Re-Engineering and Initial Computational Study on Non-Organic Waste and Hazardous Waste Incinerators †

Abstract

1. Introduction

2. Literature Study

3. Methodology

3.1. Tools and Materials

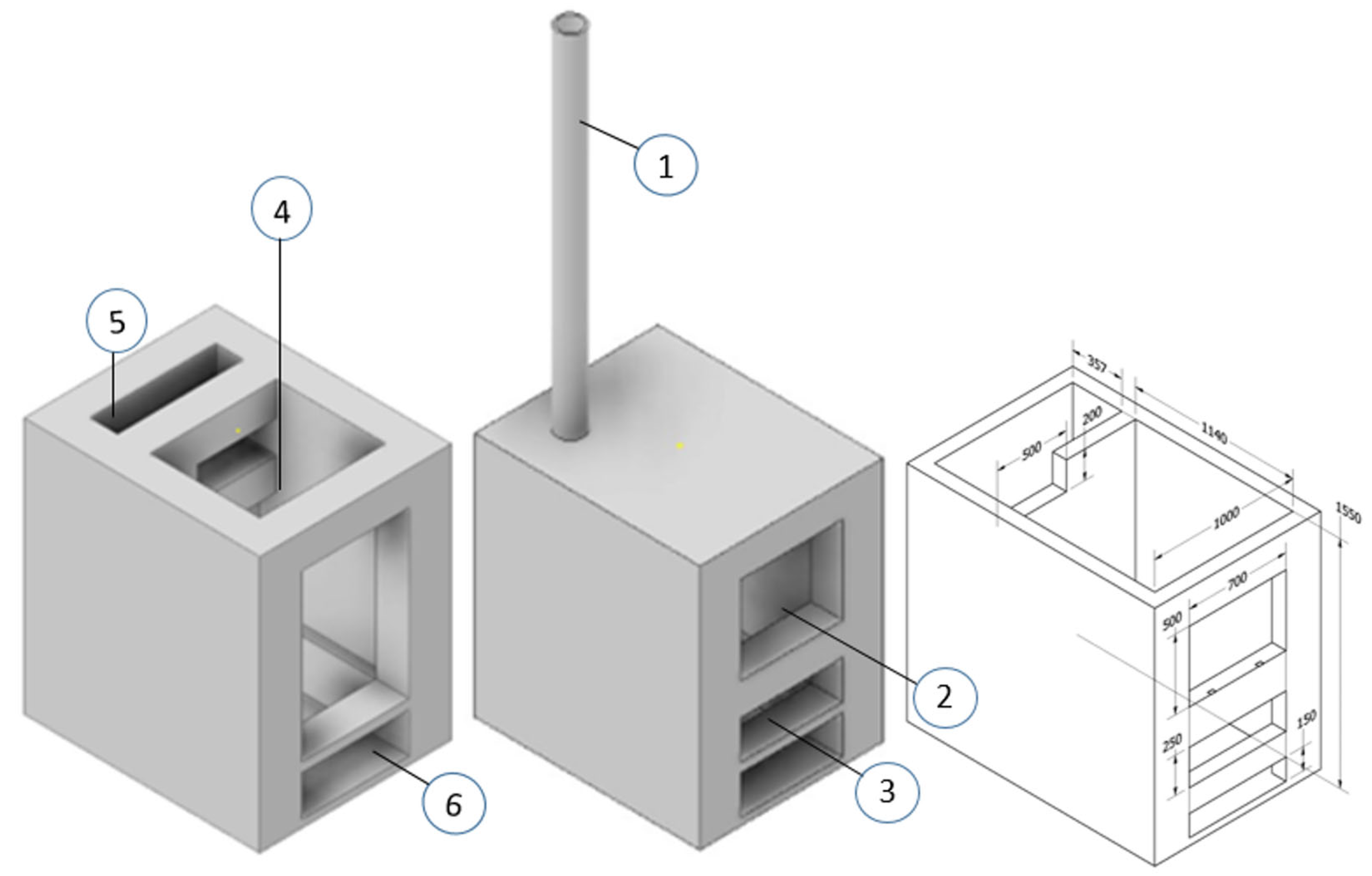

3.2. Experiment Procedure

- Dimension: 1815 mm × 1200 mm × 1550 mm.

- Main frame: Elbow still (50 mm × 50 mm × 5 mm.

- Main frame burner: 1400 mm × 1200 × 1600 mm.

- Flue circulation room: 357 mm × 1200 mm × 1600 mm.

