Abstract

Artificial intelligence (AI) is a branch of computer science that deals with the adoption of human behavioral elements in computer-based systems. Some of these systems support learning, understanding, making inferences, and adaptability. In recent years, artificial intelligence has brought a rapid technological revolution to many different sectors of industry. It is a tool that can greatly influence the different stages of the design process. In this particular study, the goal was to integrate AI into the design process of a product, and more specifically of a soccer shoe, using additive manufacturing technology as a prototyping method. Different stages to be followed during the design of a product include mind mapping, digital sketches, Computer-Aided Design (CAD), rendering, and prototyping, both digital and physical. By integrating AI tools into the traditional design process, designers can enhance the outcomes of their final products through the use of automation and control systems based on a holistic approach to industrial design. This paper introduces a distinct and innovative design framework that combines the benefits of AI digital applications with the expertise of the designer. The proposed design methodology will be used to create a prototype of the designed soccer shoe using rapid prototyping tools for user feedback on its form. The conclusions of the study are that AI is a tool that can be integrated into the design process of a product, improving it, while at the same time supporting the designers’ creativity and innovation.

1. Introduction

Product design methodology is defined as the steps followed by a designer or design team to produce a new product. These steps start from the initial conception of the idea to a solution to a basic problem, which is the goal of every product. The steps that make up this methodology can be changed both in terms of type and number and in the order in which they will be performed. In the initial stages, general information about the product as well as how to use it is defined. Aesthetics and ergonomics begin to be defined from these stages and continue until the end of the process [1]. The correct management and performance of the initial stages play an important role as we save time and resources, as well as receive improved solutions without restarting the process. In the next stages of the process, the design is carried out using a CAD (Computer-Aided Design) system. The design site changes depending on the product requirements. For example, in many cases, programming (computational design) is needed with an aim to design the geometry [2]. One of the key factors for which methodology changes and adapts is the context in which it will be used. For instance, a recent trend is to incorporate sustainability into product design. In this case, the entire methodology will change as many new stages will be added. Reviewing the literature, we can find many available methodologies that may differ, even within the same field [3]. In recent years, the development of artificial intelligence (AI) has been used, among other things, in the field of product design. Some of the factors driving the use of AI are the increased reduction of time needed and the development of many different solutions. Many studies test AI tools to document their advantages and disadvantages [4]. AI tools combined with new design techniques are coming to completely change the way we develop and design a product [5,6]. Collecting big data is a problem we encounter in product design. In most cases, there is a need for research in order to answer multiple questions about a product or service. Using AI tools, we can reach important conclusions in a short period of time and integrate them into the design process in order to solve them with the design of the new product [7,8]. Both the advantages and disadvantages of creating AI-derived images with the aim of integrating them into product design in Industry 4.0 are extensively reported in new studies [9]. As far as artistic design is concerned, AI adaptation tests have already been carried out within the design process, from which it has emerged that the structural information is preserved and the 3D visualization of the design is improved [10]. AI can also be utilized to enhance design optimization. It has been observed that the use of genetic algorithms in combination with Convolutional Neural Networks (CNNs) can significantly improve the quality of solutions [11]. In research carried out recently, it was discussed whether AI tools have the potential to replace the designer in the design process. More specifically, 15 designs of the same product were created using a tool that converts a text description into an image. The plans were then evaluated by groups of students participating in the study. The students evaluated the results with positive comments while expressing their concern about how easily the entire design process could be performed without human assistance [12,13]. A corresponding study created a framework that aims to use AI in product design with a key focus on the customer of the product. As part of the study, three different products were created. In the end, an evaluation of the created framework was performed [14]. Finally, the field of product design education is an area that can be greatly improved by incorporating AI [15,16]. The current paper presents the integration of AI tools into a product design methodology. More specifically, two AI tools are used, which can convert text to an image and an image to a 3D model. As part of this study, a case study was carried out on the design of soccer shoes. Finally, the process was evaluated and a prototype product was created using 3D printing.

