Development of a High-Stability Boost Converter Using Supercapacitor Integration Using the Perturb and Observe Control Method for Photovoltaic Application †

Abstract

1. Introduction

2. Literature Review

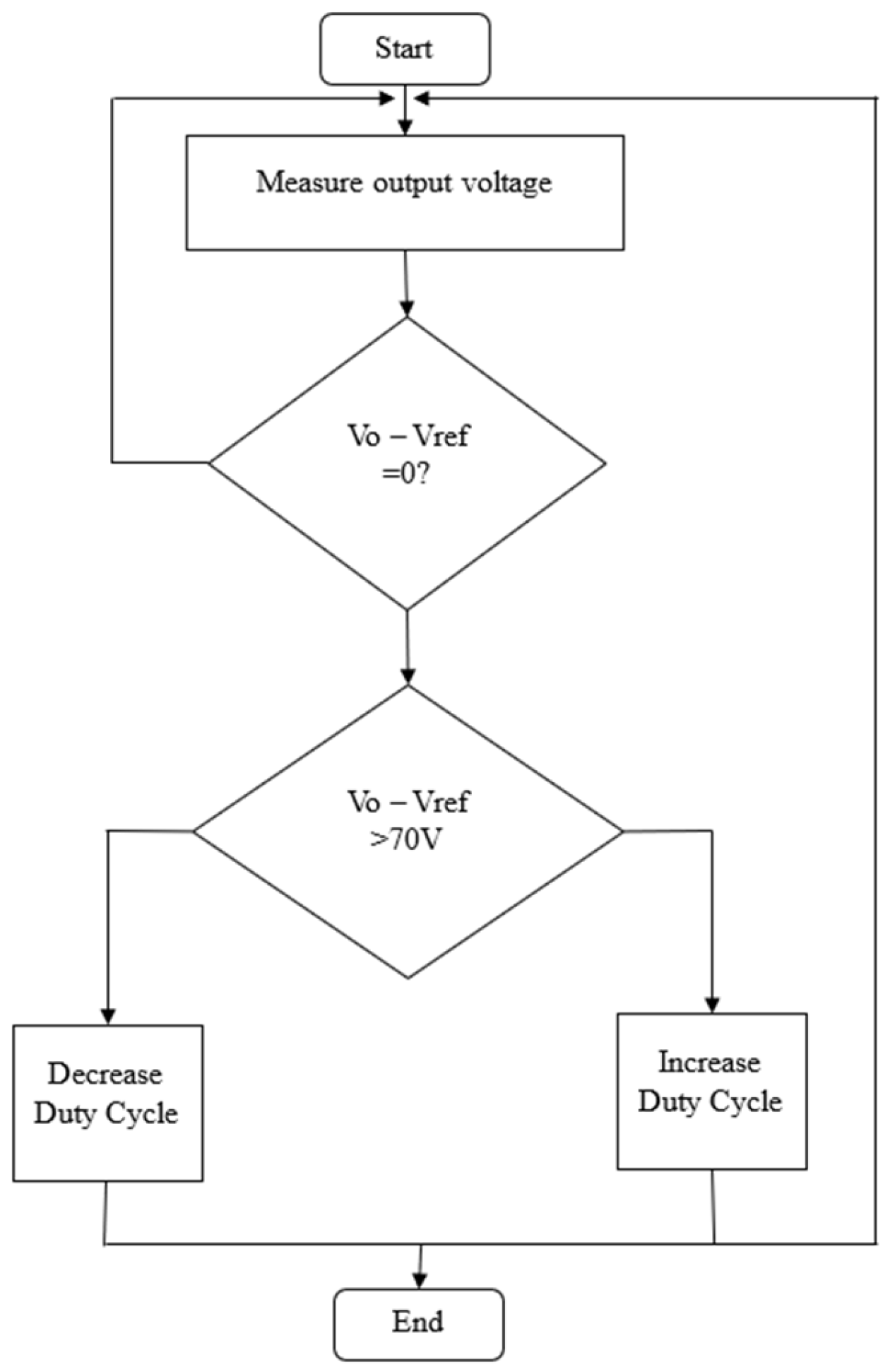

2.1. Perturb and Observe (PO) Method

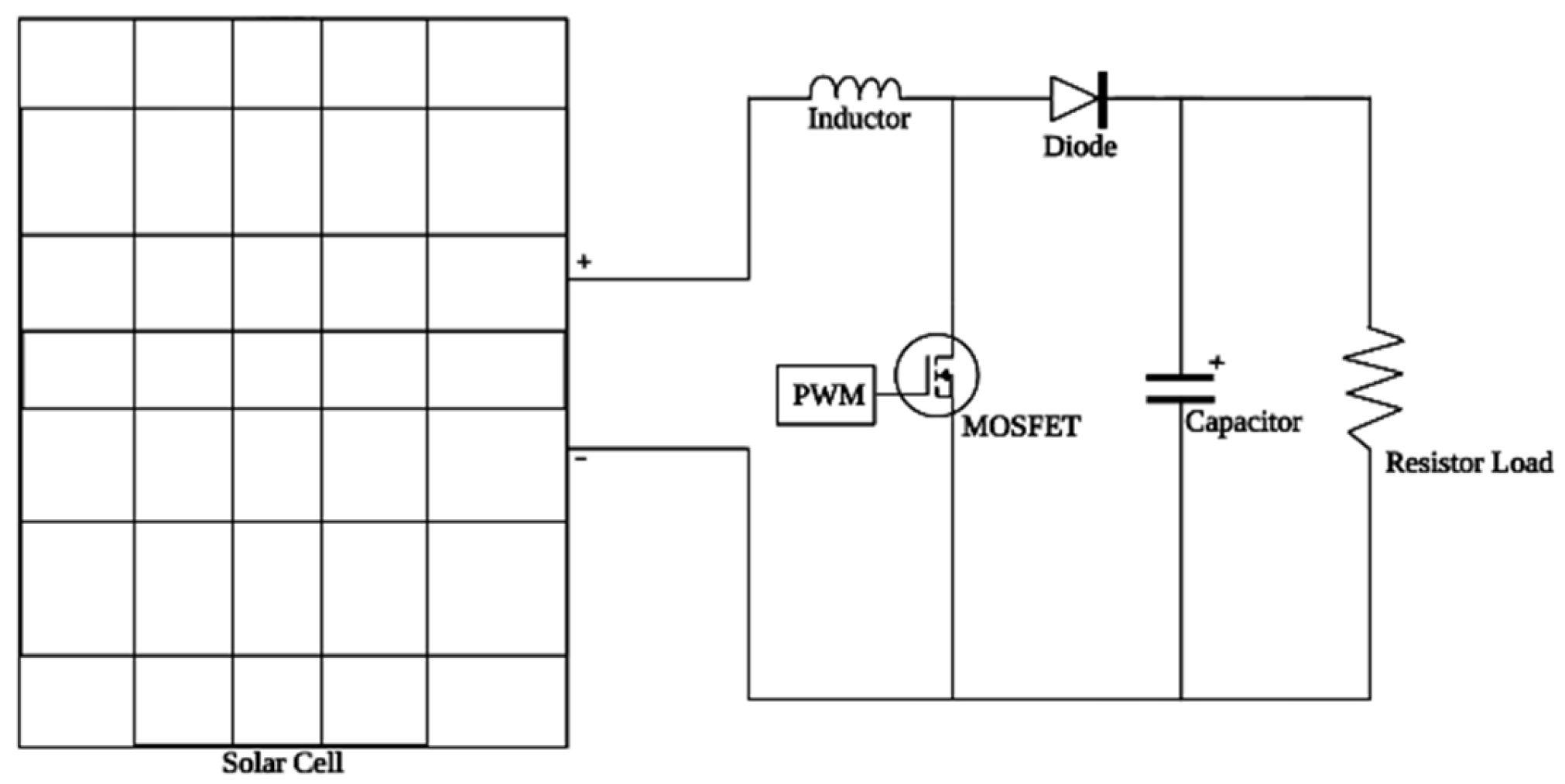

