1. Introduction

In the contemporary technological landscape, there is a continuous influx of novel digital devices owing to the incessant drive for innovation. While this swift evolution caters to the preferences of consumers who eagerly seek the latest gadgets, it also creates a new problem, which is the proliferation of E-waste. Each time a new version of smartphones, tablets, and other similar devices comes out, it adds to the growing pile of old electronics that people throw away. This increase in electronic waste is a big problem for the environment because it uses up a lot of resources and creates a lot of trash.

The supply chain is a complex network that connects raw materials, components, and finished goods. As a complex network that connects raw materials, components, and finished goods, the supply chain plays a pivotal role in this cycle of production and consumption It plans their path from the beginning to the point of sale, guaranteeing a smooth and effective experience for clients.

Supply chain management (SCM) aims to maximise overall system profit and meet customer service standards by efficiently coordinating suppliers, manufacturers, warehouses, and retail spaces. This involves producing and distributing goods in optimal quantities, timings, and locations. A circular supply chain, also known as a closed-loop supply chain, involves the return of products from customers for purposes like repair, resale, refurbishment, or recycling. This creates a cycle, starting from the initial stages with suppliers and manufacturers and ultimately returning to customers. The technological era is witnessing the rapid introduction of new digital products, resulting in the generation of 57.4 million tonnes of electronic waste in 2021, with only 17.4% of hazardous-metal-containing e-waste being recycled globally [

1]. Mobile phones, which are among household electronics, are the primary contributors to electronic waste, with over 5 billion expected to be discarded this year, as noted by the WEEE (Waste Electrical and Electronic Equipment) forum [

2]. Technological advancements and shorter product life span drive businesses to produce a variety of electronic devices, fostering widespread consumer adoption and contributing to significant electronic waste (e-waste) generation [

3,

4]. In 2018, 50 million tonnes of e-waste were produced globally, and without intervention, it is expected to exceed 120 million tonnes by 2050, with only 20% currently being recycled.

Environmental conservation is a crucial and challenging global research focus, particularly concerning the harmful impact of materials from mobile phone waste. China, the USA, and India are major contributors to cell phone waste [

5]. In 2021, global e-waste recorded 57.4 million metric tonnes, with a projected increase to 74.7 million tonnes in the coming years, highlighting the urgency of environmental research [

6,

7]. This increasing trend highlights the urgent need for environmental conservation initiatives, particularly in directing the harmful impact of materials from mobile phone waste.

To relieve these challenges, businesses must work together to employ circular supply chain management (CSCM) and circular economy practices. CSCM intends to enhance overall system benefits by incorporating suppliers, manufacturers, and retail spaces for effective production and distribution [

3,

5]. By tactically planning logistics and collaborating with stakeholders, companies can minimise material waste, reduce import costs, promote reuse, cut supply chain expenses, and improve overall profitability [

8]. Implementing circular supply chain and economy concepts is vital for companies, minimising material waste, reducing import costs, promoting reuse, cutting supply chain expenses, and enhancing overall profitability [

9]. This approach addresses environmental concerns, challenges in natural resource extraction costs, and the impact of population growth [

10]. Despite its adverse effects, mobile phones are recognized as a source for systematic recovery and reuse of key minerals, contributing to the conservation of valuable natural resources [

7,

11]. Existing research on electronic waste covers various products, but the specific aspects related to cell phones, such as systematic recovery and key mineral reuse, remain underexplored, highlighting the focus of this study.

RQ 1: What is the most valuable material that is becoming trash as a result of mobile phone wastage, and how does this affect the company’s economic growth?

RQ 2: Which material induced the most harmful impact on the environment?

This study highlights the most costly materials discarded as a result of mobile phone waste and examines the associated annual costs and business impacts. It also prioritises identifying the most hazardous environmental materials. Filling a gap in earlier research, this paper focuses on material wastage from phone disposal, providing a unique perspective on its environmental and business implications.