2. Methods

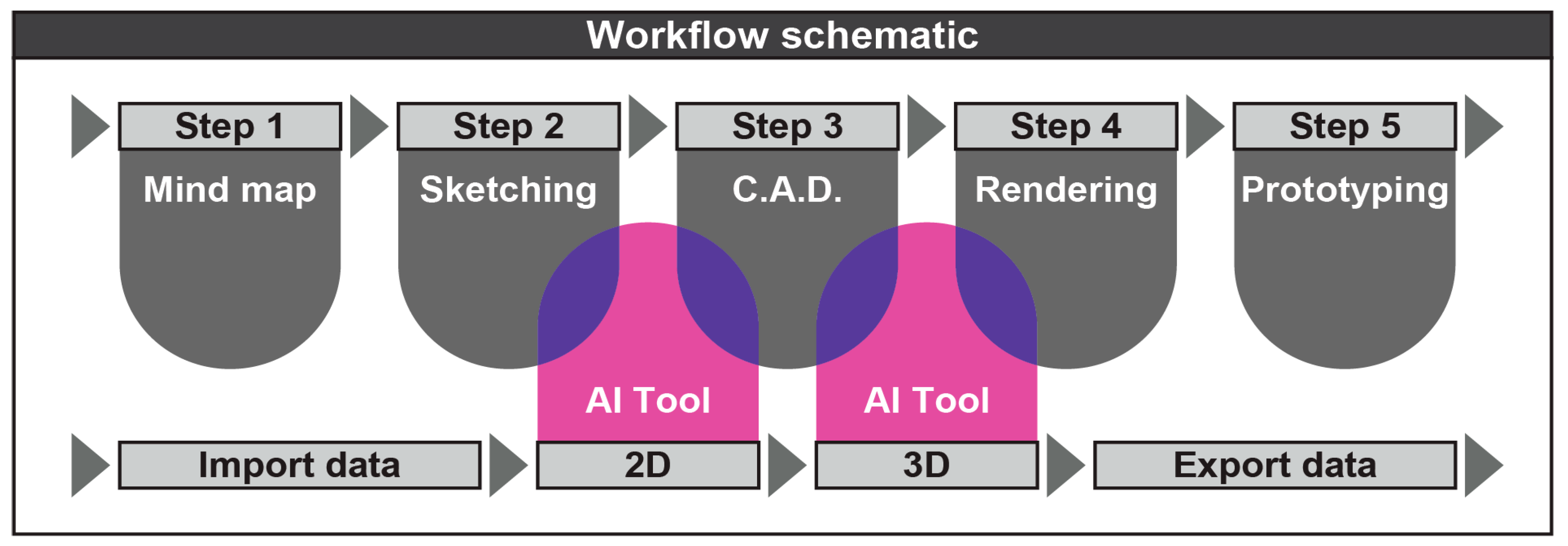

Product design is a process based on a methodology. The specific methodology consists of a number of steps, which can often be differentiated both in their type and in their order. In this particular study, the following steps were used: (a) a mind map, (b) digital sketches, (c) CAD, (d) rendering, and (e) prototyping. The main goal was to integrate AI tools into the methodology. Some of the benefits of AI tools are the speed of creation, adaptability to various styles/effects, and in many cases the verisimilitude of the end result. On the other hand, some of the limitations of using AI tools are the limited capabilities of free plans, the difficulty of integrating human assistance into the process, and in many cases the high cost. In this study, two AI tools were used. The first tool is called Fusion BrainTM, which has the ability to create an image through the description given by the user. The second tool is called CSMTM (Common Sense Machines), which enables the creation of 3D files by using an image. Alternative applications of the two AI tools are CraiyonTM, Krita AI DiffusionTM, and Stable Diffusion OnlineTM for creating images, and MeshyTM, 3D AI StudioTM, and Alpha3DTM for creating 3D geometries. Fusion BrainTM is free and gives an unlimited number of trials. Accordingly, CSMTM in its free version has features such as growth/texture export and rendering. Fusion BrainTM and CSMTM are integrated into the product design methodology between steps (b) digital sketches, (c) CAD, and (d) rendering. Each tool is used with the aim of assisting and not completely replacing human intervention in each step of the methodology. For this reason, as shown in Figure 1, the two AI tools do not replace the human steps but are inserted in between them, as shown by the purple color. At the same time, the blue colored areas symbolize that the AI tools will replace only some parts of the steps.

Figure 1.

Description of the entire process.