2.2. Boost Converter

2.2.1. Solar Panels

2.2.2. Switch

2.2.3. Diode

2.2.4. Inductor

2.2.5. Capacitor

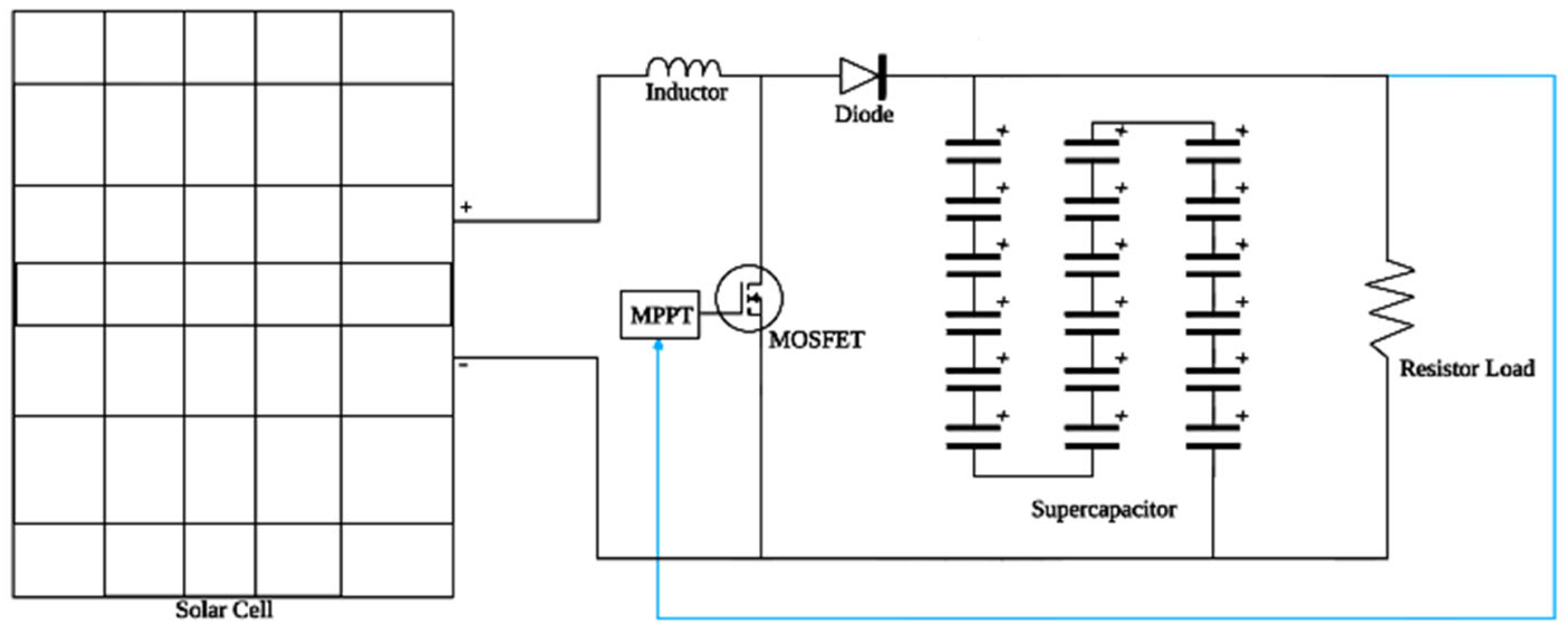

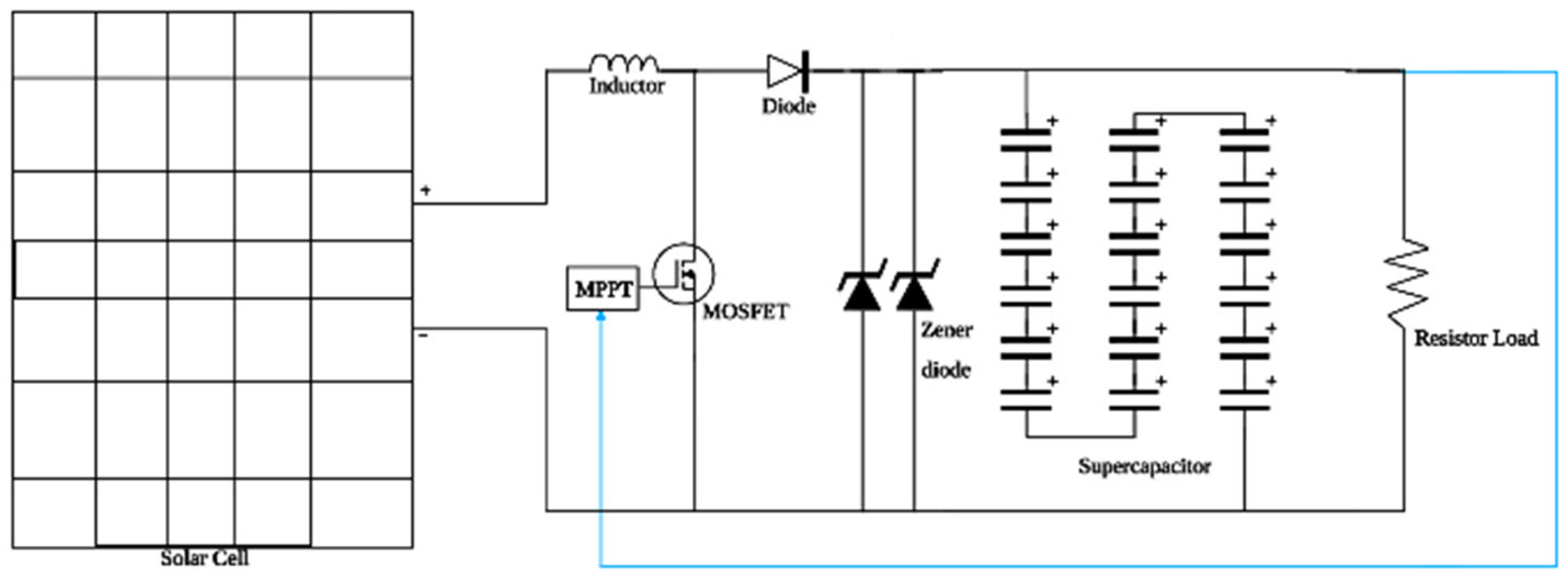

2.2.6. Supercapacitor

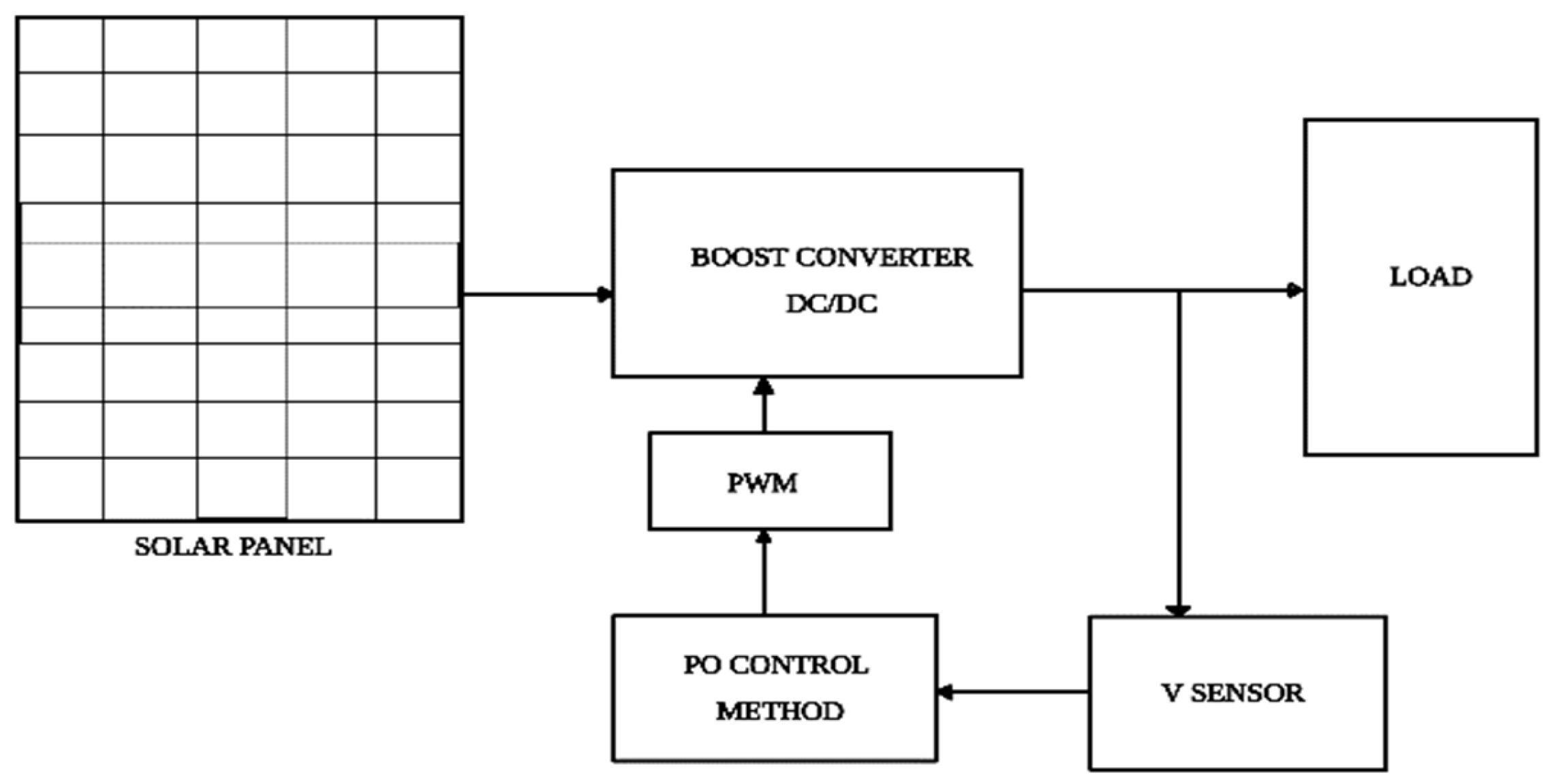

3. System Design

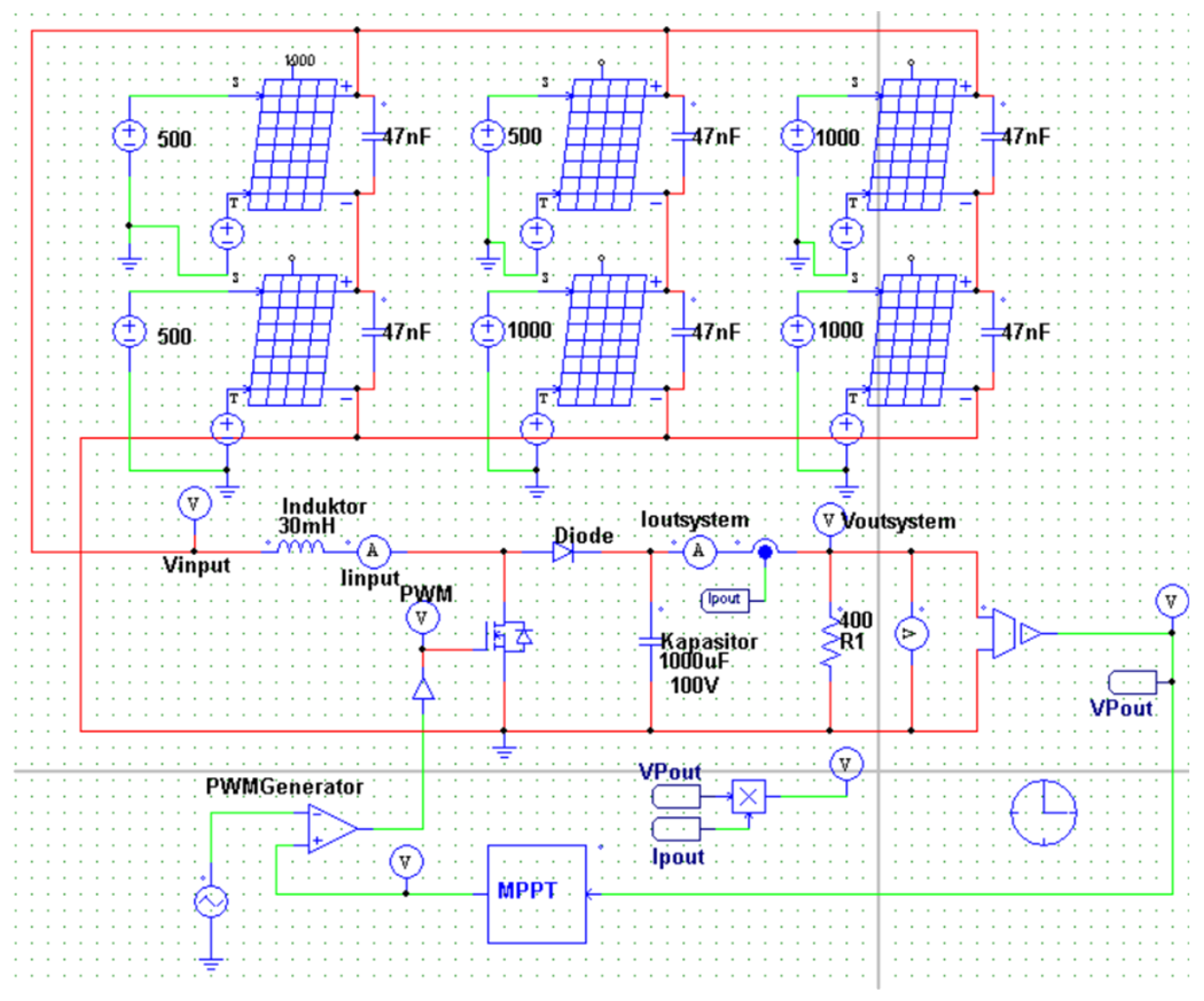

