Textile Pressure Sensors: Innovations and Intellectual Property Landscape †

Abstract

1. Introduction

2. Materials and Methods

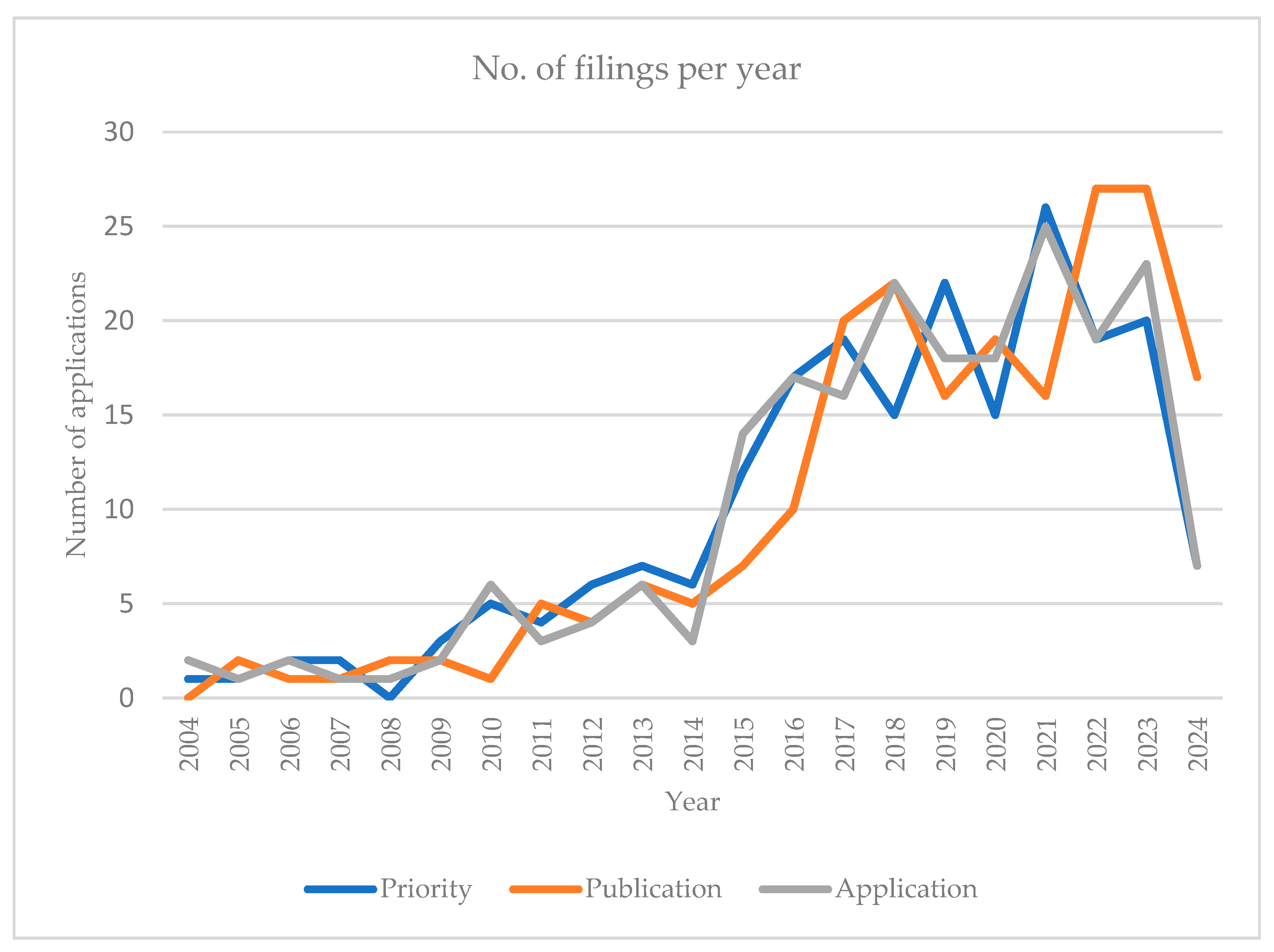

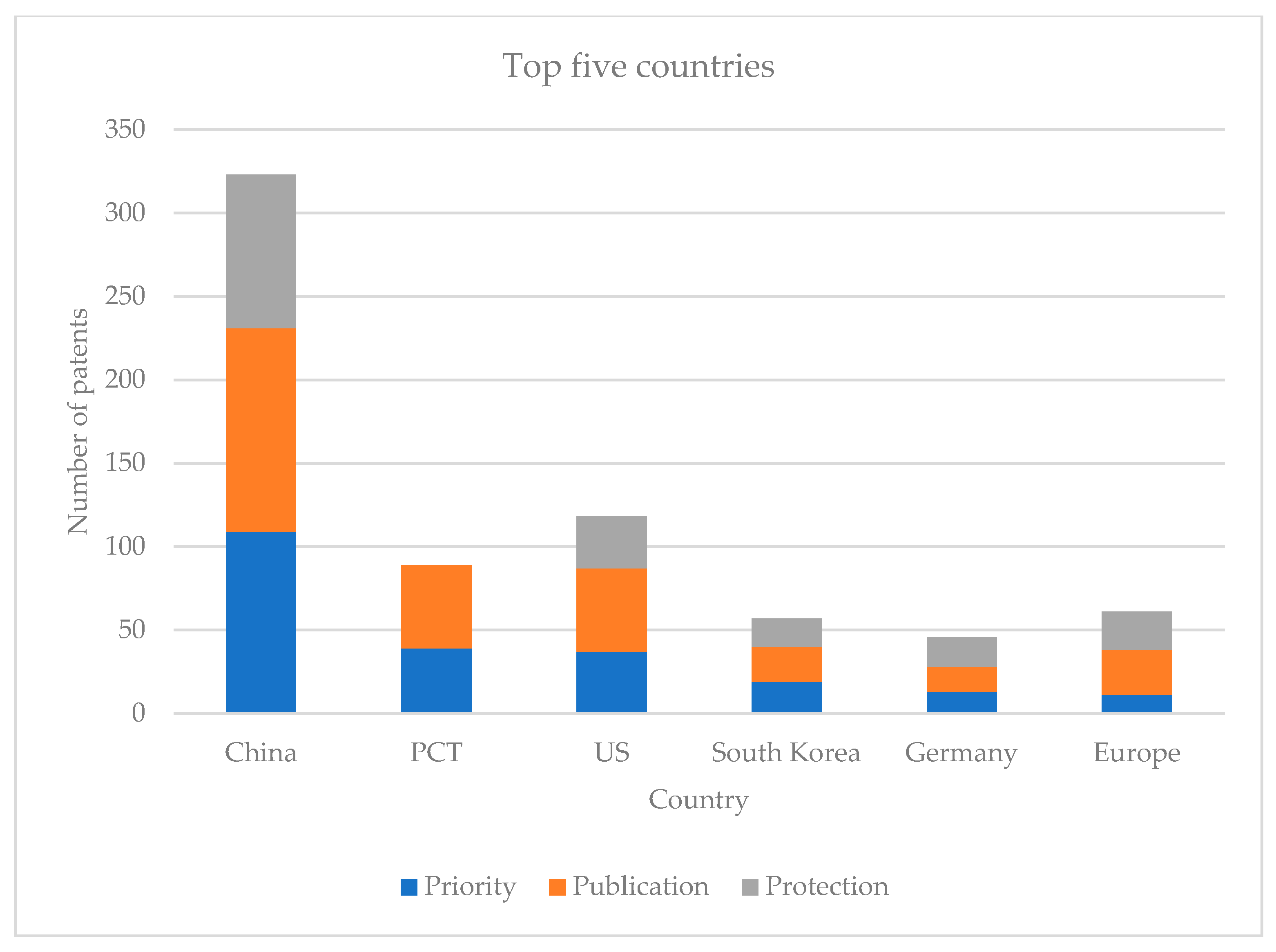

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- Patentscope

- Google Patents

- Espacenet

- Orbit Intelligence

| Search Step | Results | Query |

| 1 | 21 | (TEXTILE PRESSURE SENSOR)/TI/AB/CLMS/ICLM |

| 2 | 52 | (FABRIC PRESSURE SENSOR)/TI/AB/CLMS/ICLM |

| 3 | 0 | (KNITTED PRESSURE SENSOR)/TI/AB/CLMS/ICLM |

| 4 | 87 | (TEXTILE PRESSURE SENSOR)/TI/AB/CLMS/DESC/ODES/ICLM |

| 5 | 130 | (FABRIC PRESSURE SENSOR)/TI/AB/CLMS/DESC/ODES/ICLM |

| 6 | 206 | 1 OR 2 OR 4 OR 5 |

| 7 | 59 | (TEXTILE PRESSURE SENSOR)/KEYW/TI/AB |

| 8 | 134 | (FABRIC PRESSURE SENSOR)/KEYW/TI/AB |

| 9 | 1 | (KNITTED PRESSURE SENSOR)/KEYW/TI/AB |

| 10 | 288 | 6 OR 7 OR 8 OR 9 |

References

- Dell’Eva, F.; Oliveri, V.; Sironi, R.; Perego, P.; Andreoni, G.; Ferrante, S.; Pedrocchi, A.; Ambrosini, E. Ink-based textile electrodes for wearable functional electrical stimulation: A proof-of-concept study to evaluate comfort and efficacy. Artif. Organs 2024, 48, 1138–1149. [Google Scholar] [CrossRef]

- Perego, P.; Moltani, A.; Andreoni, G. Sport monitoring with smart wearable system. Stud. Health Technol. Inform. 2012, 177, 224–228. [Google Scholar] [CrossRef]

