Performance Optimization of a Formula Student Racing Car Using the IPG CarMaker, Part 1: Lap Time Convergence and Sensitivity Analysis †

Abstract

1. Introduction

2. Methodology

2.1. Lap Time Simulations and Driver Model

2.2. Vehicle Model

2.3. Lap Time Convergence, Parameter Sensitivity Analysis, and Validation

3. Results

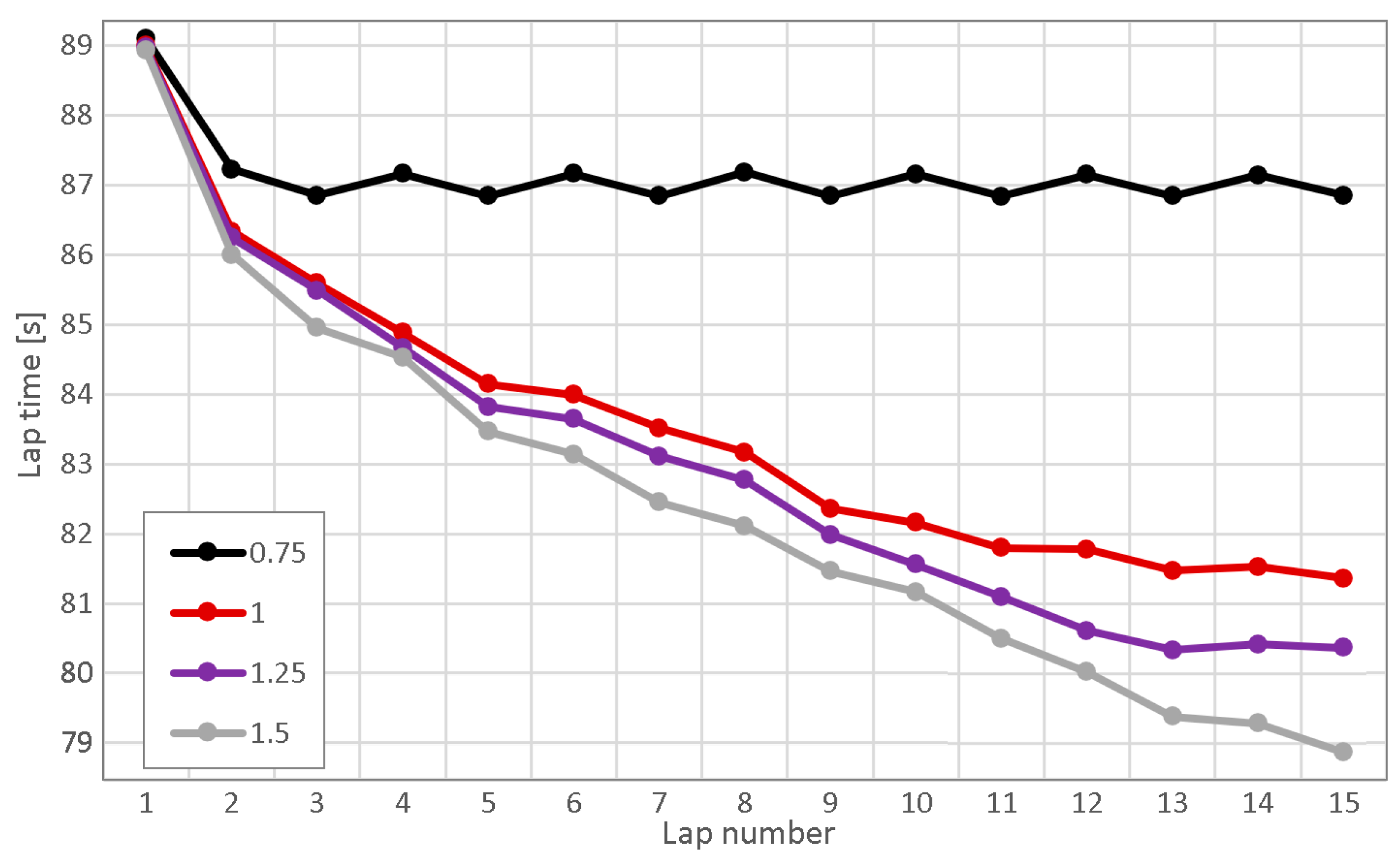

3.1. Convergence—Virtual Driver Adaptation Process

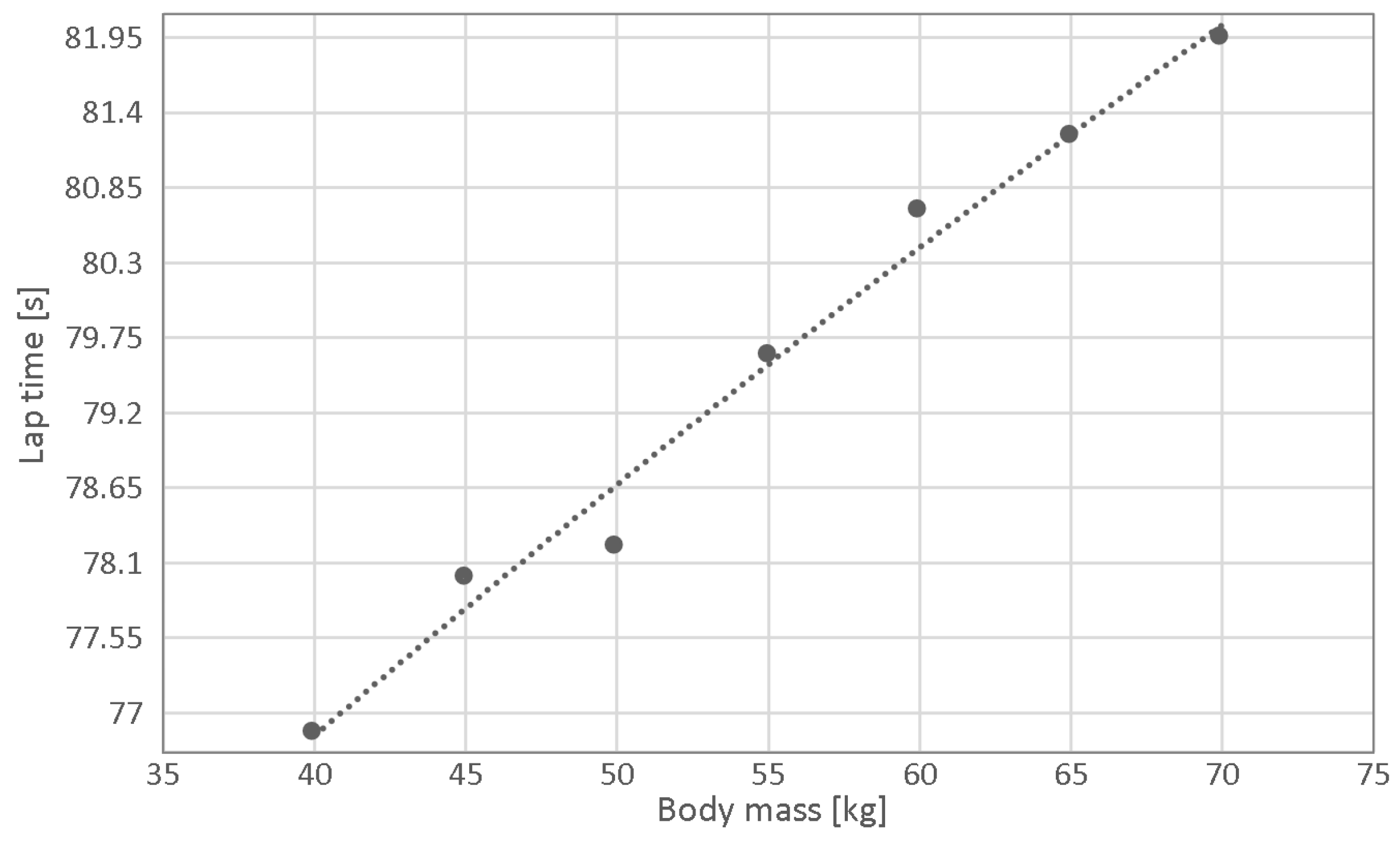

3.2. Parameter Sensitivity

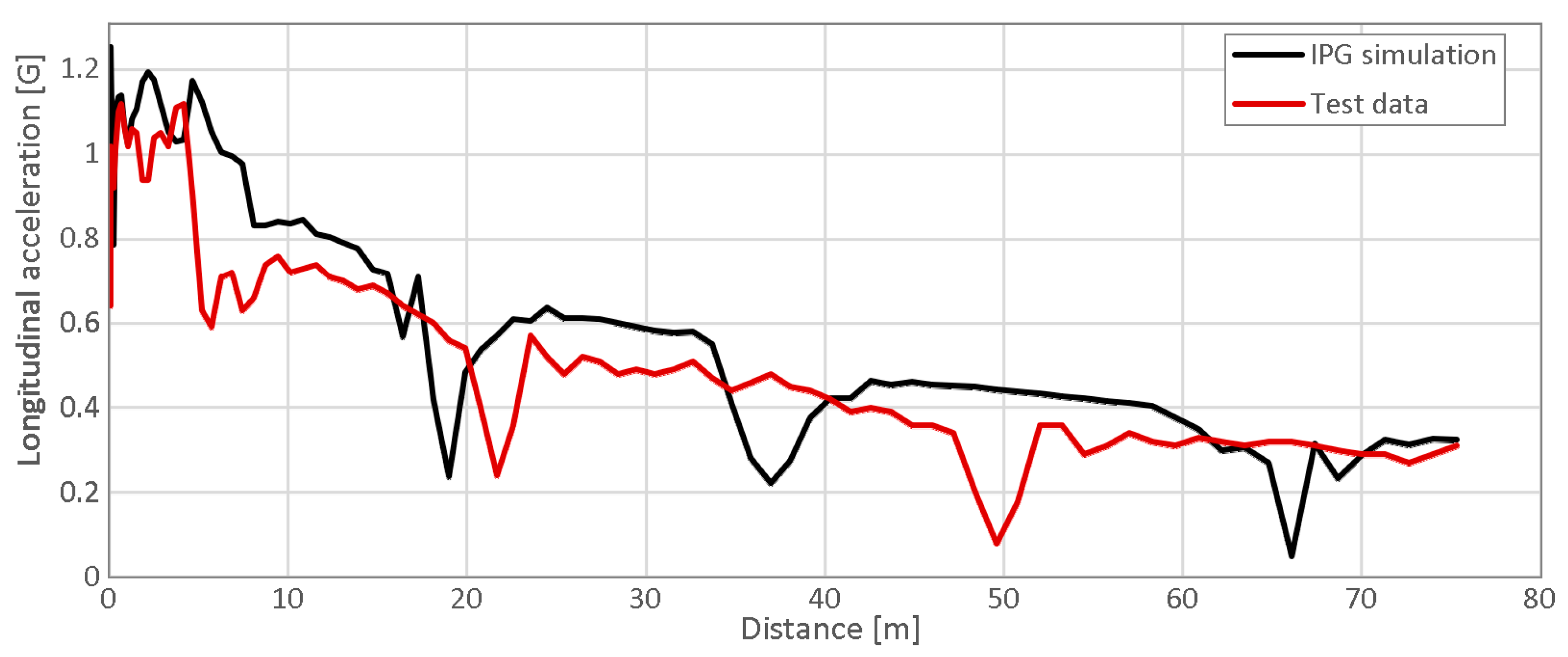

3.3. Validation of IPG CarMaker Simulations

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stein, E.; de Borst, R.; Hughes, T.J.R. Encyclopedia of Computational Mechanics, Vols. 1., 2., 3.; John Wiley and Sons: Hoboken, NJ, USA, 2004; ISBN 0-470-84699-2. [Google Scholar]

