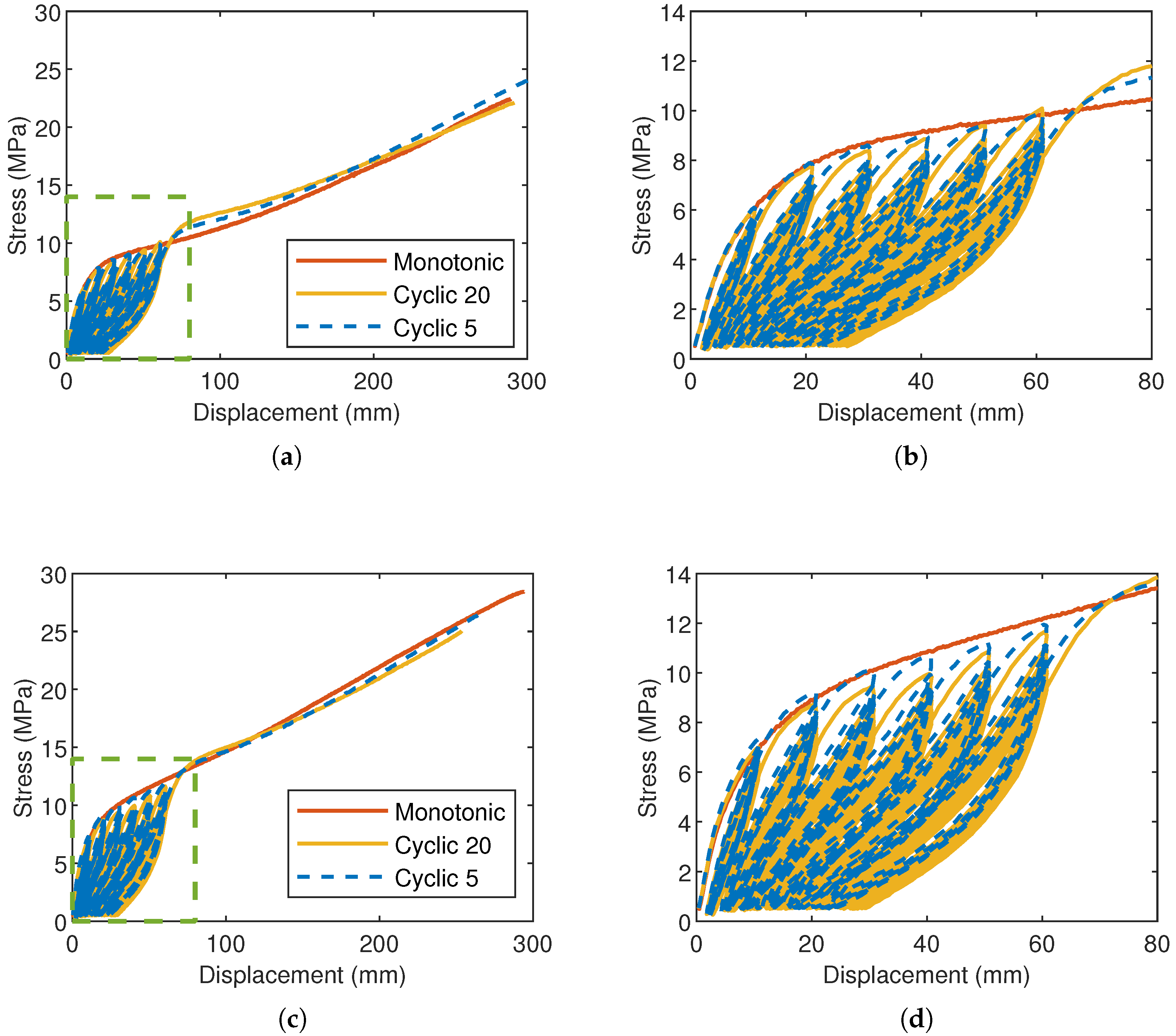

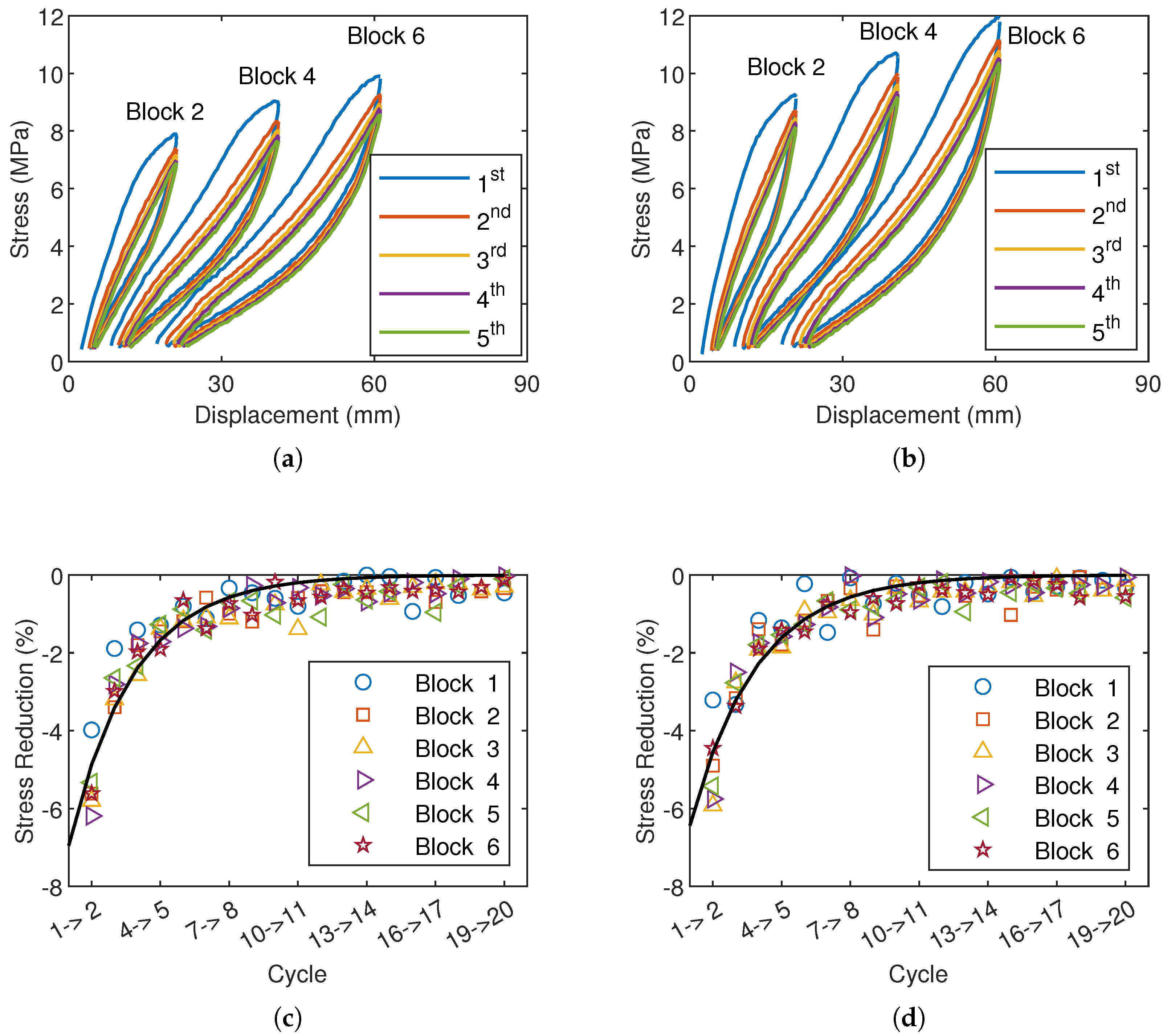

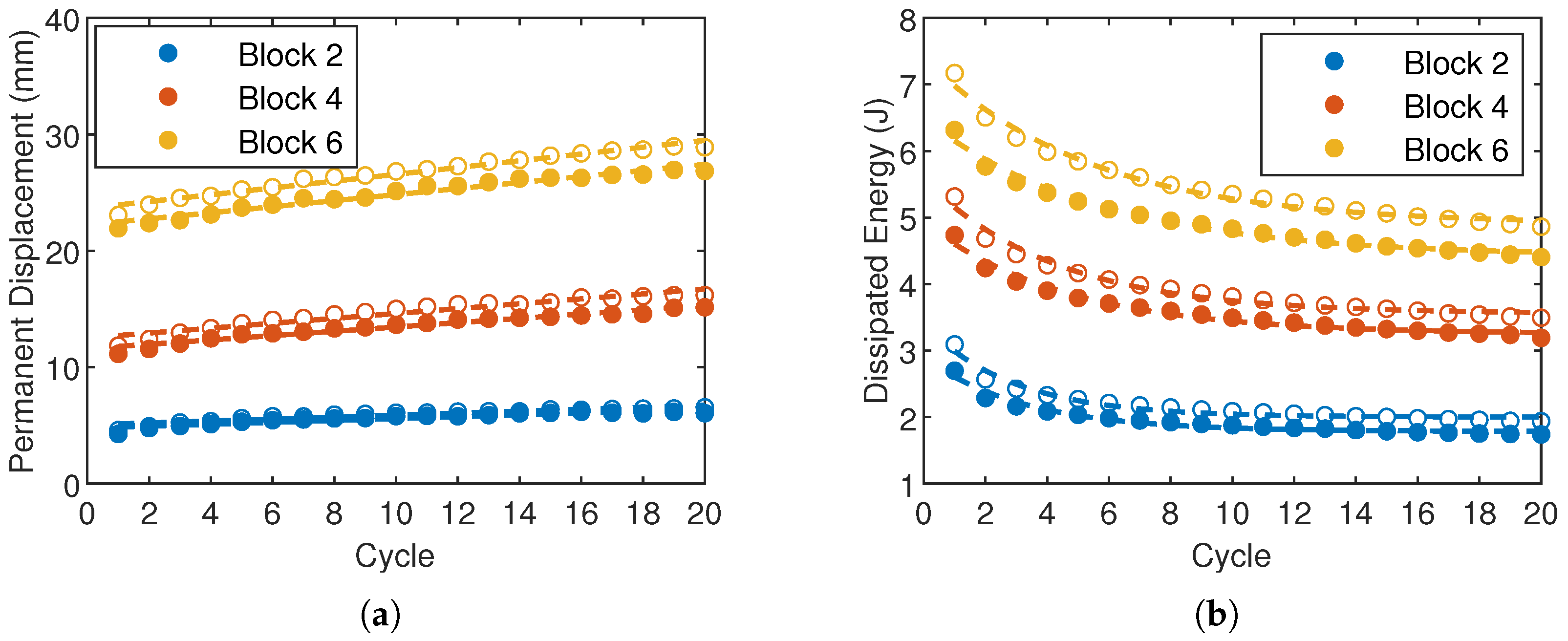

3.2. Cyclic Loadings

- Both materials are characterized by continuous stress softening when subjected to repeated loadings at a given deformation level.

- Following the first cycles, in which the loss of stiffness is more pronounced, a stabilized cyclic response is gradually reached.