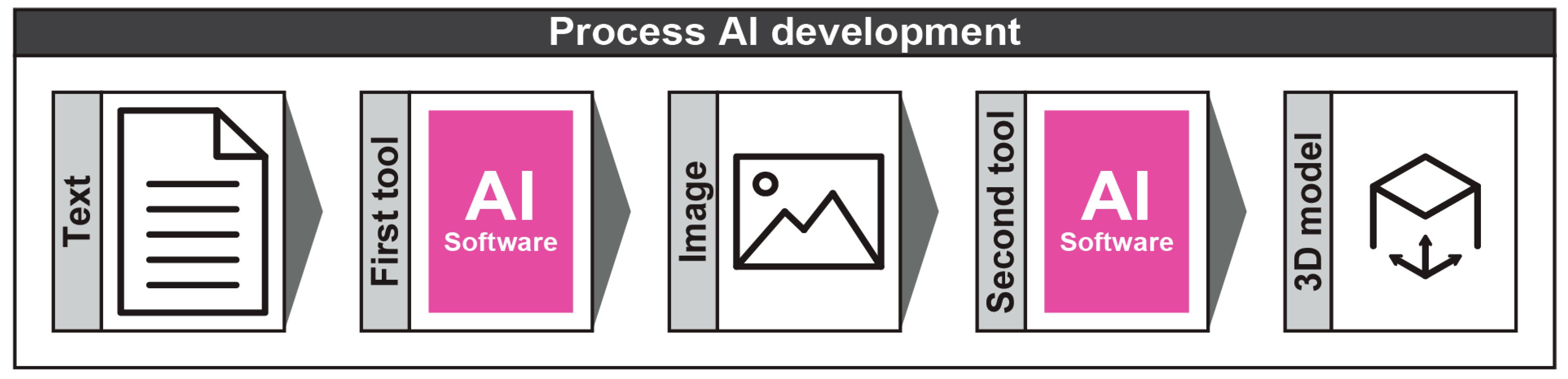

The present study began with the creation of a mind map. Through the mind map, basic characteristics, properties, techniques, details, and, in general, a record of both the problem we want to solve and its basic solutions are defined mainly in text form. In this particular case, the aim is to design and manufacture, in prototype form, a pair of soccer shoes; therefore, data are recorded about this product. Then, using digital two-dimensional design software, sketches are created that depict the various details of the product. The creation of the sketches is based on the information on the mind map without blindly following it. In the next step, the first AI tool (2D) is used. In this tool, text is entered with the aim of developing an image of the product. In the text, there is a detailed description of the mind map and the sketches. The resulting image is fed into the second AI tool (3D). With the second tool, the initial three-dimensional form of the product is created with the properties of the colors. In the next step, the 3D model is modified in order to promote the creation of improved photorealistic images. The results of the first AI tool can help to define the colors and various other details for the presentation of the final photorealistic model. Finally, a prototype geometry is created using a 3D printer and painted accordingly. Figure 2 shows how and in which order the two AI tools are used.

Figure 2.

The stages of implementing AI tools.

