Collaborative Augmented Digital Twin: A Novel Open-Source Augmented Reality Solution for Training and Maintenance Processes in the Shipyard of the Future †

Abstract

:1. Introduction

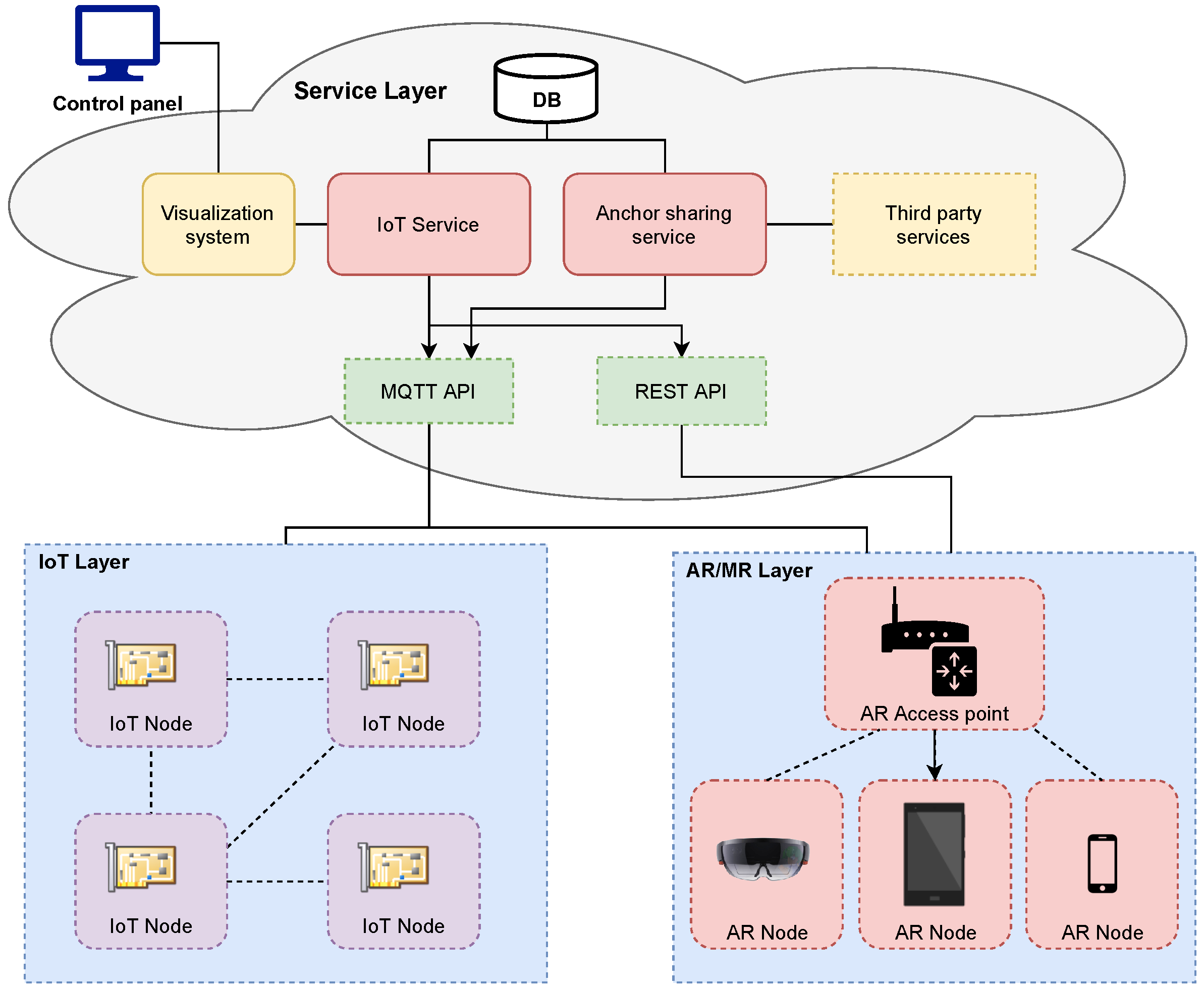

2. Design of the System

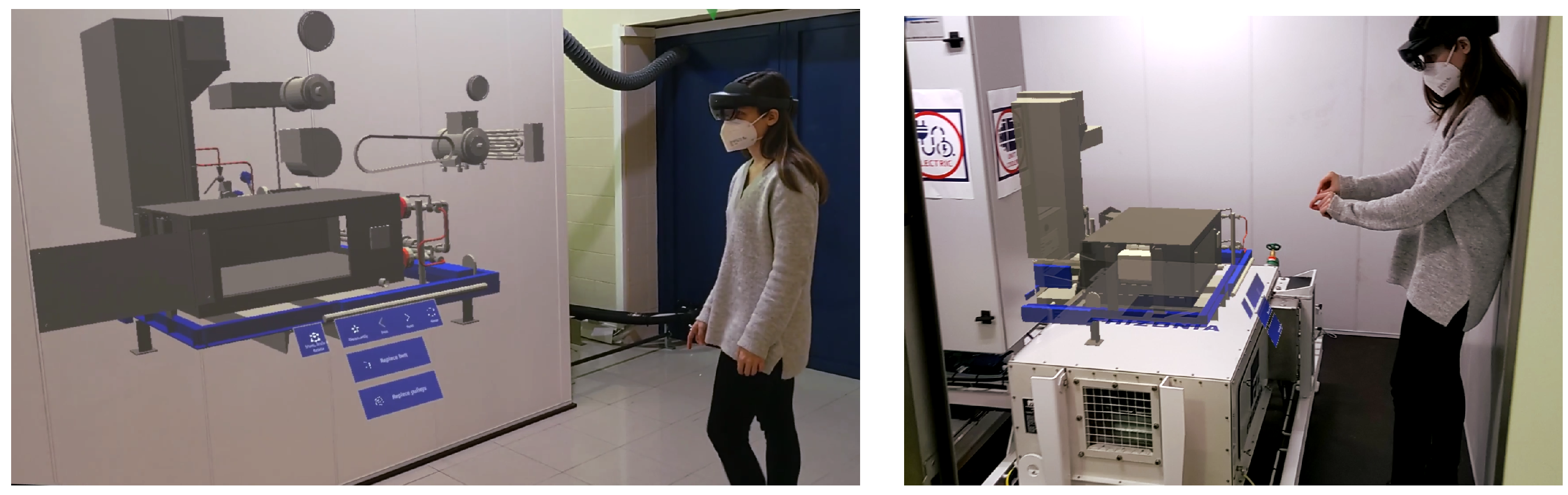

3. Experiments

4. Discussion

Funding

Conflicts of Interest

References

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Blanco-Novoa, O.; Vilar-Montesinos, M. A review on industrial augmented reality systems for the industry 4.0 shipyard. IEEE Access 2018, 6, 13358–13375. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J. DRAFT Modeling, Simulation, Information Technology & Processing Roadmap; Technology Area 11; NASA—National Aeronautics and Space Administration: Washington, DC, USA, 2010. [Google Scholar]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Microsoft HoloLens Official Web Page. Available online: https://www.microsoft.com/en-us/hololens (accessed on 31 July 2021).

- Unity 3D Development Platform Official Web Page. Available online: https://unity.com/ (accessed on 31 July 2021).

| Clients | Average | Standard Deviation | Variance |

|---|---|---|---|

| 5 | 24.0804 | 13.4883 | 0.25171 |

| 10 | 40.777 | 20.925 | 0.53113 |

| 15 | 61.4403 | 30.2245 | 1.02500 |