CSCM is initiated when customers return outdated or faulty products, creating a closed-loop process beneficial for company growth. Major global electronics companies leverage this concept to minimise the waste of valuable materials, especially in motherboard production. By refurbishing and reselling products, these companies actively contribute to reducing e-waste and adopting environmentally friendly strategies [

6]. The circular supply chain has a multitude of partners, such as manufacturers and recyclers. Every stream has its drivers and barriers, so CSCM seems to be resolved, and the effectiveness of each driver and its strategies also.is understood [

7]. CSCM is an effective way to reduce the trend of e-waste and energy consumption and achieve the target of manufacturing and consumption. It also plays a vital role in the circular economy by imposing interventions and mandatory standards for refurbished and remanufactured products [

12].

2. Literature Review

This investigation will highlight the concept and provide an overview of the relative studies on CSCM, Circular Economy, and electronic waste management. It will also provide a list of the materials that become trash and identify the material that has the highest adverse impact on the environment. It will also highlight the research gap and contribution.

2.1. Relative Studies in the CSCM

CSCM is the process that starts when the customer returns the outdated product or returns the product for repair. This process is generally a closed-loop process and can act as an advantage for the company’s growth. There are certain reasons for this discussed ahead. Major electronics companies around the world use the idea of a circular supply chain to reduce the waste of precious material that is used in making motherboards as well as to refurbish that product and resell it in the global market. This attitude of the companies helps in reducing e-waste and moving forward to green strategies [

6]. The CSCM has a multitude of partners, such as manufacturers and recyclers. Every stream has its drivers and barriers, so CSCM seems to be resolved, and the effectiveness of each driver and its strategies is understood [

7]. CSCM is an effective way to reduce the trend of e-waste and energy consumption to achieve the targets of manufacturing and consumption. It also plays a vital role in the circular economy by imposing interventions and mandatory standards for refurbished and remanufactured products [

12]. CSCM used to focus on material reuse and reduction in the raw material at the initial stage of the product development as well as cost savings and building entity reputation in society [

11,

13]. However, there is a need to link and evaluate the whole process and the performance of CSCM at different stages of the system.

CSC can be established in the electronics industry by implementing Design for Disassembly, which involves designing products for easy dismantling to recover components and materials for reuse or recycling. Standardising the indexing of subcomponents can facilitate their separation and recovery, supporting material feedstocks for an established supply chain. Also, technical revolutions are needed for closed-loop systems, covering design, manufacturing, and end-of-life management phases [

3,

5]. Additionally, adopting a modular design strategy facilitates product improvements, customisation, and a longer life cycle, reducing emissions and enhancing reuse and recycling. Applying green engineering principles markets a circular economy by aiming at sustainable materials management and technological advancements [

4,

14]. An industry-led association can systematically index all electronic components, treating e-waste as a useful resource. These steps mutually aim to further resource efficiency, reduce waste, and boost sustainability in material management and production processes in the electronics industry [

15].

2.2. Relative Studies in E-Waste Management

Technological expansion and invention create a short life of the equipment because the globe faces the issue of the production rate of E-waste [

16]. Electronic gadgets contain toxic metals that can cause environmental damage and affect human health [

17]. This issue occurs because of the short life cycle of devices and new technological inventions. This means mobile phone life cycles are less than two years, which leads to major toxic pollutants such as brominated plastics, nickel, lead, mercury, and cadmium [

18]. Decreasing and recovering toxic and valuable metal has been of utmost importance in mobile waste recycling. The reuse of this material in CSCM creates cost profitability and band value by minimising waste material [

19]. The forward supply chain logistics of products flow through the supplier, manufacturer, distributor, and retailers to customers [

20]. The generation of waste can be reduced by implementing a reverse logistics flow of the supply chain in which waste is collected, inspected, and deposited in different waste elimination stages such as repair, refurbishment, remanufacturing, and recycling, and the parts that can not be recovered through above stages are sent for disposal [

21].

