Investigation of Tooth Friction Conditions of Electric Vehicle Gearbox with Plastic Gears †

Abstract

1. Introduction

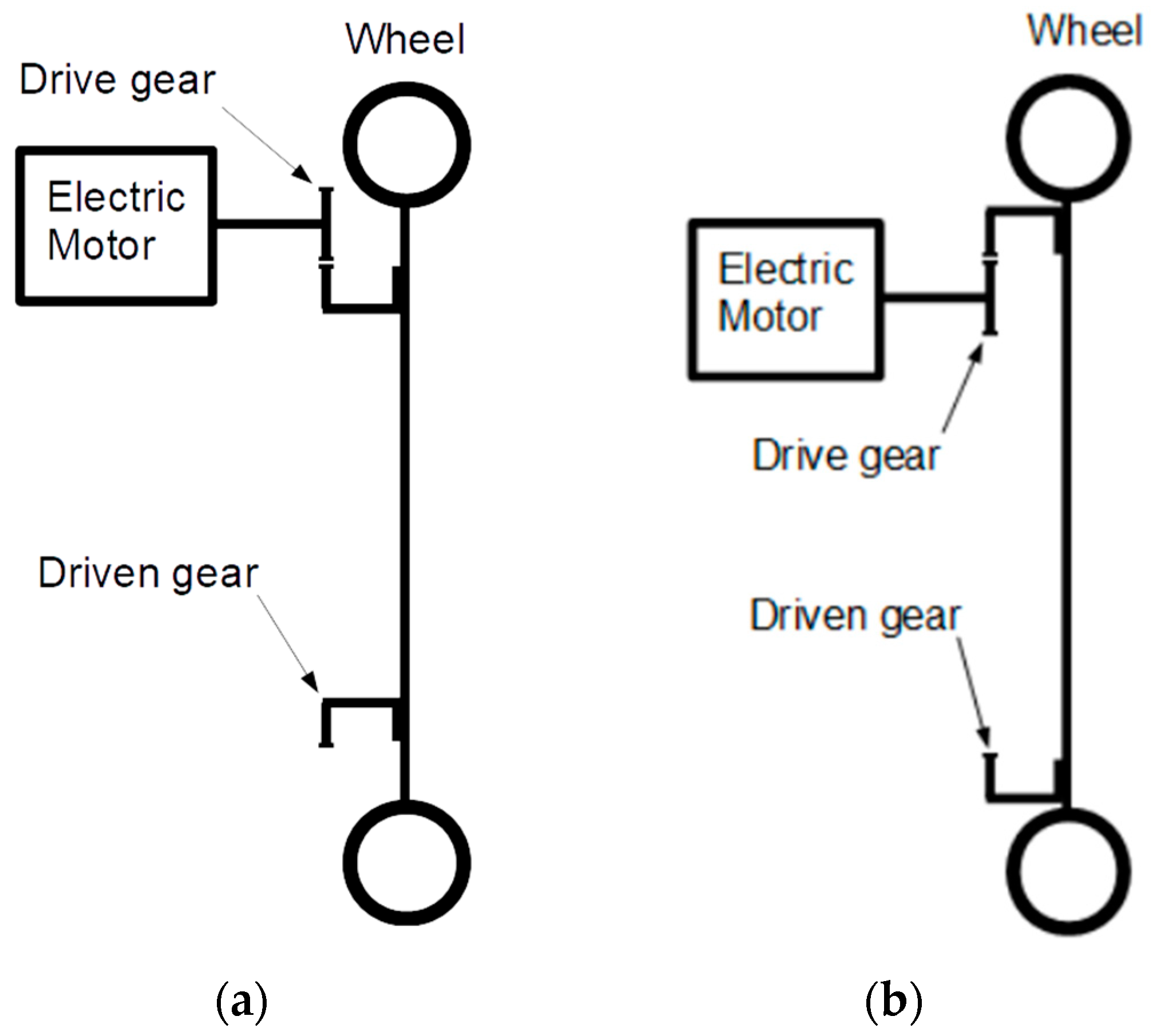

2. Presentation of the Concept of the Single-Stage Gear Unit Model

- The power source is an internal-rotor permanent-magnet motor;

- The gearbox is a single-stage unit with plastic gears;

- The gearbox has no separate housing, bearings and sealed oil lubrication;

- So, a rigid frame and running gear must be designed and constructed;

- The bearing and seal friction loss on the drive side are reflected in the engine model;

- The bearing and seal friction loss on the output side are reflected in the vehicle running resistance;

- The lubrication of the gearbox is achieved by greasing every run.