- Ash room: 1400 mm × 1200 × 150 mm.

- Chamber wall: Refractory stone.

- Casing of incinerator: Iron plate 3 mm thick.

- Chimney: 300 mm height 25 mm.

- System: Without burner.

- Thermocouple: Type K (0~+1000 °C).

4. Result and Discussion

4.1. Result of Construction Process

4.2. Experimental Data and Discussion

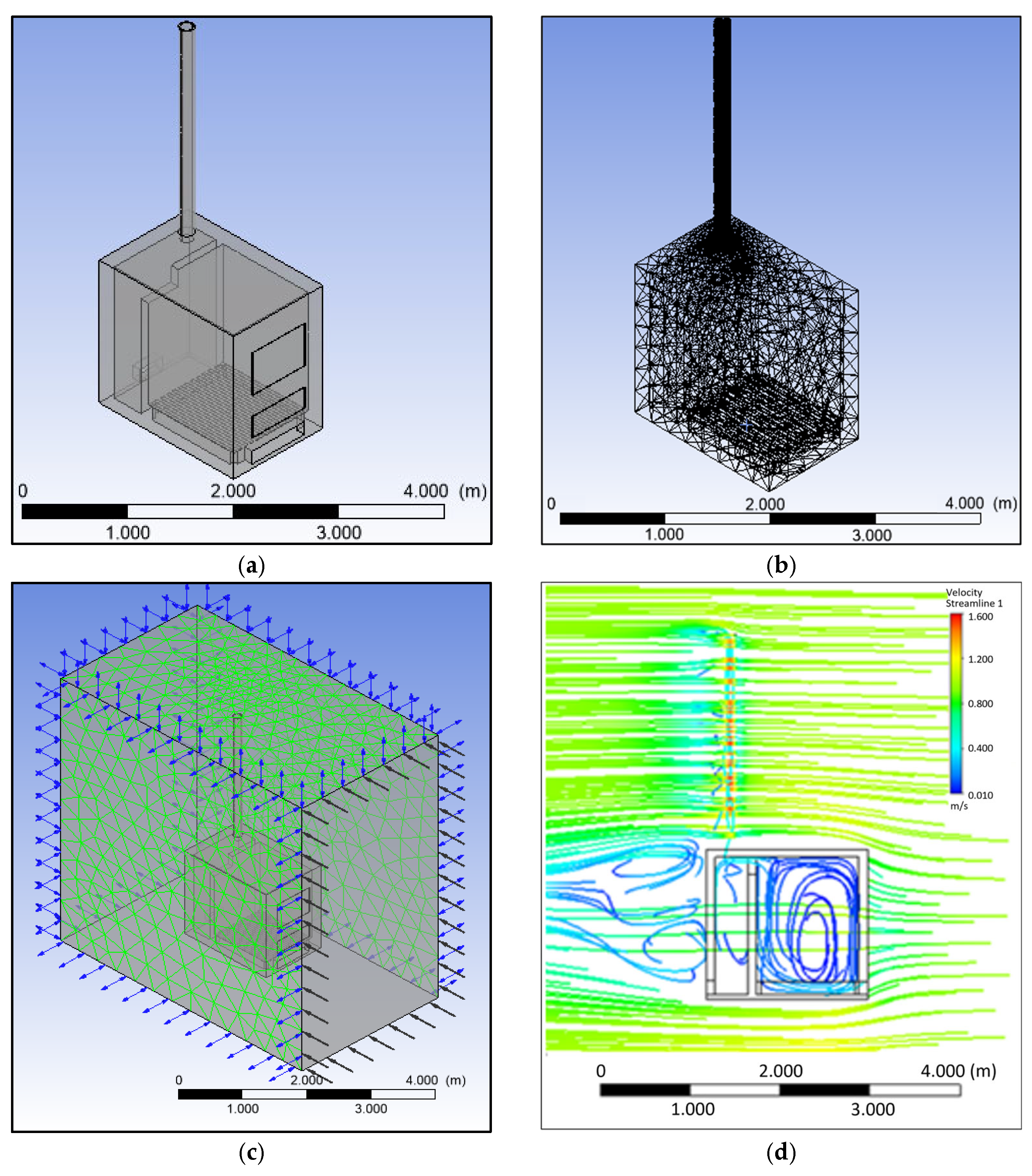

4.3. Initial of Computational Study

5. Summary

- The incinerator manufacturing process begins with making the frame and then continues with making the chamber space by arranging refractory stones. The insulator is installed on the chamber wall with glass wool and then covered with a casing made of a 2.8 mm thick iron plate. The previously made chimney and incinerator door are subsequently installed. The finishing is conducted by filling and painting to prevent corrosion. The last step is to install the thermocouple temperature measuring components and thermo control.