2.3. Key Material in Mobile Phones

This paper focuses on six key materials: gold, silver, copper, palladium, cobalt, and lithium. Also, mercury is a material that cannot be neglected. These materials account for around 34.5% of the overall weight of mobile phones. However, they are significant from a social, environmental, and economic point of view. Their economic significance plays a major role in their selection. Because of the importance of recycling as well as supply and availability, it should be mentioned that a lot of other materials may meet these requirements as well. Among the examples are indium and rare earth elements; nonetheless, recycling them is more difficult to understand (European Commission, 2018a). Out of the above-mentioned materials, the two main materials are cobalt and palladium. These have been chosen by the collected data during the literature reviews, and from the economic point of view, the most precious materials are gold and silver.

2.4. Environmental Impact

All waste disposal impacts the environment negatively, and as electronic products, mobile phones, in particular, have hazardous materials like mercury, lithium, and cobalt. This has more impact on the environment, even though it has been found that there is a CO2 emission of around 81% when manufacturing mobile phones, while their transportation and disposal also produce a 5% and 10% adverse impact on the environment.

Although mercury is a chemical element, mercury is also the metal that comes in mobile phones, and it is figured that around 2 g of mercury is inside the phones. Another major obstacle regarding the advances in cell phone technology concerns the sophisticated design and material used, such as a Liquid Crystal Display (LCD) or Light Emitting Diode (LED) screens and built-in batteries [

15,

16]. These sophisticated components also have hazardous materials that are very important to see while recycling. Improper disposal of electronic waste, like mobile phones containing mercury and lithium, harms the environment. Mercury pollutes soil, water, and air, affecting marine life and human health. Lithium mining and battery production also cause environmental damage. Recycling efforts are underway, but current methods face challenges like low recycling rates and lack of awareness.

2.5. Research Highlights and Gap

There are enormous studies that identify the e-waste problem and mobile phone wastage, as well as the statistics on cell phone wastage and its environmental impact due to the disposal of electronic trash (Taher Ben Yahya, March 2021). However, a specific study related to the most precious material that comes out of mobile phones and which material has the highest impact on the environment is not sufficient [

4,

14]. Additionally, a greater study describes the need for the environmental impact and how the circular supply chain and circular economy affect a company’s economic growth. In addition to this literate gap, the majority of the studies are concerned with household e-waste and the disposal of this, but there are fewer specific studies on mobile phone wastage, material disposal, and environmental impact. This study helps to advance the understanding of cell phone disposal and the precious material contribution to the growth of a company, as well as the environmental impact due to material disposal.

