Abstract

In recent years, Construction 4.0 has integrated Industry 4.0 technologies into the construction sector, with robots playing a key role in improving productivity and safety. However, few studies address strategies for implementing robots in specific contexts, particularly in developing countries. This study proposes a roadmap for robot implementation in the Peruvian construction sector. It identifies barriers and benefits and then validates the roadmap through expert consultation. The roadmap consists of four phases: aligning the company, evaluating technology, planning implementation, and executing while assessing practices. This provides valuable guidance for construction companies adopting robotic technology.

1. Introduction

In Peru, labor productivity in construction projects is alarmingly low, with only 28% of activities considered productive [1]. This situation, together with the decrease in quality, labor shortage and lack of safety, has generated the need to adopt innovative tools in the sector [2]. The implementation of automation and robotics technologies is presented as a viable solution to improve productivity, safety and quality [3]. However, there are several barriers to their implementation, which vary by country and type of industry [4]. Although studies on these barriers have been conducted in international companies, most have focused on developed countries [4] and have not addressed the context of developing countries such as Peru. Faulty implementation of robots can lead to negative results [5], as many organizations lack a clear implementation model [6]. Therefore, it is essential to develop a roadmap to guide this implementation. This research focuses on guiding the use of robots in multifamily projects, analyzing the obstacles from the perspective of Peruvian experts and seeking to reduce the gap between theory and practice in the adoption of robotics in the construction sector.

2. Literature Review

During the review of international literature, models for overcoming barriers to the implementation of robots in construction projects and models for implementing robots in construction projects were identified. A summary describing the main models identified in Table 1 is shown below.

Table 1.

Models for overcoming barriers and implementing robots in construction projects.

Based on the above, it is noted that research has conducted literature reviews and barrier analysis for the implementation of robots with the objective of providing general recommendations for their implementation in the construction industry. However, there is still no defined model for the implementation of robots in the construction industry, much less for any specific item. That is, there are only brief guidelines without details that do not guarantee the success of the implementation of this technology. Therefore, this research seeks to develop a roadmap for the implementation of robots in the execution of construction projects.