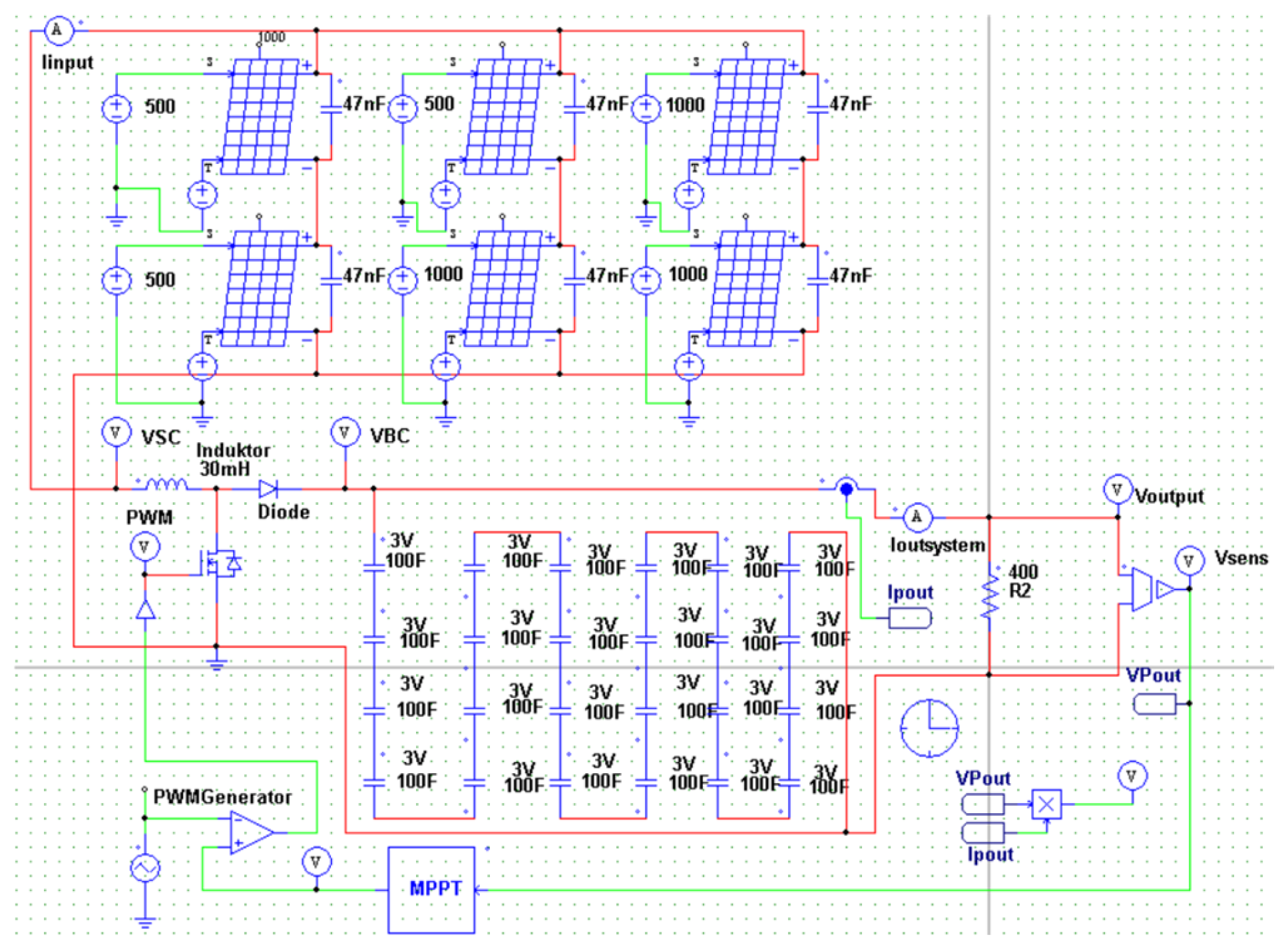

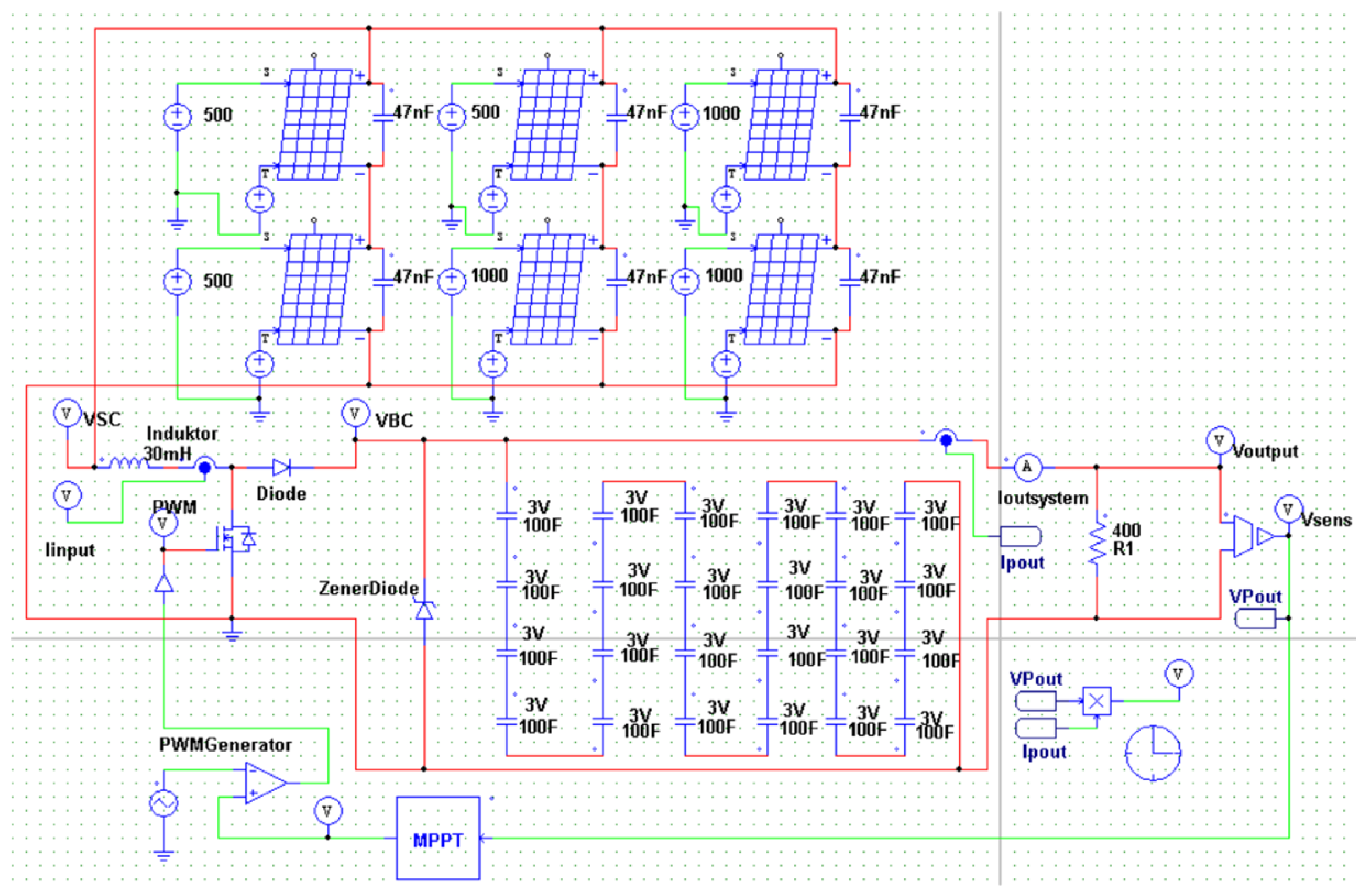

Simulation Design

4. Result and Analysis

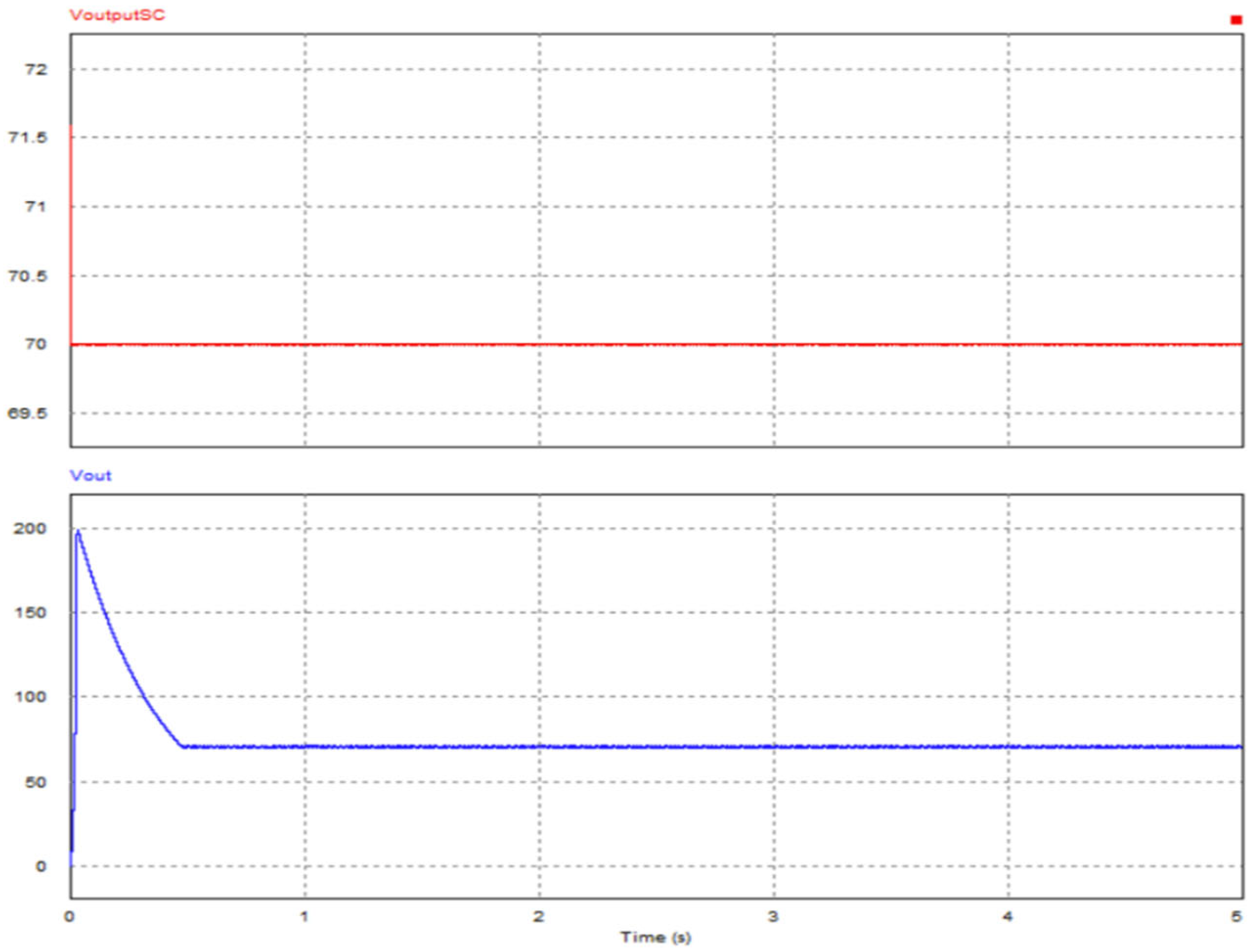

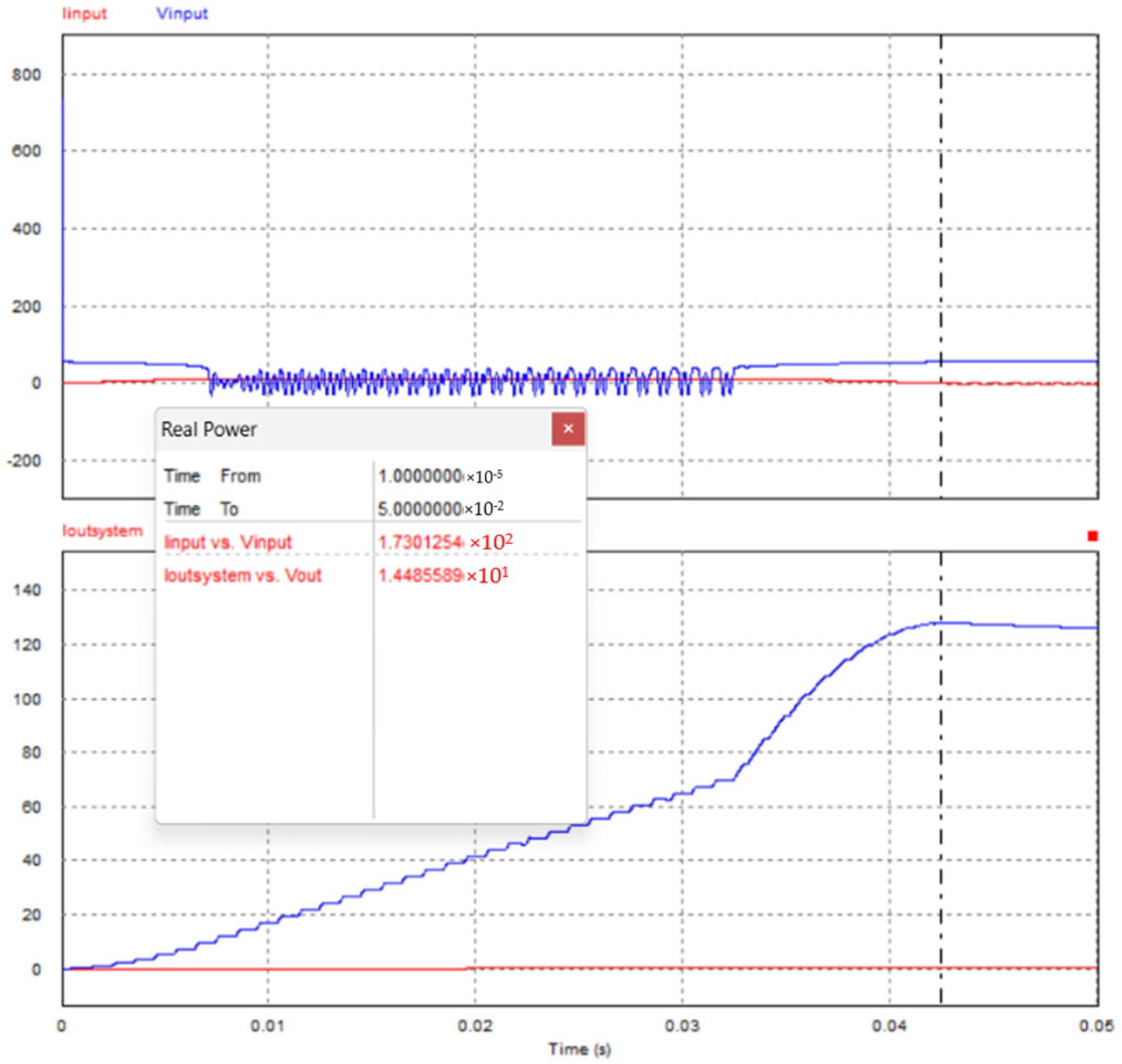

4.1. Simulation Result

4.2. Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soedibyo; Amri, B.; Ashari, M. The