- Cardinale, M.; Varley, M.C. Wearable Training-Monitoring Technology: Applications, Challenges, and Opportunities. Int. J. Sports Physiol. Perform. 2017, 12 (Suppl. 2), S255–S262. [Google Scholar] [CrossRef]

- De Fazio, R.; Mastronardi, V.M.; De Vittorio, M.; Visconti, P. Wearable Sensors and Smart Devices to Monitor Rehabilitation Parameters and Sports Performance: An Overview. Sensors 2023, 23, 1856. [Google Scholar] [CrossRef] [PubMed]

- Donisi, L.; Cesarelli, G.; Pisani, N.; Ponsiglione, A.M.; Ricciardi, C.; Capodaglio, E. Wearable Sensors and Artificial Intelligence for Physical Ergonomics: A Systematic Review of Literature. Diagnostics 2022, 12, 3048. [Google Scholar] [CrossRef] [PubMed]

- Maceira-Elvira, P.; Popa, T.; Schmid, A.-C.; Hummel, F.C. Wearable technology in stroke rehabilitation: Towards improved diagnosis and treatment of upper-limb motor impairment. J. NeuroEngineering Rehabil. 2019, 16, 142. [Google Scholar] [CrossRef]

- Prasanth, H.; Caban, M.; Keller, U.; Courtine, G.; Ijspeert, A.; Vallery, H.; von Zitzewitz, J. Wearable Sensor-Based Real-Time Gait Detection: A Systematic Review. Sensors 2021, 21, 2727. [Google Scholar] [CrossRef]

- Chen, Y.; Yan, X.; Zhu, Y.; Cui, M.; Kong, L.; Kuang, M.; Zhang, X.; Wang, R. A carbon nanotube-based textile pressure sensor with high-temperature resistance. RSC Adv. 2022, 12, 23091–23098. [Google Scholar] [CrossRef] [PubMed]