4. Discussion

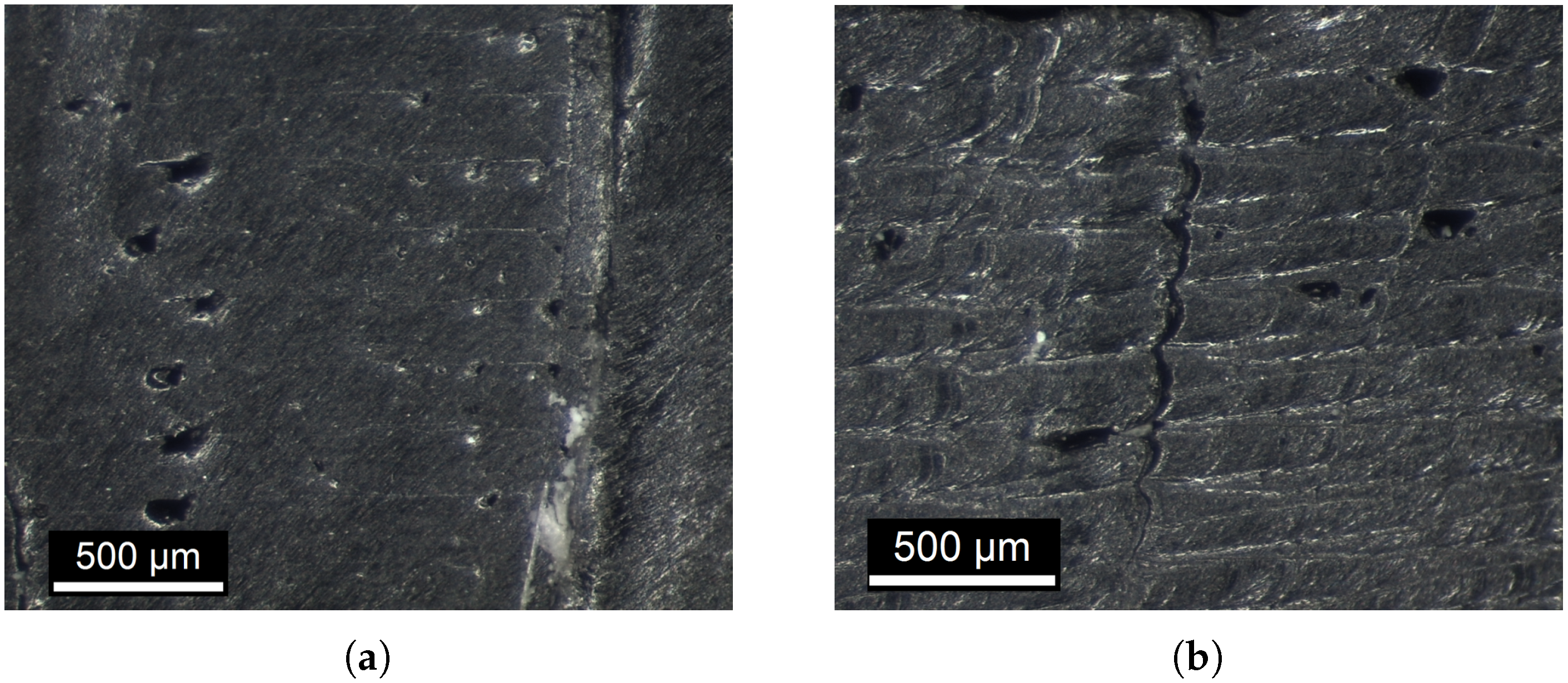

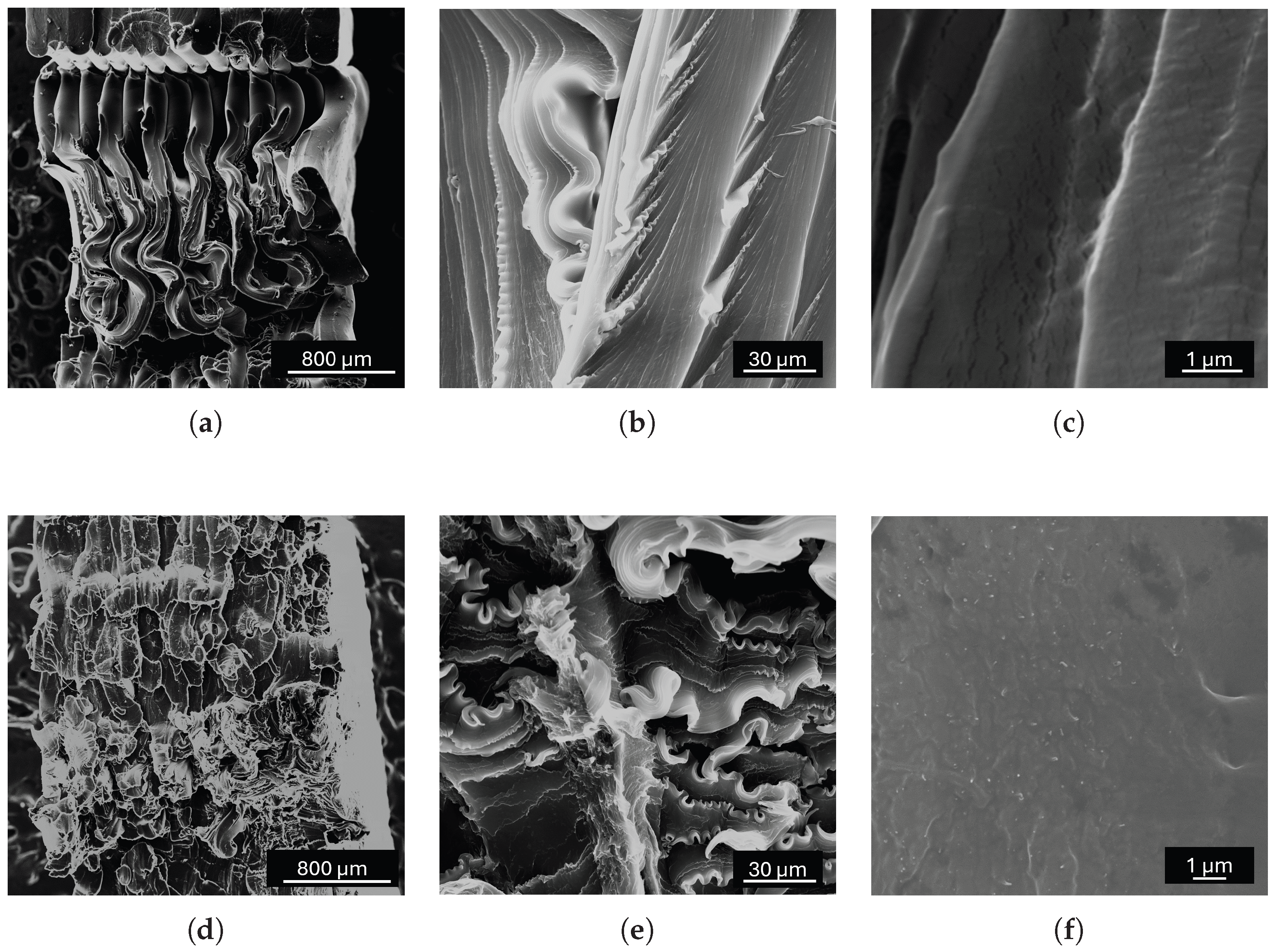

4.1. Monotonic Response and Fracture

4.2. Analysis of Cyclic Data

4.2.1. Response During the 1st Cycle

4.2.2. Response Under Repeated Loadings

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Desai, S.M.; Sonawane, R.Y.; More, A.P. Thermoplastic polyurethane for three-dimensional printing applications: A review. Polym. Adv. Technol. 2023, 34, 2061–2082. [Google Scholar] [CrossRef]

