Development and Prototyping of Oxygen Analyzer †

Abstract

1. Introduction

2. Methodology

2.1. Data Acquisition

2.2. Components and Tools

2.3. Block and Flow Diagram

Working Principle

2.4. Design

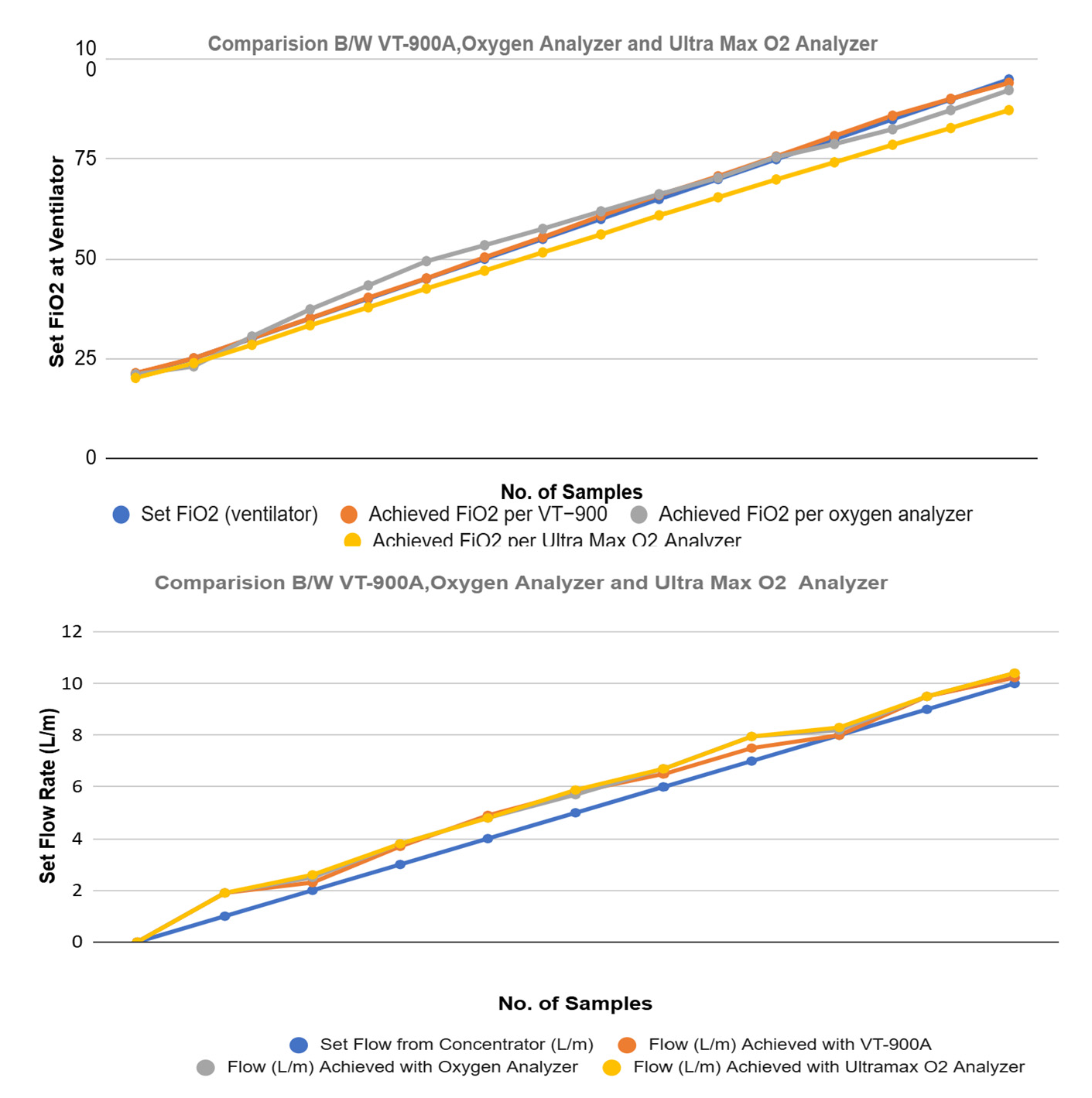

3. Result and Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kshetry, R.L.; Gupta, A.; Chattopadhyaya, S.; Srivastava, M.; Sharma, S.; Singh, J.; Gupta, A.D.; Rajkumar, S. Design and Analysis of a Low-Cost Electronically Controlled Mobile Ventilator, Incorporating Mechanized AMBU Bag, for Patients during COVID-19 Pandemic. J. Healthc. Eng. 2022, 2022, 6436818. [Google Scholar] [CrossRef] [PubMed]

- Soares, G.F.; Almeida, O.M.; Menezes, J.W.; Kozlov, S.S.; Rodrigues, J.J. Air–oxygen blenders for mechanical ventilators: A literature review. Sensors 2022, 22, 2182. [Google Scholar] [CrossRef] [PubMed]

- Willett, M. Oxygen sensing for industrial safety—Evolution and new approaches. Sensors 2014, 14, 6084–6103. [Google Scholar] [CrossRef] [PubMed]