- This incinerator is capable of processing solid medical waste into ash except for needles, plastic, and glass with a temperature reaching 998 °C with a capacity of 5 kg of waste and 8 kg of fuel infusion bottles, syringes, glass bottles, baby diapers, and expired medicines.

- The results of the incinerator recycle residue-produced paving blocks fulfill the specifications of the SNI, and as the initial simulation changed, further study that possibly involves mass and heat transfer is recommended.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anshory, L. Chemistry Lesson Guide; Ganesa Exact Bandung: Bandung, Indonesia, 1988. [Google Scholar]

- Azwar, A. Introduction to Environmental Health Science; Yayasan Mutiara: Jakarta, Indonesia, 1990. [Google Scholar]

- Decree of the Minister of Health of the Republic of Indonesia No. 1204/MENKES/SK/X/2004. 2024. Available online: https://peraturan.bpk.go.id/Details/111721/permenkes-no-7-tahun-2019 (accessed on 10 February 2025).

- Kavanagh, A. Incineration: A Burning Issue or a Load of Rubbish?’ Examining Public Attitudes to Municipal Solid Waste Incineration. Ph.D. Thesis, Environmental Resource Management Department of Geography, National University of Ireland, Maynooth, Ireland, 2006. [Google Scholar]

- Yan, F.; Zhu, F. Preliminary Study of PM2.5 Formation During Municipal Solid Waste Incineration. Procedia Environ. Sci. 2016, 31, 475–481. [Google Scholar] [CrossRef]

- de B. Parsons, H. Disposal of Municipal Refuse, and Rubbish Incineration. Trans. Am. Soc. Civ. Eng. 2024, 57, 2. [Google Scholar] [CrossRef]

- Saragih, J.L.; Herumurti, W. Evaluation of the Incinerator Function in Destroying B3 Waste at the Dr. Ramelan TNI Hospital, Surabaya. J. Tek. Pomits 2013, 2, 138–143. [Google Scholar]

- Ratman, C.R.; Syafrudin. Implementation of B3 Waste Processing at PT. Toyota Motor Manufacturing Indonesia. J. Presipitasi 2007, 7, 62–70. [Google Scholar]

- Girsang, V.E.; Herumurti, W. Evaluation of B3 Solid Waste Management from Incineration at Dr Soetomo Hospital, Surabaya. J. Tek. Pomits 2013, 2, 46–50. [Google Scholar]

- Nugroho, A.; Handayani, D.S. Solid Waste Management at Kudus District Regional Hospital. J. Presipitasi 2008, 5, 99–103. [Google Scholar]

- Hidayah, E.N. Operational Capability Test of Incinerator to Reduce Clinical Waste at Haji General Hospital Surabaya. J. Rekayasa Perenc. 2007, 4, 9–18. [Google Scholar]

- Pramita, N. Evaluation of Waste Management at Gatot Soebroto Army Central Hospital. J. Presipitasi 2007, 2, 51–55. [Google Scholar]

- Decision Of The Head Of The Environmental Impact Control Agency of the Republic of Indonesia, Kep-03/Bapedal/09/1995. 1995. Available online: https://sib3pop.menlhk.go.id/uploads/Regulasi/BAPEDAL031995.pdf (accessed on 10 February 2025).

- Margono; Rahardjo, H.P. Design and Construction of Radioactive Waste Incinerator Prototype. Nucl. Devices J. 2011, 5, 1–8. [Google Scholar]

- Lolo, D.P. Analysis of Incinerator Use in Waste Processing in Merauke City. Sci. J. 2014, 3, 200211. [Google Scholar]

- Safrizal. Distributed Generator of Municipal Waste Power Plant (PLTSa) Incinerator Type Alternative Electricity Solution for Medan City. J. Tek. 2014, 121–128. [Google Scholar]

- Sarjito, S.; Riyadi, T.W.B. A Parametric Study of Wind Catcher Model in a Typical System of Evaporative Cooling Tower Using CFD. Appl. Mech. Mater. 2014, 660, 659–663. [Google Scholar] [CrossRef]