3. Methodology

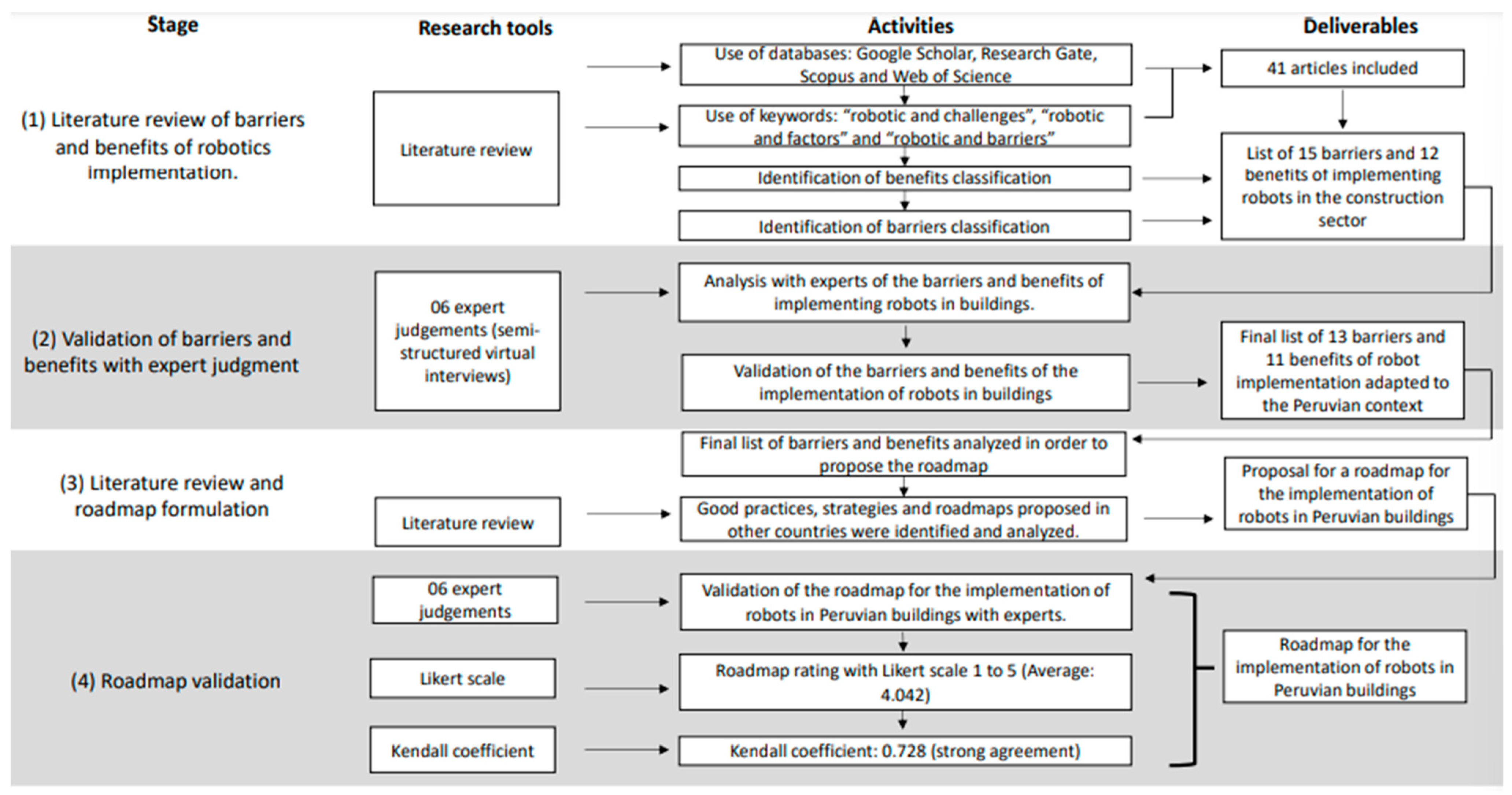

The present research took into consideration the logical process of the Horseshoe research framework [9]. Figure 1 below details the stages of the proposed methodology and Table 2 shows the professionals selected for the expert judgment process:

Figure 1.

Research methodology.

Table 2.

Professionals selected as experts for validation of the roadmap.

4. Results

4.1. Barriers and Benefits to the Implementation of Robots

Through the literature review of 41 scientific articles and the subsequent validation of the list of barriers with six professional experts, a list of 13 barriers and 11 benefits was obtained, as shown in Table 3 and Table 4 respectively.

Table 3.

List of identified barriers.

Table 4.

List of identified benefits.

4.2. Proposed Roadmap for Implementation in Buildings

- (a)

- Roadmap approach

The roadmap is designed for medium and large construction companies capable of leading robot implementation, particularly those with a culture of innovation that encourages technological exploration. Companies using this roadmap should have strong policies for measuring and controlling construction processes to identify areas for improvement through technology. The roadmap frames robot implementation as a project aligned with the company’s strategy, ensuring it contributes to overall business success. Additionally, an innovation management system is needed to support the implementation project

- (b)

- Adaptation of the roadmap

The roadmap will be tailored to each company’s specific needs, considering internal processes, innovation management systems, and organizational goals. Aligning the project with the company’s innovation management system is crucial for effective integration, ensuring opportunities are identified, feasibility is assessed, and results are evaluated. This system should support continuous adaptation throughout the implementation of robots.

- (c)

- Structure of the roadmap: “4PIF”

The roadmap is structured in 4 principles, 4 drivers and 4 phases (4P + 4I + 4F = 4PIF), hereafter called “4PIF”, which are outlined below:

- -

- Principles: They will allow addressing implementation barriers by providing guidelines on the behavior of team members and stakeholders.

- -

- Drivers: Will maximize the positive impacts of the benefits associated with the implementation of robots and will be used to define the success metrics of the implementation project.