| 20 | 86.0936 | 38.2146 | 1.61572 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidal-Balea, A.; Blanco-Novoa, O.; Fraga-Lamas, P.; Vilar-Montesinos, M.; Fernández-Caramés, T.M. Collaborative Augmented Digital Twin: A Novel Open-Source Augmented Reality Solution for Training and Maintenance Processes in the Shipyard of the Future. Eng. Proc. 2021, 7, 10. https://doi.org/10.3390/engproc2021007010

Vidal-Balea A, Blanco-Novoa O, Fraga-Lamas P, Vilar-Montesinos M, Fernández-Caramés TM. Collaborative Augmented Digital Twin: A Novel Open-Source Augmented Reality Solution for Training and Maintenance Processes in the Shipyard of the Future. Engineering Proceedings. 2021; 7(1):10. https://doi.org/10.3390/engproc2021007010

Chicago/Turabian StyleVidal-Balea, Aida, Oscar Blanco-Novoa, Paula Fraga-Lamas, Miguel Vilar-Montesinos, and Tiago M. Fernández-Caramés. 2021. "Collaborative Augmented Digital Twin: A Novel Open-Source Augmented Reality Solution for Training and Maintenance Processes in the Shipyard of the Future" Engineering Proceedings 7, no. 1: 10. https://doi.org/10.3390/engproc2021007010

APA StyleVidal-Balea, A., Blanco-Novoa, O., Fraga-Lamas, P., Vilar-Montesinos, M., & Fernández-Caramés, T. M. (2021). Collaborative Augmented Digital Twin: A Novel Open-Source Augmented Reality Solution for Training and Maintenance Processes in the Shipyard of the Future. Engineering Proceedings, 7(1), 10. https://doi.org/10.3390/engproc2021007010