Abstract

Additive manufacturing technology can realize the rapid integrated manufacturing of complex shape models, and has become a new method for integrated design and manufacturing of complex components of high performance weapons and equipment. This article summarizes the current application status of additive manufacturing technology in various aspects of pilot control unit design, such as the layout design of the control stick switch for demand analysis, the evaluation of the control stick length and grip diameter size for selection tests, and the cost control of different test types for ground tests. Research was conducted on material costs, manufacturing time, model strength, and other aspects. Additive manufacturing technology can reduce the design and testing cycle of pilot control units, which is conducive for comparing the parameters and design effects of different models of units, and can lead to better detailed design from the perspective of human engineering in the scheme design stage. Meanwhile, the integrated design effectively reduces the weight of the system, with a preliminary estimated weight reduction effect of 19.7%. Finally, the potential risks of additive manufacturing technology in practical applications were analyzed, and further considerations and prospects were proposed for its application in the design of pilot control units in the future.

1. Introduction

The pilot control unit system is an important human-machine interface in the cockpit, which can convert the pilot’s control actions into corresponding electrical commands as inputs for manual maneuvering of the aircraft, while providing the pilot with a sense of control. The rapid development of the aviation industry has gradually increased the design requirements for pilot control devices, and there is an urgent need for new design processes and technologies to play a role in improving the quality of control design.

Additive Manufacturing, also known as 3D printing, is a manufacturing method that uses 3D model data and layer by layer stacking to create entities. Compared with traditional manufacturing, additive manufacturing has enormous social and economic benefits, as well as environmental and technological advantages. It can significantly shorten the product development cycle, and the characteristics of timely and on-demand production can be widely applied in intelligent manufacturing. Compared with subtractive manufacturing, additive manufacturing can produce functional components with complex internal structures, personalized customization, and optimized physical properties, while reducing material waste. Its application in the aviation field is not only increasing year by year, but also has great potential in reducing industrial energy consumption.

In recent years, with the deep accumulation of theoretical research on additive manufacturing technology, many domestic and foreign aerospace companies such as Boeing, Airbus, Lockheed Martin, Bombardier, Rolls Royce, BAE, Astrium, MBDA, AVIC, CASC, and CASIC have also conducted additive manufacturing experiments and applications on some important components [1].

BUAA has established long-term and close cooperation with multiple domestic aviation host manufacturers. In 2005, it used laser additive manufacturing to form titanium alloy small and secondary load-bearing metal structural components, and installed the formed parts on model aircraft, achieving installation and application. In 2007, key components such as large, integral, and complex titanium alloy main load-bearing aircraft reinforcement frames and main windshield integral window frames, as well as key components such as A100 ultra-high strength steel aircraft landing gear, were manufactured.

The team led by Professor Huang Weidong from NWPU used laser additive manufacturing to produce the central wing edge strip of C919, with a maximum manufacturing size of 2.83m and a maximum deformation of less than 1mm, filling the gap in China’s inability to produce large titanium alloy structural components.

AVIC Beijing Institute of Aeronautical Manufacturing Engineering has used laser additive manufacturing technology to repair the damaged part of a titanium alloy oblique flow integral impeller in an aircraft engine, and has successfully passed the test drive assessment with all indicators meeting the requirements.

With the increasing demand for restorative repair support in the overhaul of new advanced aircraft products, as well as the development of green maintenance concepts and changes in maintenance methods, aircraft maintenance engineering is deepening towards surface engineering and remanufacturing engineering [2]. Aircraft repair has shifted from replacement repair to repair/remanufacturing, expanding from general component repair to critical component repair, from structural component repair to functional component repair, and from surface layer repair to comprehensive repair of surface layer and substrate. The application scope of repair and remanufacturing continues to expand.

The pilot control unit system includes control stick, pedal, and arm support. This article mainly studies the application of additive manufacturing in the design of pilot control units, and explains the advantages, risks, and prospects of additive manufacturing technology from the aspects of scheme design, selection analysis, and experimental verification.

2. Application of Research

2.1. Overview

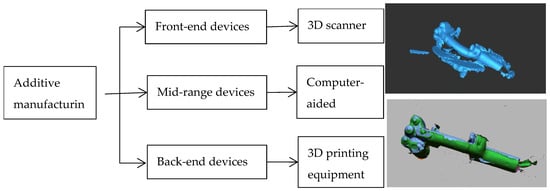

The well-equipped additive manufacturing equipment is divided into front-end devices, mid-range devices, and back-end devices [3], as shown in Figure 1. The front-end equipment is mainly a 3D scanner, which completes complex, fast, and high-precision modeling processes; Mid end devices are mainly computer-aided design systems responsible for reading, processing, and machining model data; The back-end equipment is mainly a 3D printer, responsible for completing the final manufacturing of the designed product, and is the basic device of the entire additive manufacturing equipment.