- Hedenstierna, G.; Tokics, L.; Scaramuzzo, G.; Rothen, H.U.; Edmark, L.; Öhrvik, J. Oxygenation impairment during anesthesia: Influence of age and body weight. Anesthesiology 2019, 131, 46–57. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, S.; Mihara, Y.; Hikasa, Y.; Okahara, S.; Ishihara, T.; Shintani, A.; Morimatsu, H. Current ventilator and oxygen management during general anesthesia: A multicenter, cross-sectional observational study. Anesthesiology 2018, 129, 67–76. [Google Scholar] [CrossRef] [PubMed]

- Shuk, P.; Jantz, R. Oxygen gas sensing technologies: A comprehensive review. In Proceedings of the 2015 9th International Conference on Sensing Technology (ICST), Auckland, New Zealand, 8–10 December 2015. [Google Scholar]

- Fluke Biomedical. Available online: https://www.flukebiomedical.com (accessed on 29 January 2024).

| Set FiO2 (Ventilator) | Achieved FiO2 Per VT−900 | Error (VT−900) | Achieved FiO2 Per Oxygen Analyzer | Error (Oxygen Analyzer) | Achieved FiO2 per Ultra Max O2 Analyzer | Error (Ultra Max O2 Analyzer) |

|---|---|---|---|---|---|---|

| 21 | 21.29 | 0.29 | 21 | 0 | 20.1 | 0.9 |

| 25 | 25.04 | 0.04 | 23 | 2 | 23.8 | 1.2 |

| 30 | 30.075 | 0.075 | 30.5 | 0.5 | 28.4 | 1.6 |

| 35 | 35.06 | 0.06 | 37.3 | 2.3 | 33.3 | 1.7 |

| 40 | 40.23 | 0.23 | 43.3 | 3.3 | 37.81 | 2.19 |

| 45 | 45.075 | 0.075 | 49.4 | 4.4 | 42.5 | 2.5 |

| 50 | 50.35 | 0.35 | 53.4 | 3.4 | 47 | 3 |

| 55 | 55.375 | 0.375 | 57.5 | 2.5 | 51.6 | 3.4 |

| 60 | 60.77 | 0.77 | 61.9 | 1.9 | 56.1 | 3.9 |

| 65 | 66.025 | 1.025 | 66.2 | 1.2 | 60.9 | 4.1 |

| 70 | 70.69 | 0.69 | 70.3 | 0.3 | 65.42 | 4.58 |

| 75 | 75.67 | 0.67 | 75.5 | 0.5 | 69.9 | 5.1 |

| 80 | 80.8 | 0.8 | 78.8 | 1.2 | 74.2 | 5.8 |

| 85 | 85.9 | 0.9 | 82.5 | 2.5 | 78.61 | 6.39 |

| 90 | 90.14 | 0.14 | 87.3 | 2.7 | 82.8 | 7.2 |

| 95 | 94.14 | 0.86 | 92.32 | 2.68 | 87.3 | 7.7 |

| 100 | 99.45 | 0.55 | 95.6 | 4.4 | 91.45 | 8.55 |

| Error | 0.46470588 | 2.10470588 | 4.10647058 |

| Set Flow from Concentrator (L/m) | Flow (L/m) Achieved with VT-900A | Error with VT−900A | Flow (L/m) Achieved with Oxygen Analyzer | Error with Oxygen Analyzer | Flow (L/m) Achieved with Ultramax O2 Analyzer | Error with Ultra Max O2 Analyzer |

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 1 | 1.9 | 0.9 | 1.9 | 0.9 | 1.9 | 0.9 |

| 2 | 2.3 | 0.3 | 2.5 | 0.5 | 2.6 | 0.6 |

| 3 | 3.7 | 0.7 | 3.8 | 0.8 | 3.8 | 0.8 |

| 4 | 4.9 | 0.9 | 4.8 | 0.8 | 4.8 | 0.8 |

| 5 | 5.8 | 0.8 | 5.7 | 0.7 | 5.88 | 0.88 |

| 6 | 6.5 | 0.5 | 6.7 | 0.7 | 6.7 | 0.7 |

| 7 | 7.5 | 0.5 | 7.95 | 0.95 | 7.95 | 0.95 |

| 8 | 8 | 0 | 8.2 | 0.2 | 8.3 | 0.3 |

| 9 | 9.5 | 0.5 | 9.5 | 0.5 | 9.5 | 0.5 |

| 10 | 10.23 | 0.23 | 10.4 | 0.4 | 10.4 | 0.4 |

| Error | 0.4845454 | 0.586363 | 0.62090909 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pokharel, B.; Thiyam, D.B.; Devkota, S.; Sah, D.K. Development and Prototyping of Oxygen Analyzer. Eng. Proc. 2024, 82, 82. https://doi.org/10.3390/ecsa-11-20447

Pokharel B, Thiyam DB, Devkota S, Sah DK. Development and Prototyping of Oxygen Analyzer. Engineering Proceedings. 2024; 82(1):82. https://doi.org/10.3390/ecsa-11-20447

Chicago/Turabian StylePokharel, Bidheyak, Deepa Beeta Thiyam, Sachin Devkota, and Devanand Kumar Sah. 2024. "Development and Prototyping of Oxygen Analyzer" Engineering Proceedings 82, no. 1: 82. https://doi.org/10.3390/ecsa-11-20447

APA StylePokharel, B., Thiyam, D. B., Devkota, S., & Sah, D. K. (2024). Development and Prototyping of Oxygen Analyzer. Engineering Proceedings, 82(1), 82. https://doi.org/10.3390/ecsa-11-20447