1. Introduction

In recent decades, the use of plastics, particularly PET, has rapidly increased across various industries. Since the 1970s, the production of PET bottles has grown exponentially [

1], and, in 2022, global plastic production reached 400.3 million metric tons, a 1.6% increase compared to the previous year [

2]. Single-use packaging materials pose significant environmental challenges, as PET has a degradation time of over 500 years [

3,

4]. This research aims to develop a material composition that allows for the extensive use of rPET in the manufacturing of recycled products without compromising material quality after multiple processing cycles. Polymer foams are materials in which gas bubbles are suspended within a polymer matrix. They can be produced from almost any thermoplastic and cross-linked polymer using foaming techniques. In chemical foaming, gasses are generated by chemical blowing agents that decompose during processing. These decomposition products create bubbles that expand in the cooling melt, forming a closed-cell foam structure. The cell density increases towards the core, resulting in a structural foam [

5,

6].

The chain scission occurring during PET recycling poses a challenge during chemical foaming. This research aims to develop a process for producing closed-cell foam structures from recycled PET (rPET). Experiments successfully produced closed-cell foam structures in rPET matrices using a chemical blowing agent [

7]. However, the increased fluidity resulting from the chain scission hindered foam formation. Using the chain extender CESA Extend optimizes molecular chain length, improving foam formation. In our research, we set out to enhance the mechanical strength of the foam structures by adding impact modifiers to the mixture. The mixture was then tested using the Charpy impact test [

8]. We wanted to determine whether it was possible to produce an integrated foam structure with a closed-cell configuration from recycled PET using chemical foaming. Overcoming the challenges caused by chain scission and improving the mechanical properties of the foam structure are crucial for the industrial application of this technology.

One of the barriers to the widespread adoption of PET foams is PET’s resistance to burning, as PET’s droplet combustion contributes to flame spread. The use of flame-retardant additives serve to reduce the flammability of PET foams and improve their fire resistance classification. Effective flame retardation requires the selection of suitable flame retardants while considering efficiency, environmental impact, cost, and processing compatibility [

9]. Endothermic–exothermic hybrid foaming is a pioneering technique that opens new possibilities for the advancement of foam materials. Due to their finer cell size distribution, increased cell number, faster foaming, and improved mechanical properties, hybrid foams can be widely used. For example, this material can be used for thermal insulation, packaging, and as construction material in several industries, such as the automotive industry [

10]. During hybrid foaming, the exothermic components, like azodicarbonamide, generates heat upon decomposition, while the endothermic component, such as citric acid, absorbs heat. This temperature fluctuation influences the foaming process, resulting in finer cell size distribution, increased cell number, and improved mechanical properties. Finer cell size leads to improved strength, stiffness, and thermal conductivity of the foam, while the increased cell number enhances the foam’s thermal insulation properties. Additionally, the hybrid foaming process results in faster foaming, translating to shorter manufacturing times and costs [

11].

The goal is to develop an optimal polymer foam structure, with tensile strength consideration playing a key role alongside strain properties. Polymers with higher tensile strength prove more challenging during the foaming process due to the increased resistance of polymer chains to stretching [

12]. During foaming, molecular chains stretch in the vicinity of cell growth, leading to local viscosity increases. This growth inhibition prevents the merging of adjacent cells. PET, with its outstanding tensile strength, has therefore proven to be more difficult to utilize during the foaming process [

13]. This phenomenon is explained by the increased stretch resistance of PET chains, hindering cell growth. Polymers with higher stretch resistance have more difficulty in regard to forming foam structures. However, by preventing cell coalescence, a more porous structure can be created [

14].

M. Tao et al. [

15] examined the impact of polymer chain stretch resistance on foamability, using polymers with different stretch resistances to conduct foaming experiments. They examined the density, pore size, and mechanical properties of the foams. The research showed that the stretch resistance of polymer chains significantly affects foamability. Polymers with lower stretch resistance were easier to foam but resulted in less porous foams. Zhang Wei et al. [

16] focused on the preparation and characterization of chlorinated polyethylene reinforced polypropylene foam, with a particular emphasis on how the mechanical properties of the material before foaming, such as tensile strength and elongation, influence the final foam structure. They found that materials exhibiting higher tensile strength and elongation prior to forming produced foams with more uniform and stable cellular structures. This correlation highlights the importance of optimizing pre-foaming mechanical properties to achieve desirable outcomes in the final foamed product.