Comparative Study of Buck_Boost, Cuk, Sepic and Zeta Converters for Maximum Power Point Tracking Photovoltaic Using P&O Method. In Proceedings of the 2015 2nd International Conference on Information Technology, Computer, and Electrical Engineering (ICITACEE), Semarang, Indonesia, 16–18 October 2015; pp. 327–332. [Google Scholar]

- Agrawal, A.; Gupta, R. Optimized sensor charge controller for bus voltage stabilization in hybrid battery-supercapacitor fed islanded microgrid system. J. Energy Storage 2023, 59, 106482. [Google Scholar] [CrossRef]

- Alam, M.A.; Minai, A.F.; Bakhsh, F.I. Isolated Bidirectional DC-DC Converter: A Topological Review. e-Prime-Adv. Electr. Eng. Electron. Energy 2024, 8, 100594. [Google Scholar] [CrossRef]

- Anshory, I.; Jamaaluddin, J.; Wisaksono, A.; Sulistiyowati, I.; Rintyarna, B.S.; Fudholi, A.; Fudholi, A.; Rahman, Y.A.; Sopian, K. Optimization DC-DC boost converter of BLDC motor drive by solar panel using PID and firefly algorithm. Results Eng. 2024, 21, 101727. [Google Scholar] [CrossRef]

- Mousa, H.H.H.; Youssef, A.R.; Mohamed, E.E.M. State of the art perturb and observe MPPT algorithms based wind energy conversion systems: A technology review. Int. J. Electr. Power Energy Syst. 2021, 126, 106598. [Google Scholar] [CrossRef]