- Ho, J.-G.; Kim, Y.; Min, S.-D. Customized Textile Capacitive Insole Sensor for Center of Pressure Analysis. Sensors 2022, 22, 9390. [Google Scholar] [CrossRef]

- Su, M.; Li, P.; Liu, X.; Wei, D.; Yang, J. Textile-Based Flexible Capacitive Pressure Sensors: A Review. Nanomaterials 2022, 12, 1495. [Google Scholar] [CrossRef]

- Andreoni, G.; Standoli, C.E.; Perego, P. Defining Requirements and Related Methods for Designing Sensorized Garments. Sensors 2016, 16, 769. [Google Scholar] [CrossRef] [PubMed]

- Barbieri, M.; Andreoni, G. Carbon Allotrope-Based Textile Biosensors: A Patent Landscape Analysis. Eng. Proc. 2023, 58, 107. [Google Scholar] [CrossRef]

- Patentscope. Available online: https://patentscope.wipo.int/search/en/advancedSearch.jsf (accessed on 19 August 2024).

- Google Patents. Available online: https://patents.google.com/advanced (accessed on 19 August 2024).

- Espacenet. Available online: https://worldwide.espacenet.com (accessed on 19 August 2024).

- Orbit Intelligence. Available online: https://www.orbit.com (accessed on 19 August 2024).

- Chen, Z.; Zhang, Y. Manufacturing Method of Flexible Textile Pressure Sensor and Flexible Textile Pressure Sensor. Chinese Patent Application No. CN115790920A. Available online: https://worldwide.espacenet.com/patent/search/family/085433606/publication/CN115790920A?q=CN115790920A (accessed on 23 August 2024).