2.1. First AI Tool (2D)

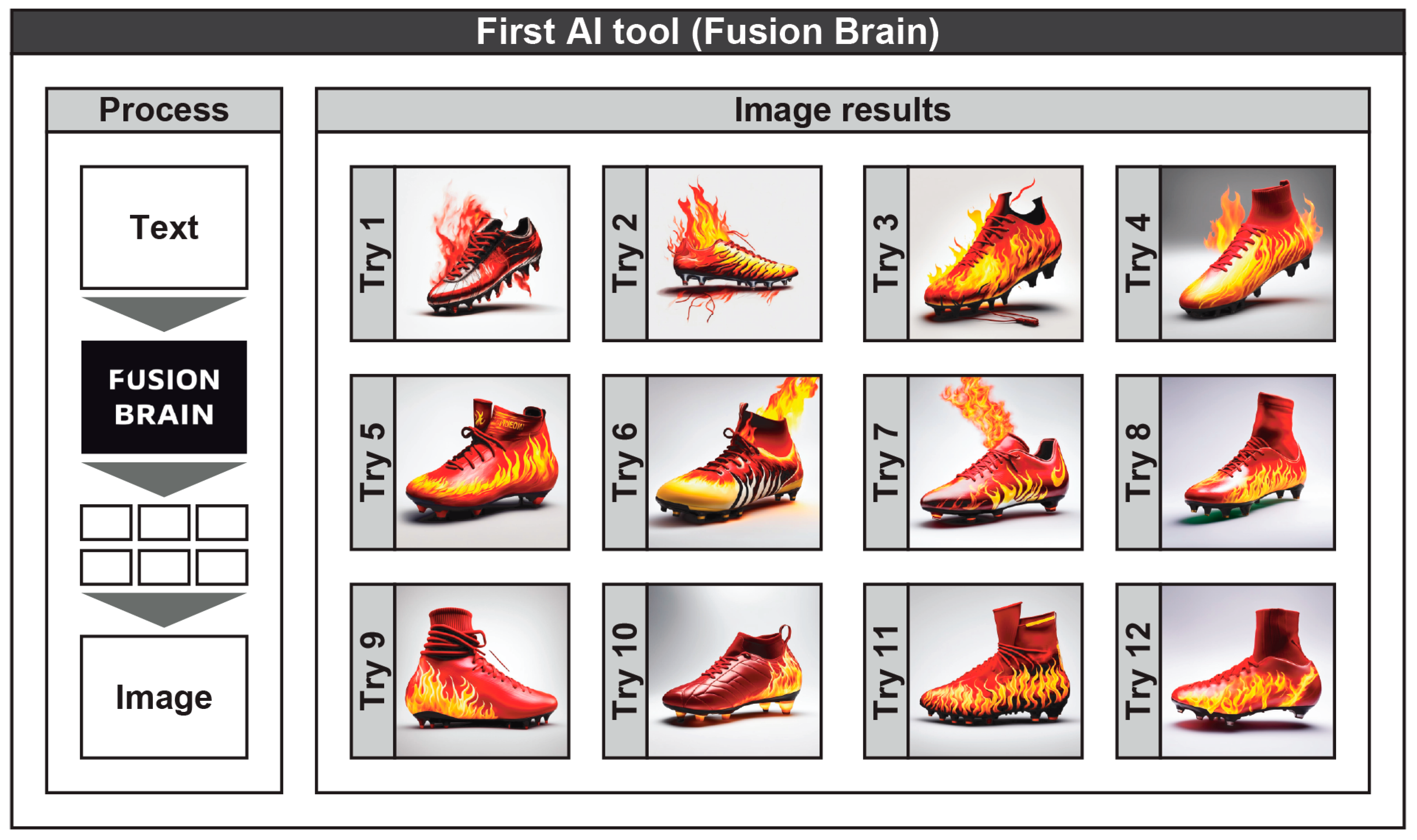

Fusion BrainTM is an AI tool based on the Kandinsky model. Kandinsky is an AI model used to create realistic images with respect to textual descriptions. To produce an image from Fusion BrainTM, the following steps must be performed: (a) define the image parameters (style, color, and size), (b) provide a description of the content of the image, (c) define the image format (JPEG or PNG), (d) execute the process, (e) check the results, and finally, (f) save the image. At this point in the study, a basic description was made according to the results of the mind map and the sketches. In this description, many changes were made in order to create the best result according to our preferences. Figure 3 depicts twelve attempts after minor changes to the original text. From the results, we can observe that after all of the changes in the text, the final images produced show an improvement compared to the initial ones.

Figure 3.

The trials and results of the images in Fusion BrainTM.

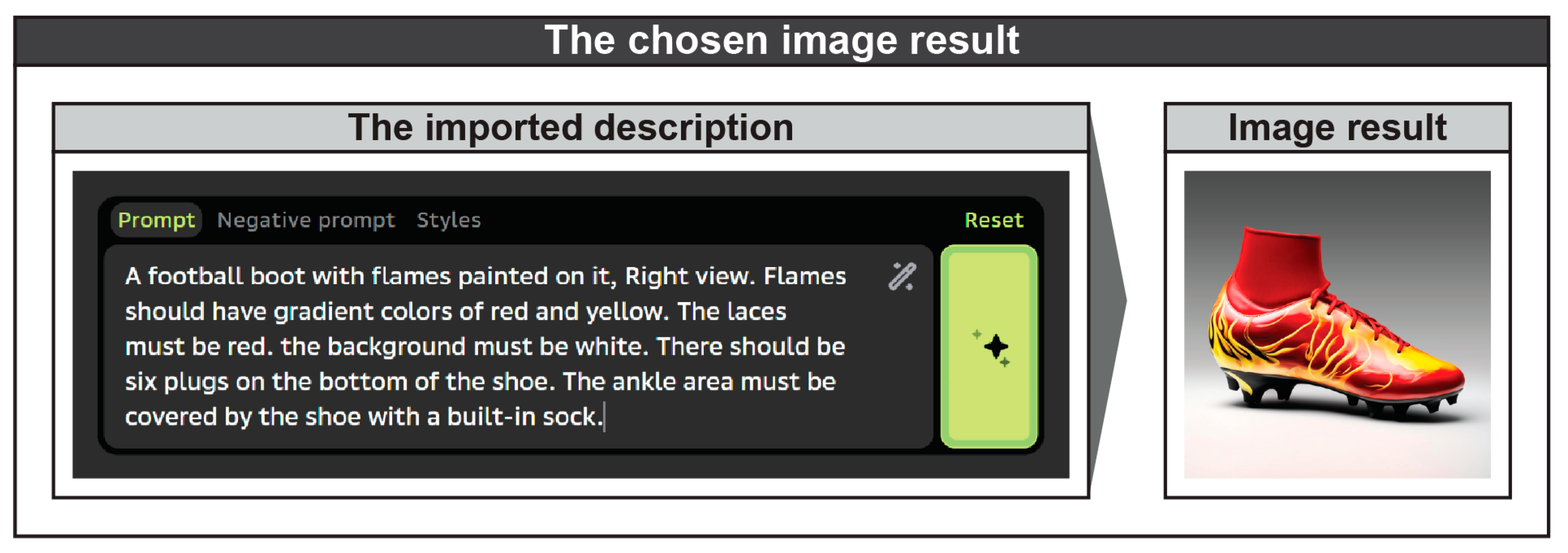

Having created a description that produces results very close to our initial goal, we can continue to the next stage of the methodology. It is important to mention that the results of the AI tool were better controlled when the description contained short sentences with specific information. By providing more general information, the AI tool could create better and more impressive results but these did not match the original goal of the methodology. The final text of the description and the resulting image produced are shown below in Figure 4.

Figure 4.

The final text description used and the final 2D result.