Figure 1.

Block diagram of additive manufacturing equipment.

2.2. Control Stick Design

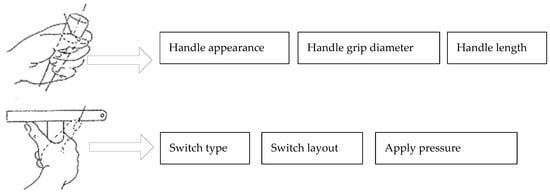

The control stick is a human-machine interface that provides pitch and roll control for pilots, including the control stick handle, housing, load mechanism, sensors, pull rods, and other components. In the planning phase, it is necessary to carry out the exterior design of the handle and the layout design of the switch. Compared to previous design processes, the introduction of additive manufacturing technology can advance the trial production of the handle, allowing for the printing of multiple versions of the actual product during the design phase. The design effect is clear at a glance, making it easier to conduct human–machine efficiency design analysis. At the same time, the handle manufactured by 3D printing is lightweight, making it easy to transport and carry. In the selection test stage, the pilot provides subjective opinions, and the designer implements the opinions into the design scheme, reducing the cycle and cost of later scheme iterations. The measurement items and design elements are shown in Figure 2.

Figure 2.

Measurement items and design elements.

In the design process of the control stick handle, the design of the handle switch is an important link, which is the main interface between the pilot control unit system and other systems, including the task system, weapon system, and the flight control system, etc. The design points of the handle switch include switch type, size, shape, height, pressing force, etc. In addition, electromagnetic compatibility, power supply compatibility, interface definition, and service life also need to be considered.

In the scheme stage, use additive manufacturing technology to trial produce switch samples, as shown in the figure, to determine and adjust the switch type, height, etc; By conducting selection experiments and combining subjective preference evaluations from pilots, the design of switch structures and the layout of handle switches were optimized to improve the system’s human-machine efficiency design, greatly reducing the design iteration cycle and production costs of switches.

2.3. Pedal Design

Pedals are human-machine interfaces that provide pilots with yaw and brake control, including pedals, main supports, load mechanisms, sensors, adjustment devices, and other components. Additive manufacturing technology is used for integrated design of main supports, which can effectively reduce equipment weight. The main support structure is complex and irregular in shape, as shown in Figure 3. To meet electromagnetic compatibility requirements, the main support should be made of metal material. Currently, weight reduction is achieved through methods such as digging grooves and reducing wall thickness, Further structural optimization can be carried out in combination with topology design in the later stage.

Figure 3.

Schematic diagram of the appearance of the main support.

2.4. Arm Support Design

The arm support provides support for the arm when the pilot uses the side stick, and has folding/unfolding, high/low adjustment, and front/rear adjustment functions. At present, in some ground tests, it is not required for the arm support to have folding and adjustment functions, and 3D-printed parts are used instead of real parts, greatly reducing manufacturing costs.

3. Advantages and Risks

3.1. Development Cycle

Unlike traditional design methods and processes that have long project cycles, low pilot involvement, low design and production efficiency, and high time investment, the most prominent feature of additive manufacturing technology is to involve pilots in the product design process [4]. On the basis of increasing pilot participation, designers can quickly and accurately obtain user perceptions and needs, greatly shortening the product iteration design and production cycle, saving time and cost, and improving production efficiency. At the same time, it not only meets the requirements of "fast and accurate", but also better meets the personalized and diversified needs of users.

3.2. Development Cost

For traditional manufacturing, the more complex the product shape, the higher the manufacturing cost. 3D printing will not consume more time or cost due to the increased complexity of product shapes. It undoubtedly has advantages in meeting the manufacturing needs of multiple parts with complex shapes that may arise due to changes in the plan in the early stage. At the same time, advancing the selection test effectively improves the evaluation efficiency, avoids the consumption of materials, molds, labor, etc. caused by repeated processing and manufacturing, and saves the high cost expenses caused by multiple mold opening schemes.

3.3. Material Use

With the integration of additive manufacturing and materials science, the raw materials for additive manufacturing will show a diversified trend [5]. Composite materials, functionally graded materials, memory alloys, nanomaterial and other materials can print more types of solid parts. At the same time, more high-performance new materials will also emerge.

In terms of titanium alloys, Ti-6Al-4V (TC4), as a typical α+β—type titanium alloy, is widely used in the manufacturing of aviation engine fans and compressor blades and vanes due to its high specific strength, specific stiffness, good toughness, and excellent chemical and mechanical properties [6].