- Pacejka, H.B. Tire and Vehicle Dynamics, 2nd ed.; Butterworth-Heinemann: London, UK, 2006; ISBN 980-0-7506-6918-4. [Google Scholar]

- Shabana, A. Dynamics of Multibody Systems; Cambridge University Press: New York, USA, 2010; ISBN 978-0-521-85011-7. [Google Scholar]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipies—The Art of Scientific Computing, 3rd ed.; Cambridge University Press: New York, NY, USA, 2007; ISBN 978-0-511-33555-6. [Google Scholar]

- Crolla, D.A. Automotive Engineering—Powertrain, Chassis System and Vehicle Body; Butterworth-Heinemann: Oxford, UK, 2009; ISBN 978-1-85617-577-7. [Google Scholar]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics, Revised ed.; SAE International: Warrendale, PA, USA, 2021; ISBN 978-1-4686-0356-9. [Google Scholar]

- IPG Automotive GmbH. Index Page. Available online: https://www.ipg-automotive.com/en/ (accessed on 1 July 2024).

- Allwright, J. Four Wheel Steering (4WS) on a Formula Student Racing Car. SAE-A Veh. Technol. Eng. 2015, 1, 1–12. [Google Scholar] [CrossRef]

- Leung, K.T.; Whidborne, J.F.; Purdy, D.; Barber, P. Road vehicle state estimation using low-cost GPS/INS. Mech. Syst. Signal Process. 2011, 25, 1988–2004. [Google Scholar] [CrossRef]

- Fallah, S.; Sorniotti, A.; Gruber, P. A Novel Robust Optimal Active Control of Vehicle Suspension Systems. IFAC Proc. Vol. 2014, 47, 11213–11218. [Google Scholar] [CrossRef]

- Hegedűs, T.; Fényes, D.; Szabó, Z.; Németh, B.; Gáspár, P. LPV control design based on ultra-local model for trajectory tracking problem. IFAC-PapersOnLine 2022, 55, 175–180. [Google Scholar] [CrossRef]

- Takács, D.; Ambrus Zelei, A. Performance Optimization of a Formula Student Racing Car Using IPG CarMaker—Part 2: Aiding Aerodynamics and DRS Package Design. Eng. Proc. 2024, in press. [Google Scholar]

- Luo, Y.; Chen, Y.; Lu, K.; Chen, L.; Zhang, J. Modeling and analysis of heterogeneous traffic flow considering dynamic information flow topology and driving behavioral characteristics. Phys. A 2024, 637, 129521. [Google Scholar] [CrossRef]

- Formula Student Germany Rulebook for 2024. Available online: https://www.formulastudent.de/fileadmin/user_upload/all/2024/rules/FS-Rules_2024_v1.1.pdf (accessed on 1 July 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takács, D.; Zelei, A. Performance Optimization of a Formula Student Racing Car Using the IPG CarMaker, Part 1: Lap Time Convergence and Sensitivity Analysis. Eng. Proc. 2024, 79, 86. https://doi.org/10.3390/engproc2024079086

Takács D, Zelei A. Performance Optimization of a Formula Student Racing Car Using the IPG CarMaker, Part 1: Lap Time Convergence and Sensitivity Analysis. Engineering Proceedings. 2024; 79(1):86. https://doi.org/10.3390/engproc2024079086

Chicago/Turabian StyleTakács, Dominik, and Ambrus Zelei. 2024. "Performance Optimization of a Formula Student Racing Car Using the IPG CarMaker, Part 1: Lap Time Convergence and Sensitivity Analysis" Engineering Proceedings 79, no. 1: 86. https://doi.org/10.3390/engproc2024079086

APA StyleTakács, D., & Zelei, A. (2024). Performance Optimization of a Formula Student Racing Car Using the IPG CarMaker, Part 1: Lap Time Convergence and Sensitivity Analysis. Engineering Proceedings, 79(1), 86. https://doi.org/10.3390/engproc2024079086