- Sarjito. An Investigation of the Scope for Improvement of the Performance of Multi-Stage Downdraught Evaporative Coolers Using CFD. Appl. Mech. Mater. 2013, 315, 835–840. [Google Scholar] [CrossRef]

- Sarjito; Aklis, N.; Hartanto, T. An optimization of flap and slat angle airfoil NACA 2410 using CFD. AIP Conf. Proc. 2017, 1831, 020038. [Google Scholar]

| Temperature | Air Velocity | |||

|---|---|---|---|---|

| Combustion Chamber | Recirculation Zone | Chimney | Surrounding Air | Incoming Air |

| 506.1 °C | 302.2 °C | 145.0 °C | 2.64 km/h | 1.66 km/h |

| 563.0 °C | 319.0 °C | 260.0 °C | ||

| 628.1 °C | 339.5 °C | 287.6 °C | ||

| 637.1 °C | 458.8 °C | 309.4 °C | ||

| 705.3 °C | 598.4 °C | 358.4 °C | ||

| In Percentage | In kg/Sample | Sample Making Needs | |||||||

|---|---|---|---|---|---|---|---|---|---|

| No | Cement | Sand | Residue | Cement | Sand | Residue | Cement | Sand | Residue |

| 1 | 30% | 60% | 10% | 0.9 | 1.8 | 0.3 | 0.5 | 0.9 | 0.2 |

| 2 | 30% | 40% | 30% | 0.9 | 1.2 | 0.9 | 0.5 | 0.6 | 0.5 |

| 3 | 30% | 20% | 50% | 0.9 | 0.6 | 1.5 | 0.5 | 0.3 | 0.8 |

| 1.4 | 1.8 | 1.4 | |||||||

| In total | |||||||||

| No | JMD | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|---|

| 1 | 0% | 2.175 | 2.275 | 2.240 |

| 2 | 10% | 250.000 | 255.100 | 244.900 |

| 3 | 30% | 237.000 | 234.900 | 235.100 |

| 4 | 50% | 210.800 | 225.200 | 225.500 |

| No | JMD | Sample 1 | Sample 2 | Sample 3 |

|---|---|---|---|---|

| 1 | 0% | 2.120 | 2.220 | 2.180 |

| 2 | 10% | 231.600 | 233.700 | 224.200 |

| 3 | 30% | 212.400 | 205.500 | 210.000 |

| 4 | 50% | 177.700 | 194.800 | 174.700 |

| No | JMD | Sample 1 | Sample 2 | Sample 3 | Average | |

|---|---|---|---|---|---|---|

| 1 | 0% | 2.48% | 2.220 | 2.180 | 2.61% | OK |

| 2 | 5% | 7.94% | 233.700 | 224.200 | 8.78% | OK |

| 3 | 10% | 11.63% | 205.500 | 210.000 | 12.63% | OK |

| 4 | 15% | 18.63% | 194.800 | 174.700 | 17.88% | OK |

| No | JMD | Sample (MPa) | Average (MPa) | Result | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 1 | 0% | 36.4 | 25.7 | 21.4 | 27.83 | Succeed |

| 2 | 10% | 1.8 | 2.7 | 4.10 | 2.90 | Fail |

| 3 | 30% | 14.8 | 7.5 | 9.7 | 10.64 | Succeed |

| 4 | 50% | 36.4 | 7.4 | 9.6 | 10.68 | Succeed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oktavani, M.I.; Sarjito; Yulianto, A. Re-Engineering and Initial Computational Study on Non-Organic Waste and Hazardous Waste Incinerators. Eng. Proc. 2025, 84, 54. https://doi.org/10.3390/engproc2025084054

Oktavani MI, Sarjito, Yulianto A. Re-Engineering and Initial Computational Study on Non-Organic Waste and Hazardous Waste Incinerators. Engineering Proceedings. 2025; 84(1):54. https://doi.org/10.3390/engproc2025084054

Chicago/Turabian StyleOktavani, Muhammad Iqsal, Sarjito, and Agus Yulianto. 2025. "Re-Engineering and Initial Computational Study on Non-Organic Waste and Hazardous Waste Incinerators" Engineering Proceedings 84, no. 1: 54. https://doi.org/10.3390/engproc2025084054

APA StyleOktavani, M. I., Sarjito, & Yulianto, A. (2025). Re-Engineering and Initial Computational Study on Non-Organic Waste and Hazardous Waste Incinerators. Engineering Proceedings, 84(1), 54. https://doi.org/10.3390/engproc2025084054