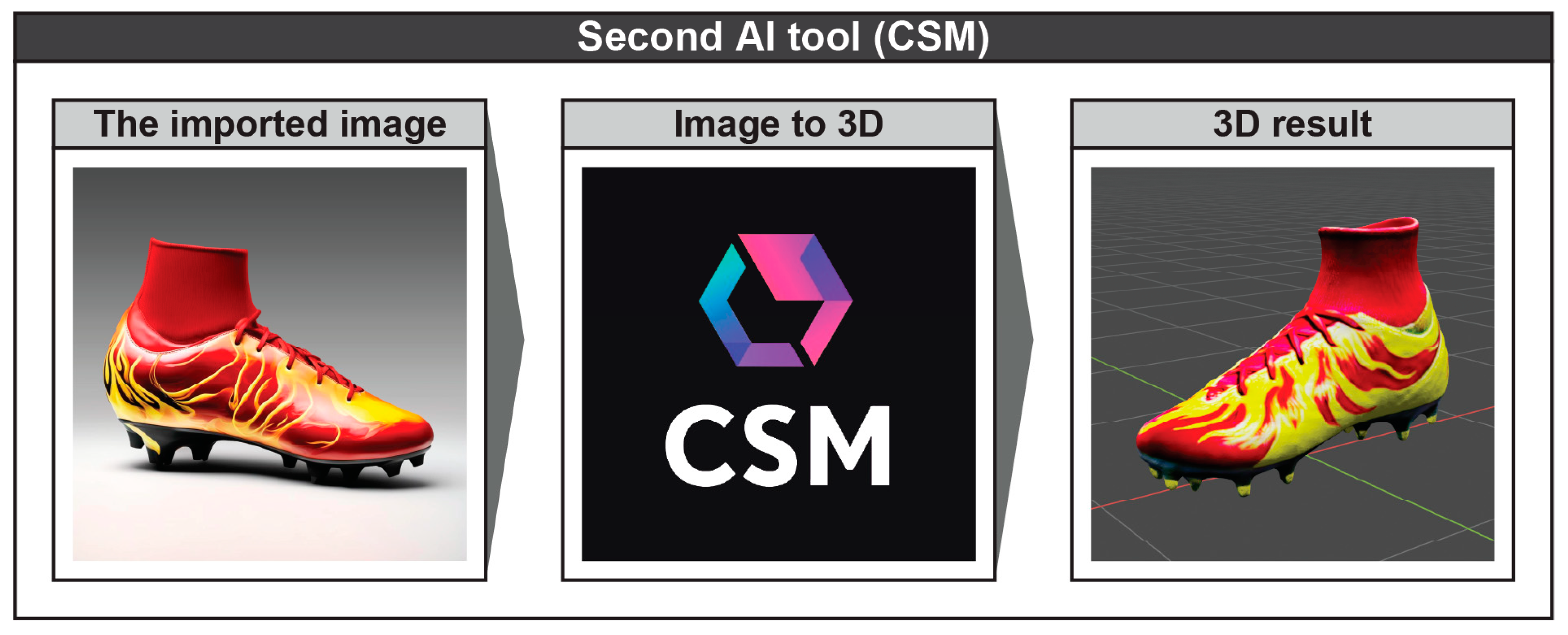

2.2. Second AI Tool (3D)

CSMTM (Common Sense Machines) is an AI tool that uses neural inverse graphics in combination with other techniques with an aim to create three-dimensional geometries. Some of the features of CSMTM are Video to 3D, Image to 3D, and Text to 3D conversions. In this study, Image to 3D conversion was used, in which we used the image produced by the first AI tool. To produce a 3D geometry from CSMTM, the following steps must be performed: (a) reference image import, (b) definition of basic mesh options, (c) mesh generation, (d) geometry adjustment, e.g., dimensions, (e) final corrections, and (f) 3D model export. When the CSMTM received the image data, it created in a short time a three-dimensional mesh geometry. At the same time, the color of the geometry according to the input image information was used. It is important to mention that the texture of the 3D model did not accurately follow the colors and shapes of the imported image. Instead, the result reveals that the AI tool improvised in the way it created the texture. Figure 5 shows the input image produced by the first AI tool (2D) and the result produced by using the second AI tool (3D).

Figure 5.

The results from image conversion to 3D geometry.