2.1. The Gear Materials

- Smooth, quiet running;

- Corrosion resistance;

- Wear resistance;

- Impact resistance;

- Low weight.

2.2. Definition of the Lubrication System

- The base oil viscosity of lubricating greases for bearings and gears under low loads and relatively high speeds is typically around 20 cSt at 40 °C.

- For lubrication of general ball and roller bearings, a base oil viscosity of 80–200 cSt is appropriate.

- For heavy-duty, low-speed equipment (industrial equipment), a base oil viscosity of 150–500 cSt is required. Greases with even higher base oil viscosities are also available for special conditions.

2.3. Drive Unit Parameter Vector Determination

- Transmission ratio, [−], i;

- Module, mm, m;

- Centre distance, mm, aw;

- Gear width, mm, b;

- Pressure angle, rad, α;

- Helix angle, rad, β.

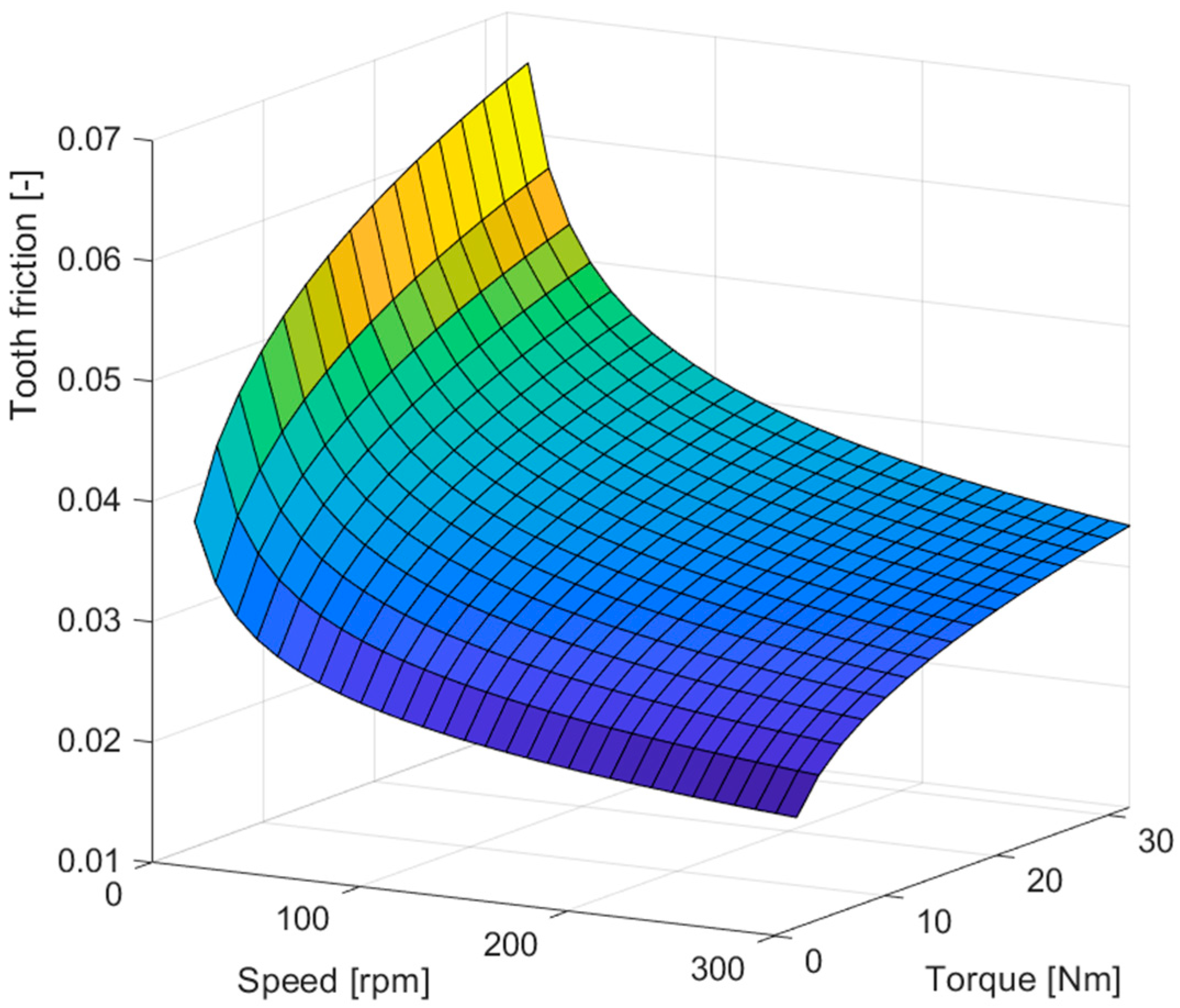

2.4. Tooth Friction Change Analysis

- Gear unit parameters: p = [6 4 200 20 0.349 0];

- Test range: nw = 10…300 rpm; Mw = 2…32 Nm;

- Viscosity of the selected lubricating grease base oil: ν = 220 mm2/s.