- -

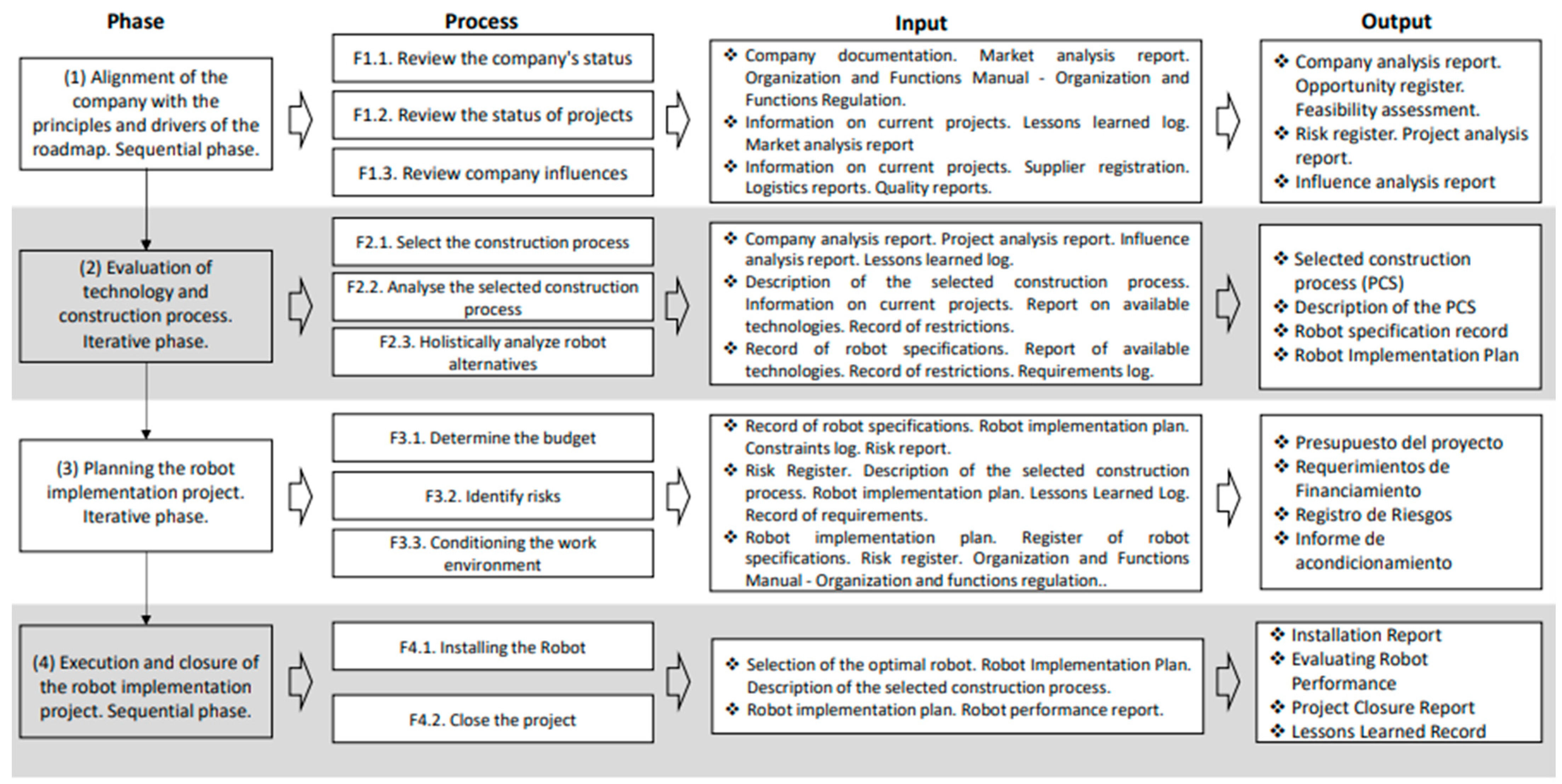

- Phases: They will organize the activities of the implementation project, ensuring the effective completion of the tasks necessary to achieve the stated objectives and ensure consistency with the principles and drivers. A total of 11 processes have been defined, which are necessary to guide the implementation of the robot and are distributed in the 4 phases. Each process presents a brief description, as well as its inputs, tools and outputs.

Phase 1: Review of the company’s organizational context

This phase seeks to understand in detail the operational and strategic environment of the company in relation to the implementation of robotic technology. During this phase, three key processes are carried out.

Phase 2: Comprehensive evaluation of robotic solutions

This phase focuses on the selection and comprehensive analysis of the best robotic solution to integrate into the selected construction process. This phase comprises the identification of the construction process, the detailed analysis of its activities and requirements, as well as the thorough evaluation of all robot alternatives available in the market. The objective is to make informed and strategic decisions that ensure the successful implementation of the robot on site, thus optimizing the efficiency and quality of the operations.

Phase 3: Cost management and site preparation

This phase focuses on two key aspects for the implementation of the robot in the construction project. On the one hand, the necessary budget is calculated, and potential risks are identified to establish mitigation measures. On the other hand, the work site is prepared for the installation of the robot, ensuring a safe and conducive environment. These processes ensure efficient management of financial resources and adequate site preparation, laying the groundwork for a successful robot implementation.

Phase 4: Integration of the robot and project closure

This phase culminates the robot implementation project in the multifamily project. Through the first process, the correct installation and operation of the robot on site is ensured. The second process evaluates whether the objectives have been achieved and compiles the results, facilitating an effective transition of the project to completion and providing feedback for future improvements.

- (d)

- Roadmap processes, as Figure 2.

Figure 2. Roadmap processes: inputs, tools and outputs.