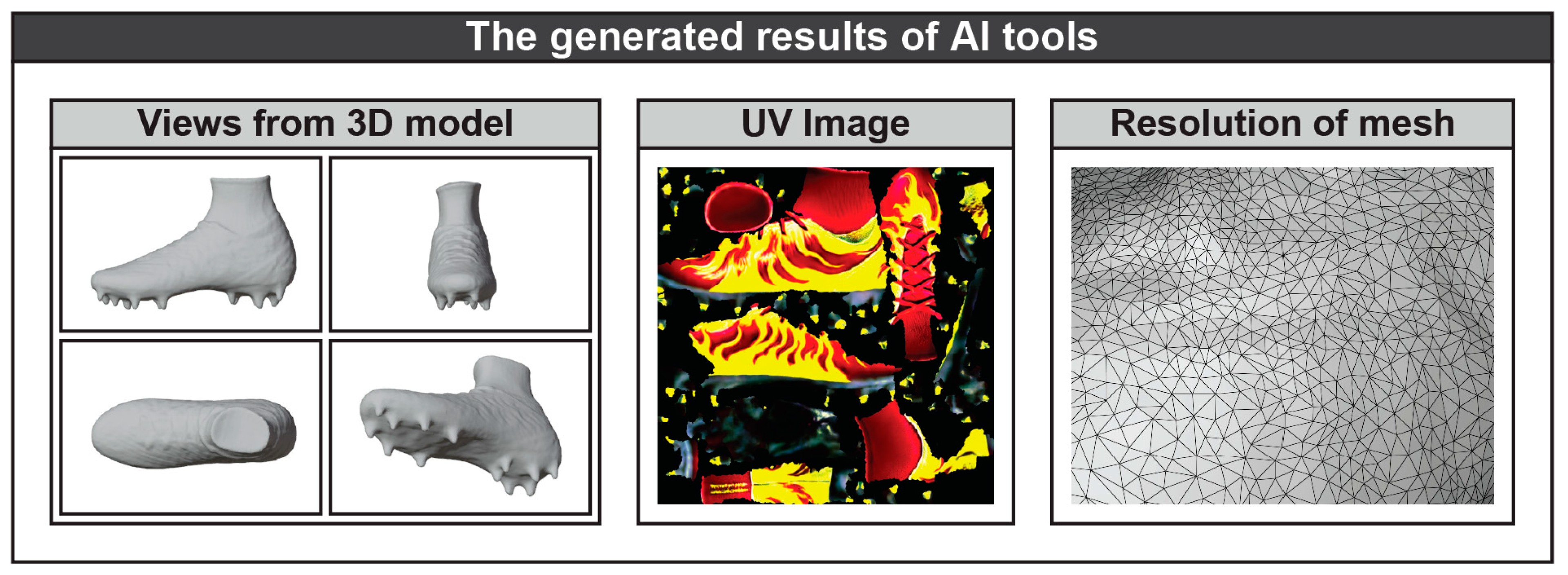

The 3D geometry produced by the second AI tool (3D) was created in “.obj” format, i.e., mesh format. This particular format can be edited using most 3D design software, which makes it very useful. From the views of the 3D model that was produced, we notice that several details were created even in areas that were not visible in the original image. Regarding the quality of the result, as can be seen from the images, it is rather high. Even when we turn off the texture display, the geometry has detailed geometry information on it. The grid density is adequate, showing all of the details without making the file too large. More specifically, the generated result contains 50,000 triangles and 150,000 vertices. Finally, the deployment was created as a “.png” format image with a resolution of 2048 × 2048 pixels. 3D model, UV image and mesh are presented in Figure 6.

Figure 6.

The details of the 3D geometry.