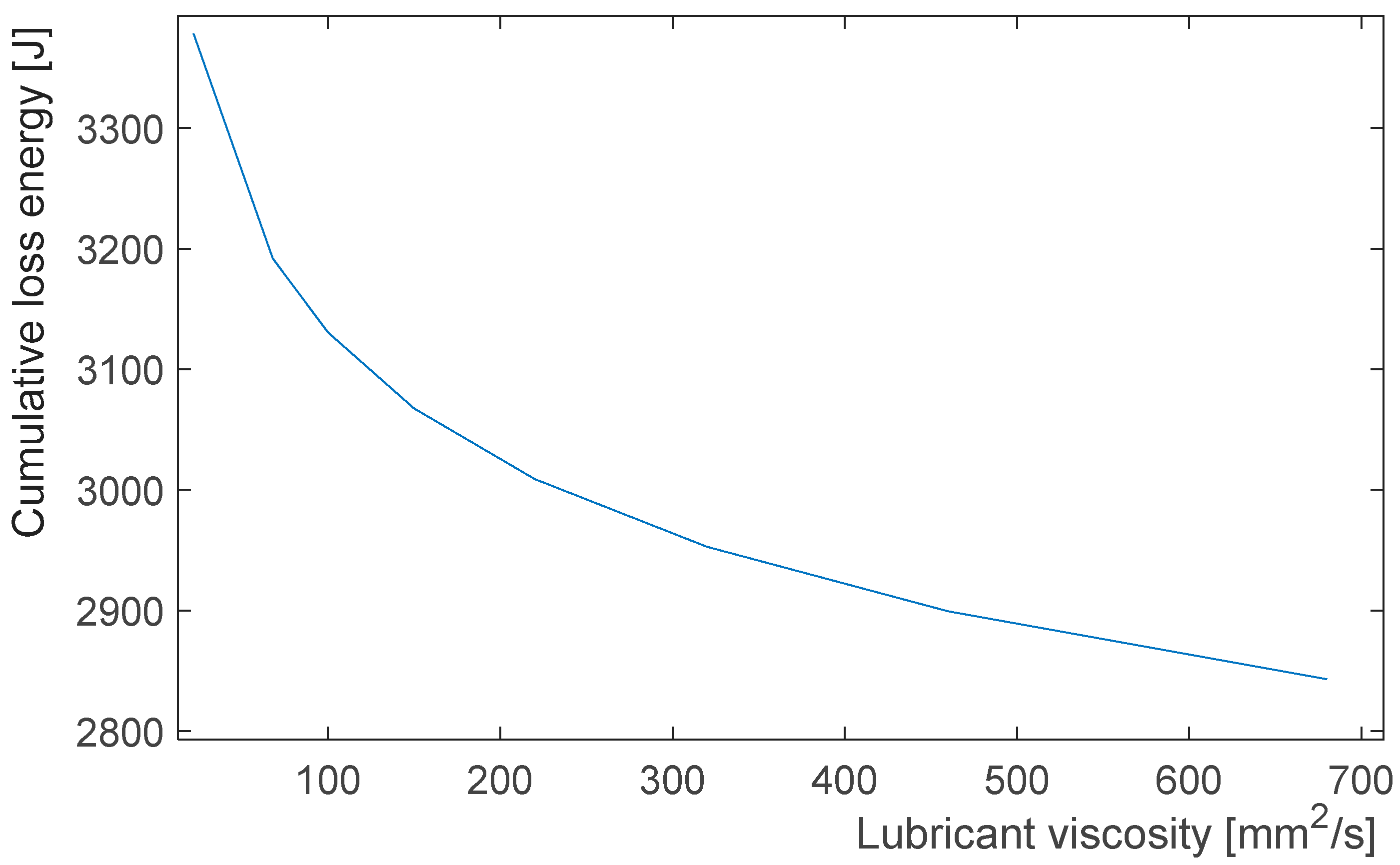

2.5. Relationship Between Lubricant Viscosity and Cumulative Loss Energy

3. Testing and Inspection of Gear Teeth Under Competition Conditions

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Concli, F. Thermal and efficiency characterization of a low-backlash planetary gearbox: An integrated numerical-analytical prediction model and its experimental validation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 996–1005. [Google Scholar] [CrossRef]

- Lakatos, I.; Titrik, Á. Determination of Power and Torque Curves of Vehicles Based on Diagnostic Methods. In Proceedings of the 12th International Conference on Heat Engines and Environmental Protection, Budapest, Hungary, 27–29 May 2015. [Google Scholar]

- Németh, A.; Fischer, S. Investigation of the glued insulated rail joints applied to CWR tracks. Facta Univ. Ser. Mech. Eng. 2021, 19, 681–704. [Google Scholar] [CrossRef]

- Szalai, S.; Kocsis Szürke, S.; Harangozó, D.; Fischer, S. Investigation of deformations of a lithium-polymer cell using the Digital Image Correlation Method (DICM). Rep. Mech. Eng. 2022, 3, 116–134. [Google Scholar] [CrossRef]

- Horváth, E.; Kőrös, P. Systematic approach to software related tasks in electric fuel-efficiency vehicle development. In Proceedings of the IEEE 19th International Conference on Intelligent Engineering Systems (INES 2015), Bratislava, Slovakia, 3–5 September 2015. [Google Scholar]

- Istenes, G.; Pusztai, Z.; Kőrös, P.; Horváth, Z.; Friedler, F. Kriging-assisted multi-objective optimization framework for electric motors using predetermined driving strategy. Energies 2023, 16, 4713. [Google Scholar] [CrossRef]