- Qi, H.J.; Boyce, M.C. Stress-strain behavior of thermoplastic polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Wang, S.; Tang, S.; He, C.; Wang, Q. Cyclic Deformation and Fatigue Failure Mechanisms of Thermoplastic Polyurethane in High Cycle Fatigue. Polymers 2023, 15, 899. [Google Scholar] [CrossRef] [PubMed]

- Hohimer, C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. 3D printed conductive thermoplastic polyurethane/carbon nanotube composites for capacitive and piezoresistive sensing in soft pneumatic actuators. Addit. Manuf. 2020, 34, 101281. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Lin, X.; Gao, L.; Liu, T.; Lu, Y.; Wang, R. Research of TPU materials for 3D printing aiming at non-pneumatic tires by FDM method. Polymers 2020, 12, 2492. [Google Scholar] [CrossRef]

- Dezianian, S.; Azadi, M. Multi-Material Metamaterial Topology Optimization to Minimize the Compliance and the Constraint of Weight: Application of Non-Pneumatic Tire Additive-Manufactured with PLA/TPU Polymers. Polymers 2023, 15, 1927. [Google Scholar] [CrossRef]

- Xiao, J.; Gao, Y. The manufacture of 3D printing of medical grade TPU. Prog. Addit. Manuf. 2017, 2, 117–123. [Google Scholar] [CrossRef]

- Chennell, P.; Feschet-Chassot, E.; Sautou, V.; Mailhot-Jensen, B. Preparation of ordered mesoporous and macroporous thermoplastic polyurethane surfaces for potential medical applications. J. Biomater. Appl. 2018, 32, 1317–1328. [Google Scholar] [CrossRef]

- Zhao, W.; Li, M.; Peng, H.X. Functionalized MWNT-doped thermoplastic polyurethane nanocomposites for aerospace coating applications. Macromol. Mater. Eng. 2010, 295, 838–845. [Google Scholar] [CrossRef]

- Ahmed, S.; Nauman, S.; Khan, Z.M. Development of TPU/CNPs flexible composite strain sensors using Additive Manufacturing (AM) for Structural Health Monitoring (SHM) of aerospace components. In Proceedings of 18th International Bhurban Conference on Applied Sciences and Technologies, IBCAST 2021, Islamabad, Pakistan, 12–16 January 2021; pp. 47–54. [Google Scholar] [CrossRef]

- Dey, A.; Eagle, I.N.R.; Yodo, N. A review on filament materials for fused filament fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain rate sensitivity of polycarbonate and thermoplastic polyurethane for various 3d printing temperatures and layer heights. Polymers 2021, 13, 2752. [Google Scholar] [CrossRef] [PubMed]

- Faisal, M.F.; Akbar, N.I.; Zayed, A.H.H. Development and Analysis of Additively Manufactured Non-Pneumatic Tires for Mars Rover. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1305, 012026. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Bertocco, A.; Iannitti, G.; Caraviello, A.; Esposito, L. Lattice structures in stainless steel 17-4PH manufactured via selective laser melting (SLM) process: Dimensional accuracy, satellites formation, compressive response and printing parameters optimization. Int. J. Adv. Manuf. Technol. 2022, 120, 4935–4949. [Google Scholar] [CrossRef]

- Ricci, S.; Zucca, G.; Iannitti, G.; Ruggiero, A.; Sgambetterra, M.; Rizzi, G.; Bonora, N.; Testa, G. Characterization of Asymmetric and Anisotropic Plastic Flow of L-PBF AlSi10Mg. Exp. Mech. 2023, 63, 1409–1425. [Google Scholar] [CrossRef]

- Ricci, S.; Iannitti, G. Mechanical Behavior of Additive Manufacturing (AM) and Wrought Ti6Al4V with a Martensitic Microstructure. Metals 2024, 14, 1028. [Google Scholar] [CrossRef]