Bhagat et al. [

17] investigated the impact of nucleating agents on the foaming behavior and tensile properties of polypropylene composite foams. The research demonstrated that the mechanical properties of polypropylene before the foaming process, such as tensile strength and elongation, play a crucial role in determining the quality of the final foam structure. By improving these pre-foaming properties with specific nucleating agents, the researchers were able to produce foams with enhanced toughness and more uniform cellular structures.

The research aims to investigate whether the pre-foaming tensile strength and/or strain of a material can be used to predict the porosity of the foam structure.

2. Materials and Methods

The blue crystalline regranulated PET (rPET) used for the tests was provided by Fehérvári Csoport Zrt. (Fehérvári Csoport Zrt., Székesfehérvár, Hungary) with an intrinsic viscosity (IV) of 0.8 dL/g. The chain extender additive used was CESA Extend NCA0025531-ZA supplied by Clariant (Clariant, Muttenz, Switzerland), which contains Joncryl ADR 4368, an epoxy-based styrene–acrylic multifunctional oligomer reagent. The DuPont Elvaloy PTW impact modifier enhanced the mechanical resistance of the samples. The blowing agent used was Tracel IM 7200, an endothermic compound provided by Tramaco (Tramaco, Tornesch, Germany), with a gas generation of 50 mL/g, 70% blowing agent content, and a decomposition temperature of 220 °C. Additionally, Tracel IM 3170 MS (Tramaco, Tornesch, Germany), an exothermic blowing agent with a gas generation of 120 mL/g and a decomposition temperature of 170 °C, was used. To improve the material’s resistance to burning, samples were produced with various mixtures of flame retardants. The flame retardants used included Clariant Exolit AP 422 (Clariant, Muttenz, Switzerland), with a decomposition temperature of 270 °C. Clariant Exolit OP 1240 (Clariant, Muttenz, Switzerland), a non-halogenated flame retardant for polyester injection molding, has a decomposition temperature of 300 °C. Additionally, Budenheim Budit 342 (Budenheim, Budenheim, Germany), a halogen-free flame retardant made from melamine polyphosphate (MPP), exhibits a decomposition temperature of 325 °C. Finally, Budenheim Budit 617 (Budenheim, Budenheim, Germany), another flame retardant, has a decomposition temperature of 340 °C. The high phosphate and nitrogen content help prevent fires by promoting char formation and stopping the material from igniting or smoldering. It is especially efficient due to its high phosphorus content and can achieve a UL 94 V-0 rating at low dosages. The combined use of ammonium polyphosphate (APP) and melamine in polymer composites significantly enhances the materials’ flame-retardant properties. This synergy leads to improved thermal stability and more effective char formation, which helps to inhibit fire spread. The mixture works by creating a stronger and more resilient char layer on the polymer surface during combustion, effectively reducing the material’s flammability and increasing its resistance to fire [

18]. In the research, MPP was added at a 5% concentration to the Exolit AP 422 (Clariant, Muttenz, Switzerland) to promote charring and enhance combustion inhibition.

The mixtures were dried for 5 h at 120 °C before being blended with the additives. Test specimens were prepared using an Arburg Allrounder Advance 420C Golden Edition (Arburg, Loßburg, Germany) injection molding machine with a melting temperature of 265 °C, injection speed of 45 cm

3/min, and a mold temperature of 35 °C.

Table 1 shows the composition of the test samples. We prepared control samples (without chemical foaming) from each material composition and then subjected them to tensile testing to assess their mechanical properties. Subsequently, we prepared test specimens from each sample via chemical foaming (with 0.5 phr endothermic and 3.5 phr exothermic CBA) using a conventional injection molding machine with a breath-molding technique. Finally, these specimens were subjected to computed tomography (CT) scans to visualize their internal structure and morphology.