3. Methodology

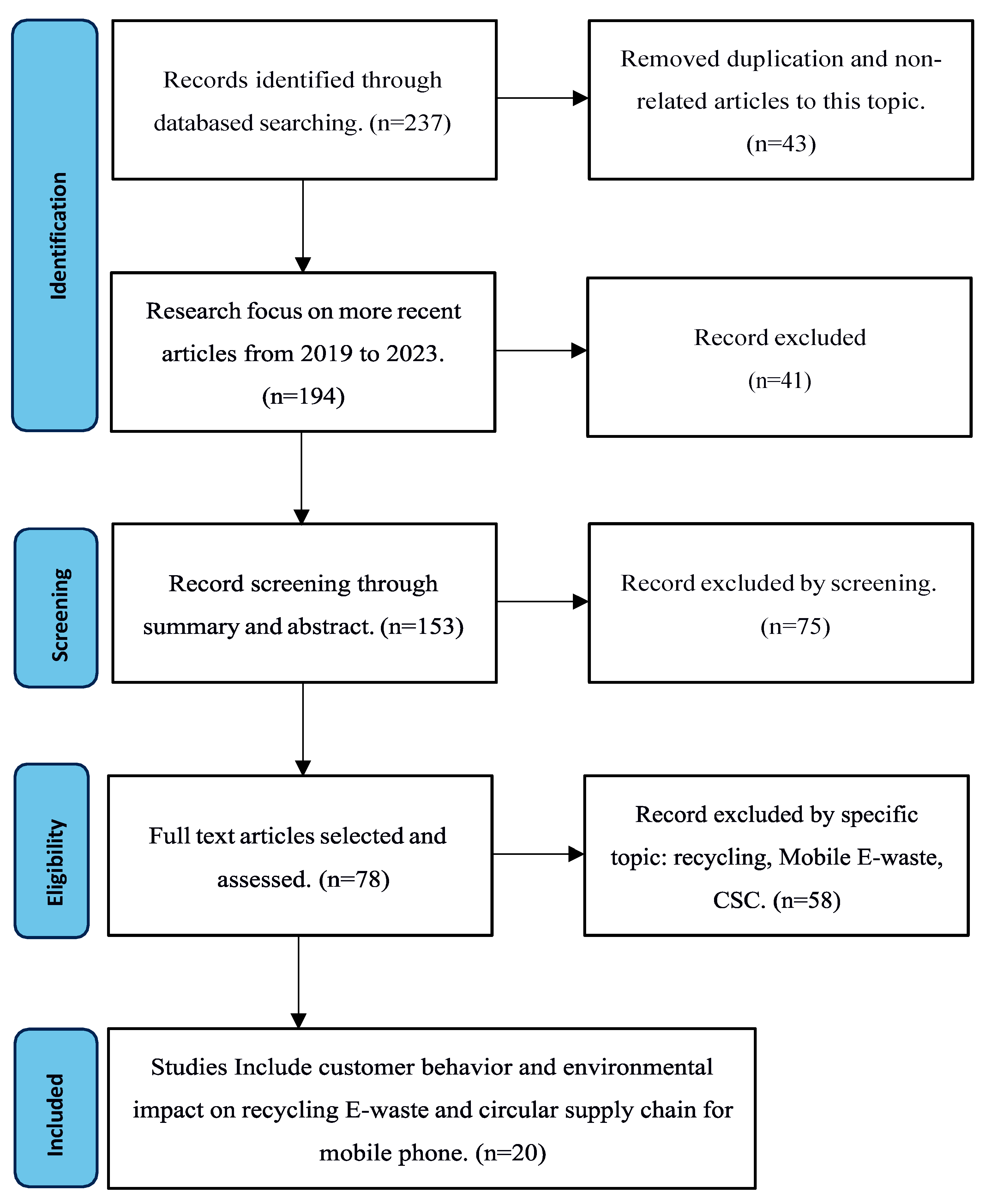

The literature review is an essential tool for methodically identifying and arranging major issues, providing relevant answers to research questions, and giving a thorough summary of issues. This review helps to find the best comprehensive quantitative method used to identify and evaluate the environmental impacts of materials found in e-waste, which is known as the Prisma technique [

14]. This method starts with the following three basic steps and then has subsets, which are described below along with

Figure 1.

3.1. Data Collection

The researchers employed a targeted search strategy using popular search engines and specific keywords related to their study objectives, such as “circular supply chain”, “e-waste”, and “mobile phones”. This search found 237 articles that were very similar to what the researchers were studying. After removing duplicates and articles not directly relevant to their study, the researchers refined their selection to 194 articles for initial screening.

3.2. Analysis

The researchers used a method called Prisma to organise and analyse the articles they found. They looked at articles published between 2019 and 2023 to make sure they were up to date. After reading summaries and abstracts, they narrowed down their selection to 78 articles. Then, they carefully read the full text of these articles and picked out 24 that were most important for their research.

3.3. Identification

Our exploration began with a targeted search on popular search engines, using keywords directly tied to our study goal. This effort yielded 237 articles closely aligned with our research focus. After a thorough cleanup process, which involved removing duplicates and articles unrelated to “Circular supply chain”, “E-waste”, and “Mobile phones”, we excluded 43 articles. This left us with a refined selection of 194 articles for the initial screening phase.

3.4. Screening

Our attention then turned to the temporal dimension of research, specifically focusing on articles published between 2019 and 2023. This intentional timeframe aimed at capturing the most recent developments in the field, resulting in a subset of 153 articles. Simultaneously, we excluded 75 articles that delved into data predating 2019, ensuring a contemporary lens for our study.

3.5. Eligibility

A comprehensive survey of article summaries and abstracts followed, leading to the exclusion of 75 papers whose study goals did not align with the objectives of our research. This process left us with a refined set of 78 articles, identified for detailed assessment in terms of introductions and full-text reviews.