- Bruère, V.M.; Lion, A.; Holtmannspötter, J.; Johlitz, M. The influence of printing parameters on the mechanical properties of 3D printed TPU-based elastomers. Prog. Addit. Manuf. 2023, 8, 693–701. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Deng, S.; Chen, R.; Duan, S.; Jia, Q.; Hao, X.; Zhang, L. Research progress on sustainability of key tire materials. SusMat 2023, 3, 581–608. [Google Scholar] [CrossRef]

- Sardinha, M.; Fátima Vaz, M.; Ramos, T.R.; Reis, L. Design, properties, and applications of non-pneumatic tires: A review. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 2677–2697. [Google Scholar] [CrossRef]

- Suvanjumrat, C.; Rugsaj, R. Study of 3D printing for forming spoke of non-pneumatic tire using finite element method. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1137, 012020. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar] [CrossRef]

- Toncheva, A.; Brison, L.; Dubois, P.; Laoutid, F. Recycled tire rubber in additive manufacturing: Selective laser sintering for polymer-ground rubber composites. Appl. Sci. 2021, 11, 8778. [Google Scholar] [CrossRef]

- Whelan, D. Thermoplastic Elastomers. In Brydson’s Plastics Materials: Eighth Edition; Butterworth-Heinemann: Oxford, UK, 2017; pp. 653–703. [Google Scholar] [CrossRef]

- Deng, Y.; Wang, Z.; Shen, H.; Gong, J.; Xiao, Z. A comprehensive review on non-pneumatic tyre research. Mater. Des. 2023, 227, 111742. [Google Scholar] [CrossRef]

- Chen, S.; Yu, H.; Ren, W.; Zhang, Y. Thermal degradation behavior of hydrogenated nitrile-butadiene rubber (HNBR)/clay nanocomposite and HNBR/clay/carbon nanotubes nanocomposites. Thermochim. Acta 2009, 491, 103–108. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, J.; Hou, G.; Ma, J.; Wang, W.; Wei, F.; Zhang, L. From nano to giant? Designing carbon nanotubes for rubber reinforcement and their applications for high performance tires. Compos. Sci. Technol. 2016, 137, 94–101. [Google Scholar] [CrossRef]

- Danafar, F.; Kalantari, M. A Review of Natural Rubber Nanocomposites Based on Carbon Nanotubes. J. Rubber Res. 2018, 21, 293–310. [Google Scholar] [CrossRef]

- Kim, H.; Jeon, J.; Lee, S.; Cho, J.; Lee, I. Printing Characteristics of TPU/MWCNT Conductive Composite Using FFF. Int. J. Precis. Eng. Manuf. 2024, 25, 1303–1309. [Google Scholar] [CrossRef]

- Testa, G.; Esposito, L.; Ceccacci, A.; Iannitti, G.; Bonora, N. Innovative design and prototyping of reconfigurable run-flat tire. Eng. Proc. 2024, Under Review. [Google Scholar]

- Zhang, R.; Deng, H.; Valenca, R.; Jin, J.; Fu, Q.; Bilotti, E.; Peijs, T. Strain sensing behaviour of elastomeric composite films containing carbon nanotubes under cyclic loading. Compos. Sci. Technol. 2013, 74, 1–5. [Google Scholar] [CrossRef]

- Sang, Z.; Ke, K.; Manas-Zloczower, I. Effect of carbon nanotube morphology on properties in thermoplastic elastomer composites for strain sensors. Compos. Part A Appl. Sci. Manuf. 2019, 121, 207–212. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, T.K.; Varadarajan, K.M. Strong, stretchable and ultrasensitive MWCNT/TPU nanocomposites for piezoresistive strain sensing. Compos. Part B Eng. 2019, 177, 107285. [Google Scholar] [CrossRef]

- Rostami, A.; Moosavi, M.I. High-performance thermoplastic polyurethane nanocomposites induced by hybrid application of functionalized graphene and carbon nanotubes. J. Appl. Polym. Sci. 2020, 137, 48520. [Google Scholar] [CrossRef]

- Sui, G.; Liu, D.; Liu, Y.; Ji, W.; Zhang, Q.; Fu, Q. The dispersion of CNT in TPU matrix with different preparation methods: Solution mixing vs melt mixing. Polymer 2019, 182, 121838. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D printed thermoelectric polyurethane/multiwalled carbon nanotube nanocomposites: A novel approach towards the fabrication of flexible and stretchable organic thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

- Zhou, M.; Zhu, W.; Yu, S.; Tian, Y.; Zhou, K. Selective laser sintering of carbon nanotube–coated thermoplastic polyurethane: Mechanical, electrical, and piezoresistive properties. Compos. Part C Open Access 2022, 7, 100212. [Google Scholar] [CrossRef]