The internal structure of the samples was examined using an industrial CT scanner. The resolution was 0.027 mm, with a tube voltage of 200 kV and a tube current of 0.1 mA. A flat panel detector was used without a filter with an integration time of 700 ms. Commercially available software (YXLON Modular Y.CT system equipped with a 225 kV micro-focus X-ray tube and a Y.XRD1260 flat panel detector) was used to determine the cell structure. Tensile strength tests were performed according to using an INSTRON 5582 (INSTRON, Kawasaki, Japan) universal testing machine with a gauge length of 100 mm and a test speed of 1 mm/min for determining the elastic modulus and 5 mm/min for determining tensile strength [

19].

3. Results and Discussion

In this section we will discuss the various tests that we carried out on our samples, and we have examined the correlations between the porosity and the tensile strength for the different material compositions we have created for this research. The analysis compared the resistance to tensile stress before mechanical foaming with the cell structure indicators that formed during the foaming process.

3.1. Correlation Between Tensile Strength and Porosity

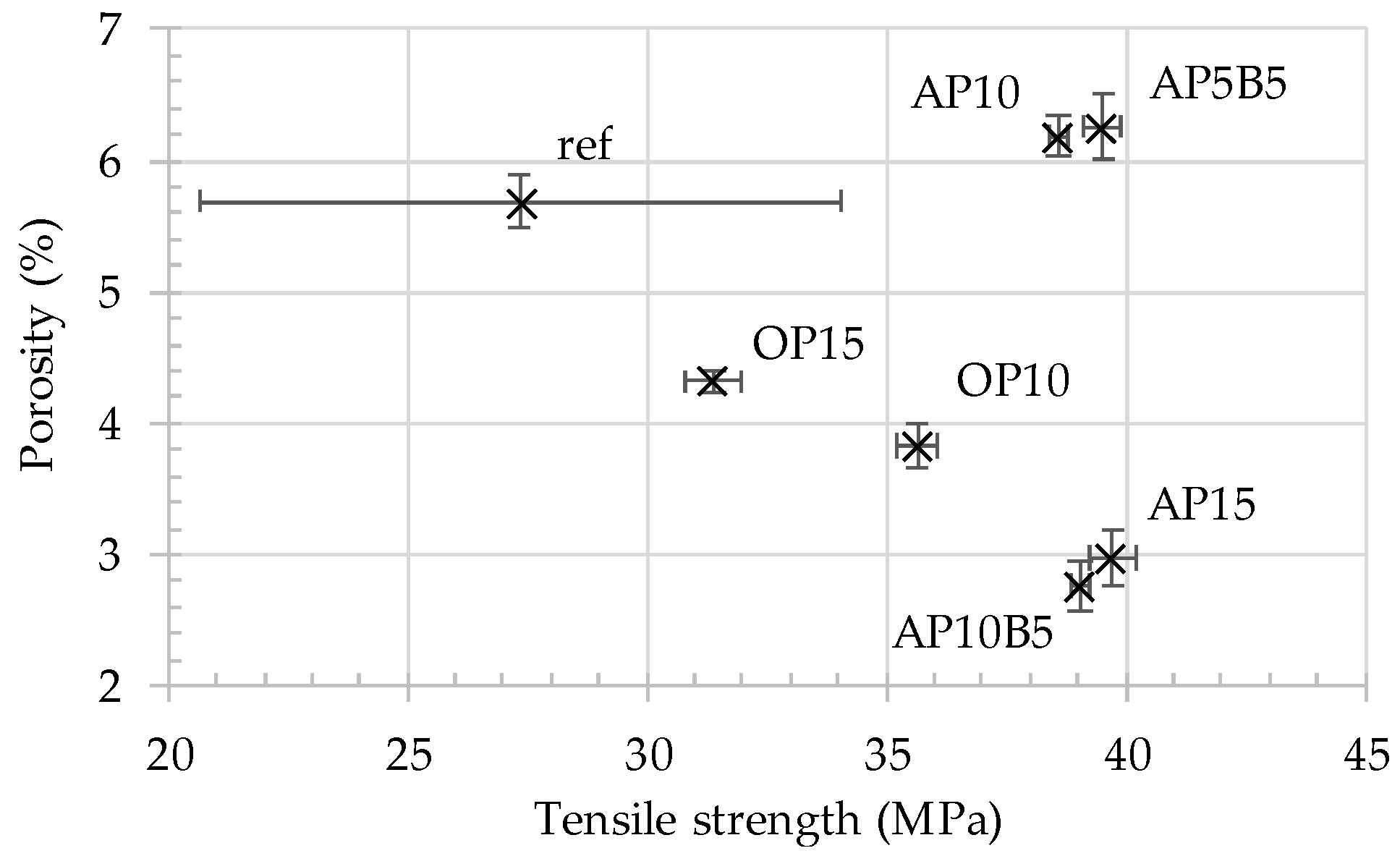

The scatter plot below indicates the significant effect that the incorporation of different flame retardants in different combinations has on the tensile strength and porosity levels of the rPET samples (