- Assyidiq, M.A.; Winardi, B.; Andromeda, T. Perancangan Boost Converter Menggunakan Voltage Feedback Pada Panel Surya. Transient 2017, 6, 404. [Google Scholar] [CrossRef]

- Benyahia, N.; Denoun, H.; Badji, A.; Zaouia, M.; Rekioua, T.; Benamrouche, N.; Rekioua, D. MPPT controller for an interleaved boost dc-dc converter used in fuel cell electric vehicles. Int. J. Hydrogen Energy 2014, 39, 15196–15205. [Google Scholar] [CrossRef]

- Powade, R.; Bhateshvar, Y. Design of semi-actively controlled battery-supercapacitor hybrid energy storage system. Mater. Today Proc. 2023, 72, 1503–1509. [Google Scholar] [CrossRef]

- Li, Q.; Huangfu, Y.; Xu, L.; Wei, J.; Ma, R.; Zhao, D.; Gao, F. An Improved Floating Interleaved Boost Converter with the Zero-Ripple Input Current for Fuel Cell Applications. IEEE Trans. Energy Convers. 2019, 34, 2168–2179. [Google Scholar] [CrossRef]

- Chincholkar, S.H.; Jiang, W.; Chan, C.Y. A Modified Hysteresis-Modulation-Based Sliding Mode Control for Improved Performance in Hybrid DC-DC Boost Converter. IEEE Trans. Circuits Syst. II Express Briefs 2018, 65, 1683–1687. [Google Scholar] [CrossRef]

- Dandil, B.; Acikgoz, H.; Coteli, R. An effective MPPT control based on machine learning method for proton exchange membrane fuel cell systems. Int. J. Hydrogen Energy 2024, 75, 344–353. [Google Scholar] [CrossRef]

- González, A.; López-Erauskin, R.; Gyselinck, J. Analysis, modeling, control and operation of an interleaved three-port boost converter for DMPPT systems including PV and storage at module level. Heliyon 2019, 5, e01402. [Google Scholar] [CrossRef] [PubMed]

- Lencwe, M.J.; Olwal, T.O.; Chowdhury, S.D.; Sibanyoni, M. Nonsolitary two-way DC-to-DC converters for hybrid battery and supercapacitor energy storage systems: A comprehensive survey. Energy Rep. 2024, 11, 2737–2767. [Google Scholar] [CrossRef]

- Jamadar, N.M.; Jadhav, H.T. Effectiveness of supercapacitor during braking operation of electric vehicle. Mater. Today Proc. 2022, 56, 314–319. [Google Scholar] [CrossRef]

- Javed, U.; Veerachary, M. Battery-integrated ZVT boost converter based stand-alone PV system. Int. J. Electr. Power Energy Syst. 2024, 155, 109633. [Google Scholar] [CrossRef]

- Junaid, K.M.; Sukhi, Y.; Anjum, N.; Jeyashree, Y.; Ahamed, A.F.; Debbarma, S.; Chaudhary, G.; Priyadarshini, S.; Shylashree, N.; Garg, S.; et al. PV-based DC-DC buck-boost converter for LED driver. e-Prime-Adv. Electr. Eng. Electron. Energy 2023, 5, 100271. [Google Scholar] [CrossRef]

- Mian, S.H.; Nazir, M.S.; Ahmad, I.; Khan, S.A. Optimized nonlinear controller for fuel cell, supercapacitor, battery, hybrid photoelectrochemical and photovoltaic cells based hybrid electric vehicles. Energy 2023, 283, 129121. [Google Scholar] [CrossRef]

| Specification | Value |

|---|---|

| Number of solar cell | 36 |

| Maximum power (Pmax) | 1000 Wp |

| Maximum voltage (Vmax) | 18 V |

| Open circuit voltage (Voc) | 21.8 V |

| Short circuit current (Isc) | 6.05 A |

| Maximum current (Imax) | 5.56 A |

| Specification | Value |

|---|---|

| Input voltage | 20–72 Vdc |

| Trigger frequency | 1 Khz |

| Duty cycle | 10–90% |

| Load resistance | 400 Ω |

| Inductor | 30 mH |

| Capacitor | 300 µF |

| Output voltage | 70 V |

| Output power | 1000 W |

| Methods | Efficiency |

|---|---|

| Boost converter before supercapacitor integration | 8.36% |

| Boost converter after supercapacitor integration | 50.29% |

| Boost converter after supercapacitor integration and with Zener diode as voltage limiter | 16.09% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidayatulah, I.; Darjat; Setiawan, I. Development of a High-Stability Boost Converter Using Supercapacitor Integration Using the Perturb and Observe Control Method for Photovoltaic Application. Eng. Proc. 2025, 84, 68. https://doi.org/10.3390/engproc2025084068

Hidayatulah I, Darjat, Setiawan I. Development of a High-Stability Boost Converter Using Supercapacitor Integration Using the Perturb and Observe Control Method for Photovoltaic Application. Engineering Proceedings. 2025; 84(1):68. https://doi.org/10.3390/engproc2025084068

Chicago/Turabian StyleHidayatulah, Imam, Darjat, and Iwan Setiawan. 2025. "Development of a High-Stability Boost Converter Using Supercapacitor Integration Using the Perturb and Observe Control Method for Photovoltaic Application" Engineering Proceedings 84, no. 1: 68. https://doi.org/10.3390/engproc2025084068

APA StyleHidayatulah, I., Darjat, & Setiawan, I. (2025). Development of a High-Stability Boost Converter Using Supercapacitor Integration Using the Perturb and Observe Control Method for Photovoltaic Application. Engineering Proceedings, 84(1), 68. https://doi.org/10.3390/engproc2025084068