- Polák, J.; Lakatos, I. Efficiency optimization of electric permanent magnet motor driven vehicle. Mach. Des. 2015, 7, 11–14. [Google Scholar]

- Polák, J.; Lakatos, I. Examination of drive line mathematical model. Mach. Des. 2016, 8, 33–36. [Google Scholar]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 57–119. [Google Scholar]

| Torque [Nm] | Speed [rpm] | Tooth Friction [−] |

|---|---|---|

| 32 | 10 | 0.06595 |

| 2 | 300 | 0.01918 |

| Working Points | 1 | 2 | 3 |

|---|---|---|---|

| Mw [Nm] | 0 | 14 | 32 |

| nw [rpm] | 285 | 285 | 285 |

| t [s] | 755 | 755 | 216 |

| Engine parameter vector: | p = [6, 4, 200, 20, 0.349 0] | ||

| Standard Viscosity Levels [mm2/s] | Cumulative Energy Loss [J] |

|---|---|

| 22 | 3378.58 |

| 68 | 3192.21 |

| 100 | 3130.91 |

| 150 | 3067.75 |

| 220 | 3009.26 |

| 320 | 2953.13 |

| 460 | 2899.77 |

| 680 | 2843.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polák, J. Investigation of Tooth Friction Conditions of Electric Vehicle Gearbox with Plastic Gears. Eng. Proc. 2024, 79, 85. https://doi.org/10.3390/engproc2024079085

Polák J. Investigation of Tooth Friction Conditions of Electric Vehicle Gearbox with Plastic Gears. Engineering Proceedings. 2024; 79(1):85. https://doi.org/10.3390/engproc2024079085

Chicago/Turabian StylePolák, József. 2024. "Investigation of Tooth Friction Conditions of Electric Vehicle Gearbox with Plastic Gears" Engineering Proceedings 79, no. 1: 85. https://doi.org/10.3390/engproc2024079085

APA StylePolák, J. (2024). Investigation of Tooth Friction Conditions of Electric Vehicle Gearbox with Plastic Gears. Engineering Proceedings, 79(1), 85. https://doi.org/10.3390/engproc2024079085