Figure 1). The AP sample series generally portrays a higher tensile strength compared to the OP sample series. The AP15 sample in particular, which contained 15 parts of Clariant Exolit AP 422, exhibits the highest tensile strength and one of the lowest porosities, suggesting that this flame retardant effectively enhances the mechanical properties while it simultaneously reduces porosity. In contrast, the OP sample series demonstrates a decrease in tensile strength. When increased amounts of Clariant Exolit OP 1240 is added to the formula, the porosity in the OP series is moderate when compared to the AP sample series. This can be attributed to the different chemical compositions and interactions of the flame retardants with the rPET matrix.

The data clearly portray that, prior to foaming, measuring the tensile strength in isolation is not a reliable predictor of the porosity of the foamed material. While the AP sample series demonstrates high tensile strengths, the porosity values do not indicate a clear pattern based on their tensile strength alone. For example, while AP15 and AP10B5 have higher tensile strengths, their porosity is significantly lower when compared to AP10 and AP5B5, which have similar tensile strengths. Thus, it appears that the type and proportion of flame retardants, along with the other additives, play a crucial role in the foaming process. For example, samples with different combinations of Exolit AP 422 and Budit 342 show varying porosities despite possessing similar tensile strengths.

This analysis underscores the complexity of the foaming process and the need for a multifaceted approach to optimize the material properties for specific applications. It is evident that, while tensile strength provides some insights, it is not sufficient in terms of drawing direct parallels with the porosity of the foamed product.