Figure 2. Roadmap processes: inputs, tools and outputs.

4.3. Roadmap Validation

To validate the roadmap proposal, civil engineering professionals with over ten years of experience and postgraduate degrees were selected as experts. They reviewed the preliminary roadmap, provided feedback, and evaluated each phase on a Likert scale from 1 (Strongly Disagree) to 5 (Strongly Agree). The average score from the six experts was 4.042, indicating an 80.83% acceptance rate. Using SPSS V. 24, Kendall’s coefficient (W) was calculated, yielding a value of 0.728, indicating strong agreement among experts, as values above 0.65 are deemed reliable for solid research [16].

5. Discussion

It is important to note that this roadmap originates from the need to optimize results in multifamily projects, which led to the incorporation of robotic technologies. Iterations were incorporated in phases 2 and 3 to allow for continuous improvement of the results, as well as moments of reflection, feedback, and learning. The proposal focuses on the construction process, ensuring that the implementation of robots brings benefits to the company in terms of productivity, quality, and safety.

Among the main strengths of the roadmap for the implementation of robots in multi-family projects is its clear structure organized in 4 principles, 4 drivers and 4 phases, which provides a clear and well-defined framework to guide the process that facilitates an orderly and consistent implementation. In addition, the roadmap focuses on companies that can lead the adoption of robotic technologies, especially medium and large companies, which increases the probability of success and makes its implementation more realistic and achievable. The experts also mentioned the usefulness of the organizational context review phase. This phase allows a detailed understanding of the operational and strategic environment of the company before proceeding with the implementation of robotic technology, which ensures that the technological solution is aligned with the specific needs and capabilities of the organization. The evaluation of the results obtained during the implementation project was also highly valued, as the roadmap includes mechanisms to measure the impact of robotics on the construction processes that are critical for informed decision-making and to ensure that the implementation meets the stated objectives. Also, a significant strength is the detailed definition and delineation of the construction process, which experts high-lighted as a key factor for the success of the implementation as specific planning ensures that the selected robot perfectly fits the project requirements. The structure for evaluating automation alternatives is another positive point, as it is not limited to the implementation of a single robot but considers several options. A crucial aspect men-tioned by the experts is the incorporation of feedback loops which indicates that the roadmap is designed to be dynamic and adaptable, this allows adjustments based on the experience gained and the results obtained throughout the process, promoting constant improvement and adaptation of the strategy based on the results obtained. This flexibility is essential to continuously optimize the implementation and ensure its success.

Overall, the roadmap received a positive rating in the evaluation carried out by the experts, obtaining an average of 4.042 on the Likert scale, representing an acceptance level of 80.83%. This high level of validation indicates that the roadmap is seen as an appropriate and valuable tool to guide the process of adopting robots in construction.

Among the main limitations identified, the roadmap presents certain constraints. The initial costs associated with the acquisition and installation of robots can be high, which represents an obstacle for companies with limited financial resources, so it is aimed primarily at medium and large companies. The introduction of new technologies, such as robotics, can encounter resistance from employees and managers who are accustomed to traditional methods, making it necessary for companies to promote an environment of innovation and openness towards these new technologies. In addition, the incorporation of robots into existing construction processes may face both technical and organizational challenges, which will require significant adjustments in work methods. On the other hand, the proposal focuses on a business perspective, without considering government initiatives. In this sense, the application of the roadmap is designed for medium and large companies, which will allow them to considerably increase the probability of success in the implementation of robots.

6. Conclusions

The results of this research indicate that the proposed roadmap developed from the identification of barriers and benefits is adequate to guide the implementation of robots in multifamily projects in Lima. The literature review identified the most significant barriers and benefits. The validation of the barriers and benefits with experts and the survey of professionals confirmed their relevance for this research. Statistical analysis of the surveys allowed grouping and defining the categories of barriers and benefits that were key to the development of the proposed roadmap. The roadmap developed includes specific strategies to address these barriers and maximize benefits. The evaluation of the roadmap with the participation of experts validated the feasibility of the proposal presented demonstrating that the roadmap is a suitable tool for the implementation of robots in multifamily projects. This paper contributes to the field of construction automation by proposing a roadmap adapted to the Peruvian context, addressing the barriers and benefits of implementing robots in multifamily construction. The ‘4PIF’ framework represents a novelty by offering a holistic and adaptable approach that aligns each phase of the process with the company’s strategic objectives, maximizing the positive impact of the technology. This roadmap not only has a theoretical contribution to the literature on the adoption of robots in developing countries, but also offers a replicable model to guide other companies in the implementation of robots in multifamily projects, using strategies to overcome obstacles and take advantage of the benefits of robotics.