3.6. Inclusion

After a meticulous evaluation of the full text, 24 articles emerged as particularly relevant to our research endeavour. These selected articles establish meaningful connections between studies on human behaviour and the environmental effect of recycling E-waste, especially within the context of a circular supply chain for mobile phones. This subset of 24 articles serves as a crucial foundation for our comprehensive exploration of the subject matter, providing valuable insights into the interplay of human actions and environmental sustainability.

We utilised this method to find the results from the different kinds of literature and obtained the gap. According to this, we proceeded further. This can aid us in getting insight into which topic there is a gap in research, so this study focuses on that and finds the solution accordingly.

4. Results and Conclusions

Electronic waste, including laptops, mobile phones, household items, speakers, and televisions, totals around 40 million tonnes annually globally. Mobile phones contribute significantly, with users replacing them every 18 months. Unfortunately, only 12.5% of this electronic waste is recycled, while a substantial 85% ends up in landfills or is incinerated, releasing harmful gases. Common components like LED screens, batteries, and PCBs contain hazardous materials like lead and mercury, posing health risks to the central nervous system and kidneys.

The widespread implementation of Circular Supply Chain Management (CSCM) in the electronics industry has enormous potential to reduce electronic waste and address its environmental impact on a global scale. Through CSCM, companies can efficiently recycle valuable materials such as gold, silver, copper, and mercury from old mobile phones and laptops. This reduces the need for new resources and lowers production costs. By adopting CSCM, companies not only promote environmental sustainability by diverting materials from landfills and reducing harmful emissions but also contribute to a circular economy by encouraging resource reuse and creating job opportunities. Additionally, CSCM can bring significant financial benefits to companies by improving supply chain sustainability, cutting import expenses, and boosting overall profitability. In summary, embracing CSCM in the electronics sector could transform e-waste management, mitigate environmental risks, and benefit both companies and communities worldwide.

Companies need a defined framework in order to implement a circular supply chain for mobile phones. The following is a detailed instruction manual that they can first evaluate and interpret: analyse waste volume and type and identify waste sources by evaluating the current supply chain. Second, they should establish specific goals: establish clear objectives for the reduction, reuse, and recycling of e-waste. Thirdly, they ought to concentrate on engaging suppliers: assist suppliers in using eco-friendly materials and creating designs that are simple to disassemble. Following that, they must design for sustainability: pay attention to principles of durable, repairable, and recyclable design. Reverse logistics: provide a mechanism for gathering discarded phones from clients while providing rewards for recycling. Recycling of e-waste: collaborate with reliable recyclers to appropriately get rid of and salvage materials. Data security: put procedures and instruments in place to safeguard private data while it is being recycled. Openness and reporting: preserve openness by recording and disclosing recycling percentages. Continuous improvement: keep an eye on performance and adjust as needed on a regular basis. Cooperation and initiatives: take part in sector-wide initiatives to tackle e-waste and exchange best practices for a more environmentally friendly sector. By using this framework, businesses can effectively promote a greener supply chain and reduce e-waste from mobile phones.

Implementing a CSCM allows companies to recycle these materials, reducing landfill and toxic gas emissions and mitigating environmental hazards. Recycling fosters employment, contributing to a circular economy and creating a win-win scenario for companies and communities. For instance, from mobile phone PCBs, a company can annually recycle substantial amounts of copper (189.1 ± 11.6 tonnes), valued at around USD 1.13 million. This strategic approach minimises material scarcity, reduces import costs, enhances supply chain sustainability, and elevates overall company profit margins while addressing environmental concerns. This can create win-win conditions for the company and the environment.

In the future, there should be work conducted on making recycling methods better for dangerous materials in mobile phones to make them more eco-friendly. This might mean finding new ways to extract and reuse valuable metals like gold, silver, and copper more easily. Also, it could involve looking into safer ways to deal with harmful materials such as mercury and lithium, which are very dangerous materials. Another idea is to explore creating safer options to use instead of these risky components when making mobile phones. By focusing on these areas, future research can help improve how mobile phones are recycled and lessen their harm to the environment.