3.2. Correlation Between Tensile Strain and Porosity

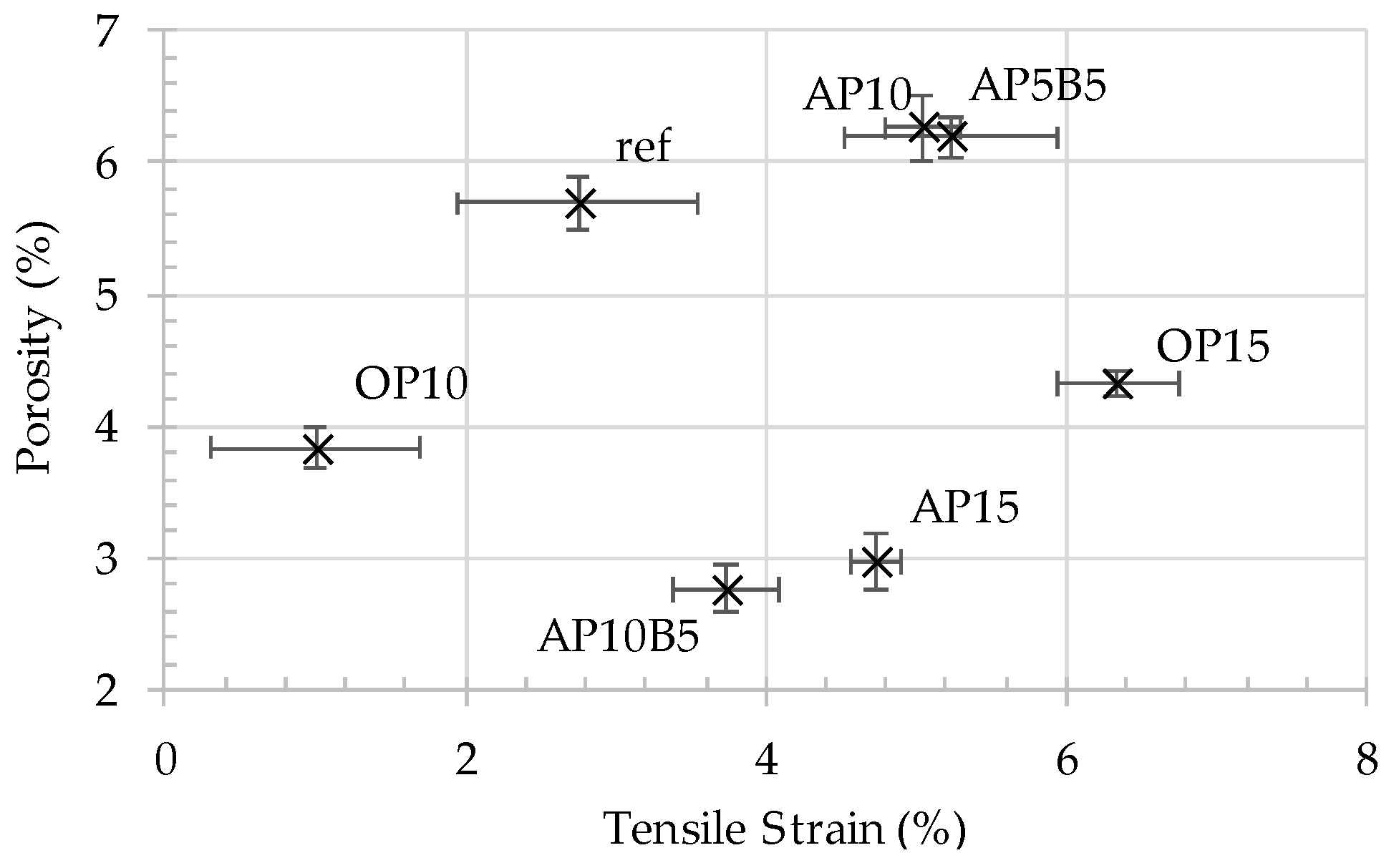

Samples with similar strain values can exhibit minor variations in porosity (

Figure 2). For instance, AP10 and AP5B5 both have strains of around 5%, yet their porosities are 6% and 6.3%, respectively, indicating a small difference in porosity due to the similar strain. Conversely, AP15, with a strain of 4.73%, has a substantially lower porosity of 3%, suggesting that lower porosity is achievable even with moderate strain values (

Figure 3).

The additives used in the AP series, particularly the varying amounts of Clariant Exolit AP 422 and Budenheim Budit 342, show a clear impact on the strain and porosity. Higher amounts of Clariant Exolit AP 422 in AP15 lead to lower porosity despite moderate strain. The OP series, containing Clariant Exolit OP 1240, exhibits high strain values but varying porosities, suggesting that the type of flame retardant significantly affects the foam structure and the mechanical properties.

When the scatter plot is analyzed, it reveals that the strain before foaming does not directly predict the resulting porosity. Various samples with similar strain values can exhibit different porosities, indicating that other factors, such as the type and concentration of flame retardants and blowing agents, play a crucial role in determining the final foam structure.

The type of additives significantly impacts the mechanical properties and foamability of the rPET samples. For example, Clariant Exolit AP 422 effectively reduces porosity while maintaining moderate strain, whereas Clariant Exolit OP 1240 contributes to high strain but results in varied porosity outcomes.