Author Contributions

Conceptualization, A.G. and A.A.E.-R.; methodology, all authors; validation, all authors; formal analysis, all authors; investigation, all authors; A.G.; writing—original draft preparation, A.G. and A.A.E.-R.; writing— review and editing, all authors; visualization, all authors; supervision, A.A.E.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Huamán, C. Proposal of a Roadmap to Improve the Implementation of Lean Construction in Companies of the Construction Sector. Undergraduate Thesis, Universidad Nacional de Ingeniería, Rimac, Peru, 2021. [Google Scholar]

- Mahbub, N.R. Readiness of a Developing Nation in Implementing Automation and Robotics Technologies in Construction: A Case Study of Malaysia. J. Civ. Eng. Archit./Tu Mu Gong Cheng Yu Jian Zhu 2012, 6, 858. [Google Scholar] [CrossRef][Green Version]

- Mahbub, R. Framework on the Barriers to the Implementation of Automation and Robotics in the Construction industry. Int. J. Innov. Manag. 2015, 3, 21–36. [Google Scholar]

- Oke, A.E.; Kineber, A.F.; Albukhari, I.; Dada, A.J. Modeling the robotics implementation barriers for construction projects in developing countries. Int. J. Build. Pathol. Adapt. 2021, 42, 386–409. [Google Scholar] [CrossRef]

- Law, K.K.; Chang, S.; Siu, M.F. Factors influencing adoption of construction robotics in Hong Kong’s industry: A multistakeholder perspective. J. Manag. Eng. 2022, 38, 04021096. [Google Scholar] [CrossRef]

- Hatoum, M.B.; Nassereddine, H. Developing a Framework for the Implementation of Robotics in Construction Enterprises. In Proceedings of the EG-ICE 2020 Workshop on Intelligent Computing in Engineering, Online, 1–4 July 2020; Volume 27, pp. 453–462. [Google Scholar]

- Jäkel, J.; Rahnama, S.; Klemt-Albert, K. Construction Robotics Excellence Model: A framework to overcome existing barriers for the implementation of robotics in the construction industry. In Proceedings of the ISARC, Bogota, Colombia, 13–15 July 2022. [Google Scholar] [CrossRef]

- Pan, M.; Pan, W. Understanding the Determinants of Construction Robot Adoption: Perspective of Building Con-tractors. J. Constr. Eng. Manag. 2020, 146, 4020040. [Google Scholar] [CrossRef]

- Kunz, J.; Fischer, M. CIFE Research Questions and Methods; Stanford Digital Repository: Stanford, CA, USA, 2007. [Google Scholar]

- Davila Delgado, J.M.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Fleming, E.; Callaghan, N.; Craig, N. Robotics and automation as a solution to bridging the UK housing gap. In Proceedings of the 35th Conference of the Association of Researchers in Construction Management, 35th ed.; Gorse, C., Neilson, C.J., Eds.; ARCOM: Herndon, VA, USA, 2019; pp. 557–566. [Google Scholar]

- Bademosi, F.; Issa, R. Factors Influencing Adoption and Integration of Construction Robotics and Automation Technology in the US. J. Constr. Eng. Manag. 2021, 147, 04021075. [Google Scholar] [CrossRef]

- Afsari, K.; Halder, S.; Ensafi, M.; Devito, S.; Serdakowski, J. Fundamentals and Prospects of Four-Legged Robot Application in Construction Progress Monitoring. EPiC Ser. Built Environ. 2021, 2, 274–283. [Google Scholar]

- Aghimien, D.; Ikuabe, M.; Aghimien, L.; Aigbavboa, C.; Ngcobo, N.; Yankah, J. PLS-SEM assessment of the im-pediments of robotics and automation deployment for effective construction health and safety. J. Facil. Manag. 2022, 22, 458–478. [Google Scholar] [CrossRef]

- Boya, B.A.; Akinradewo, O.; Aigbavboa, C.; Ramabodu, M. Implementation of automation and robotics: Benefits to the construction industry. In Proceedings of the Construction Business and Project Management Conference, Cape Town, South Africa, 22–24 June 2022; Available online: https://www.researchgate.net/publication/363196463_Implementation_of_automation_and_robotics_Benefits_to_the_construction_industry (accessed on 17 January 2024).

- Valencia, D.; Lillo, R.E.; Romo, J. A Kendall correlation coefficient between functional data. Adv. Data Anal. Classif. 2019, 13, 1083–1103. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).