- Hohimer, C.; Aliheidari, N.; Mo, C.; Ameli, A. Mechanical behavior of 3D printed multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. In Proceedings of the ASME 2017 Conference on Smart Materials, Adaptive Structures and Intelligent Systems SMASIS2017, Snowbird, UT, USA, 18–20 September 2017. [Google Scholar]

- Testa, G.; Bonora, N.; Esposito, L.; Iannitti, G. Design of an electromechanical testing machine for elastomers’ fatigue characterization. Eng. Proc. 2024, Under Review. [Google Scholar]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers-Tension. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Giannis, S.; Adams, R.D. Failure of elastomeric sealants under tension and shear: Experiments and analysis. Int. J. Adhes. Adhes. 2019, 91, 77–91. [Google Scholar] [CrossRef]

- Rodríguez-Parada, L.; De La Rosa, S.; Mayuet, P.F. Influence of 3D-printed TPU properties for the design of elastic products. Polymers 2021, 13, 2519. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, W.; Huang, J.; Peng, C.; Wang, H.; Yuan, C.; Chen, G.; Zeng, B.; Dai, L. Simplification of Hyperelastic Constitutive Model and Finite Element Analysis of Thermoplastic Polyurethane Elastomers. Macromol. Theory Simulations 2020, 29, 2000009. [Google Scholar] [CrossRef]

- Khan, U.; May, P.; O’Neill, A.; Vilatela, J.J.; Windle, A.H.; Coleman, J.N. Tuning the mechanical properties of composites from elastomeric to rigid thermoplastic by controlled addition of carbon nanotubes. Small 2011, 7, 1579–1586. [Google Scholar] [CrossRef] [PubMed]

- Mullins, L. Softening of rubber. Rubber Chem. Technol. 1969, 42, 339–362. [Google Scholar] [CrossRef]

- Palmieri, G.; Sasso, M.; Chiappini, G.; Amodio, D. Mullins effect characterization of elastomers by multi-axial cyclic tests and optical experimental methods. Mech. Mater. 2009, 41, 1059–1067. [Google Scholar] [CrossRef]

- Dargazany, R.; Itskov, M. Constitutive modeling of the Mullins effect and cyclic stress softening in filled elastomers. Phys. Rev. E-Stat. Nonlinear Soft Matter Phys. 2013, 88, 012602. [Google Scholar] [CrossRef]

- Bartolomé, L.; Aurrekoetxea, J.; Urchegui, M.A.; Tato, W. The influences of deformation state and experimental conditions on inelastic behaviour of an extruded thermoplastic polyurethane elastomer. Mater. Des. 2013, 49, 974–980. [Google Scholar] [CrossRef]

- Dorfmann, A.; Ogden, R.W. A constitutive model for the Mullins effect with permanent set in particle-reinforced rubber. Int. J. Solids Struct. 2004, 41, 1855–1878. [Google Scholar] [CrossRef]

- Arifvianto, B.; Iman, T.N.; Prayoga, B.T.; Dharmastiti, R.; Salim, U.A.; Mahardika, M.; Suyitno. Tensile properties of the FFF-processed thermoplastic polyurethane (TPU) elastomer. Int. J. Adv. Manuf. Technol. 2021, 117, 1709–1719. [Google Scholar] [CrossRef]

- Boubakri, A.; Haddar, N.; Elleuch, K.; Bienvenu, Y. Impact of aging conditions on mechanical properties of thermoplastic polyurethane. Mater. Des. 2010, 31, 4194–4201. [Google Scholar] [CrossRef]

- Brieu, M.; Diani, J.; Mignot, C.; Moriceau, C. Response of a carbon-black filled SBR under large strain cyclic uniaxial tension. Int. J. Fatigue 2010, 32, 1921–1927. [Google Scholar] [CrossRef]

- Verron, E.; Chagnon, G.; Gornet, L.; Marckmann, G.; Verron, E.; Chagnon, G.; Gornet, L.; Marckmann, G.; Charrier, P.; Verron, E.; et al. Modelling the Mullins effect using damage mechanics: Efficiency and limitations. In Proceedings of the Third European Conference on Constitutive Models for Rubber (ECCMR 2003), London, UK, 15–17 September 2003. [Google Scholar]

- Chai, A.B.; Verron, E.; Andriyana, A.; Johan, M.R. Mullins effect in swollen rubber: Experimental investigation and constitutive modelling. Polym. Test. 2013, 32, 748–759. [Google Scholar] [CrossRef]

- Ricker, A.; Kröger, N.H.; Wriggers, P. Comparison of discontinuous damage models of Mullins-type. Arch. Appl. Mech. 2021, 91, 4097–4119. [Google Scholar] [CrossRef]