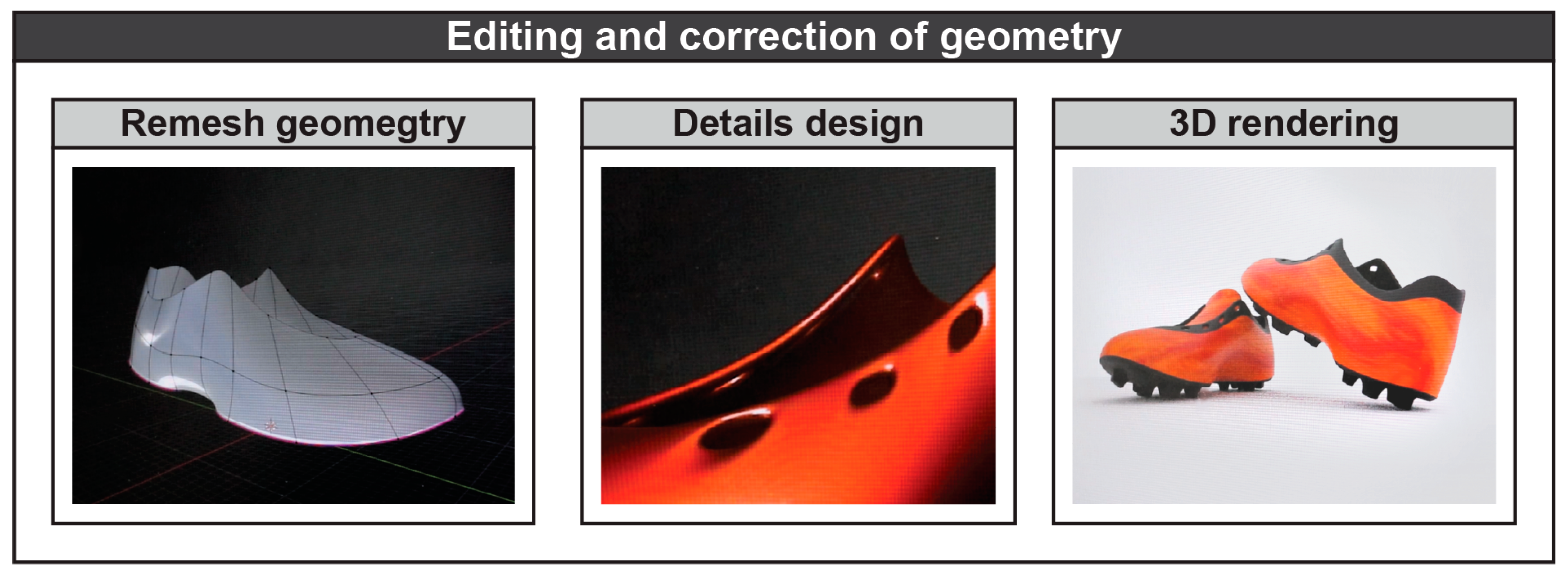

BlenderTM version 3.1.2 is a software that provides multiple features for 3D design, photorealism, animation, video editing, and more. Three-dimensional design and the photorealism of the geometry are the reasons why BlenderTM was used in this study. The 3D output produced by the second AI tool needs to be processed and edited so that the design methodology can be completed with 3D printing and prototyping. Some of the main processing difficulties were managing the polygons generated by AI. The randomness of the polygons caused the unorganized distribution of points, edges, and surfaces. More specifically, changes were made mainly to the structure of the grid to make it easier to receive and support design modifications. The new mesh following an organized distribution wrapped the AI-generated geometry. A basic geometry problem is the lack of internal shoe morphology. At this stage, the design tweaks were completed and the texture was redesigned. Based on the new texture, photo-realism was performed, which has influences from the results of the first AI tool. The modifications to the geometry, the final digital result, and the photorealism are presented in Figure 7.

Figure 7.

Using BlenderTM version 3.1.2 software to modify and prepare the geometry.

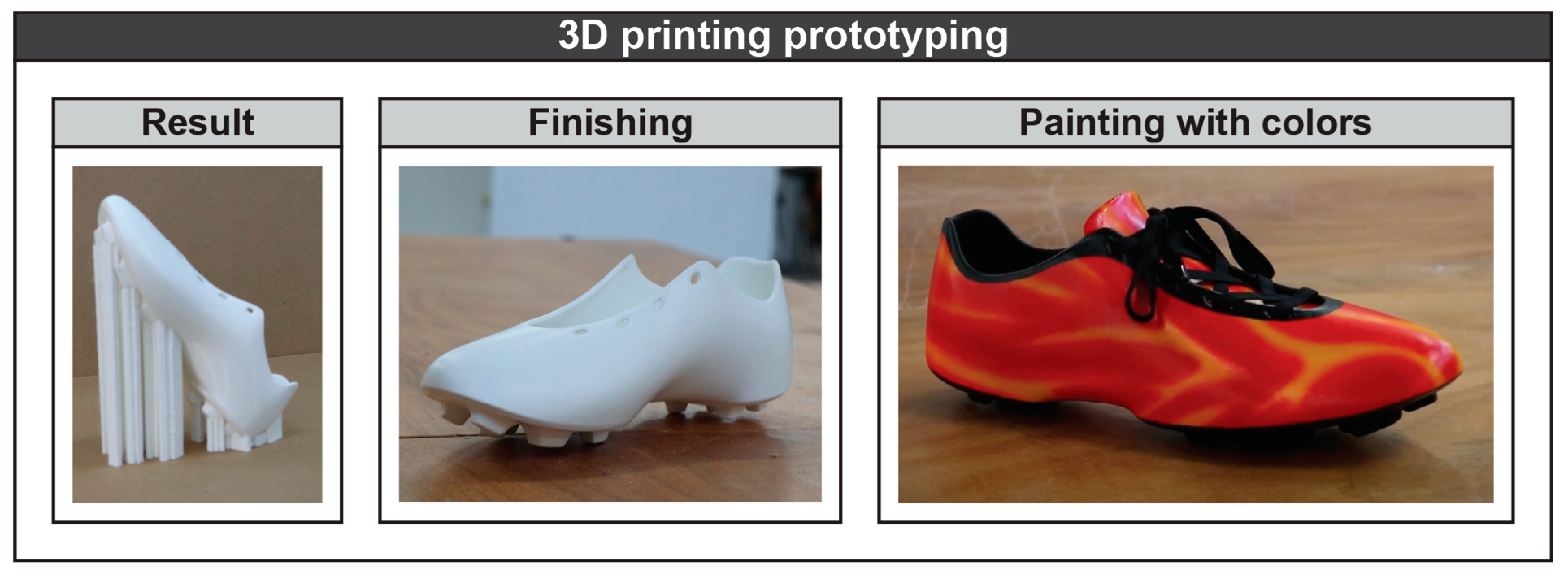

In the final stage of the study, a prototype of the soccer shoe was manufactured. Of note, 3D printing was chosen as the manufacturing method. More specifically, a CreatbotTM D600 Pro FDM (Henan Creatbot Technology Limited, Zhengzhou, China) category printer was used. PLA was chosen as the fabrication material due to its ease of use. After printing was completed, the prototype was painted using an airbrush. In this way, all of the necessary details were drawn on the geometry. Figure 8 shows images from the printing and dyeing stages as well as the final result of the study.

Figure 8.

The final 3D-printed prototype of the product.

