Development of Filler-Reinforced Sustainable Polymeric Composites for the Implementation of Green Technology in Building Construction †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Characterization Techniques

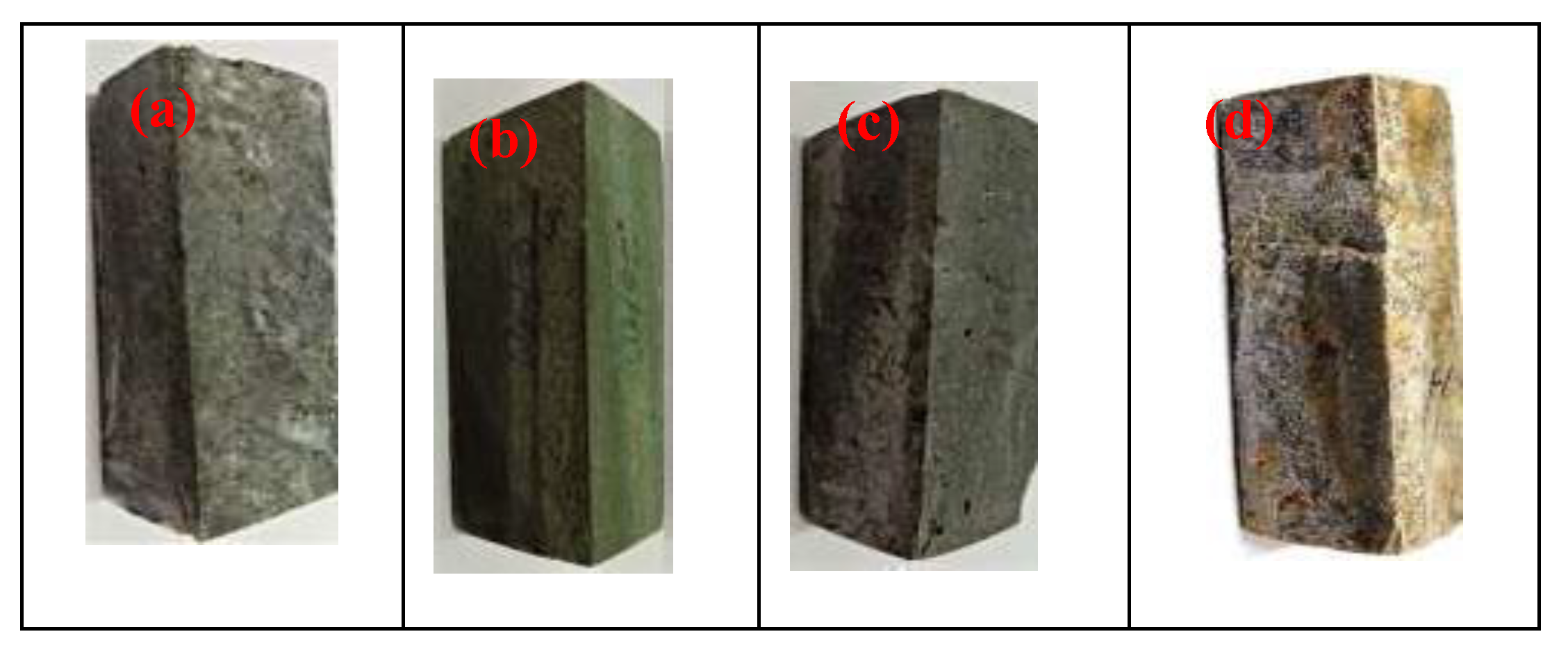

3. Results and Discussions

4. Conclusions and Future Scope

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dezaki, L.; Mohammadreza; Bodaghi, M. A review of recent manufacturing technologies for sustainable soft actuators. Int. J. Precis. Eng. Manuf.–Green Technol. 2023, 10, 1661–1710. [Google Scholar] [CrossRef]

- Manral, A.; Agarwal, A.P.; Ahmad, F.; Das, P.P.; Sharma, B.; Chaudhary, V. Experimental investigation of tribology, interfacial temperature, surface roughness, and morphological analysis of bio-composites. Biomass Convers. Biorefinery 2023, 14, 21783–21793. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Mami, O.; Adewumi, J.R. Utilisation of treated rice straw waste fibre as reinforcement in gypsum–cement unfired clay bricks. Innov. Infrastruct. Solut. 2022, 7, 308. [Google Scholar] [CrossRef]

- Singh, T.; Pattnaik, P.; Shekhawat, D.; Ranakoti, L.; Lendvai, L. Waste marble dust-filled sustainable polymer composite selection using a multi-criteria decision-making technique. Arab. J. Chem. 2023, 16, 104695. [Google Scholar] [CrossRef]

- Sahani, K.; Joshi, B.R.; Khatri, K.; Magar, A.T.; Chapagain, S.; Karmacharya, N. Mechanical properties of plastic sand brick containing plastic waste. Adv. Civ. Eng. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Mani, S.; Singh, S. Sustainable municipal solid waste management in India: A policy agenda. Procedia Environ. Sci. 2016, 35, 150–157. [Google Scholar] [CrossRef]