Composite additive manufacturing technology has entered the industrial production and application stage from the research and development stage, with further requirements for production efficiency, batch production, and standardized production, thus placing stricter demands on comprehensive technology and supporting equipment. In terms of technology, there will be more detailed assessments on the controllability, testability, and stability of the process flow of composite additive manufacturing technology [7]. As for the application of aircraft models, it is necessary to comprehensively refine and improve the specific indicators and parameters of various materials and processes, establish supporting technical specifications and guidelines, and meet the quality system requirements of aviation industry production and application.

The selection of materials for pilot control units should consider factors such as weight, strength, surface accuracy, conductivity, etc. At present, the control stick handle is made of composite materials, while the pedal main support and arm support are made of metal materials.

3.4. Weight Control

At present, additive manufacturing technology is mainly used in the design of pilot control units for control stick handles, pedal main supports, and arm support test pieces. Through the introduction of additive manufacturing technology, the weight reduction benefit of pilot control units has reached 19.7%. The weight differences is detailed in Table 1.

Table 1.

Weight Differences.

3.5. Model Strength

In the printing process of handle switches, pedal main supports, and arm support, it is necessary to strengthen weak parts, reduce residual stress in processed parts, and enhance the mechanical properties of materials.

After trial production, the model with the same design scheme, after 3D printing, meets the strength design requirements for the handle main structure, pedal main support structure, arm support adjustment slide rail and main structure. The connection between the handle switch and the rod head is slightly weak, and the connection between the front and rear adjustment device of the arm support and the main body is weak, so it needs to be supplemented and strengthened.

4. Prospects and Prospects

4.1. Personalized Design

At present, the design of the controller mainly involves evaluating the designed solutions. In the later stage, the pilot can independently mold the model, and then conduct reverse scanning and additive manufacturing technology trial production to form a grip sample, in order to deepen the research on human-machine efficiency or form customized rod heads.

4.2. Optimization of Electronic Devices

The application of additive manufacturing technology can improve the overall integrity of electronic devices by directly producing components composed of multiple parts to increase the structural strength and electromagnetic compatibility performance of a component [8], used in sensors and other devices in pilot control unit systems.

4.3. Expand Design Space

Due to the limitations of traditional manufacturing methods, products can only be designed based on the feasibility of the process, such as the shape of the air mold holes on the turbine blades of aircraft engines being circular [9]. 3D printing can design the air holes of turbine blades into ellipses or any other shape according to cooling requirements. In the design of pilot control units, the hollow structure of the pedals and the anti-slip design of the driving rod grip diameter can both be expanded.

Author Contributions

Conceptualization, L.Y. and Z.Z.; methodology, Z.Z.; software, L.Y.; validation, L.Y., Z.Z. and J.Z.; formal analysis, J.Z.; investigation, L.Y.; resources, Z.Z.; data curation, L.Y. and Z.; writing—original draft preparation, L.Y.; writing—review and editing, L.Y., Z.Z. and J.Z.; visualization, L.Y.; supervision, J.Z.; project administration, Z.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhu, Z.; Zhao, K.; Guo, L.; Yang, Y. Application and development trend of additive manufacturing technology of large-scale metal component in aerospace manufacturing. Electr. Weld. Mach. 2020, 50, 1–14. [Google Scholar]

- Gong, Q.; An, X. Application of additive manufacturing repair technology in aircraft overhaul. Civ. Aircr. Des. Res. 2020, 3, 49–53. [Google Scholar]

- Dong, J.; Long, L.; Yin, G. Application of Additive Manufacturing Technology in Automotive Industry. Machinery 2019, 2, 41–67. [Google Scholar]

- He, C.-Q.; Ye, D.-L.; Zhang, W.; Xue, Y.-H. Summary of Research on Additive Manufacturing and Its Application in Design. Packag. Eng. 2021, 42, 1–8. [Google Scholar]

- Zhang, H.; Yang, K. Overview of the Present Situation and Application of Additive Manufacturing. Packag. Eng. 2021, 42, 9–15. [Google Scholar]

- Liu, J.; Liu, S.; Yang, X.; Li, A. Progress in Lightweight Application Research of Additive Manufacturung Technology. Mater. China 2020, 39, 163–168. [Google Scholar]

- Li, P.; Chen, P.; Liu, W. The Latest Development of Advanced Composite Additive Manufacturing Technology and Its Application Tendency in Aviation. Natl. Fiberglass/Compos. Mater. Acad. Annu. Conf. 2016, 172–176, 193. [Google Scholar]

- Zhang, Q. Application of Additive Manufacturing Technique in Developing of Electronic Equipment Structure. Mech. Res. Appl. 2015, 28, 198–199. [Google Scholar]

- Wang, Q.; Sun, Y. Applications of additive manufacturing technology on Aero-engine. Aeronaut. Sci. Technol. 2014, 25, 6–10. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).