3. Conclusions

AI has attracted enormous interest in many areas of our daily lives. Integrating AI into a large number of processes can provide multiple benefits. In this study, an approach to integrating AI into product design methodology is presented. Traditional product design methodology consists of a number of steps that the designer can follow. The main steps of this methodology are mind maps, sketches, CAD, rendering, and prototyping. In this particular study, AI was integrated between the steps of sketches, CAD, and rendering. In detail, two AI tools were selected, which can produce images (2D) and 3D models with appropriate input information. Key differences between traditional design and incorporating AI tools are in (a) the design process steps, (b) large-scale creativity, and (c) reduced process time. The results of this study revealed that there was a time reduction of 59.09%, as a corresponding traditional design process takes about 22 h compared to AI integration, which takes about 9 h. The reduction in time correspondingly creates a reduction in design costs. The benefits of using artificial intelligence in the design process are mainly focused on reducing work time and increasing creativity, as it brings out many alternatives, automates procedural steps, and creates breakthrough ideas that can change the designer’s point of view. On the other hand, one of the main disadvantages of AI tools is the removal of the designer from their product as, in some places, a lack of control over the design was observed. It is clear that the integration of artificial intelligence into the product design process has evolved and improved many aspects throughout the process. It is very likely that in the future, new AI tools will eliminate current drawbacks as well as create new features and capabilities.

Author Contributions

Conceptualization, P.M. and P.K.; methodology, P.M.; software, P.M.; validation, P.M., N.E. and P.K.; formal analysis, P.M. and N.E.; investigation, P.M. and A.T.; resources, P.M. and N.E.; data curation, P.M., A.T. and N.E.; writing—original draft preparation, P.M., A.T., N.E. and P.K.; writing—review and editing, P.M., A.T., N.E. and P.K.; visualization, P.M., A.T. and P.K.; supervision, A.T. and P.K.; project administration, A.T. and P.K.; funding acquisition, P.M. and P.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Roberts, J.C.; Headleand, C.; Ritsos, P.D. Sketching Designs Using the Five Design-Sheet Methodology. IEEE Trans. Vis. Comput. Graph. 2015, 22, 419–428. [Google Scholar] [CrossRef]

- Kyratsis, P.; Manavis, A.; Gianniotis, P.; Ghiculescu, D. A Non-Conventional Methodology for Interior Product Design Using Conceptual Design Principles and Parametric Tools. Nonconv. Technol. Rev. 2019, 23, 16–22. [Google Scholar]

- Efkolidis, N.; Garcia-Hernadez, C.; Kyratsis, P. Design for Green Usability: A New User Centered Methodology for Product Development. Appl. Mech. Mater. 2015, 809, 1372–1377. [Google Scholar] [CrossRef]

- Manavis, A.; Efkolidis, N.; Kyratsis, P. Artificial Intelligence in Product Development. FORUM A+P Interdiscip. J. Archit. Built Environ. 2023, 22–25. [Google Scholar] [CrossRef]

- Kazi, R.H.; Grossman, T.; Cheong, H.; Hashemi, A.; Fitzmaurice, G. DreamSketch: Early Stage 3D Design Explorations with Sketching and Generative Design. In Proceedings of the UIST 2017, Quebec City, QC, Canada, 22–25 October 2017; pp. 401–414. [Google Scholar]

- Verganti, R.; Vendraminelli, L.; Iansiti, M. Innovation and Design in the Age of Artificial Intelligence. J. Prod. Innov. Manag. 2020, 37, 212–227. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Yüksel, N.; Börklü, H.R.; Sezer, H.K.; Canyurt, O.E. Review of Artificial Intelligence Applications in Engineering Design Perspective. Eng. Appl. Artif. Intell. 2023, 118, 105697. [Google Scholar] [CrossRef]

- Lemeš, S.; Keleštura, M.; Tabak, E.; Buzađija, N. Using Artificial Intelligence Image Generators in Product Design Within Industry 4.0. In Proceedings of the International Conference New Technologies, Development and Applications, Sarajevo, Bosnia and Herzegovina, 20–22 June 2024; pp. 485–492. [Google Scholar]

- Wang, T.; Wu, D. Computer-Aided Traditional Art Design Based on Artificial Intelligence and Human-Computer Interaction. Comput. Aided Des. Appl. 2024, 21, 59–73. [Google Scholar] [CrossRef]

- Han, S.; Sun, X. Optimizing Product Design using Genetic Algorithms and Artificial Intelligence Techniques. IEEE Access 2024, 99, 1. [Google Scholar] [CrossRef]

- Brisco, R.; Hay, L.; Dhami, S. Exploring the role of text-to-image AI in concept generation. Proc. Des. Soc. 2023, 3, 1835–1844. [Google Scholar] [CrossRef]

- Liu, V.; Vermeulen, J.; Fitzmaurice, G.; Matejka, J. 3DALL-E: Integrating text-to-image AI in 3D design workflows. In Proceedings of the 2023 ACM designing interactive systems conference, Pittsburgh, PA, USA, 10–14 July 2023; pp. 1955–1977. [Google Scholar]

- Nikalwala, D.; Patel, M.H. Enhancing Product Designing with the Help of Artificial Intelligence. In Proceedings of the 2024 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 4–8 August 2024; pp. 1–10. [Google Scholar]

- Vartiainen, H.; Tedre, M. Using Artificial Intelligence in Craft Education: Crafting with Text-to-Image Generative Models. Digit. Creat. 2023, 34, 1–21. [Google Scholar] [CrossRef]

- Chen, L.; Chen, P.; Lin, Z. Artificial Intelligence in Education: A Review. IEEE 2020, 8, 75264–75278. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).