- Owen, M.M.; Achukwu, E.O.; Romli, A.Z.; Abdullah, A.H.B.; Ramlee, M.H.; Shuib, S.B. Thermal and mechanical characterization of composite materials from industrial plastic wastes and recycled nylon fibers for floor paving tiles application. Waste Manag. 2023, 166, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Prithivirajan, R.; Jayabal, S.; Sundaram, S.K.; Sangeetha, V. Hybrid biocomposites from agricultural residues: Mechanical, water absorption and tribological behaviors. J. Polym. Eng. 2016, 36, 663–671. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, R.; Tak, Y.; Meena, R.K.; Sharma, N.; Kumar, A. Parametric optimization and ranking analysis of hybrid epoxy polymer composites based on mechanical, thermo-mechanical and abrasive wear performance. High Perform. Polym. 2021, 33, 361–382. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Development of sand-plastic composites as floor tiles using silica sand and recycled thermoplastics—A sustainable approach for cleaner production. Sci. Rep. 2022, 12, 18921. [Google Scholar] [CrossRef] [PubMed]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K.-T. An overview of mechanical properties and durability of glass-fibre reinforced recycled mixed plastic waste composites. Mater. Des. 2014, 62, 98–112. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Gnanavelbabu, A.; Prabhuraj, B.L. A sustainable assessment model for material selection in construction industries perspective using hybrid MCDM approaches. J. Adv. Manag. Res. 2019, 16, 234–259. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-criteria evaluation model for the selection of sustainable materials for building projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Tribological properties of nanoclay-infused banana fiber reinforced epoxy composites. J. Tribol. 2019, 141, 052003. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Gupta, S.K. Experimental investigations on the influence of natural reinforcements on tribological performance of sustainable nanocomposites: A comparative study with polymer technology. Tribol. Int. 2023, 191, 109195. [Google Scholar] [CrossRef]

- Raghuram, H.; Roitner, J.; Jones, M.P.; Archodoulaki, V.-M. Recycling of polyethylene: Tribology assessment. Resour. Conserv. Recycl. 2023, 192, 106925. [Google Scholar] [CrossRef]

- Ventura, A.M.; Kneissl, L.M.; Nunes, S.; Emami, N. Recycled carbon fibers as an alternative reinforcement in UHMWPE composite. Circ. Econ. Within Polym. Tribol. Sustain. Mater. Technol. 2022, 34, e00510. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- ASTM D-3171-15; Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2011.

| Type of Plastics | Property | ||||

|---|---|---|---|---|---|

| Tensile Strength | Specific Gravity | Hardness in DUROMETER | Min. Heat Deflection Temperature | Flexural Modulus of Elasticity | |

| HDPE | 5000 MPa | 0.98 | D 69 | 181 °C | 200,000 MPa |

| LDPE | 1500 MPa | 0.96 | D 55 | 131 °C | 3000 MPa |

| PET | 12,400 MPa | 1.49 | D 87 | 249 °C | 40,000 MPa |

| PP | 6300 MPa | 0.93 | D 75 | 209 °C | 225,000 MPa |

| Chemical Composition | Physical Property | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | LoI | Mean Particle Size | Specific Gravity | Surface Area |

| 87.30% | 0.84% | 0.73% | 1.40% | 0.57% | 1.12% | 3.68% | 8.55% | 6.27 µm | 2.08 g/cm3 | 36.47 m2/g |

| S. No. | Sample Designation | LDPE | HDPE | PP | PET | RHA | Sand |

|---|---|---|---|---|---|---|---|

| 1 | LD70R15S15 | 70 | - | - | - | 15 | 15 |

| 2 | HD70R15S15 | - | 70 | - | - | 15 | 15 |

| 3 | PP70R15S15 | - | - | 70 | - | 15 | 15 |

| 4 | PET70R15S15 | - | - | - | 70 | 15 | 15 |

| S. No. | Sample | Density (g/m3) | Wa (%) | Cs (MPa) | Fs (MPa) | Abrasive Wear (cm3) |

|---|---|---|---|---|---|---|

| 1 | LD70R15S15 | 1.07051 | 0.684 | 7.5015 | 1.072 | 0.04670 |

| 2 | HD70R15S15 | 1.67632 | 0.397 | 8.5327 | 1.684 | 0.17896 |

| 3 | PP70R15S15 | 1.33893 | 0.523 | 24.7933 | 5.96 | 0.07468 |

| 4 | PET70R15S15 | 1.6151 | 0.199 | 20.81 | 4.895 | 0.03095 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soni, A.; Das, P.K.; Gupta, S.K.; Alam, M.A.; Yusuf, M.; Ibrahim, H. Development of Filler-Reinforced Sustainable Polymeric Composites for the Implementation of Green Technology in Building Construction. Eng. Proc. 2024, 76, 109. https://doi.org/10.3390/engproc2024076109

Soni A, Das PK, Gupta SK, Alam MA, Yusuf M, Ibrahim H. Development of Filler-Reinforced Sustainable Polymeric Composites for the Implementation of Green Technology in Building Construction. Engineering Proceedings. 2024; 76(1):109. https://doi.org/10.3390/engproc2024076109

Chicago/Turabian StyleSoni, Ashish, Pankaj Kumar Das, Sonu Kumar Gupta, Mohammad Azad Alam, Mohammad Yusuf, and Hussameldin Ibrahim. 2024. "Development of Filler-Reinforced Sustainable Polymeric Composites for the Implementation of Green Technology in Building Construction" Engineering Proceedings 76, no. 1: 109. https://doi.org/10.3390/engproc2024076109

APA StyleSoni, A., Das, P. K., Gupta, S. K., Alam, M. A., Yusuf, M., & Ibrahim, H. (2024). Development of Filler-Reinforced Sustainable Polymeric Composites for the Implementation of Green Technology in Building Construction. Engineering Proceedings, 76(1), 109. https://doi.org/10.3390/engproc2024076109