- Mars, W.V.; Fatemi, A. Observations of the constitutive response and characterization of filled natural rubber under monotonic and cyclic multiaxial stress states. J. Eng. Mater. Technol. 2004, 126, 19–28. [Google Scholar] [CrossRef]

- Diani, J.; Fayolle, B.; Gilormini, P. A review on the Mullins effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef]

- Reyes, S.I.; Vassiliou, M.F.; Konstantinidis, D. Experimental characterization and constitutive modeling of thermoplastic polyurethane under complex uniaxial loading. J. Mech. Phys. Solids 2024, 186, 105582. [Google Scholar] [CrossRef]

- Cho, H.; Mayer, S.; Pöselt, E.; Susoff, M.; Veld, P.J.; Rutledge, G.C.; Boyce, M.C. Deformation mechanisms of thermoplastic elastomers: Stress-strain behavior and constitutive modeling. Polymer 2017, 128, 87–99. [Google Scholar] [CrossRef]

- Frick, A.; Borm, M.; Kaoud, N.; Kolodziej, J.; Neudeck, J. Microstructure and thermomechanical properties relationship of segmented thermoplastic polyurethane (TPU). AIP Conf. Proc. 2014, 1593, 520–525. [Google Scholar] [CrossRef]

- Álvarez-García, S.; Martín-Martínez, J.M. Effect of the carbon black content on the thermal, rheological and mechanical properties of thermoplastic polyurethanes. J. Adhes. Sci. Technol. 2015, 29, 1136–1154. [Google Scholar] [CrossRef]

- Avanzini, A.; Gallina, D. Effect of cyclic strain on the mechanical behavior of a thermoplastic polyurethane. J. Eng. Mater. Technol. 2011, 133, 021005. [Google Scholar] [CrossRef]

- Omnès, B.; Thuillier, S.; Pilvin, P.; Grohens, Y.; Gillet, S. Effective properties of carbon black filled natural rubber: Experiments and modeling. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1141–1149. [Google Scholar] [CrossRef]

| TPU | CNTs-Reinforced TPU | |

|---|---|---|

| Nozzle Temperature (°C) | 205 | 225 |

| Chamber Temperature (°C) | 40 | 55 |

| Nozzle diameter (mm) | 0.6 | 0.6 |

| Average Printing Speed (mm/s) | 20 | 20 |

| Extrusion multiplier (-) | 0.98 | 0.93 |

| Layer height (mm) | 0.2 | 0.2 |

| Infill density (%) | 100 | 100 |

| Infill geometry | Rectilinear 45°-oriented | Rectilinear 45°-oriented |

| Infill combination | Each layer | Each layer |

| TPU | CNTs-TPU | ||

|---|---|---|---|

| ST-Monotonic | Fracture Stress | 21.8 ± MPa | 27.6 ± MPa |

| Final Displacement | 280.5 ± mm | 284.0 ± mm | |

| ST-5 cycles | Fracture Stress | 22.6 ± MPa | 26.8 ± MPa |

| Final Displacement | 291.3 ± mm | 272.5 ± mm | |

| ST-20 cycles | Fracture Stress | 22.9 ± MPa | 25.7 ± MPa |

| Final Displacement | 298.9 ± mm | 286.6 ± mm | |

| PT-Monotonic | Fracture Stress | 17.7 ± MPa | 22.9 ± MPa |

| Final Displacement | 117.2 ± mm | 110.3 ± mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricci, S.; Pagano, A.; Ceccacci, A.; Iannitti, G.; Bonora, N. An Investigation of the Monotonic and Cyclic Behavior of Additively Manufactured TPU. Eng. Proc. 2025, 85, 18. https://doi.org/10.3390/engproc2025085018

Ricci S, Pagano A, Ceccacci A, Iannitti G, Bonora N. An Investigation of the Monotonic and Cyclic Behavior of Additively Manufactured TPU. Engineering Proceedings. 2025; 85(1):18. https://doi.org/10.3390/engproc2025085018

Chicago/Turabian StyleRicci, Sara, Alberto Pagano, Andrea Ceccacci, Gianluca Iannitti, and Nicola Bonora. 2025. "An Investigation of the Monotonic and Cyclic Behavior of Additively Manufactured TPU" Engineering Proceedings 85, no. 1: 18. https://doi.org/10.3390/engproc2025085018

APA StyleRicci, S., Pagano, A., Ceccacci, A., Iannitti, G., & Bonora, N. (2025). An Investigation of the Monotonic and Cyclic Behavior of Additively Manufactured TPU. Engineering Proceedings, 85(1), 18. https://doi.org/10.3390/engproc2025085018