- Luo, S.; Xie, X.; Zhang, T.; Yang, X. Stretchable Array Flexible Fabric Pressure Sensor and Preparation Method and Application Thereof. Chinese Patent Application No. CN115752827A. Available online: https://worldwide.espacenet.com/patent/search/family/085369427/publication/CN115752827A?q=CN115752827 (accessed on 23 August 2024).

- Wen, W.; Peng, B.; Shi, B.; Xue, C.; Wu, J.; Zhang, M. Preparation Method of MXene Fabric Pressure Sensor and MXene Fabric Pressure Sensor. Chinese Patent Application No. CN118482842A. Available online: https://worldwide.espacenet.com/patent/search/family/092192963/publication/CN118482842A?q=CN118482842A (accessed on 23 August 2024).

- Li, T.; Zhang, Y.; Deng, J.; Jin, H. Flexible Fabric Pressure Sensor Based on Liquid Metal Material and Preparation Method Thereof. Chinese Patent Application No. CN117848556A. Available online: https://worldwide.espacenet.com/patent/search/family/090529905/publication/CN117848556A?q=pn%3DCN117848556A (accessed on 23 August 2024).

- Saenz Cogollo, J.F.; Bonfiglio, A.; Fraboni, B. Textile Pressure Sensor and Method for Fabricating the Same. International Patent Application No. PCT/EP2014/066519. Available online: https://worldwide.espacenet.com/patent/search/family/051260870/publication/WO2015014950A1?q=WO2015%2F014950 (accessed on 23 August 2024).

- Wang, F.; Wang, Y.; Rao, L.; Luo, S. Resistance Type Pressure Sensor and Wearable Equipment. Chinese Utility Model No. CN206504812U. Available online: https://worldwide.espacenet.com/patent/search/family/059833881/publication/CN206504812U?q=CN206504812U (accessed on 23 August 2024).

| Database | Number of Documents Retrieved by Database Searching | Number of Documents Remaining After Screening |

|---|---|---|

| Patentscope | 173 | 121 |

| Google Patents | 365 | 180 |

| Espacenet | 291 | 206 |

| Orbit Intelligence | 288 | 213 |

| Title of Patent/Application | Application No. | Priority Date | Forward Citations | Geographic Scope of Protection |

|---|---|---|---|---|

| Conductive pressure sensitive textile | WO200175778 | 2000 | 13 | 13 |

| Textile pressure sensor | GB2443208 | 2006 | 8 | 1 |

| Pressure sensor | WO2007059971 | 2005 | 6 | 4 |

| Textile pressure sensor | WO2013120624 | 2012 | 6 | 4 |

| Pressure sensor | WO9960357 | 1999 | 5 | 1 |

| Fabric-based pressure sensor arrays, including intersecting elongated conductive strips on opposite sides of a textile sheet | US11617537 | 2011 | 4 | 1 |

| Tactile pressure sensor | WO0026627A1 | 1998 | 4 | 1 |

| Textile capacitive pressure sensor | WO2005121729 | 2004 | 4 | 1 |

| Sensors, interfaces and sensor systems for data collection and integrated remote monitoring of conditions at or near body surfaces | US20150177080 | 2015 | 3 | 12 |

| Resistance-type pressure distribution fabric sensor | CN107144379 | 2017 | 2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbieri, M.; Andreoni, G. Textile Pressure Sensors: Innovations and Intellectual Property Landscape. Eng. Proc. 2024, 82, 37. https://doi.org/10.3390/ecsa-11-20512

Barbieri M, Andreoni G. Textile Pressure Sensors: Innovations and Intellectual Property Landscape. Engineering Proceedings. 2024; 82(1):37. https://doi.org/10.3390/ecsa-11-20512

Chicago/Turabian StyleBarbieri, Massimo, and Giuseppe Andreoni. 2024. "Textile Pressure Sensors: Innovations and Intellectual Property Landscape" Engineering Proceedings 82, no. 1: 37. https://doi.org/10.3390/ecsa-11-20512

APA StyleBarbieri, M., & Andreoni, G. (2024). Textile Pressure Sensors: Innovations and Intellectual Property Landscape. Engineering Proceedings, 82(1), 37. https://doi.org/10.3390/ecsa-11-20512